Tearing knife replacing manipulator and control method thereof

A technology of tearing knives and manipulators, which is applied in the directions of manipulators, earthwork drilling and manufacturing tools, etc., can solve the problems of safety hazards and time-consuming problems, and achieve the effects of speeding up construction efficiency, reducing production costs, and ingenious design structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

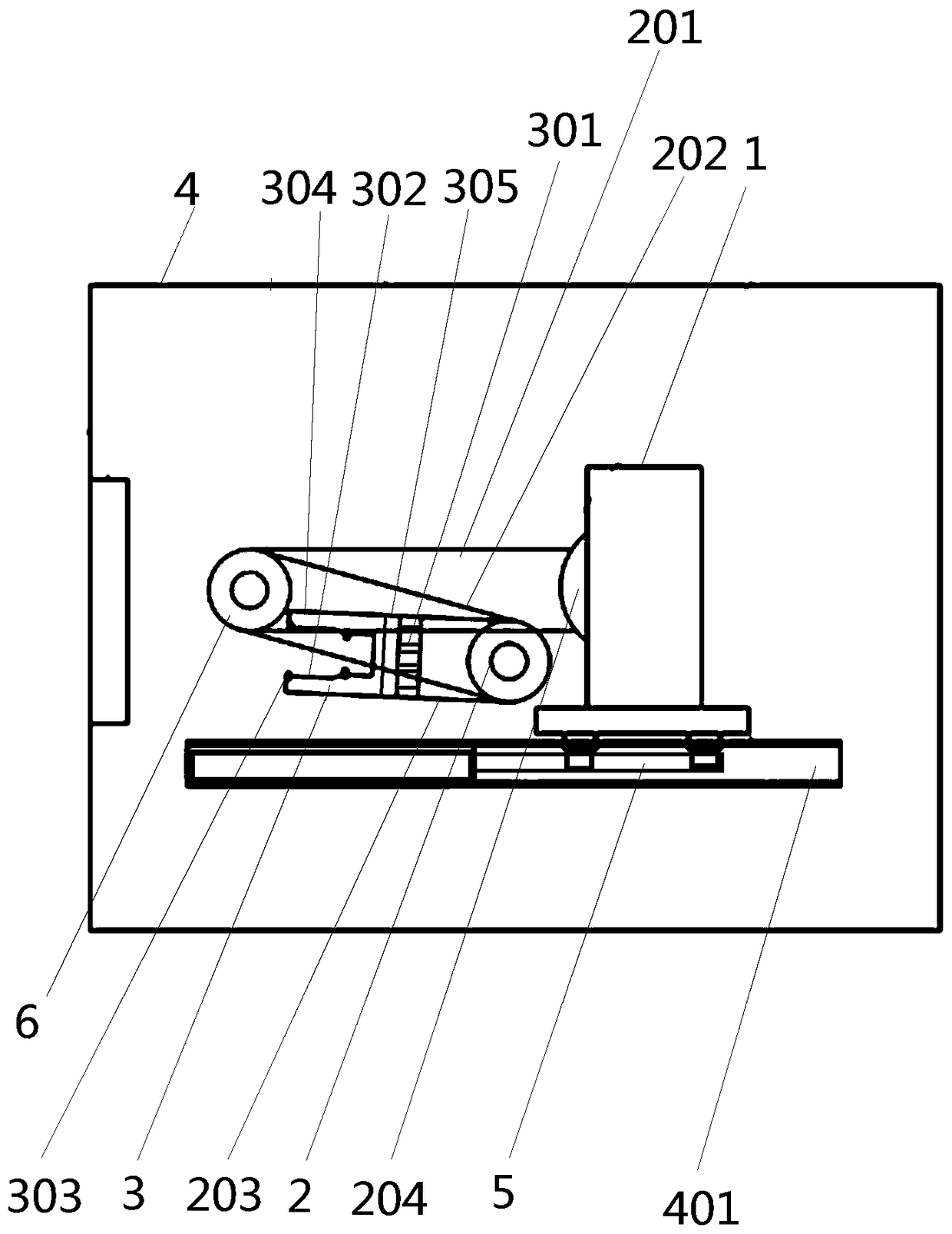

[0033] Embodiment 2, a tearing knife replacement manipulator, the second rotary cylinder can be replaced by a deceleration motor, and the deceleration motor is used to drive the rotation of the rotating arm with simple structure and convenient control, but relatively low structural strength. The other structures of this embodiment are the same as those of the first embodiment.

Embodiment 3

[0034] Embodiment 3, a tearing knife replacement manipulator, the second rotary cylinder can be replaced by a rotary hydraulic cylinder, and the rotary hydraulic cylinder is used to drive the rotation of the rotating arm, which has a strong structure and a long service life, but has a high cost. The other structures of this embodiment are the same as those of the first embodiment.

Embodiment 4

[0035] Embodiment 4, a tearing knife replacement manipulator, the micro telescopic cylinder 303 can be replaced with a micro telescopic hydraulic cylinder, and the rotary hydraulic cylinder is used to drive the rotation of the rotating arm. The structure has high strength and long service life, but the cost is high . The other structures of this embodiment are the same as those of the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com