A torque transfer device connected with a torque converter with the aid of gear engagement

A technology of torque converter and torque converter housing, applied in the field of drive train, to achieve the effect of miniaturized cost, less axial installation space, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

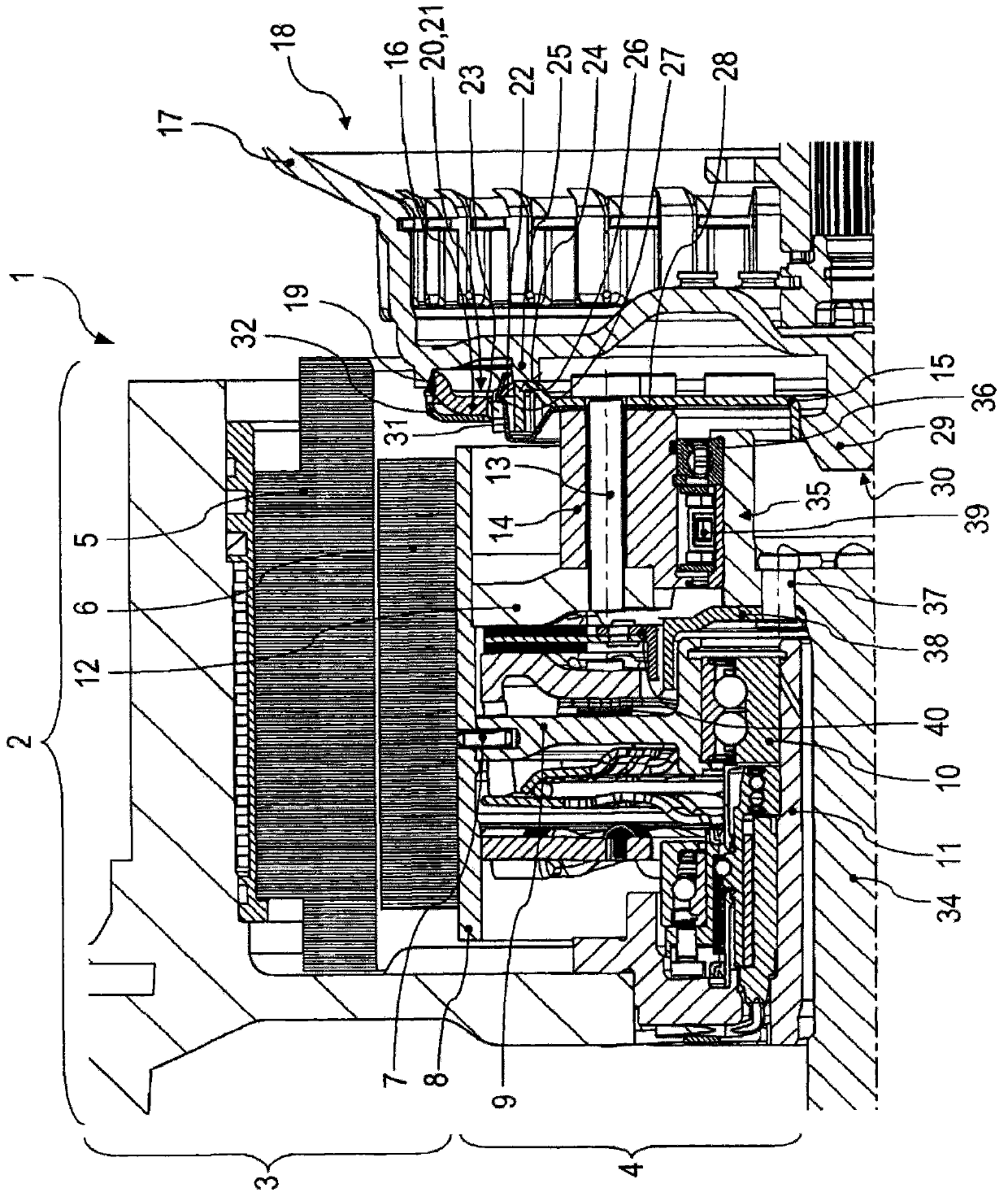

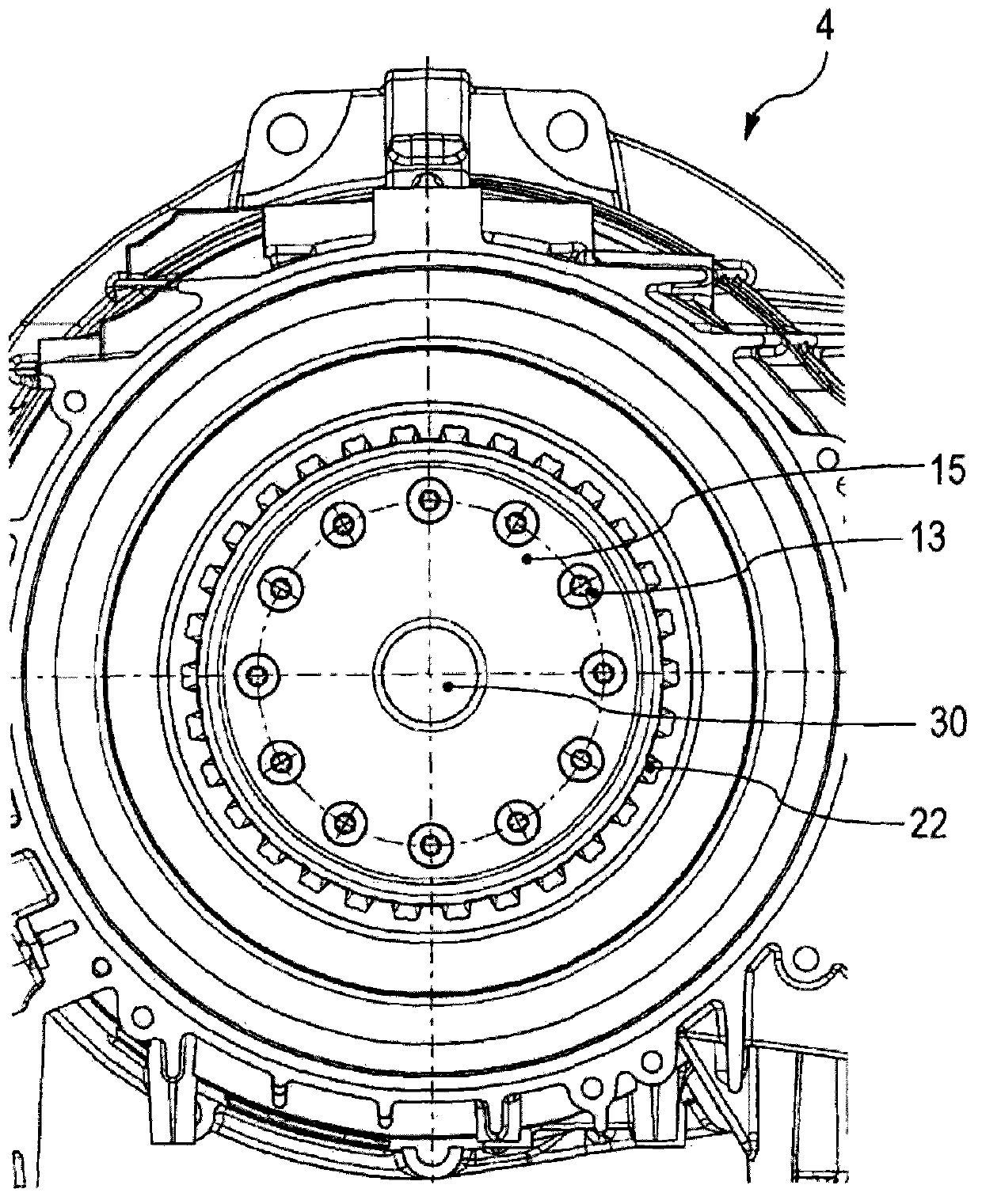

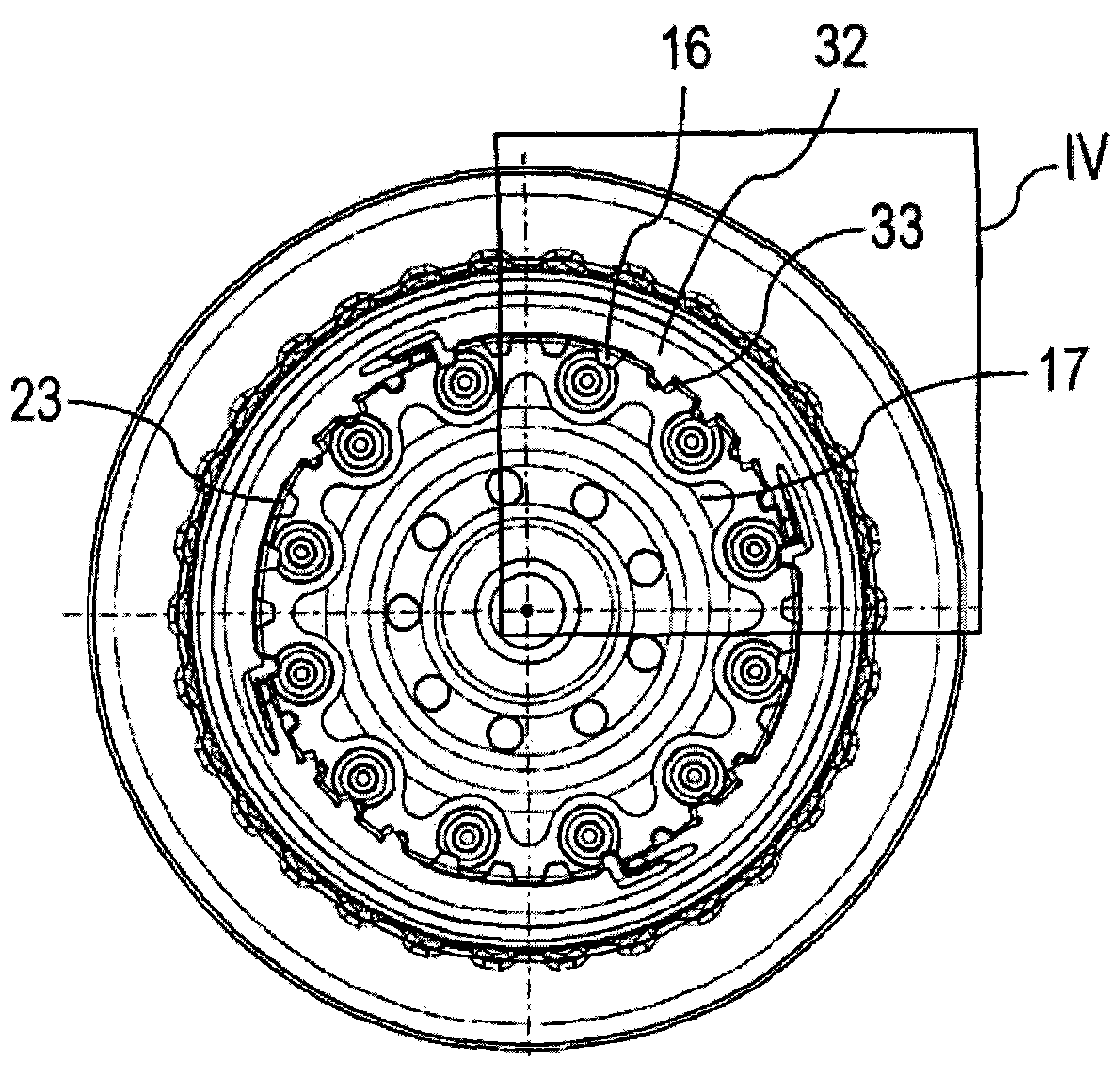

[0035] figure 1 A detail of a drive train 1 according to the invention is shown. Such a drive train 1 according to the invention is used in a motor vehicle, such as a passenger car or a truck, which uses both an internal combustion engine (not shown) and a hybrid module 2 comprising an electric machine and a converter assembly.

[0036] An electric machine designed as an electric motor is designated with reference numeral 3 . The switching assembly has the reference numeral 4 and is designed as a clutch.

[0037] The electric machine 3 has a stator 5 and a rotor 6 . The rotor 6 is connected to the tubular member 8 by pins 7 . The tubular member 8 is supported on a central bearing 10 via a connecting flange 9 . The central bearing 10 is designed as a roller bearing. The central bearing 10 is inserted into a sleeve-shaped member 11 which is part of the operating system of the conversion assembly 4 .

[0038] The torque generated by the electric motor 3 is transmitted via ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com