Safe marine drilling rotary pressure-maintaining coring method

A rotary and safe technology, applied in the direction of undisturbed core extraction device, earth cube drilling and mining, etc., can solve the problems of corer inner tube assembly disengagement, poor reliability and safety of coring device, and achieve operational Simple and convenient, fast and convenient maintenance, and improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

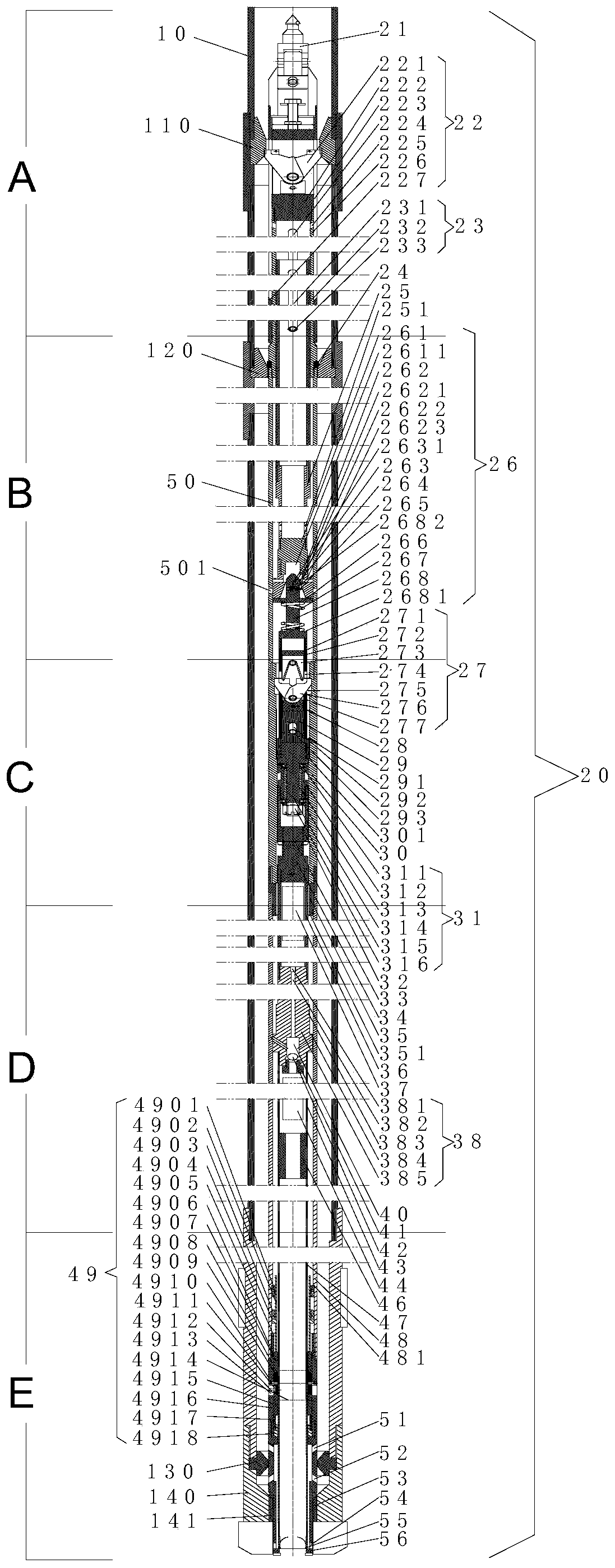

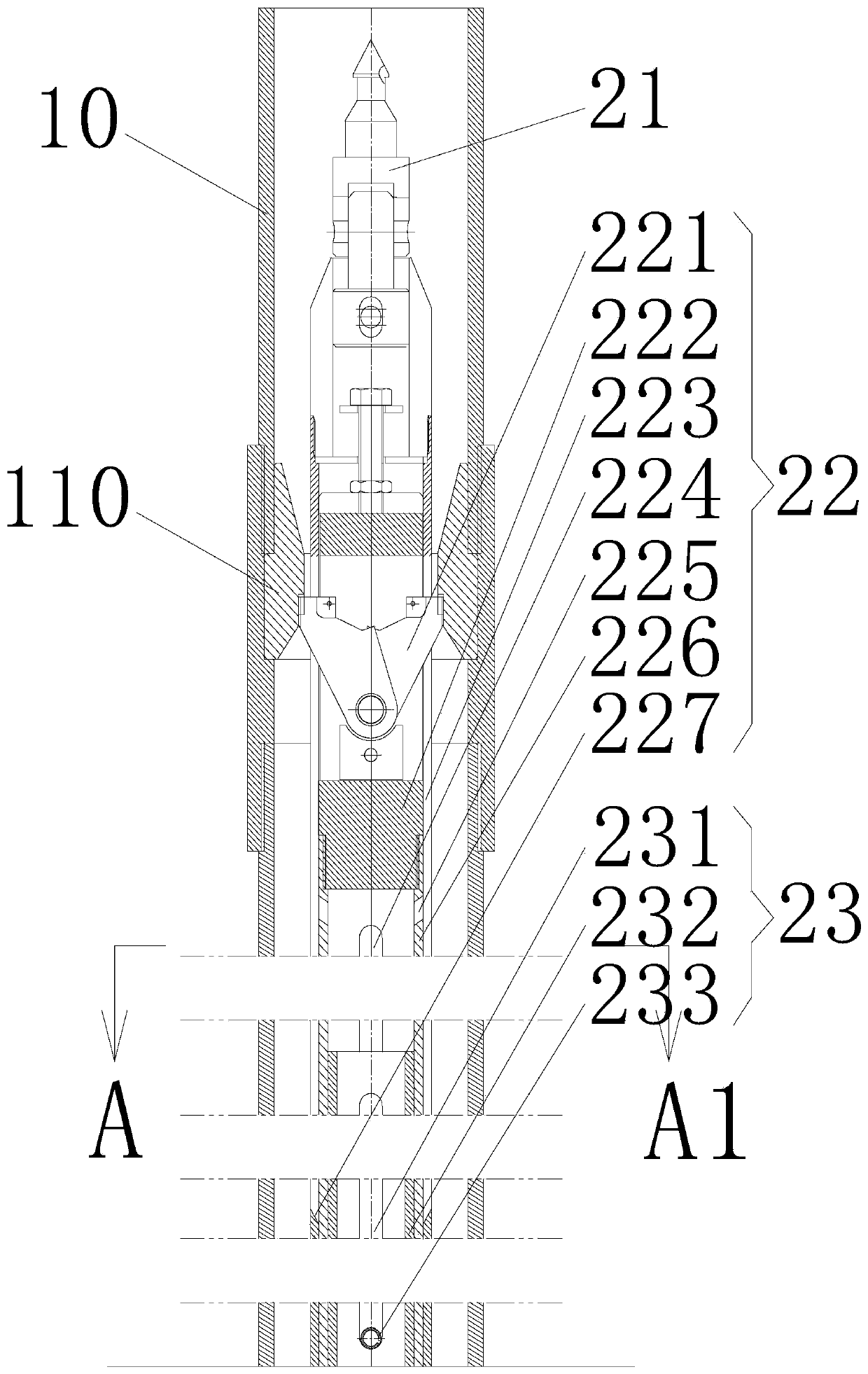

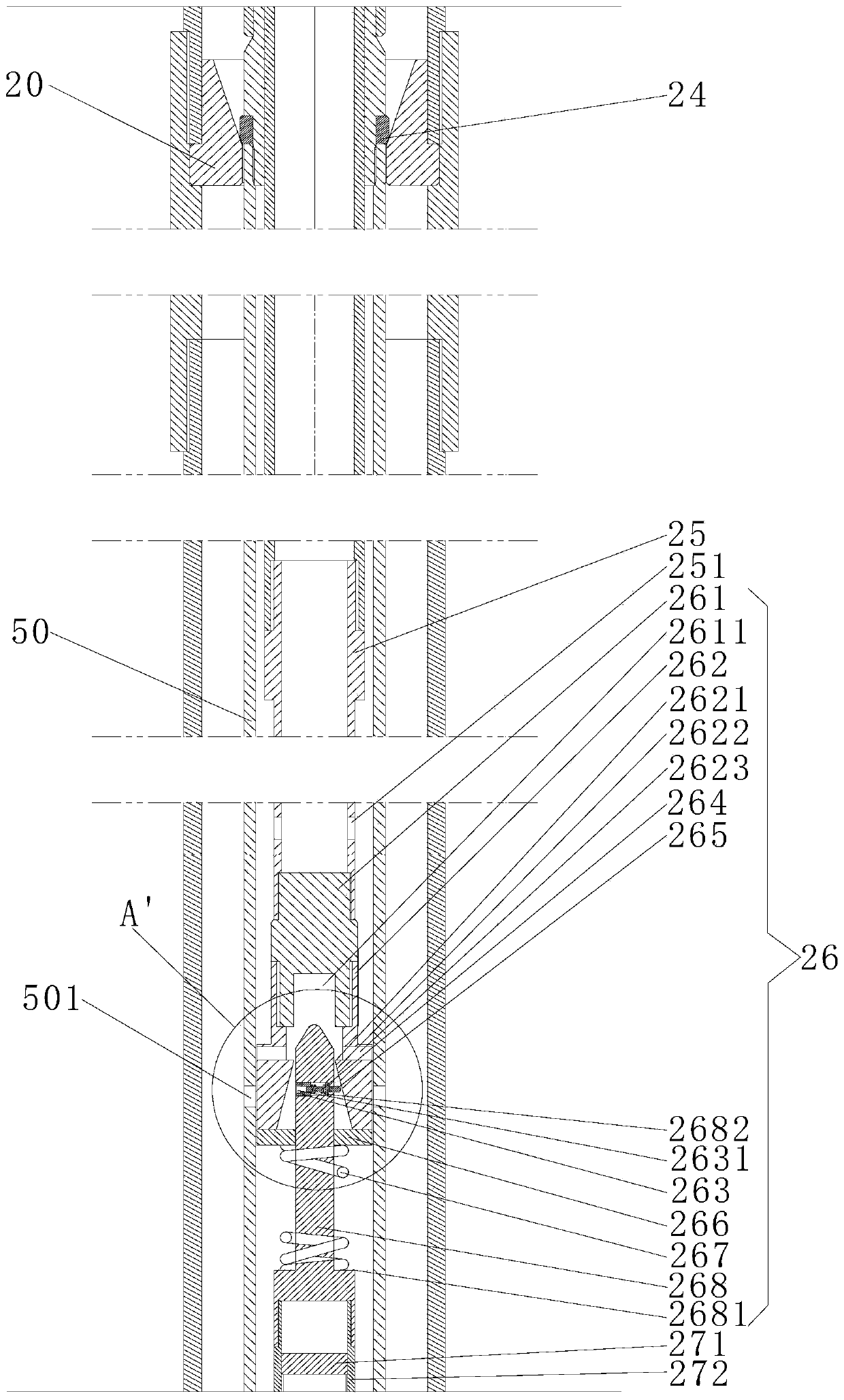

[0065] Such as Figure 1 to Figure 22 As shown, a safe offshore drilling rotary pressure-holding coring method includes the following steps:

[0066] 1) Connect the fishing spearhead 21 through an overshot (not shown in the figure), and drop the inner tube assembly 20 onto the seat ring 120 inside the outer tube assembly 10 at the bottom of the hole. Put into the release pipe, disconnect the connection between the overshot and the fishing spearhead 21 and recover the overshot to the drilling platform;

[0067]2) After the drill pipe is connected to the drilling rig, the drilling rig synchronously drills the inner pipe assembly 20 and the outer pipe assembly 10 to the bottom of the well formation through the drill pipe, and keeps the bullet a 221 of the bullet mechanism 22 and the bullet suspension mechanism 27. The bullet clips b 276 are all in an ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com