Air-tightness joint with double female ends

A technology of airtightness and outer conductor, which is applied in the direction of electrical components, two-part connection devices, contact parts, etc., and can solve problems such as poor index stability, poor environmental resistance, and inability to achieve airtightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

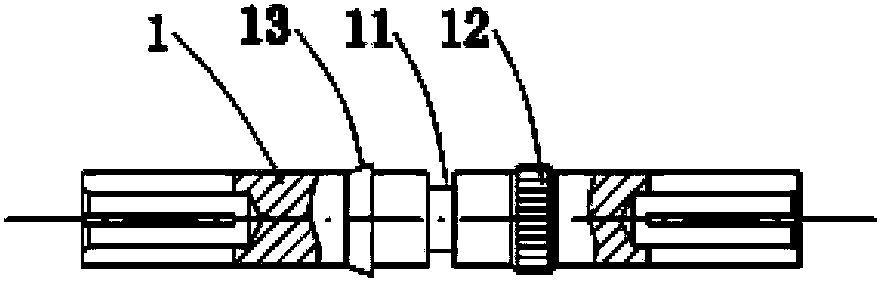

[0019] Example: Combined Figures 1A-1C , the airtight N-type double cathode of the present embodiment, which includes:

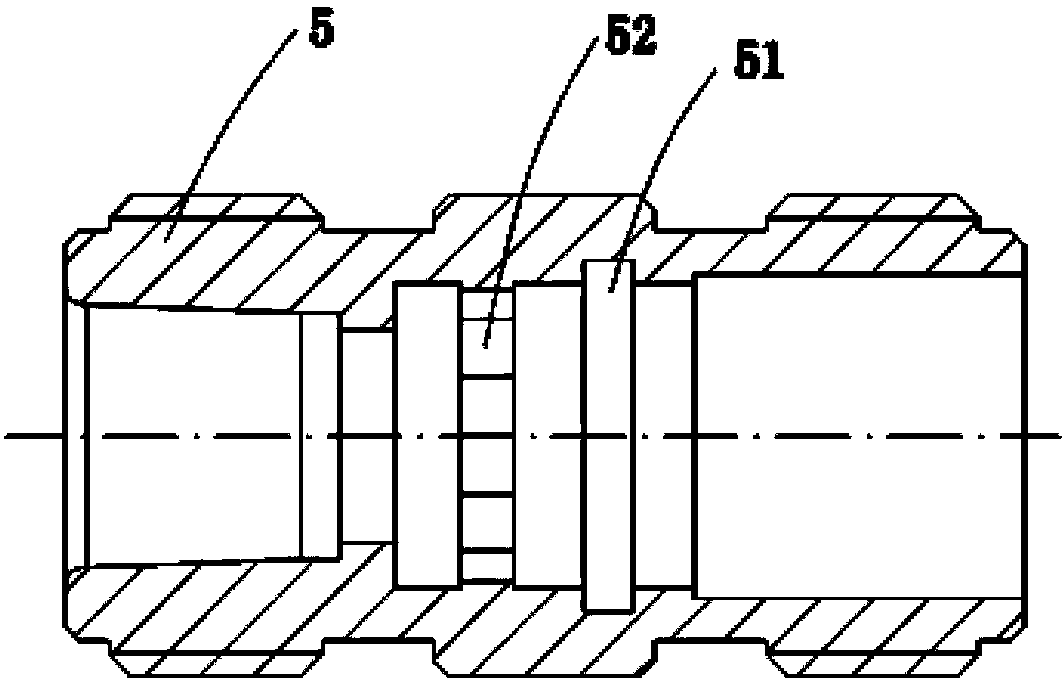

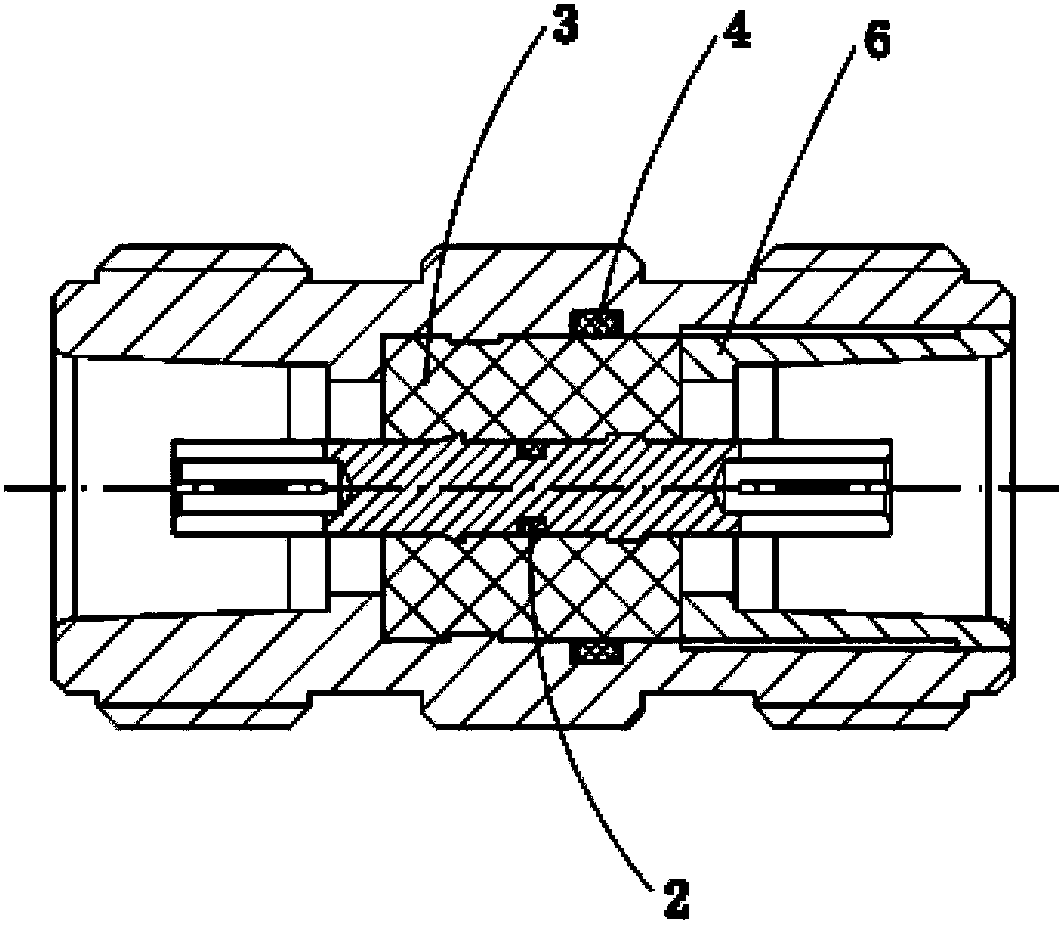

[0020] The inner conductor 1 in the center and the insulating medium 3 coaxially sleeved outside the inner conductor, the outer conductor 5 with a stepped hole cavity, the insulating medium 3 is arranged in the stepped hole of the outer conductor, and the insulating medium 3 and the outer conductor 5 coaxial settings.

[0021] A fixed block 6 is tightly connected to the stepped orifice of the outer conductor, and the fixed block 6 and the stepped surface of the stepped hole form an axial limit at both ends of the insulating medium.

[0022] There is a circumferential limit structure between the outer circumference of the insulating medium 3 and the inner cavity of the outer conductor 5. Specifically, a plurality of bosses 52 are arranged in the axial direction on the inner cavity wall of the outer conductor, and the plurality of bosses are located in the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com