Assembly structure of automobile reduction gearbox body and motor shaft

An assembly structure and motor shaft technology, which is applied in the direction of electromechanical devices, electrical components, mechanical equipment, etc., can solve the problems of motor shaft movement, vibration and noise, and affect the NVH performance of automobiles, so as to achieve stable assembly structure and reduce vibration and noise , The effect of improving NVH performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

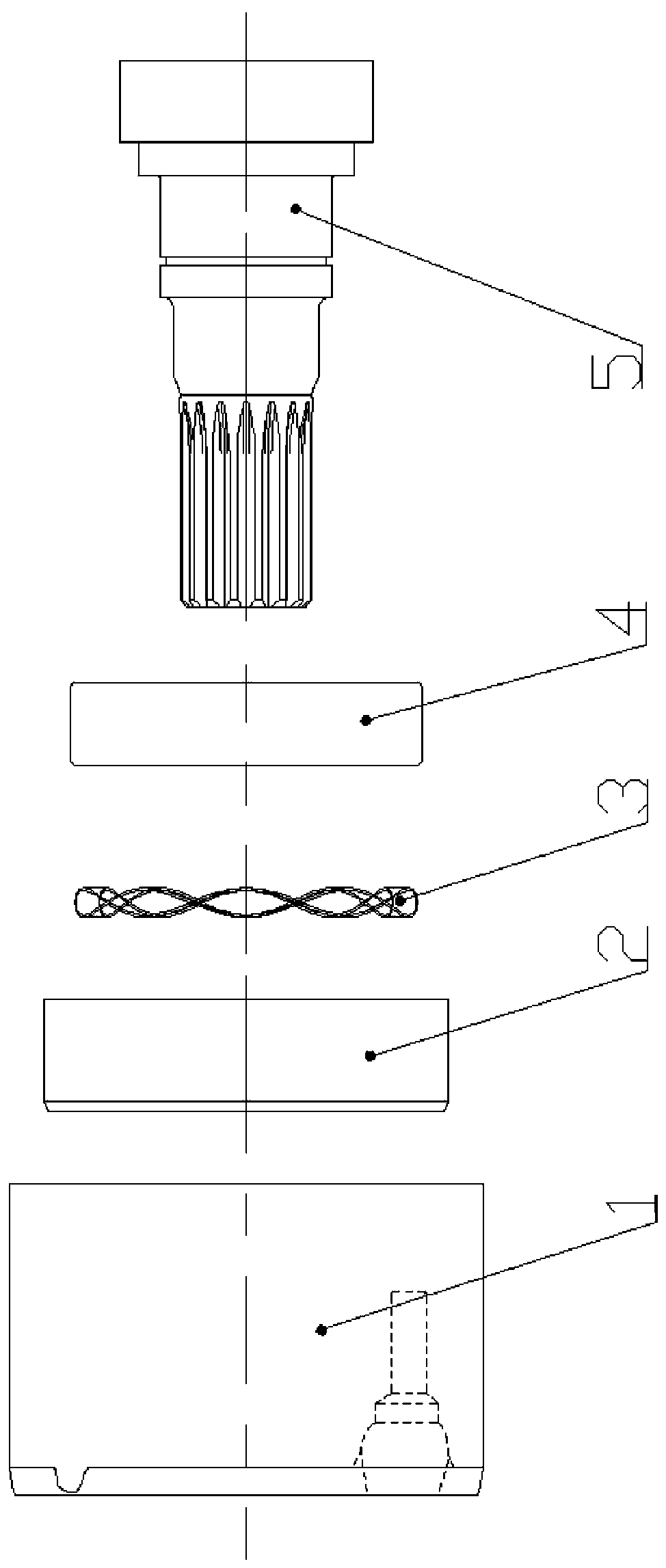

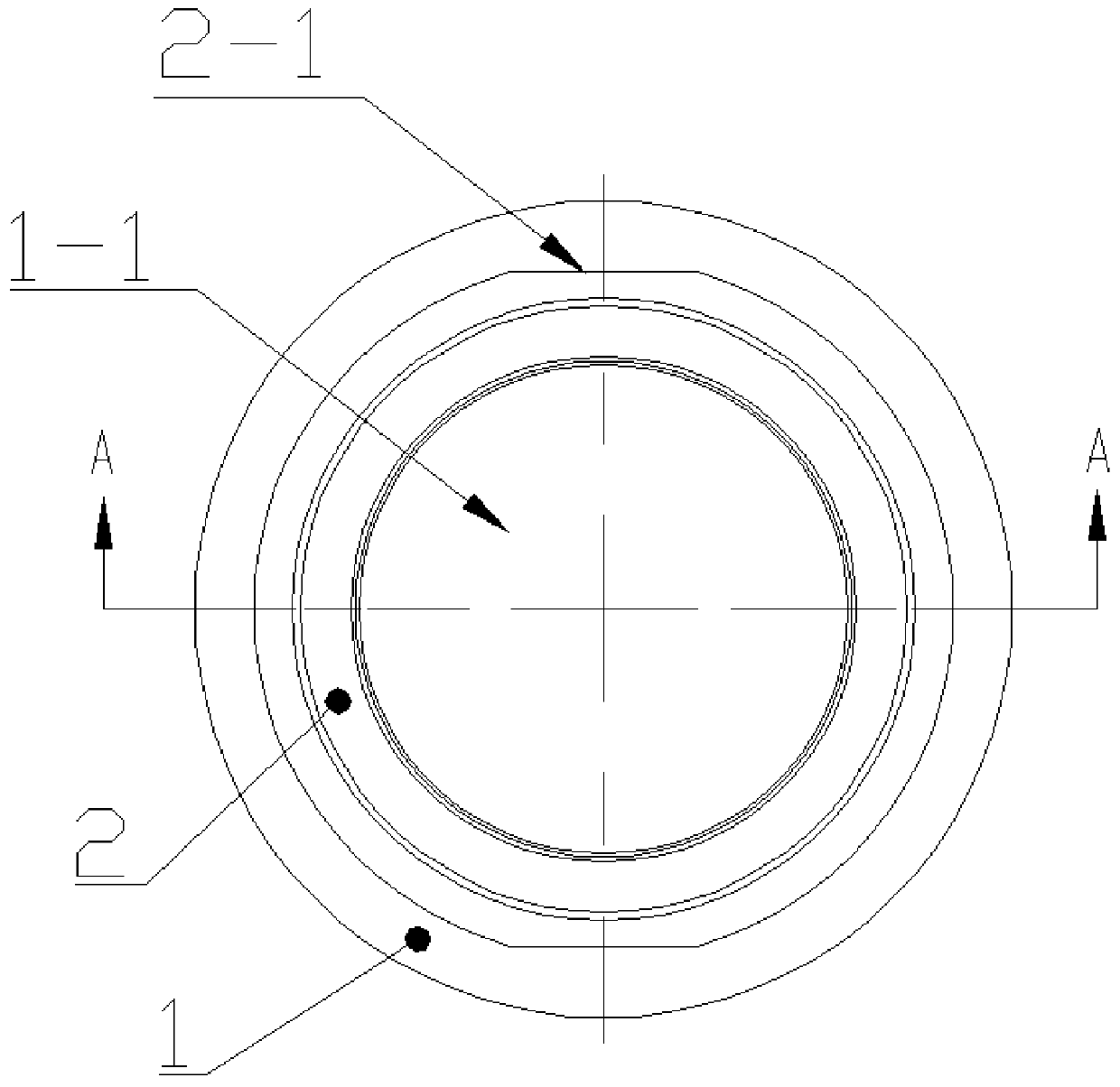

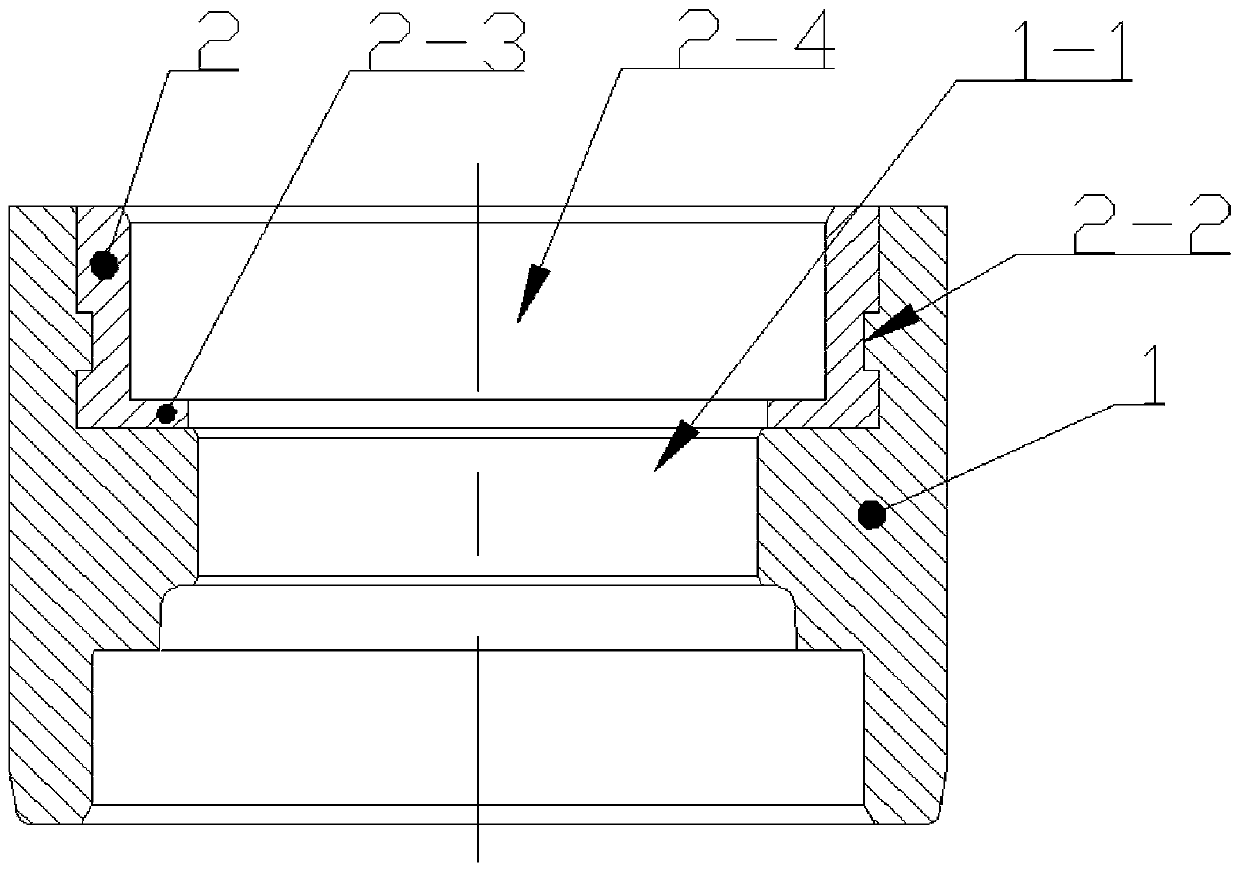

[0020] Embodiment one, see Figure 1 to Figure 3 , an assembly structure of an automobile gear box body and a motor shaft, comprising a box body 1 of the gear box and a motor shaft 5, the box body 1 is molded by aluminum water die-casting, and the motor shaft 5 is equipped with a bearing 4 and an inner part of the bearing 4 The ring is matched, and the end of the motor shaft 1 is provided with a spline for installing the power input gear of the reduction box. The box body 1 is provided with a step hole 1-1, and the step hole 1-1 is located in the large-diameter hole at the outer end of the box body 1. A steel sleeve 2 is fixed, and the steel sleeve 2 is against the shaft of the step hole 1-1. Shoulder, the shaft shoulder axially limited one end of the steel sleeve 2. The outer circumference of the steel sleeve 2 is symmetrically provided with a tangential plane 2-1 for two-way limit, the outer circumference of the steel sleeve 2 is provided with an axial limit groove 2-2, and...

Embodiment 2

[0021] Embodiment two, such as Figure 4 , Figure 5 , its basic structure is the same as that of Example 1, the difference is that the steel sleeve 2 is fixed in the large-diameter hole of the stepped hole 1-1 of the box body 1 through cold press interference fit, and the steel sleeve 2 and the box body 1 The outer end of the stepped hole 1-1 is evenly distributed on the outer end of the stepped hole 1-1. There are three saddle holes 6. Each saddle hole 6 is a blind hole arranged in the axial direction. Each saddle hole 6 is interference-fitted with a stop pin 7 pairs of steel pins. Set 2 circumferential and axial limit. The three seam holes 6 can realize the stable limit of the steel sleeve 2. The cold press interference fit assembly between the steel sleeve 2 and the box body 1 is simple, and the blind hole 6 and the stop pin 7 together form a pair of steel sleeves. 2, even if the steel sleeve 2 and the box body 1 become loose due to heat, the stable connection between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com