Patents

Literature

50results about How to "Achieve circumferential fixation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

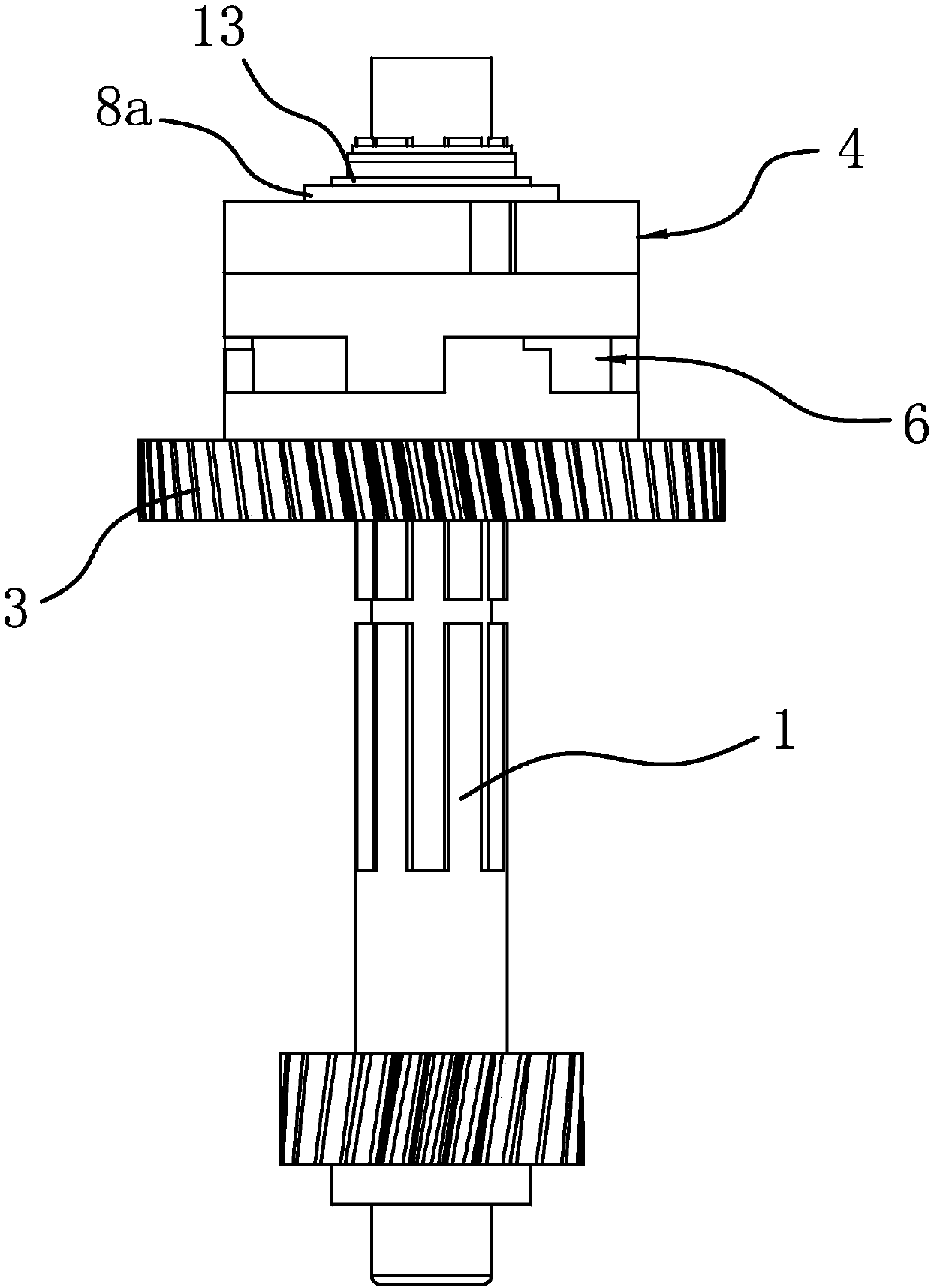

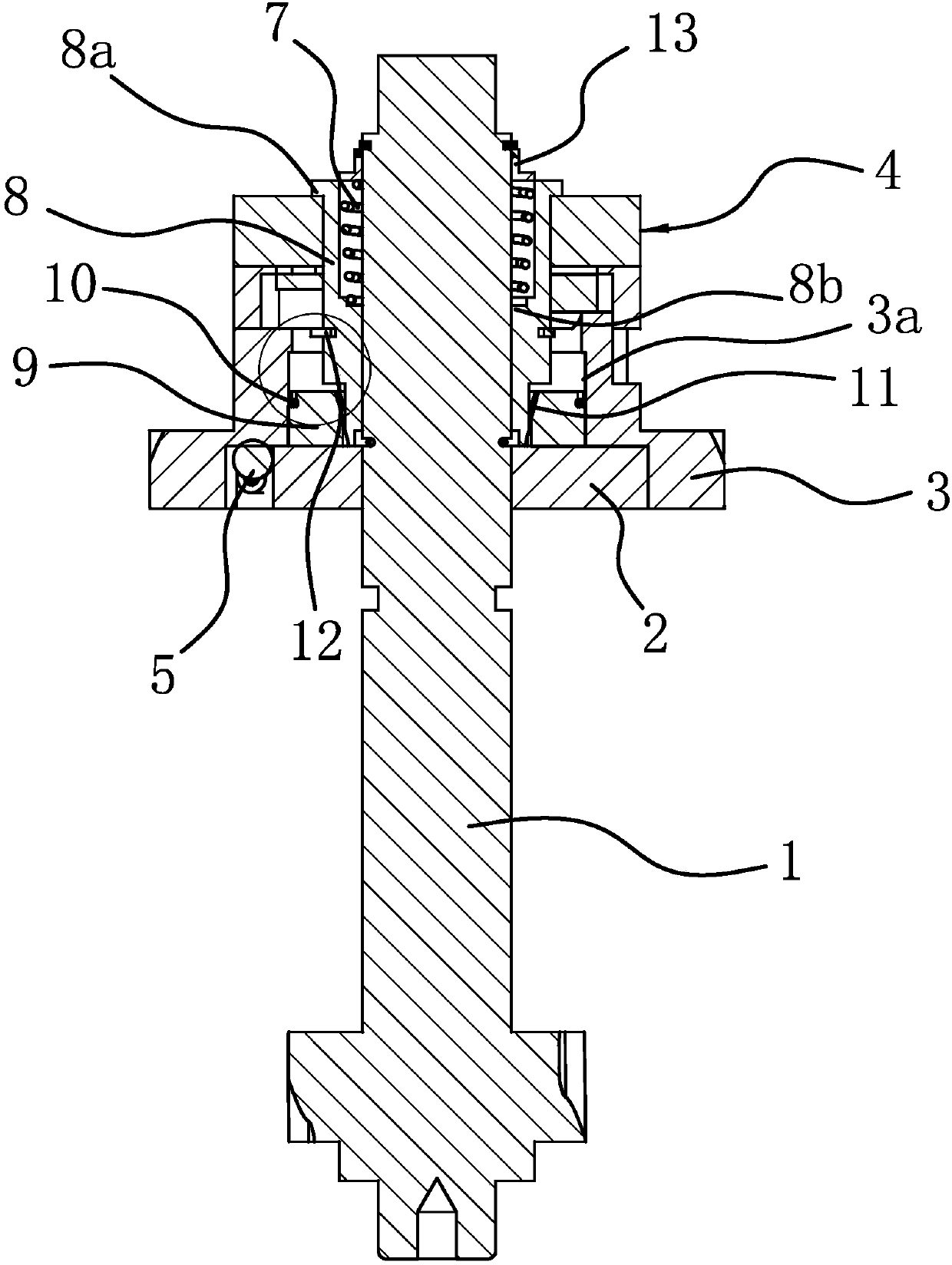

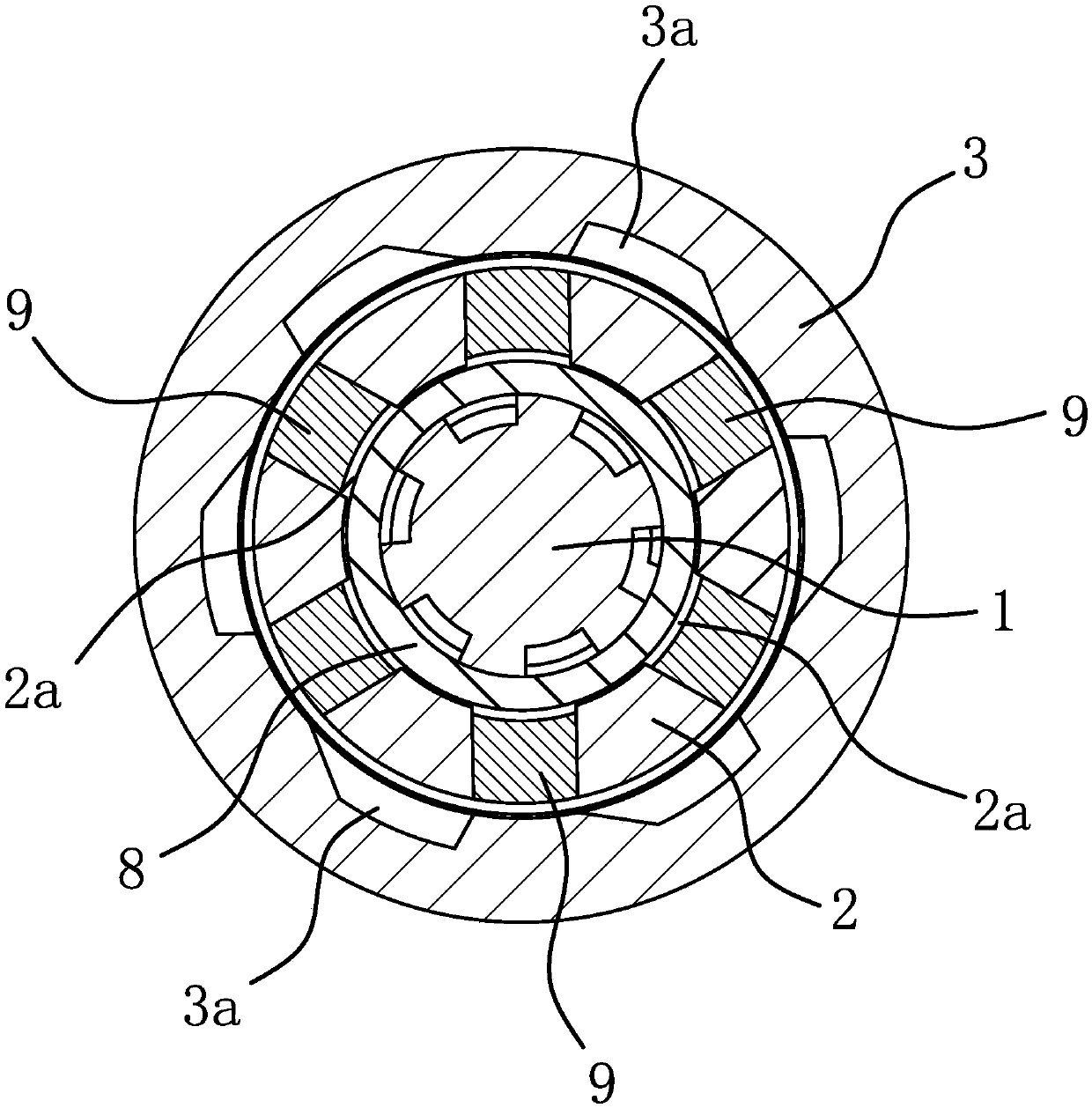

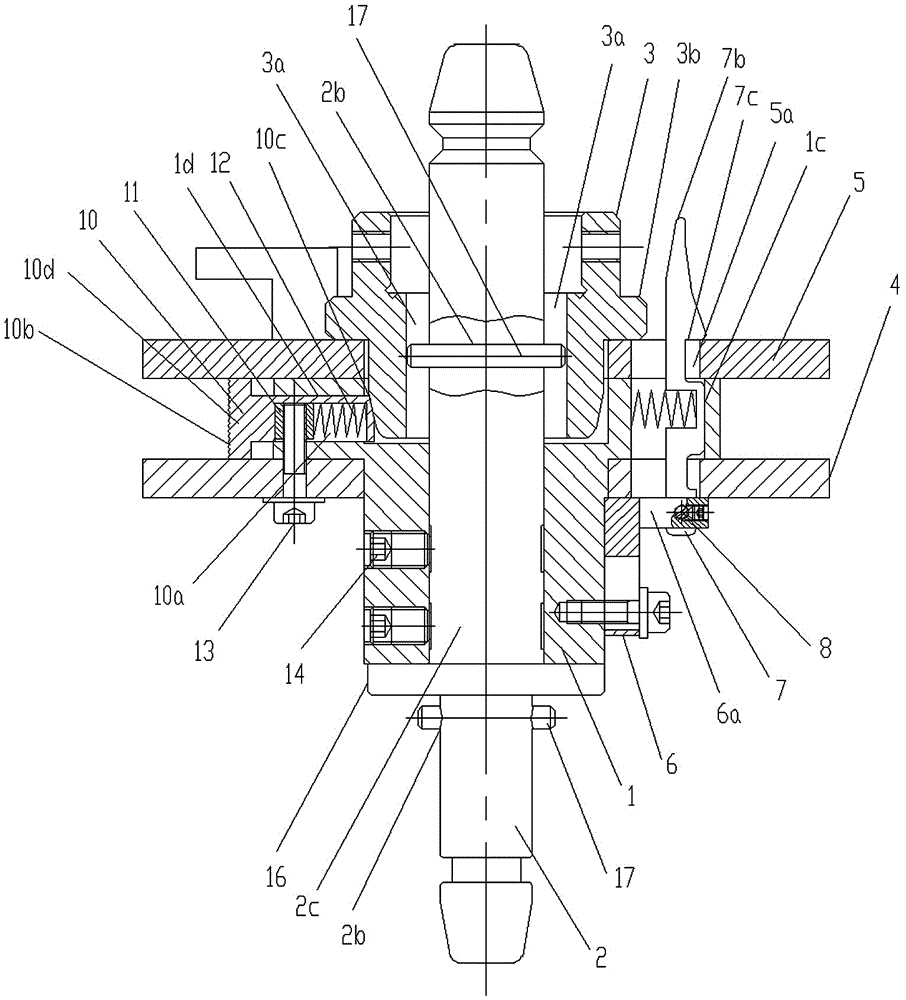

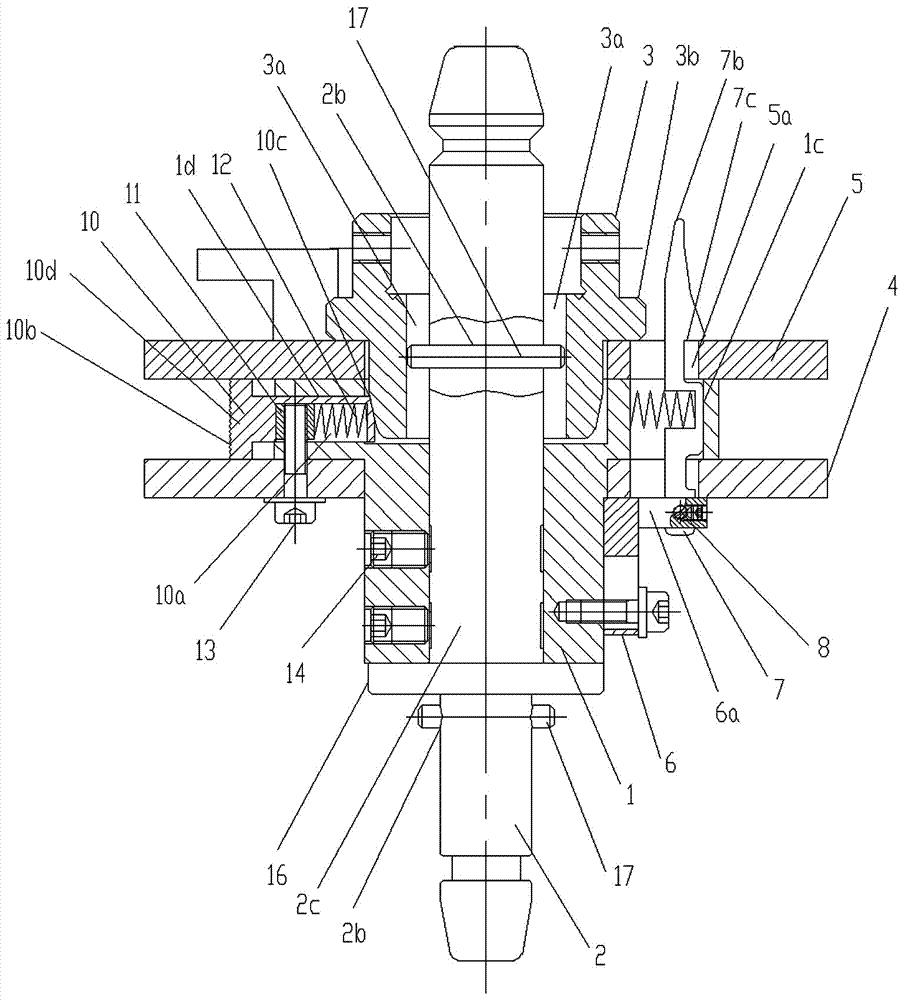

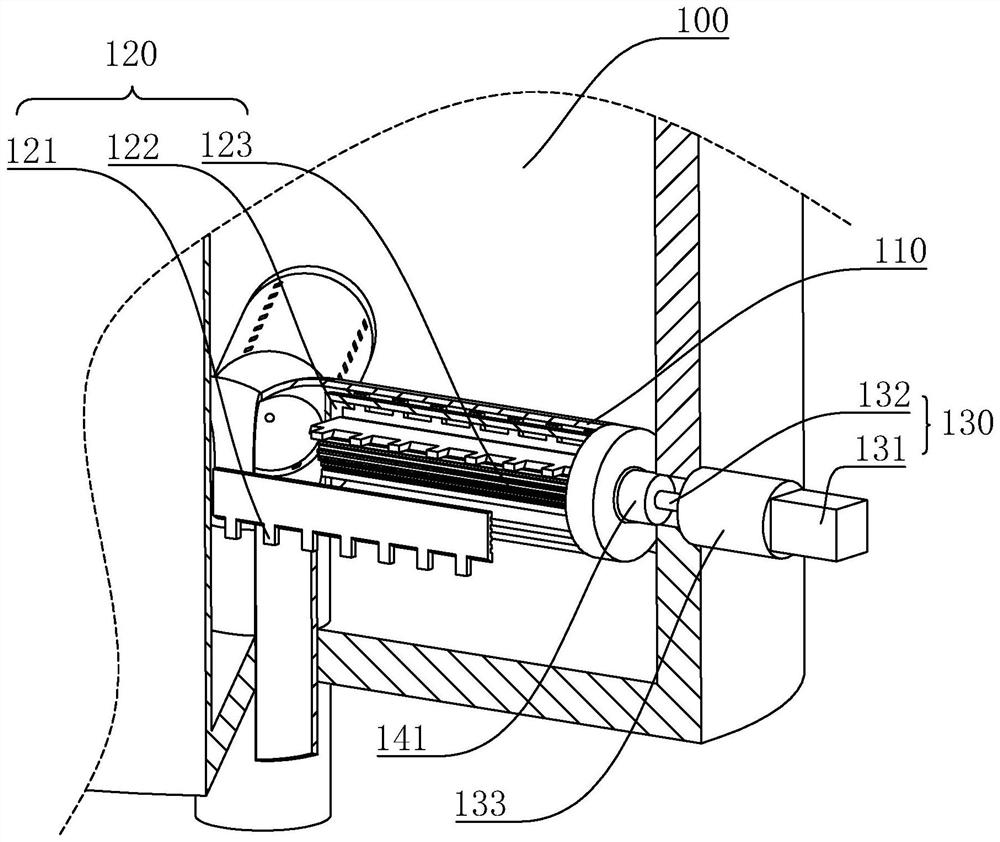

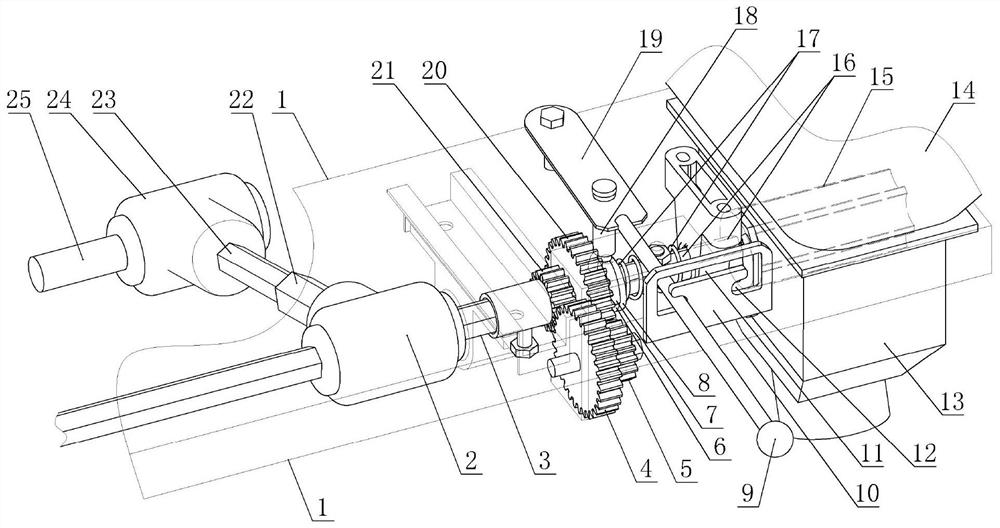

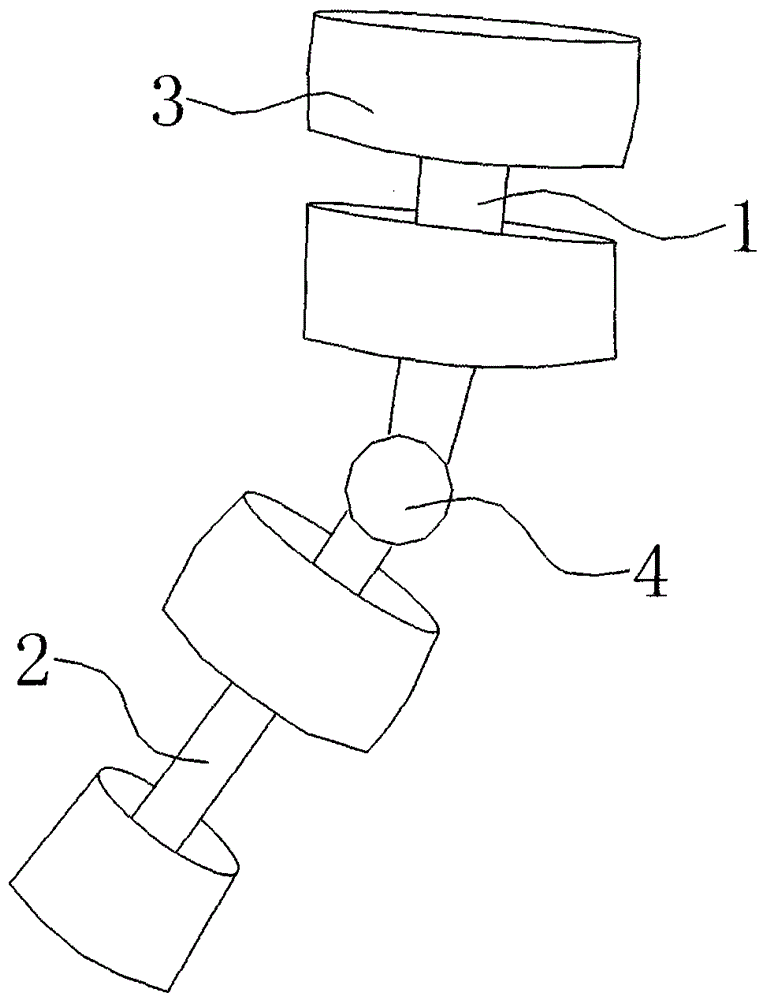

Transmission mechanism of two-way variable-speed motor

PendingCN107701664AStrong combinationReliable transmissionToothed gearingsAutomatic clutchesEngineeringMotor drive

The invention provides a transmission mechanism of a two-way variable-speed motor, belongs to the mechanical technical field, and solves the problem that an existing transmission device is poor in working stability. The transmission mechanism of the two-way variable-speed motor comprises a main shaft, an inner ring which sleeves outside the main shaft and is fixed with the main shaft in the peripheral direction, an outer ring which sleeves outside the inner ring and a combined sleeve which sleeves outside the main shaft, wherein a one-way structure is arranged between the inner ring and the outer ring; a separating structure for enabling the combined sleeve to move in a direction away from the outer ring when the outer ring rotates is arranged between the combined sleeve and the outer ring; the transmission mechanism further comprises an elastic part I for enabling the combined sleeve to get close to the outer ring; a combined part and an elastic part II are arranged between the innerring and the outer ring; and when the combined sleeve gets close to the outer ring, the combined part can be driven to move in a mode of overcoming elastic force of the elastic part II; and the innerring and the outer ring are fixedly arranged in the peripheral direction. The transmission mechanism of the two-way variable-speed motor has the advantage of being more stable in work.

Owner:屠申富 +1

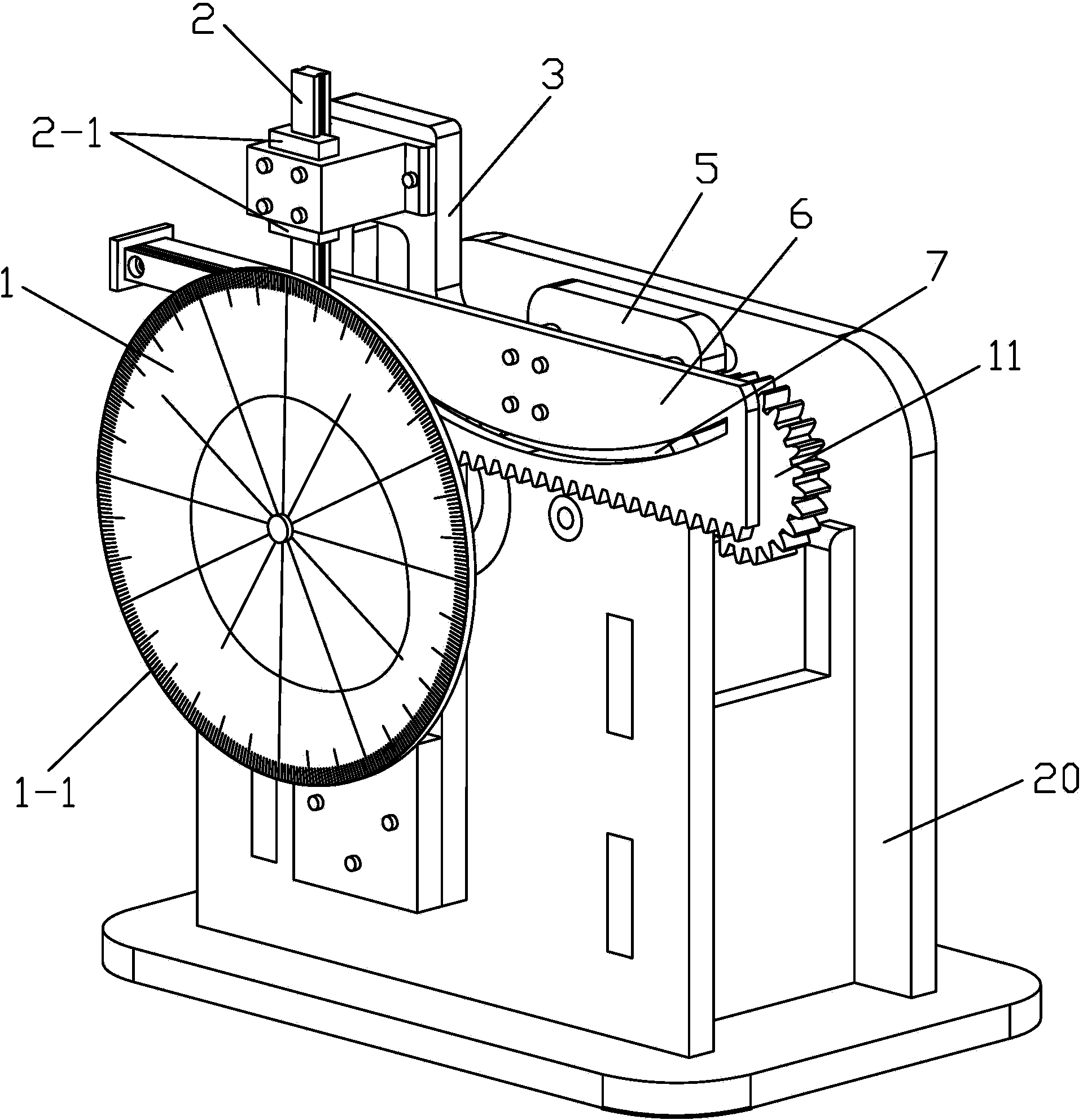

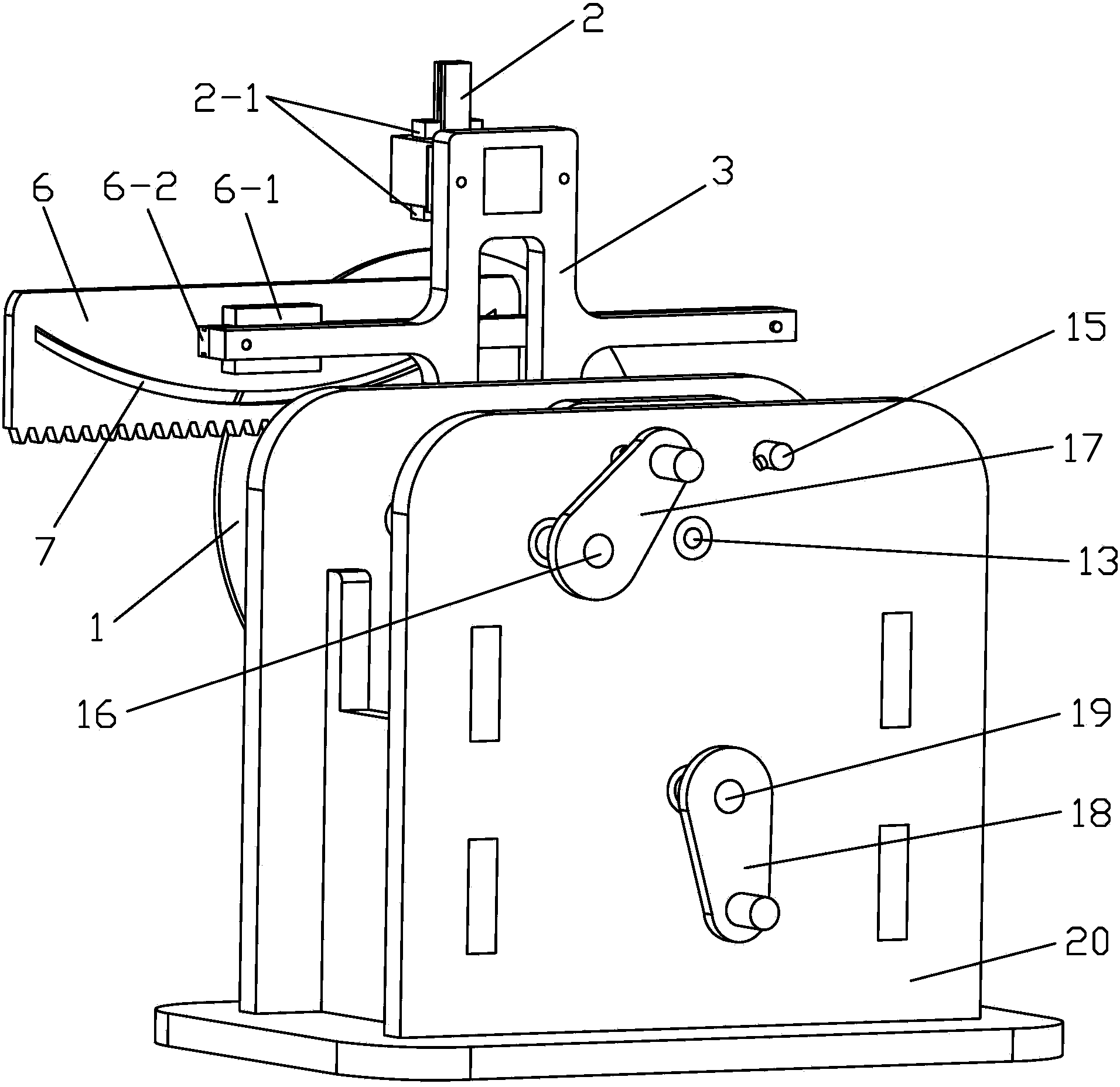

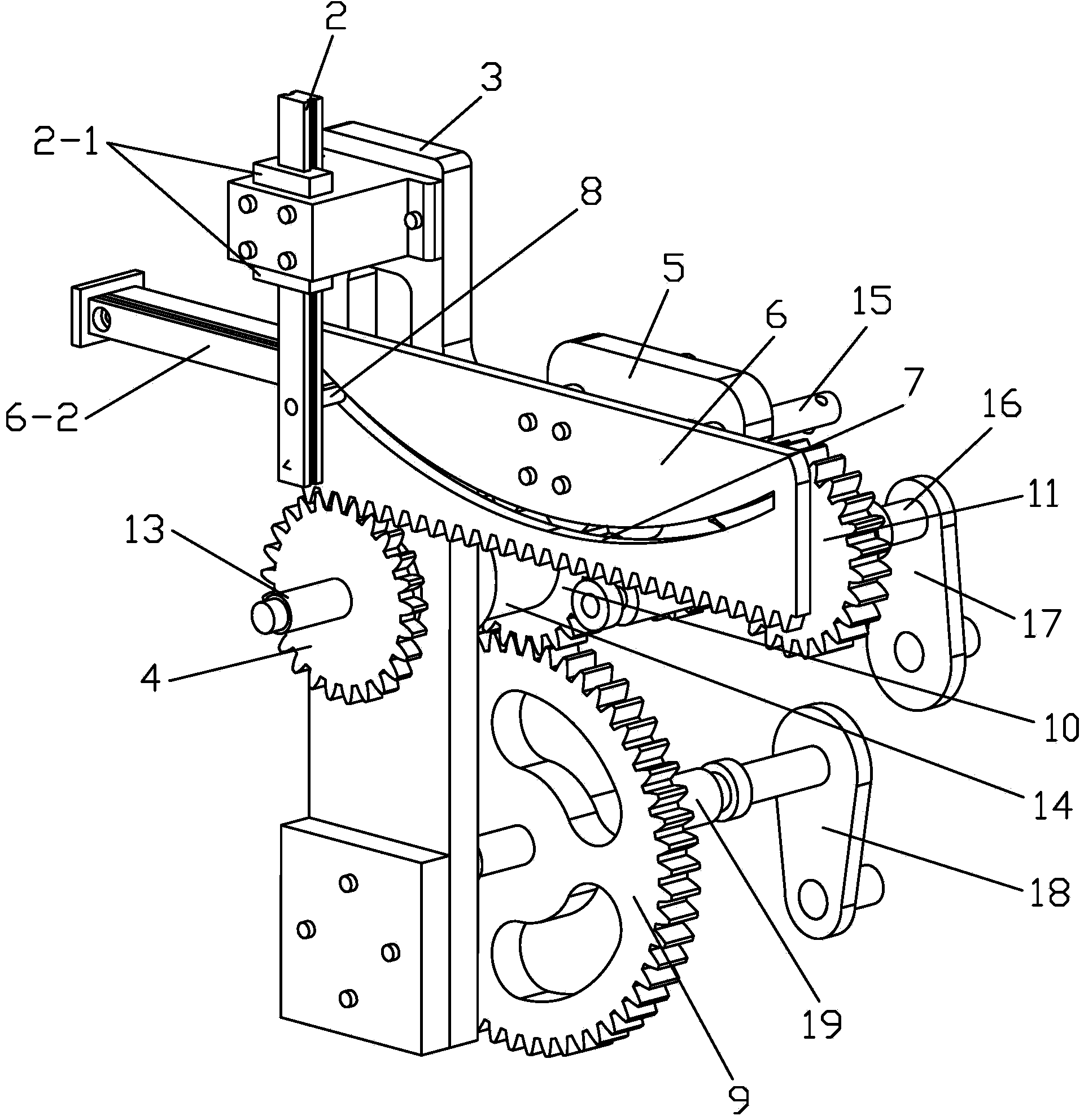

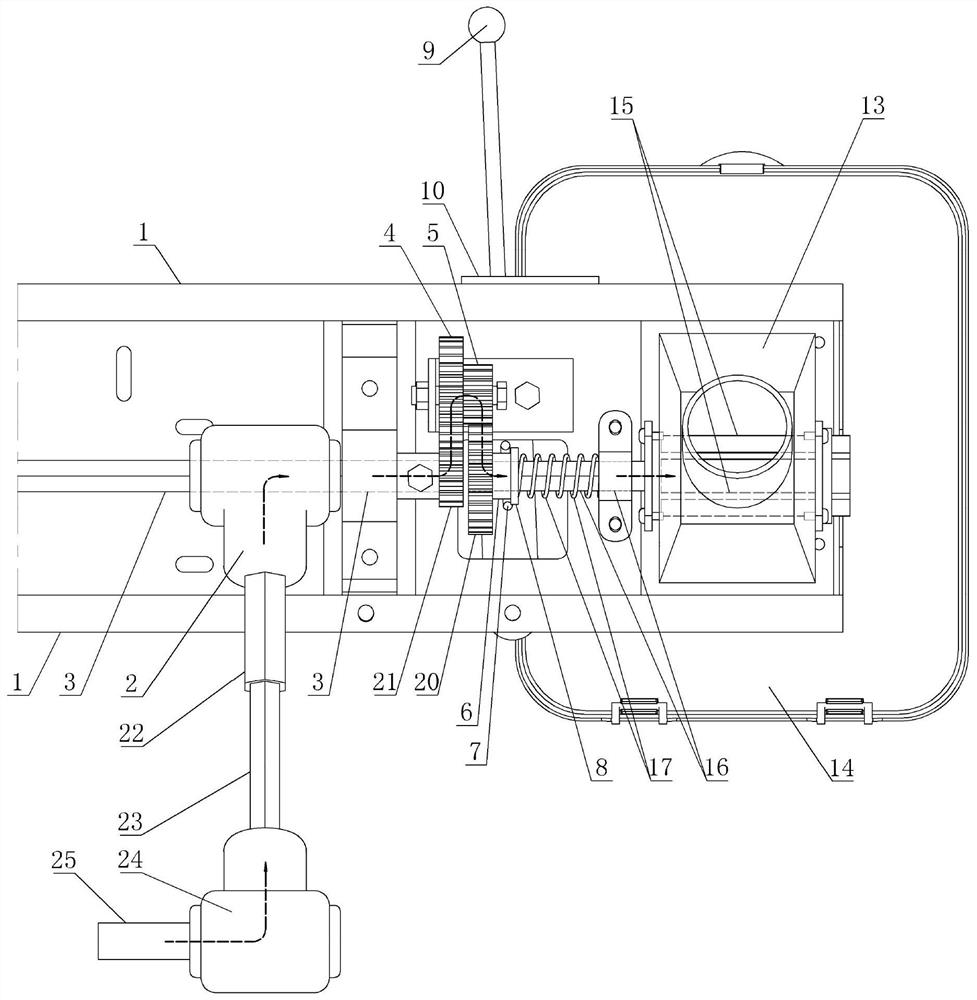

Cam profile curve plotting demonstration instrument

InactiveCN104299508AEasy to explainEasy to understandNon-circular curve drawing instrumentsEducational modelsGear wheelCam

The invention discloses a cam profile curve plotting demonstration instrument. The instrument comprises a machine frame, an outer shaft, an inner shaft and a drawing board, wherein the drawing board is arranged on the front side of the machine frame, a cross-shaped support is arranged between the drawing board and the machine frame, a bottom shaft is installed on the lower portion of the machine frame, a bottom shaft gear is installed on the bottom shaft, the outer shaft penetrates through the front side of the machine frame and the cross-shaped support and is connected with the machine frame, an outer shaft gear is installed on the outer shaft and is meshed with the bottom shaft gear, the inner shaft is connected with the outer shaft in a rotary mode, the rear end of the inner shaft is connected with the machine frame, the drawing board is installed at the front end of the inner shaft, a central gear is installed on the portion, between the drawing board and the cross-shaped support, of the inner shaft, a driven part is arranged on the upper portion of the front side of the cross-shaped support, a drawing pen is arranged on the front side of the lower portion of the driven part, a pin is fixed to the lower portion of the driven part, a rack plate is arranged between the driven part and the cross-shaped support, a cam slot is formed in the rack plate, the pin penetrates through the cam groove, and the rack plate is meshed with the central gear. The cam profile curve plotting demonstration instrument not only can be used for demonstrating cam profile curve plotting through the reversal process, but also can be used for demonstrating the movement of an original mechanism before reversal.

Owner:XIAN UNIV OF SCI & TECH

Plate fixing pin, antenna reflector plate and antenna

Owner:COMBA TELECOM TECH (GUANGZHOU) CO LTD +1

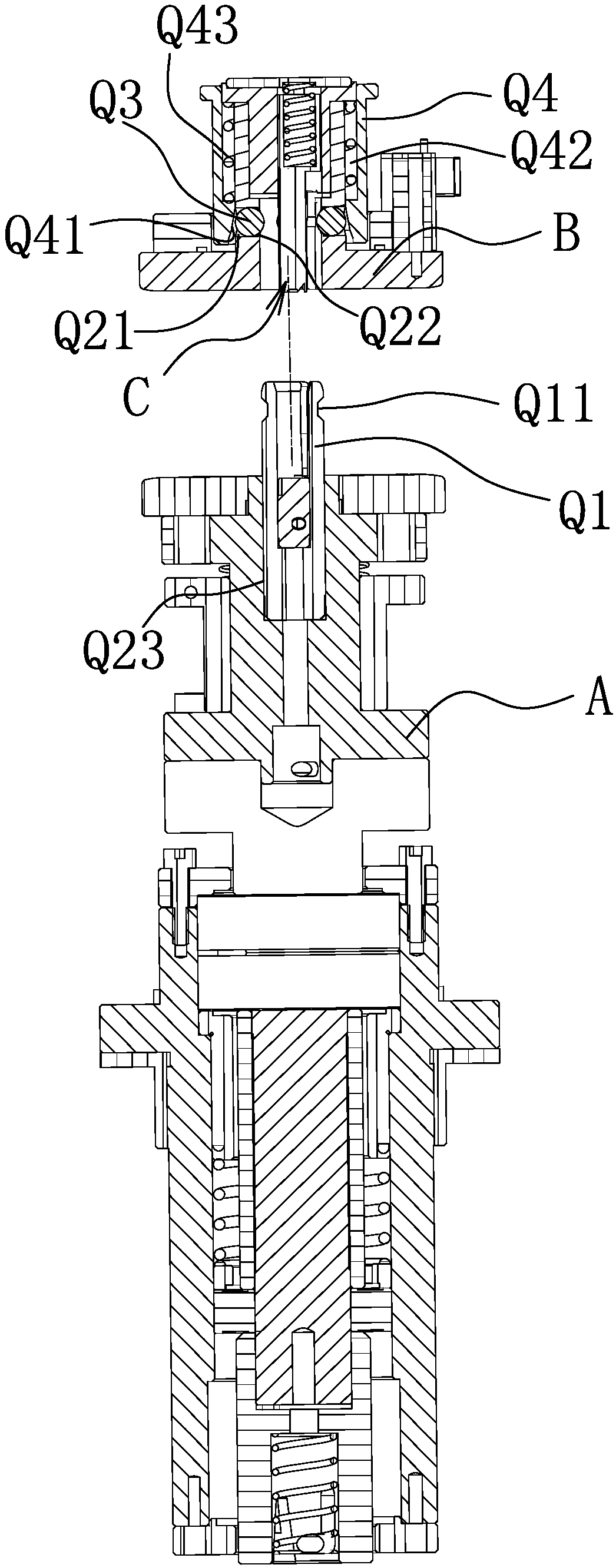

Quick-changing interface used for reconfigurable manipulator and based on magnet attraction

InactiveCN108247678ASimple structureReduce manufacturing costSecuring devicesManipulatorManipulatorEmbedded system

The invention discloses a quick-changing interface used for a reconfigurable manipulator and based on magnet attraction, and belongs to the technical field of robots. The quick-changing interface usedfor the reconfigurable manipulator and based on magnet attraction comprises an interface male end and an interface female end which are mutually matched; an electromagnet and a plug are fixedly arranged on the interface male end, a spring is arranged between the plug and the interface male end, and an armature is fixedly arranged on the position, corresponding to the electromagnet, of the interface male end; a socket matched with the plug is fixedly arranged on the position, corresponding to the plug, of the interface female end; and when the interface male end and the interface female end are butted, the electromagnet is energized, so that the electromagnet loses magnetism, and after butting is completed, the electromagnet is deenergized, so that the electromagnet and the armature are attracted. According to the quick-changing interface used for the reconfigurable manipulator and based on magnet attraction, the structure is simple, the production cost is low, and butting is convenient.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

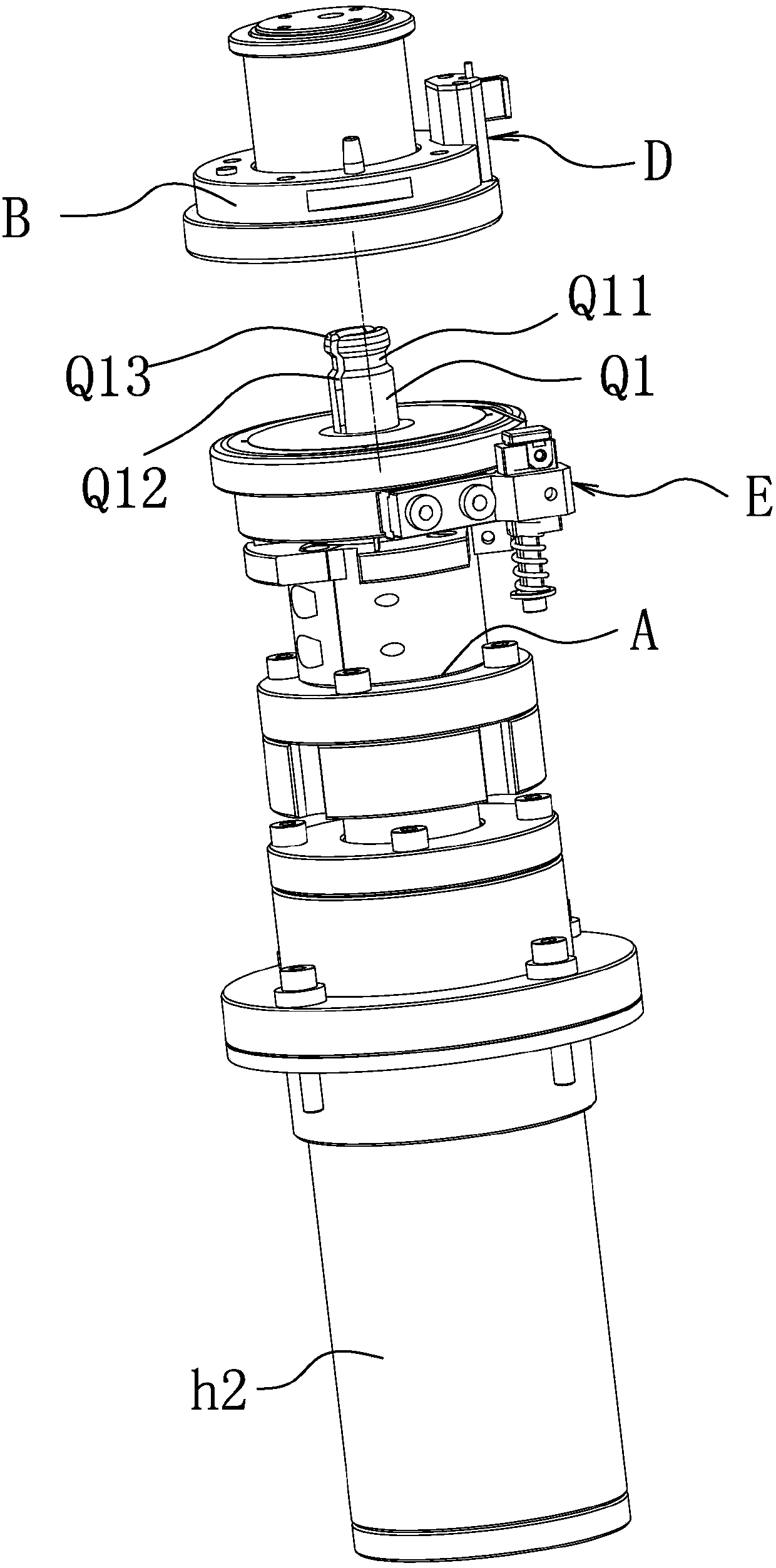

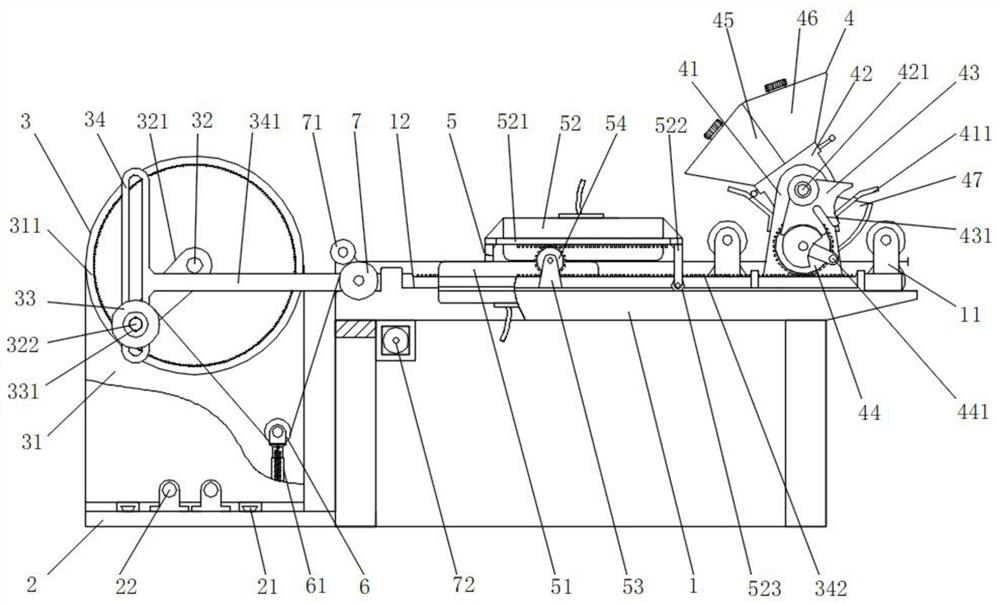

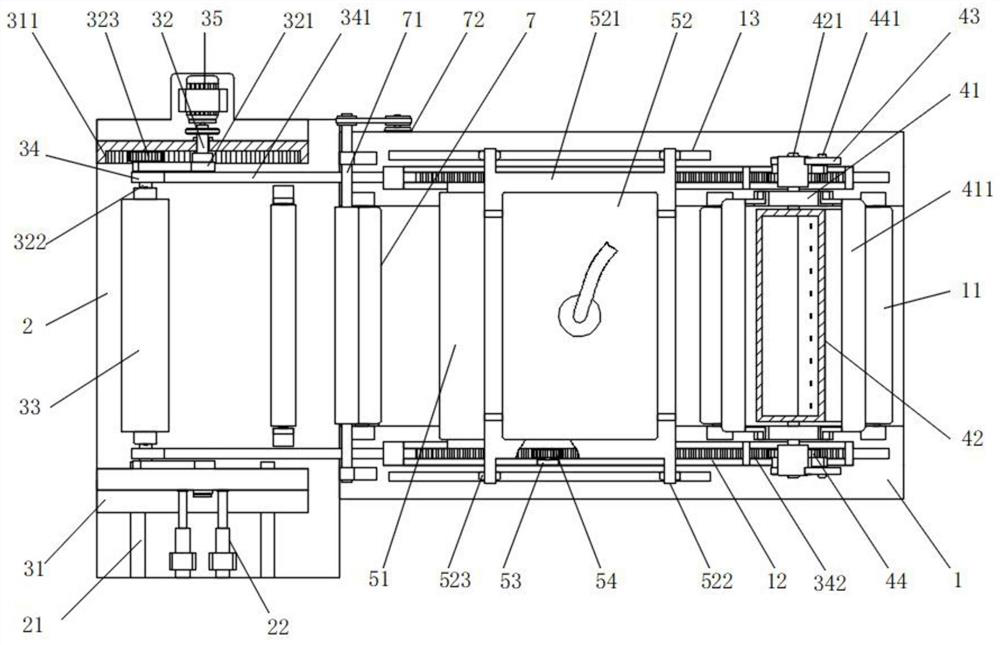

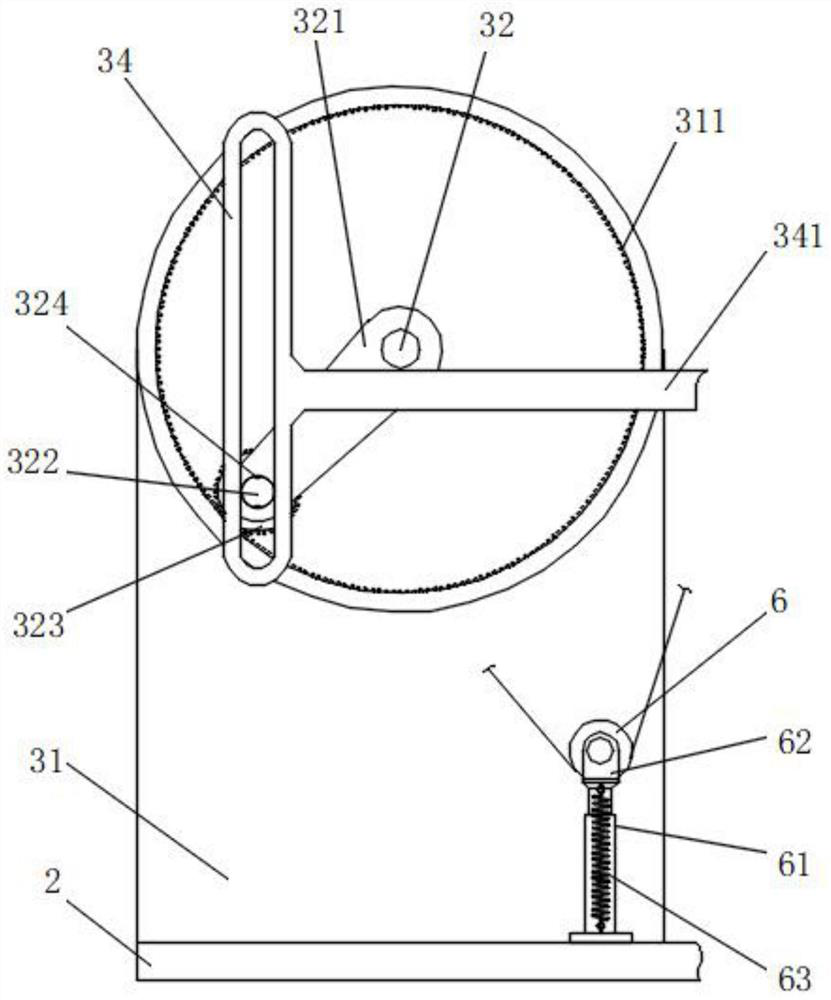

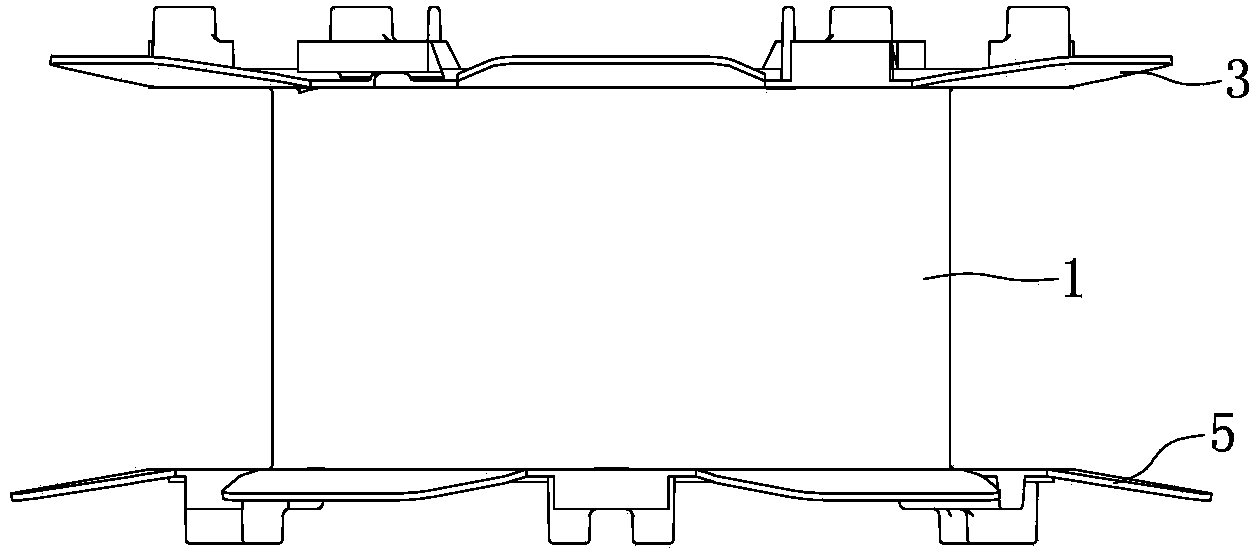

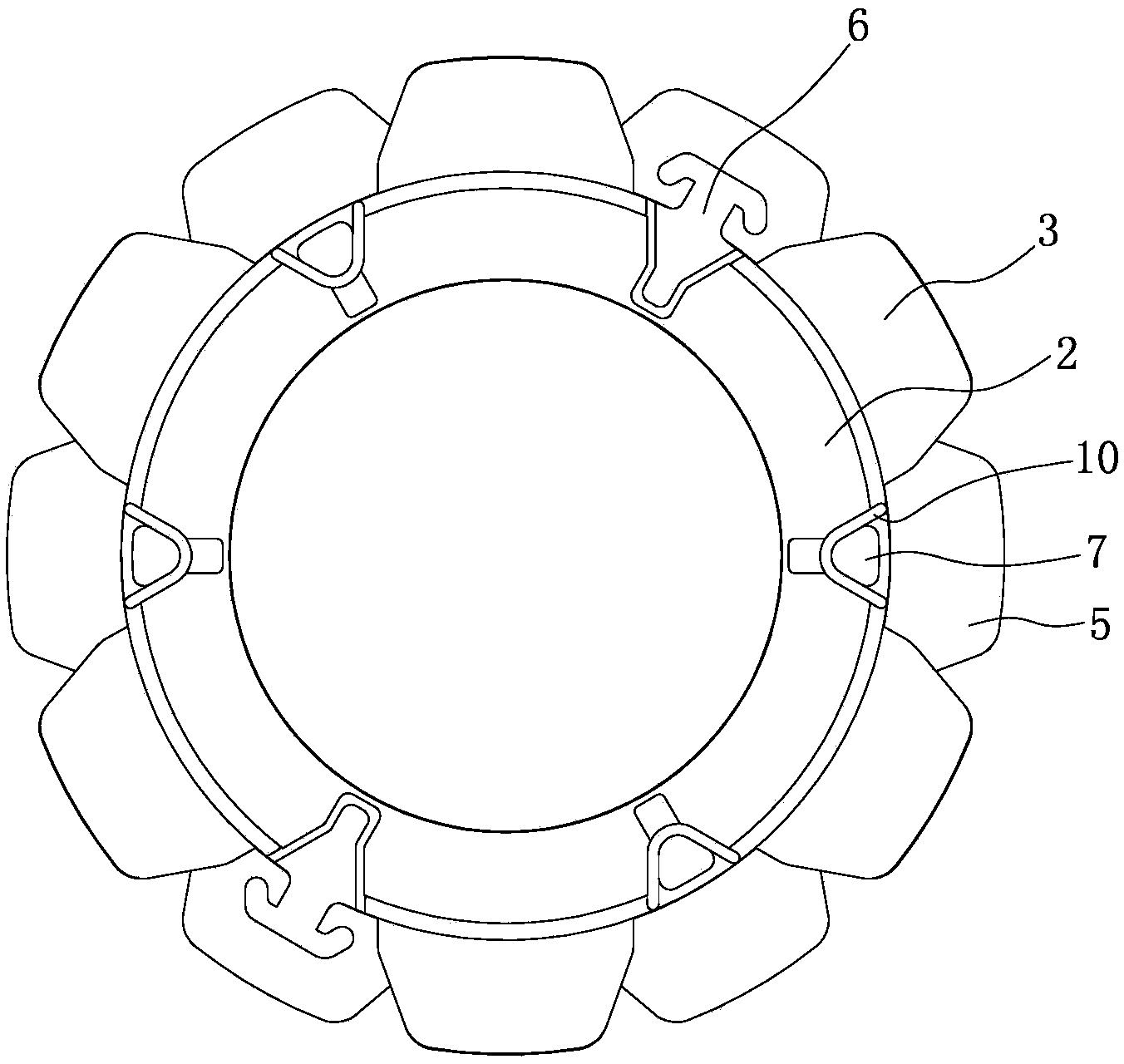

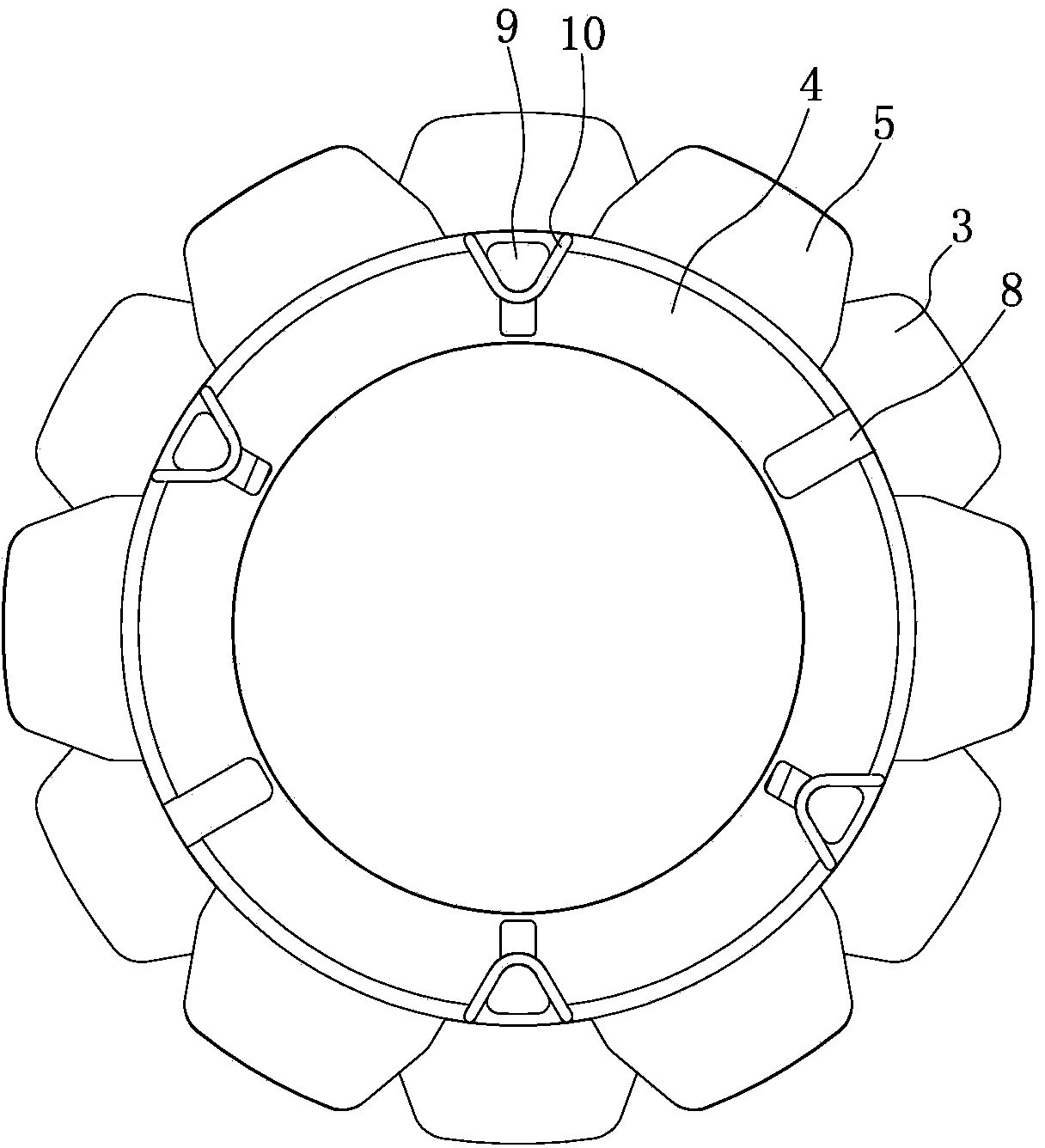

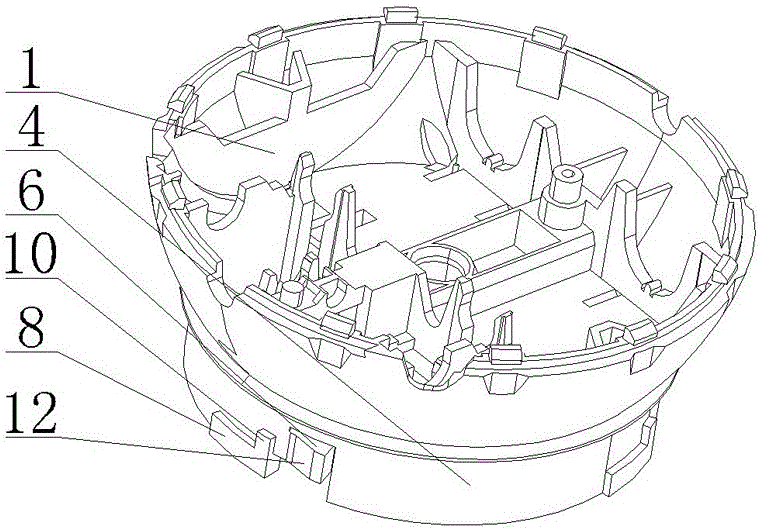

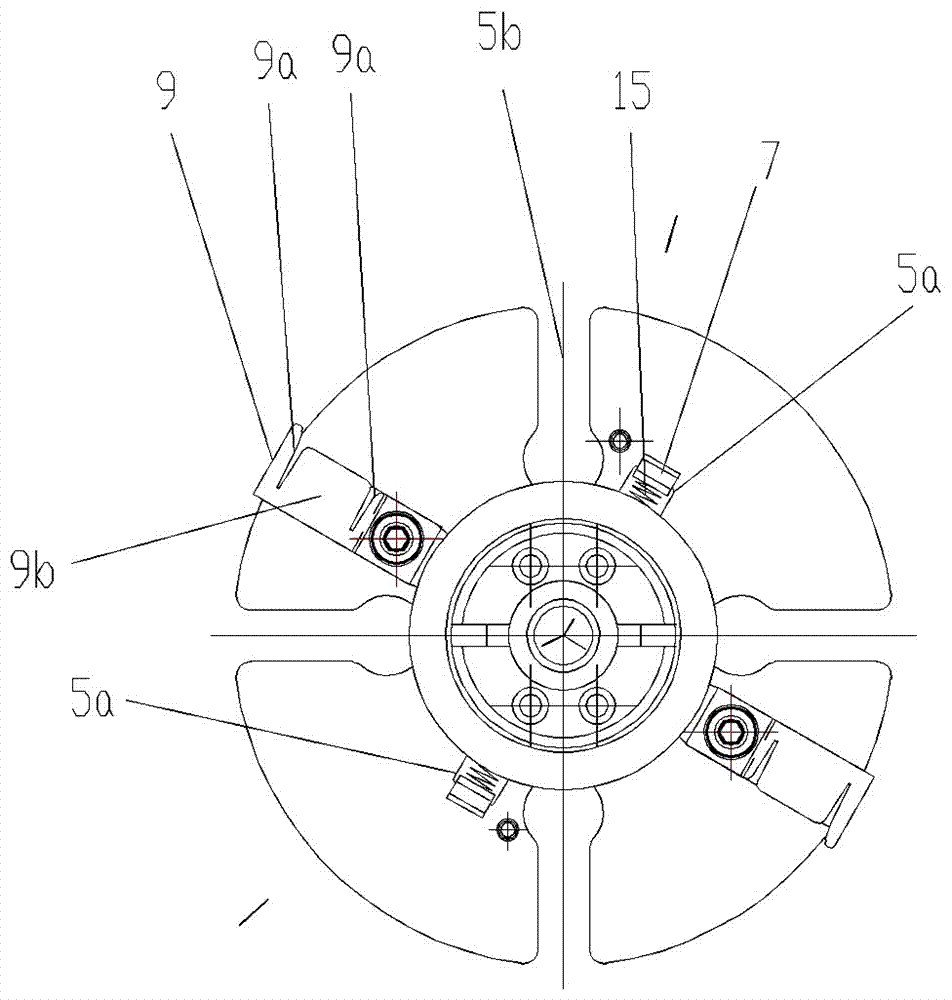

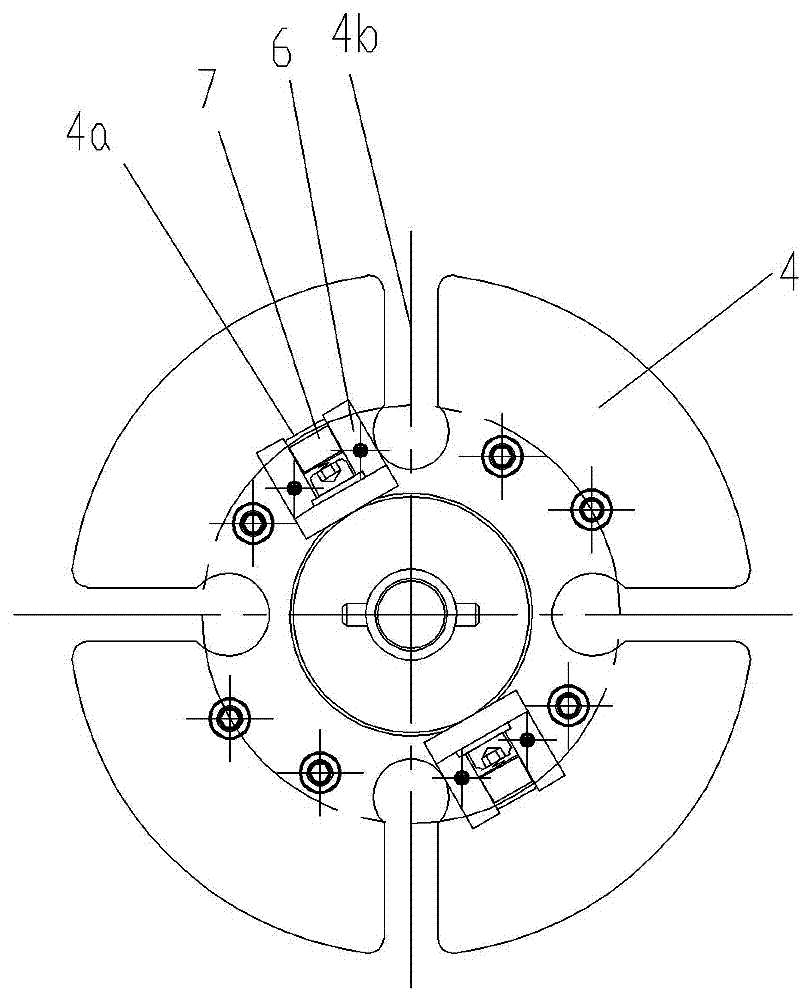

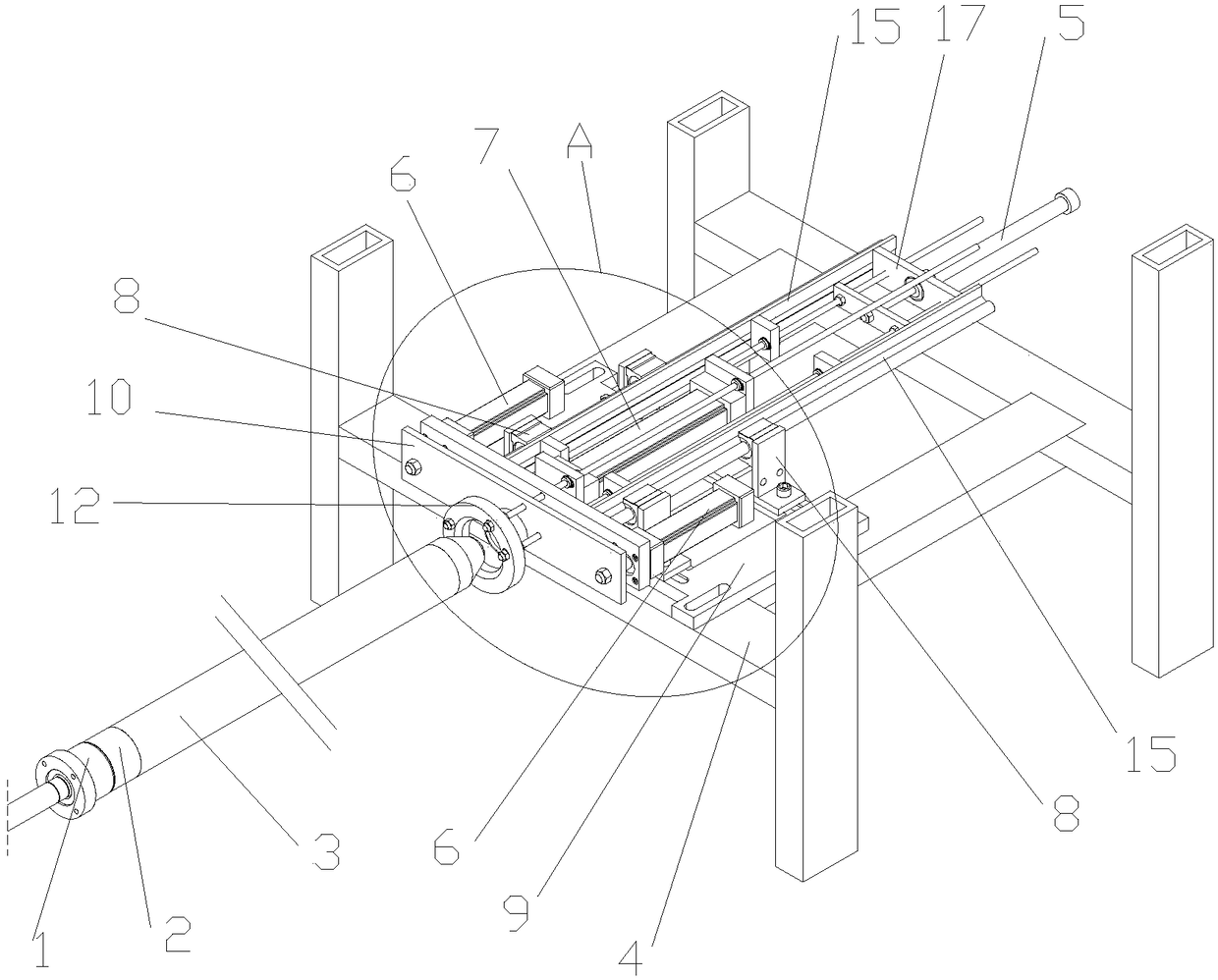

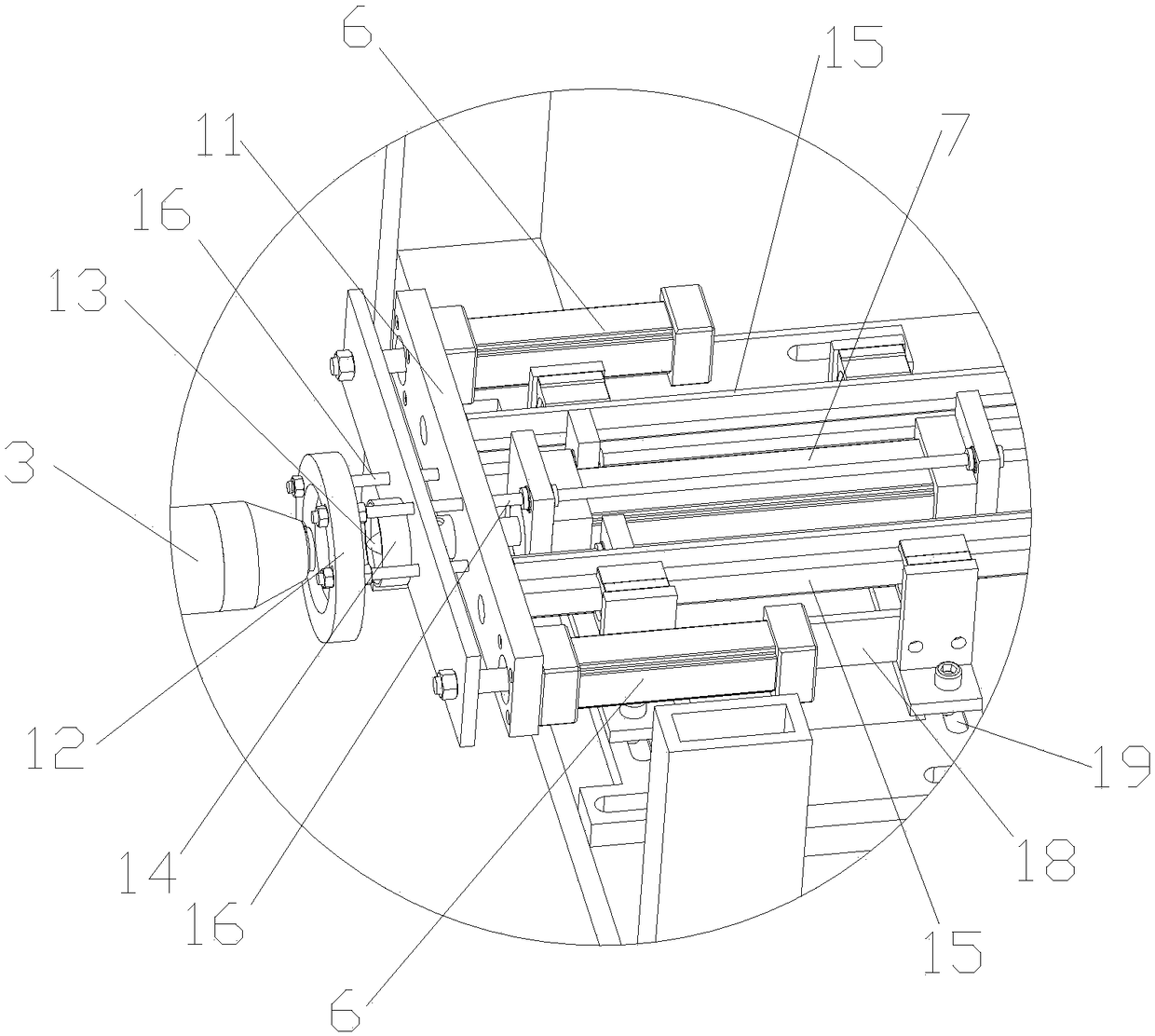

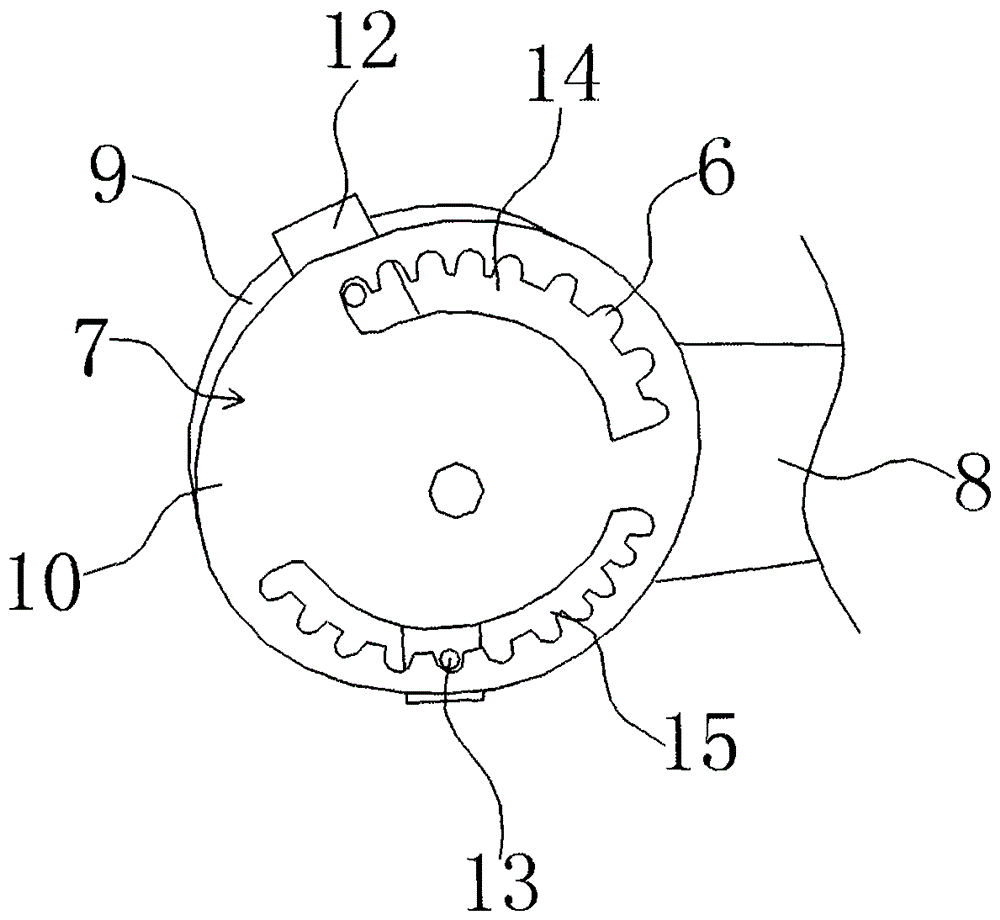

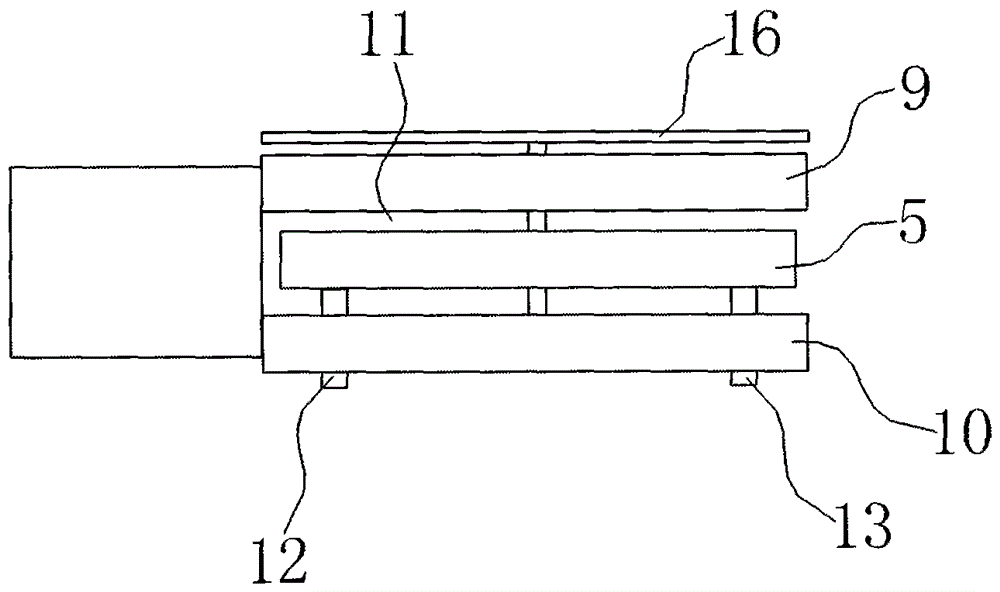

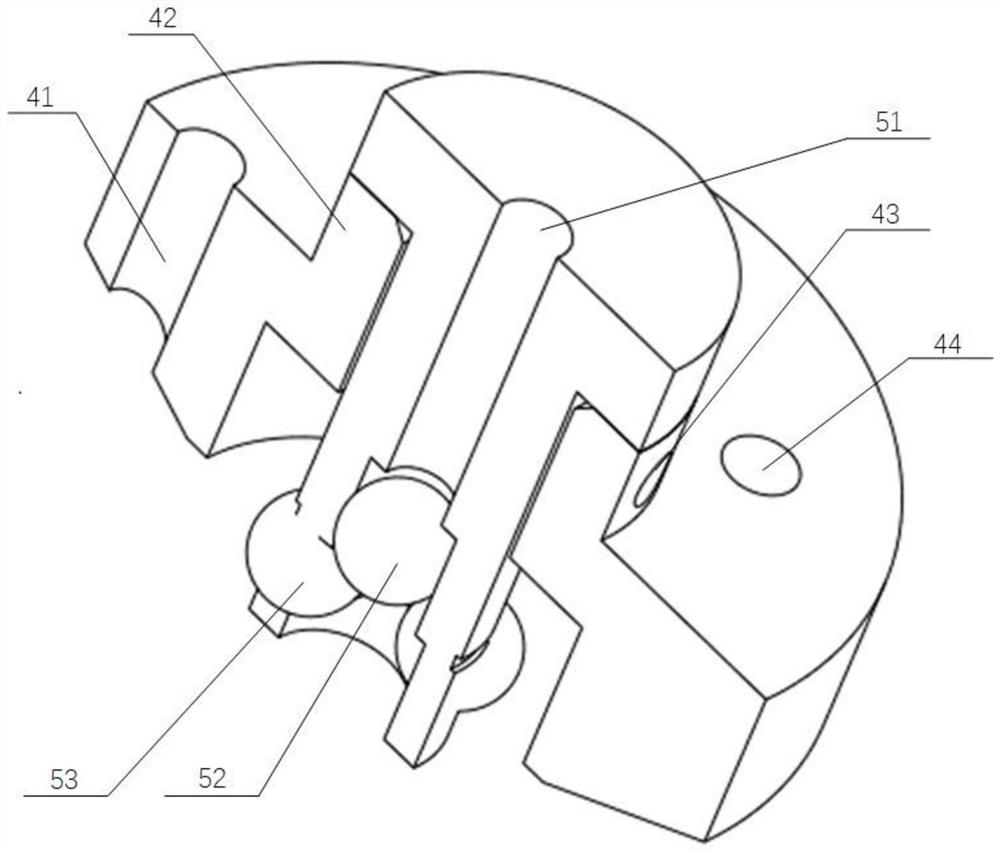

Full-automatic winding die for frameless coil winding

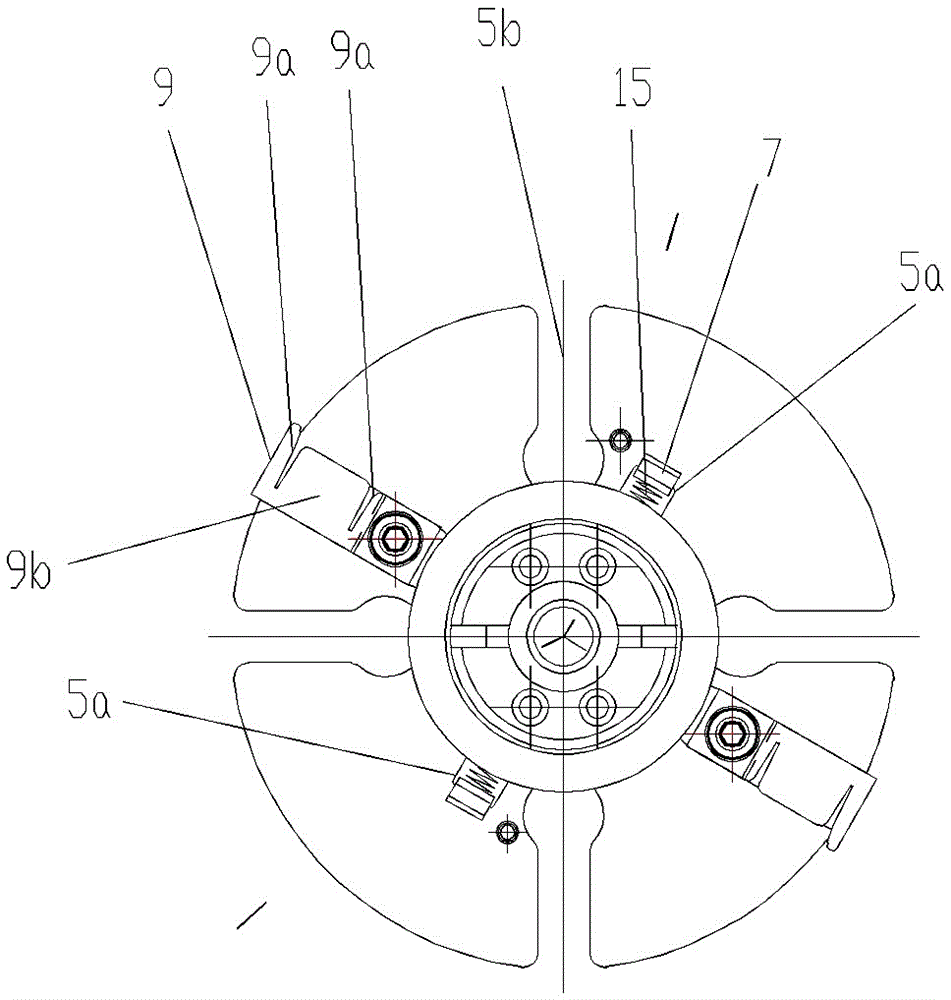

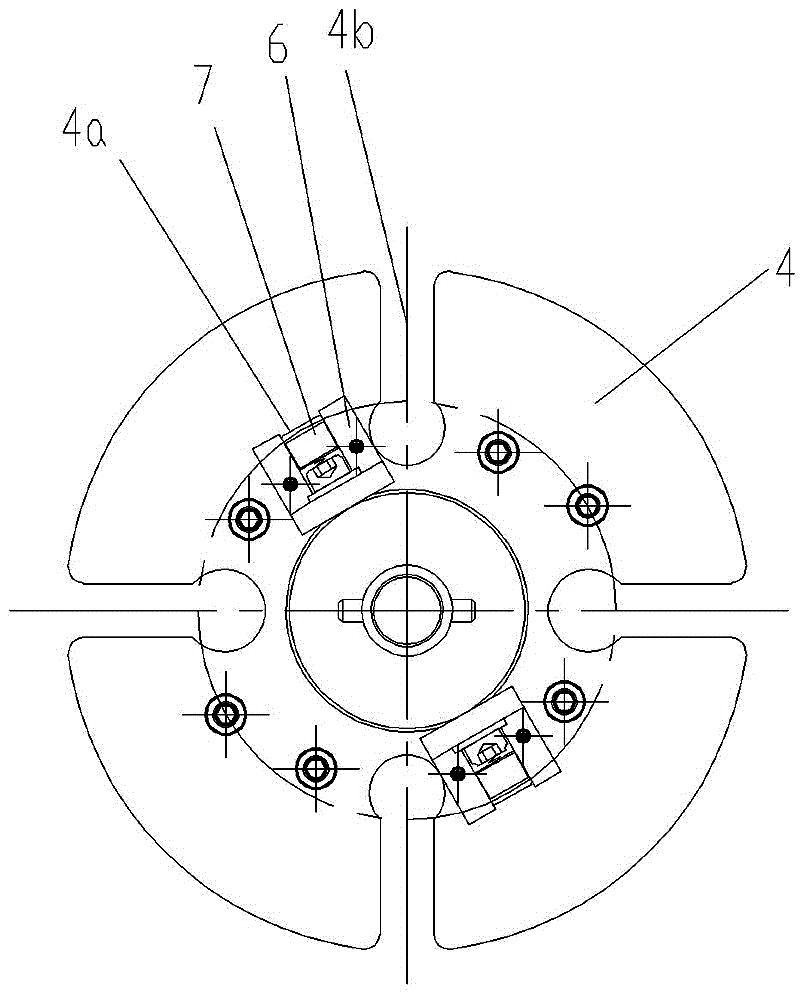

ActiveCN105529178ASimple structureEasy to assemble and disassembleInductances/transformers/magnets manufactureWinding machineEngineering

The invention relates to a full-automatic winding die for a frameless coil winding. The full-automatic winding die is characterized by comprising a die core sleeve (1), wherein the die core sleeve (1) is fixedly connected with a fixed disc (4), a die core shaft (2) is fixedly sleeved in an inner hole of the die core sleeve (1), a sidling sleeve (3) wraps the die core shaft (2) in a circumferential fixing and axial sliding way and is internally sleeved in the inner hole of the die core sleeve (1), a movable disc (5) is arranged between the sliding sleeve (3) and the die core sleeve (1), a buckle device is arranged between the die core sleeve (1) and / or the fixed disc (4) and the movable disc (5), one end, connected with a winding sliding block (10), of the die core sleeve (1) extends into the inner hole of the die core sleeve (1), and the inner end part of the winding sliding block (10) is in extruded matching with the sliding sleeve (3). After the adoption of the above technical scheme, a plurality of full-automatic winding dies for the frameless coil winding can be arranged on a full-automatic winding machine, the efficiency is greatly improved, and mass operation can be proceeded.

Owner:ANHUI HAOFANG ELECTROMECHANICS

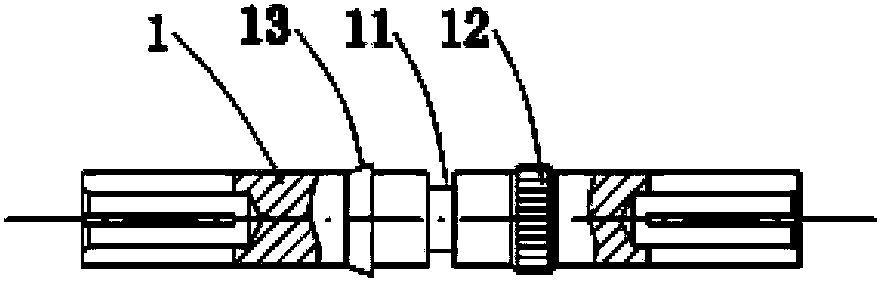

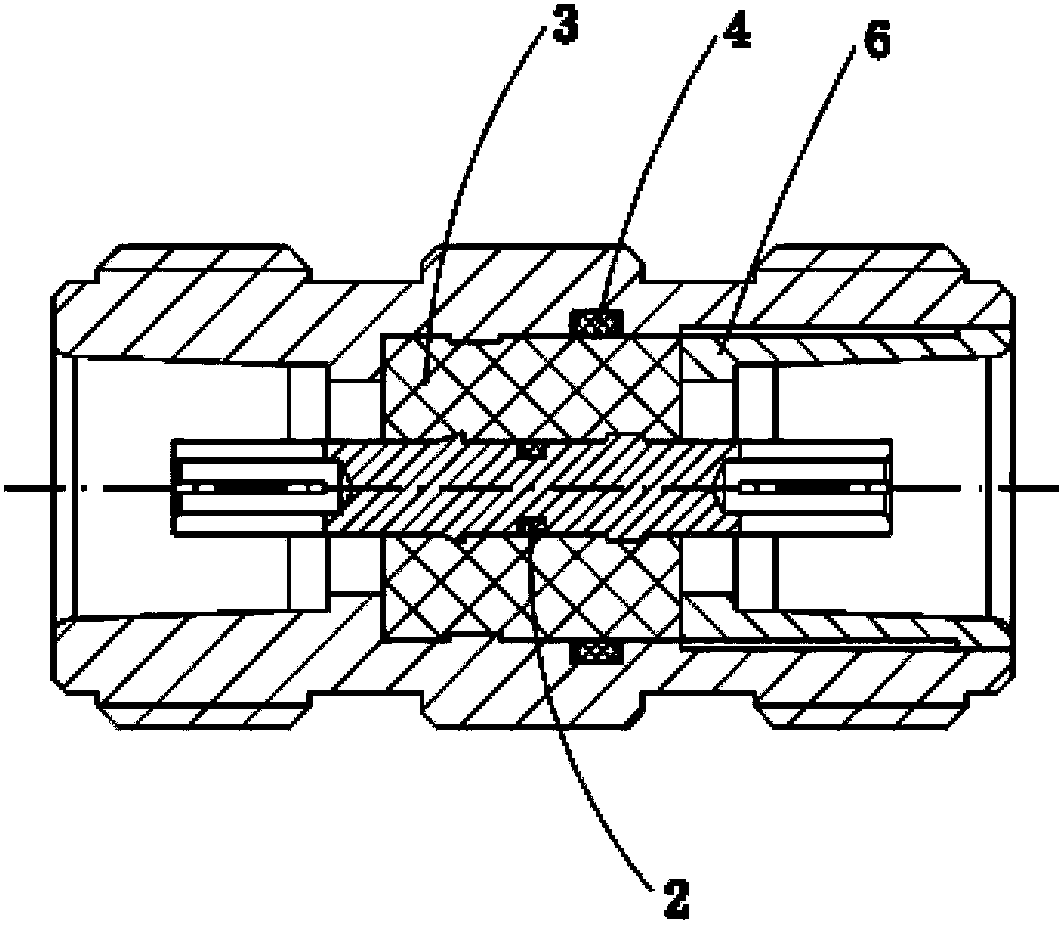

Air-tightness joint with double female ends

InactiveCN103427225AAchieve airtightnessSmooth transmissionSecuring/insulating coupling contact membersCoupling contact membersMating connectionElectrical conductor

The invention discloses an air-tightness joint with double female ends which comprises an inner conductor at the center, an insulating medium coaxially sleeved outside the inner conductor, and an outer conductor with a stepped hole type inner cavity. The insulating medium is arranged in the stepped hole of the outer conductor and is coaxially arranged together with the outer conductor; a fixing block is connected to an opening part of a stepped hole of the outer conductor in a close fit manner; the fixing block and the step surface of the stepped hole form axial limitation at two ends of the insulating medium. The air-tightness joint with double female ends has a simple structure, good air tightness, strong environment tolerance, reliable mechanical performances, excellent electric performances and high assembling efficiency, and is suitable for production on a large scale.

Owner:安徽蓝麦通信股份有限公司

Hollow coil winding jig

InactiveCN107946068AStable temperatureReduce processing difficultyInductances/transformers/magnets manufactureAir coreConductor Coil

Owner:TANAC AUTOMATION

Textile fabric processing equipment

InactiveCN111979664ARealize the function of entering and rewindingFull screed functionTextile treatment machine arrangementsTextile treatment carriersReciprocating motionGear wheel

The invention discloses textile fabric processing equipment. The textile fabric processing equipment comprises a rack, wherein a bottom plate is fixedly mounted at the bottom of one end of the rack; adriving winding mechanism is arranged at the top of the bottom plate; a material mixing and coating mechanism is arranged at one end, far away from the bottom plate, of the top of the rack; supporting rollers are arranged at two sides of the material mixing and coating mechanism; the supporting rollers are mounted at the inner side of the top of the rack; an ironing mechanism is arranged at the top of the rack; the driving winding mechanism comprises two supporting plates; the two supporting plates are mounted at the top of the bottom plate; a gear disc is arranged at the inner side of the top of each supporting plate; and the middle part of each gear disc is in rotary connection with a driving shaft. According to the textile fabric processing equipment disclosed by the invention, a transverse rod is driven to do continuous reciprocating motion through the sliding of a winding clamping shaft and a vertical sliding groove plate; and the functions of automatically preparing, mixing andcoating are realized and a sufficient ironing function of fabric is also realized, so that the processing efficiency of blank fabric processing is greatly improved.

Owner:张萍

Automobile generator rotor framework

InactiveCN103928998ASimple structureEasy to processMagnetic circuit rotating partsElectricityCopper wire

The invention discloses an automobile generator rotor framework. A first baffle (2) is arranged at one end of a barrel (1), a second baffle (4) is arranged at the other end of the barrel (1), two sets of first holes (7) are formed in the first baffle (2), and each first hole (7) is formed between two adjacent first fan blades (3). Two protruding edges (8) are arranged on the second baffle (4), the two protruding edges (8) are arranged on the same straight line, two sets of second holes (9) are formed in the second baffle (4) and are formed in the two sides of the center connecting line of the two protruding edges (8) respectively, and each second hole (9) is formed between two adjacent second fan blades (5). According to the automobile generator rotor framework, insulation liquid can be completely permeated into the innermost layer of a copper wire, a claw pole, the framework and the copper wire are completely fixed, meanwhile, the framework and the claw pole can be fixed in the circumferential direction, the framework is prevented from shifting or breaking away, and therefore the copper wire is effectively prevented from being broken, and the defect that a generator does not generate electricity is overcome.

Owner:重庆博耐特实业(集团)有限公司

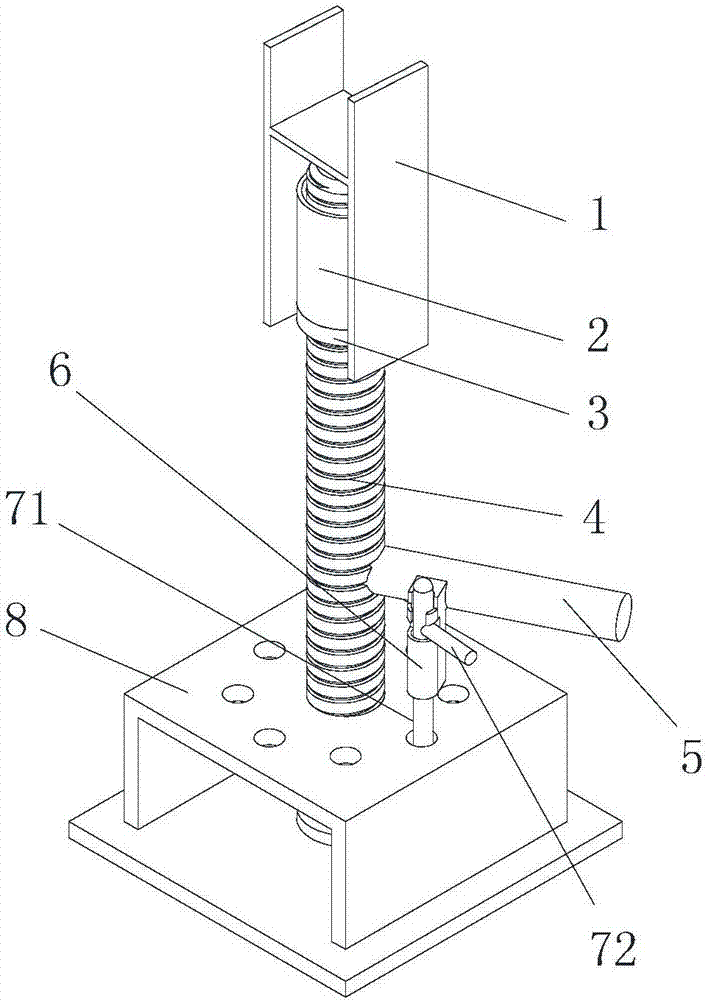

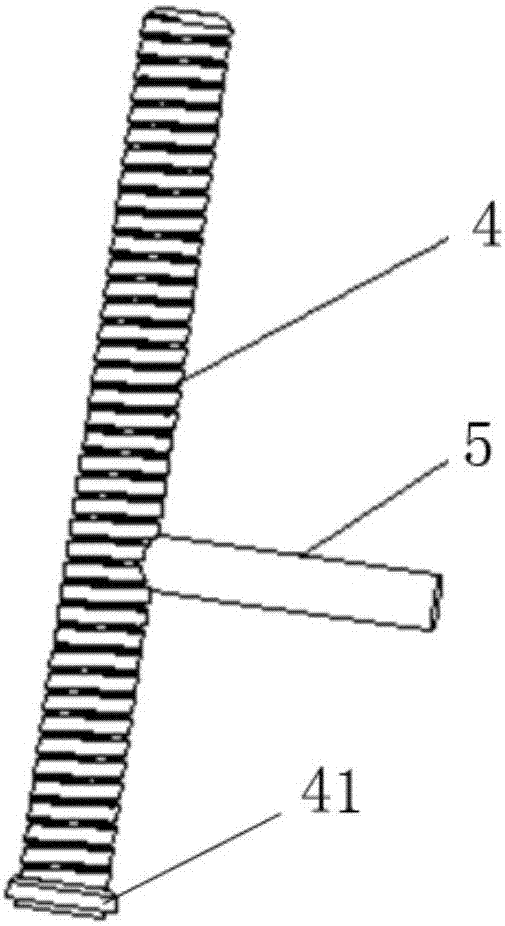

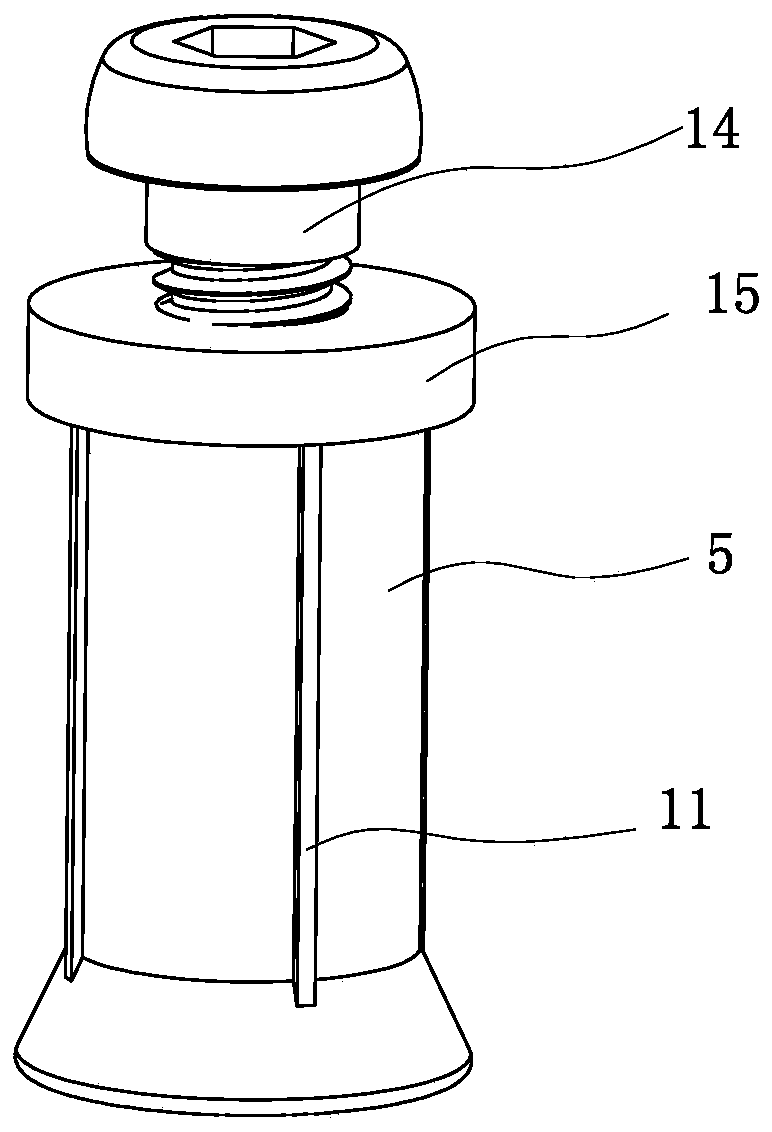

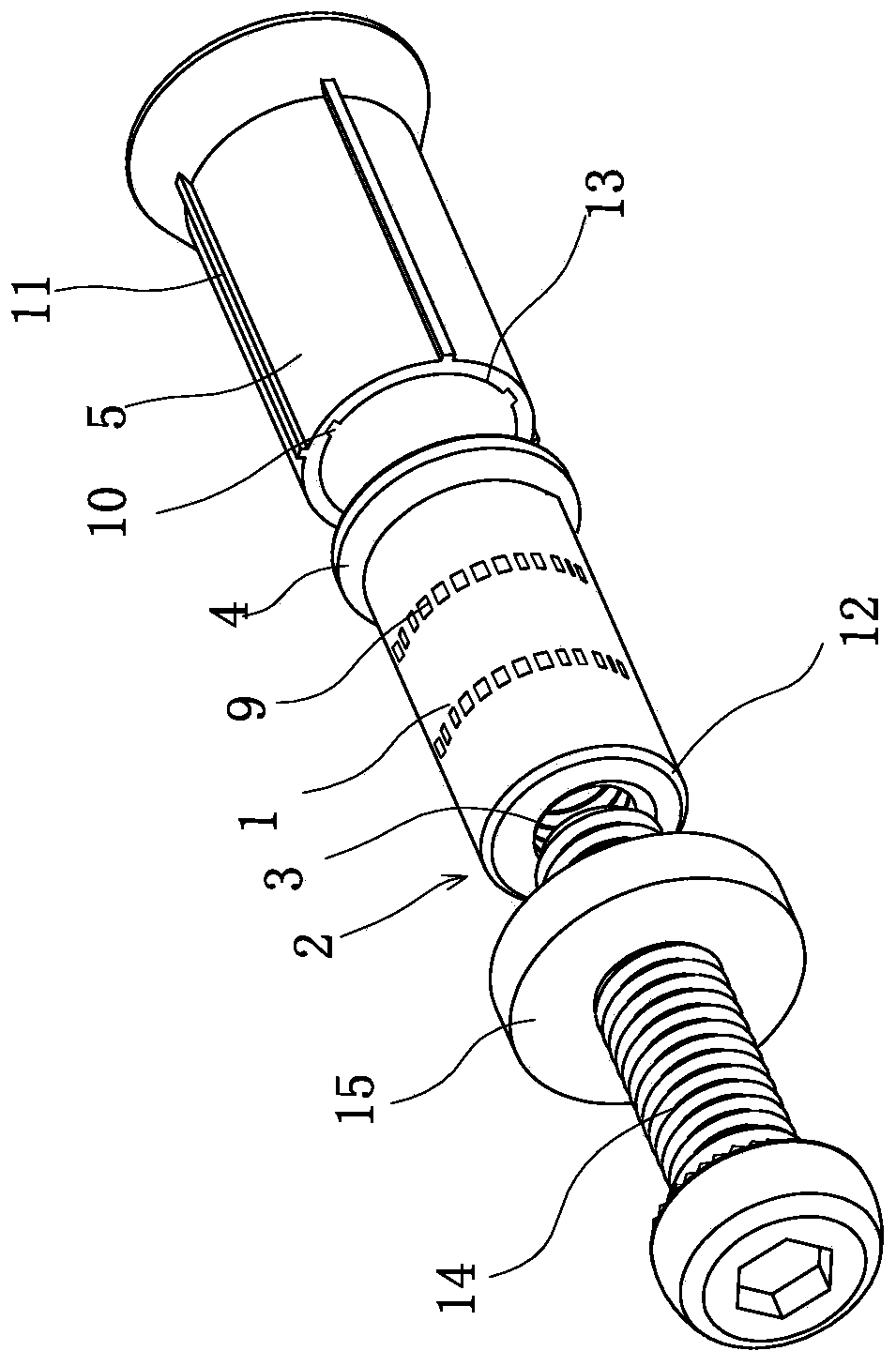

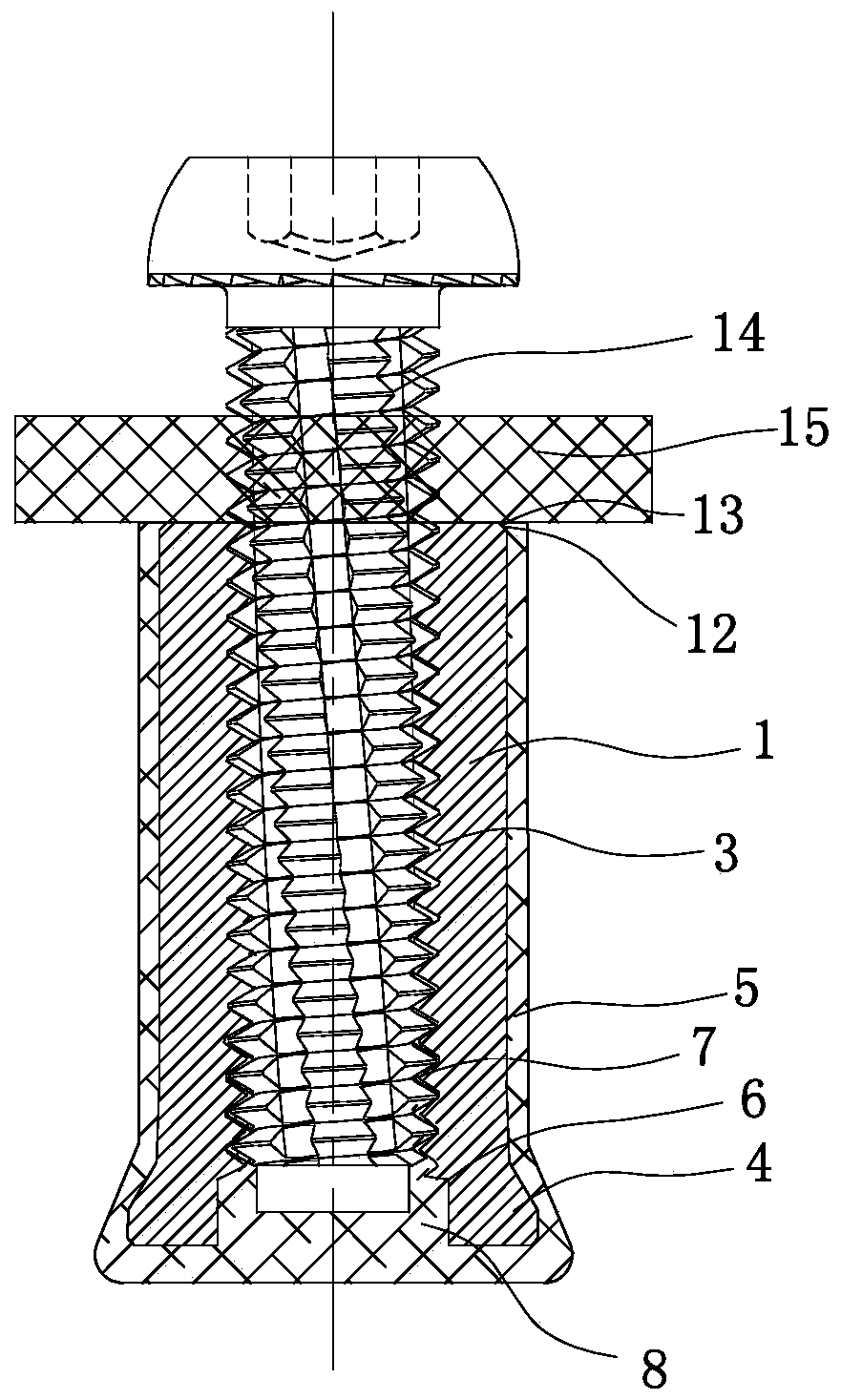

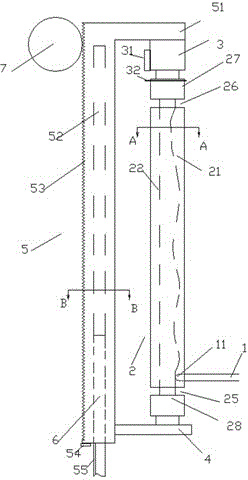

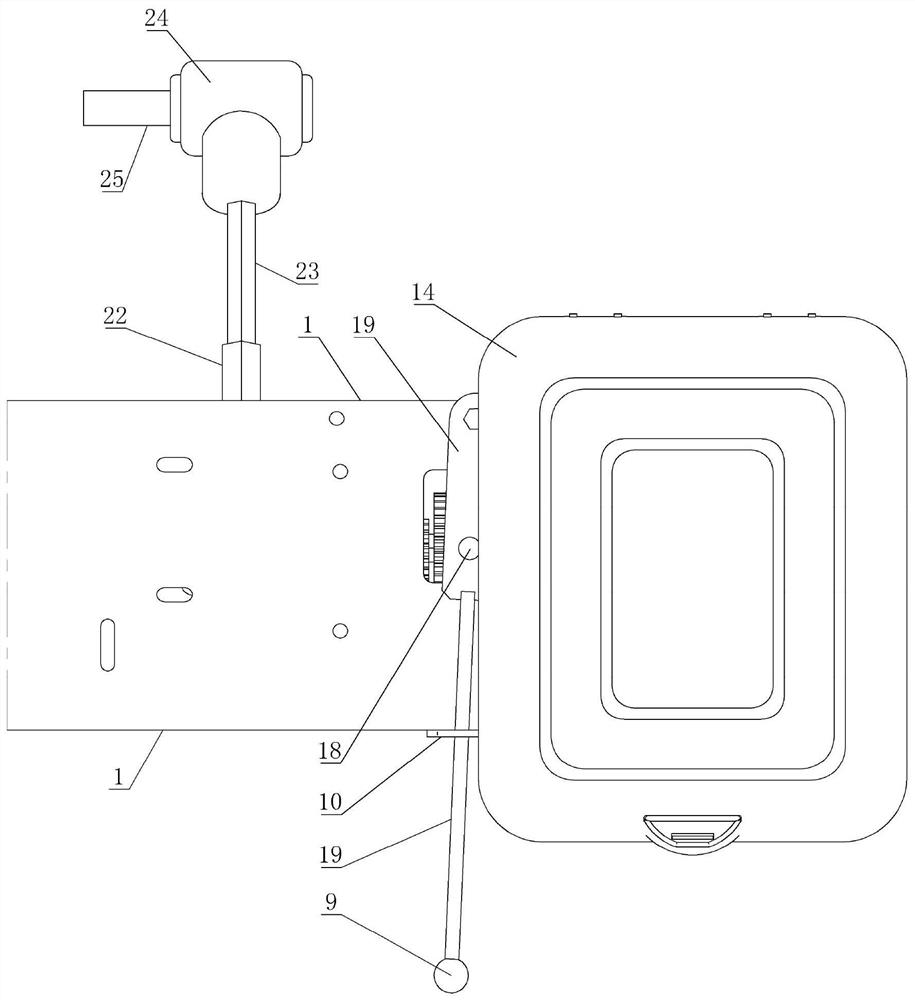

Side template vertical support anti-loose device

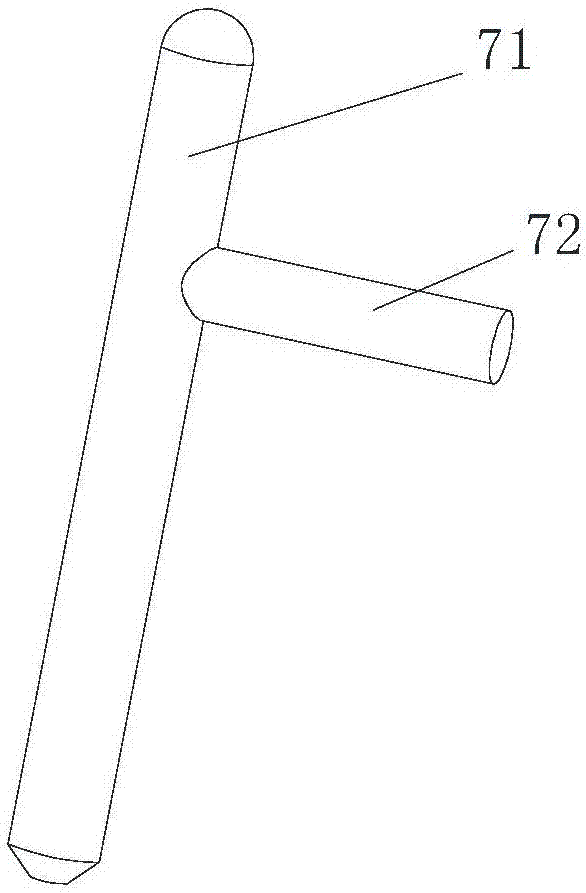

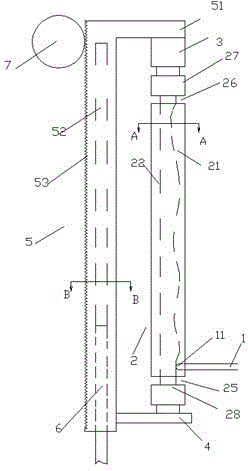

InactiveCN107299758AAchieve circumferential fixationPrevent reversalAuxillary members of forms/shuttering/falseworksArchitectural engineeringEngineering

The invention discloses a side template vertical support anti-loose device. The device comprises a top supporting block, a threaded rod and a base, the top supporting block is used for connecting side templates and located above the base, the top supporting block is connected with the threaded rod in a screw mode, and the lower portion of the threaded rod is inserted onto the base in a penetrating mode; a limit rod is fixedly connected to one side of the threaded rod, and a limit sleeve is fixedly connected to the limit rod; the anti-loose device further comprises a stop pin, a guide hole is formed in the base, the threaded rod penetrates through the guide hole, multiple stop pin holes are evenly distributed in the base in the mode of surrounding the guide hole, and the stop pin holes are matched with the stop pin; when the stop pin penetrates through the limit sleeve and is inserted into some stop pin hole, the threaded rod cannot rotate under the effect of external forces; when the stop pin is not inserted into some stop pin hole, the threaded rod can rotate under the effect of the external forces. The side template vertical support anti-loose device achieves circular fixation of the threaded rod in the working process and guarantees effective vertical supporting for the side templates.

Owner:青岛林川工程技术有限公司

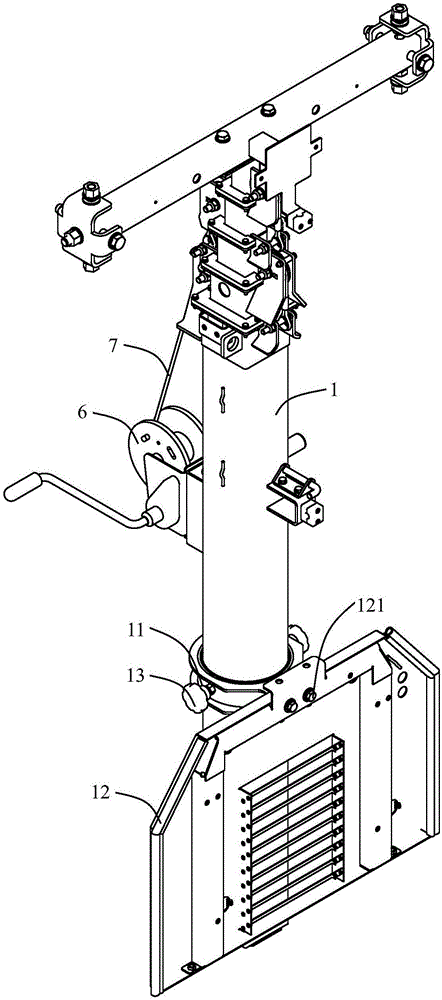

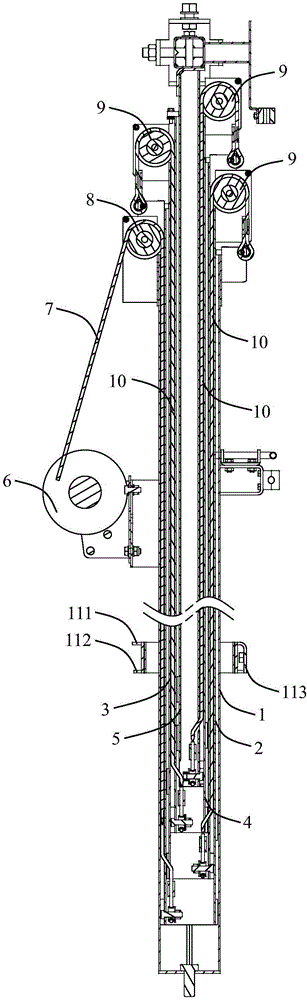

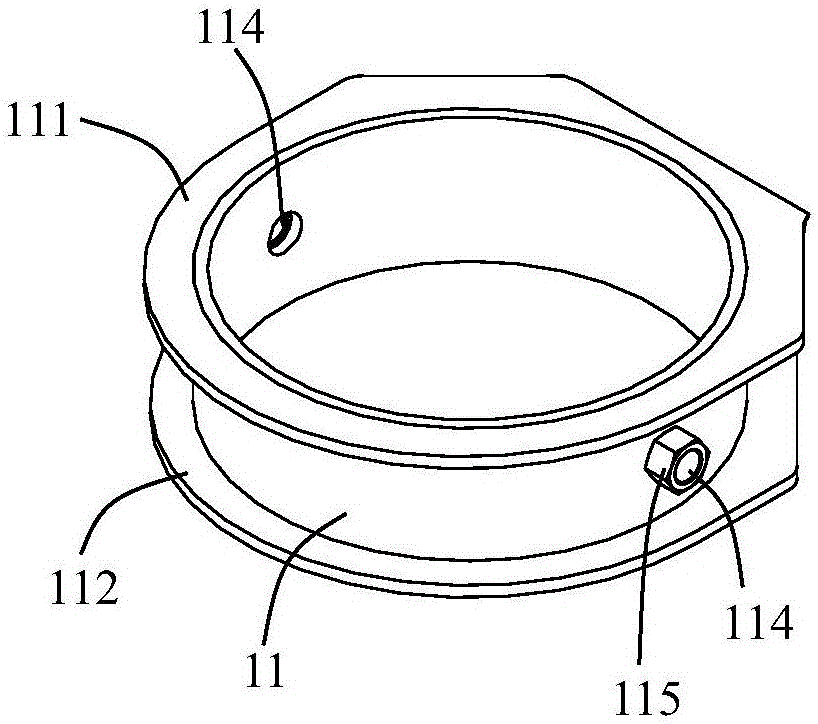

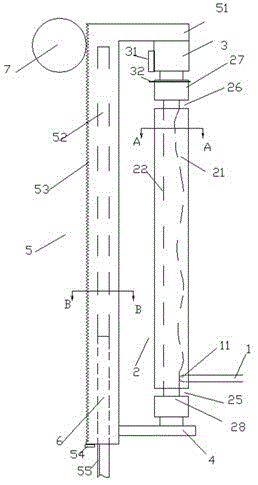

Lighthouse lifting device

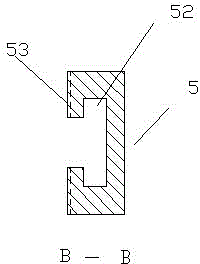

PendingCN106704995AEven by forceExtended service lifeLighting support devicesElectric circuit arrangementsTurning framesEngineering

The invention discloses a lighthouse lifting device which is mounted on a moveable frame and comprises a plurality of hollow rods, wherein the hollow rods are connected in sequence in a sleeved manner; the outermost hollow rod is fixedly arranged on the moveable frame; the innermost hollow rod is connected with a lamp; a driving mechanism is arranged on the outer side of the outermost hollow rod; a first pulley is arranged at the top of the outermost hollow rod; a first steel wire rope is arranged on the first pulley; one end of the first steel wire rope is connected with the driving mechanism; the other end of the steel wire rope crosses the first pulley and is connected with the bottom of a hollow rod adjacent to the outermost hollow rod; a second pulley is arranged at the top of a hollow rod between the outermost hollow rod and the innermost hollow rod; a second steel wire rope is arranged on the second pulley; one end of the second steel wire rope is connected with the top of a hollow rod positioned on the outer side of the hollow rod; the other end of the second steel wire rope crosses the second pulley and is connected with the bottom of a hollow rod positioned on the inner side of the hollow rod; a plurality of second pulleys are respectively distributed on two sides of the hollow rods. By adopting the lighthouse lifting device disclosed by the invention, the hollow rods can be stressed uniformly.

Owner:ATLAS COPCO WUXI COMPRESSOR

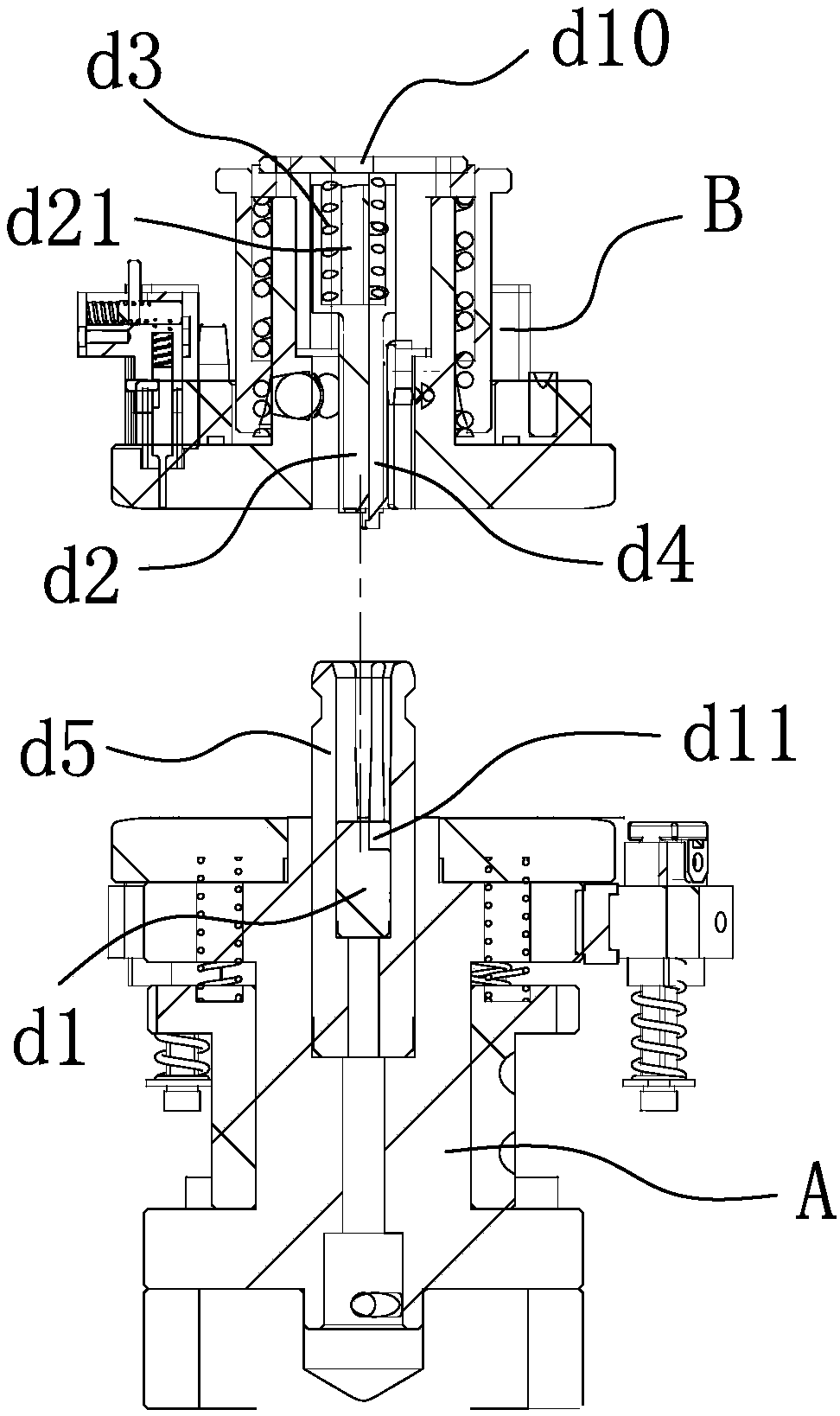

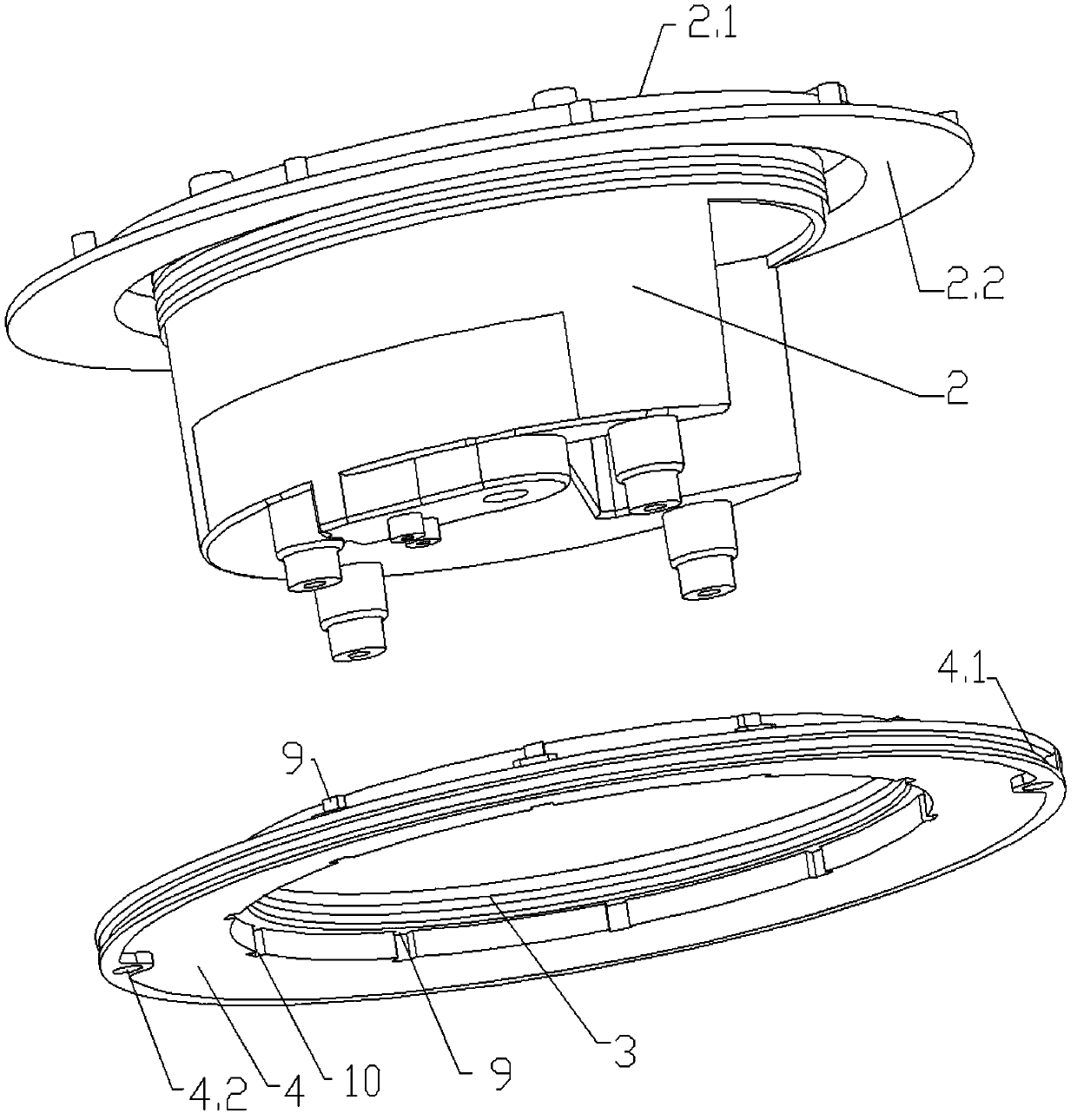

Cloth cover tightening mechanism of full automatic automobile cover

A cloth cover tightening mechanism of a full automatic automobile cover comprises a fixing seat (2), an adjusting ring (3) arranged on the fixing seat (2) through threads in a screwed and sleeved mode, a transmission ring (4) circumferentially fixed and axially and movably clamped to the adjusting ring (3) in a sleeved mode, at least one hose (7) connected with a cloth cover (5) and a tightening rope (8), wherein the end of the hose (7) is fixed to a closing rotating disc (6) of an automobile cover opening mechanism, and the tightening rope (8) is arranged along the circle of a cover opening in the lower end of the cloth cover (5). The fixing seat (2) is provided with a baffle (2.1) for limiting the excessive rotation of the adjusting ring (3), the tightening rope (8) stretches out of the cover opening in the lower end of the cloth cover (5), sequentially penetrates through the hose (7) and the closing rotating disc (6) and then is fixed to the transmission ring (4), and the number of turns of the spread cloth cover (5) and the spread tightening rope (8) is larger than the number of turns of the one-direction screwing of the adjusting ring (3) along the fixing seat (2). The tightening mechanism can automatically tighten the cover opening when the cloth cover is blown by wind, and the cloth cover is prevented from bulging and even being blown away by the wind.

Owner:胡建明

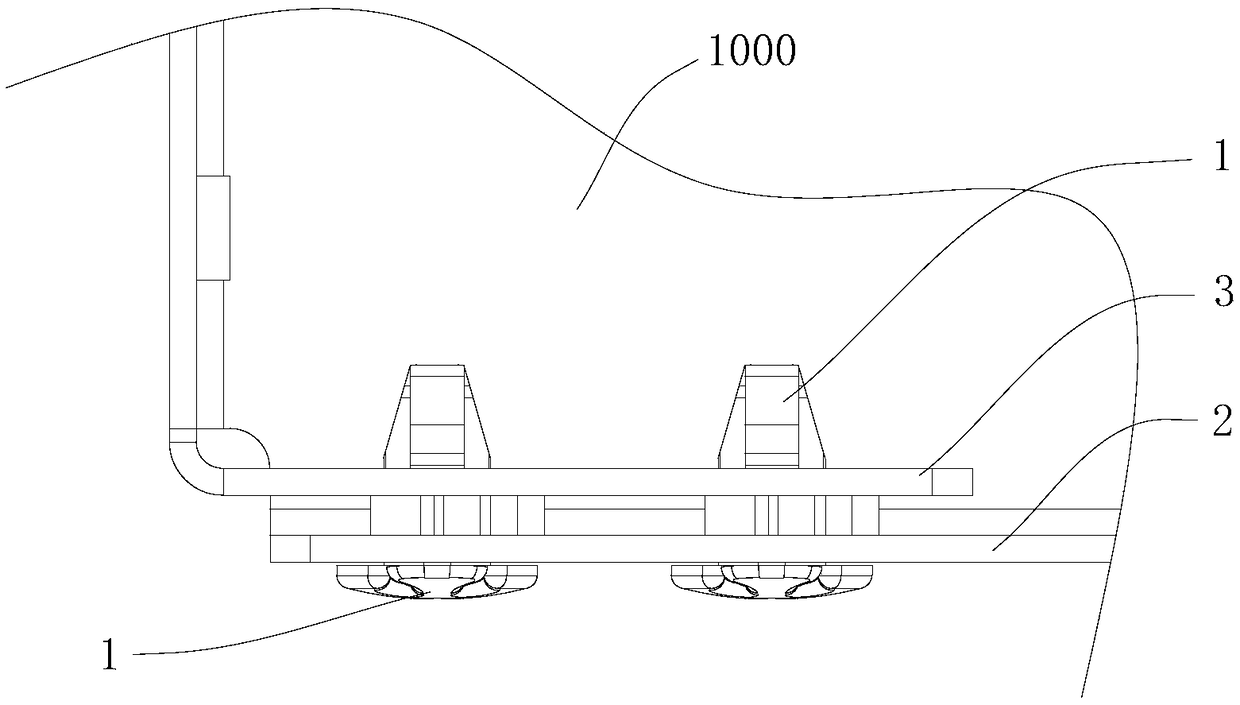

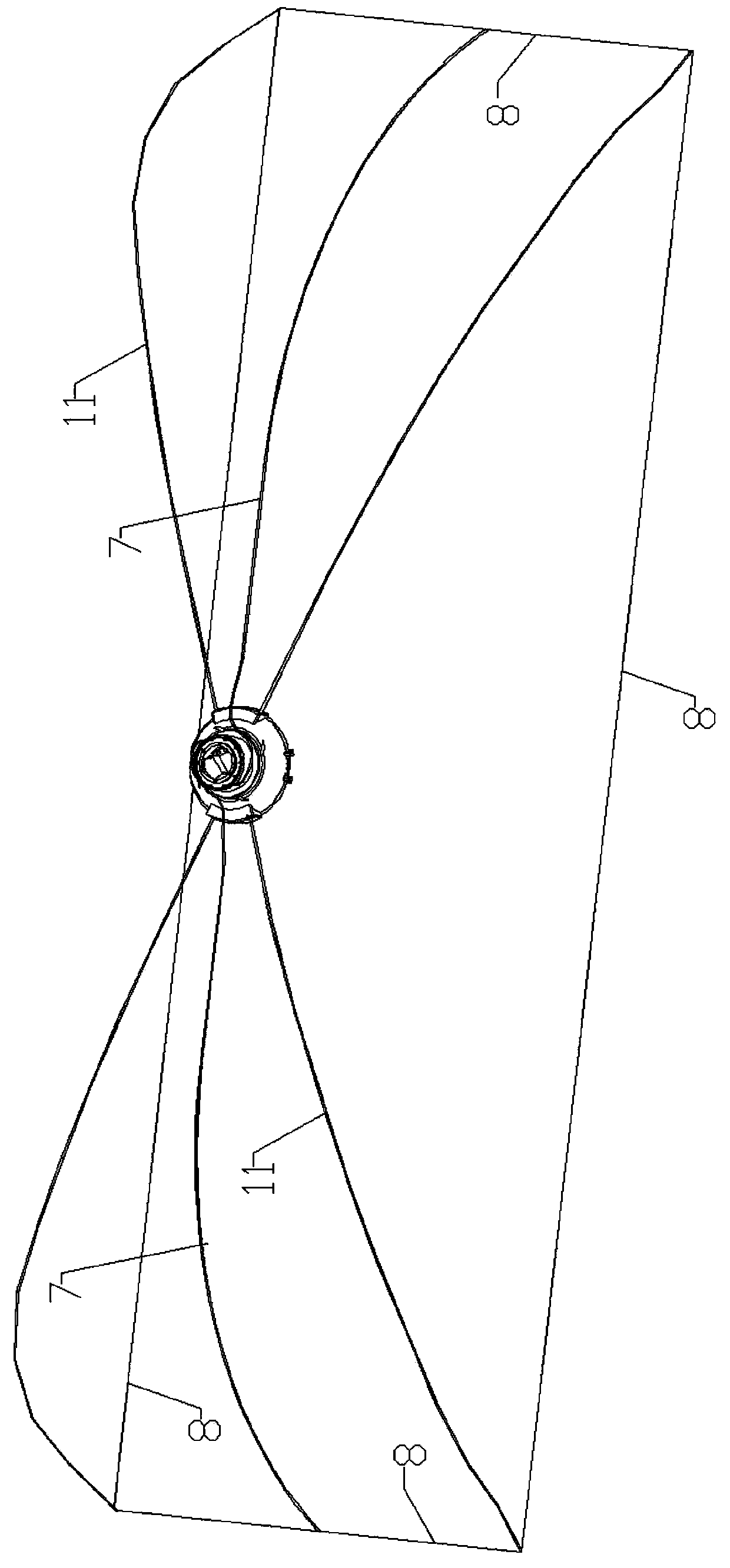

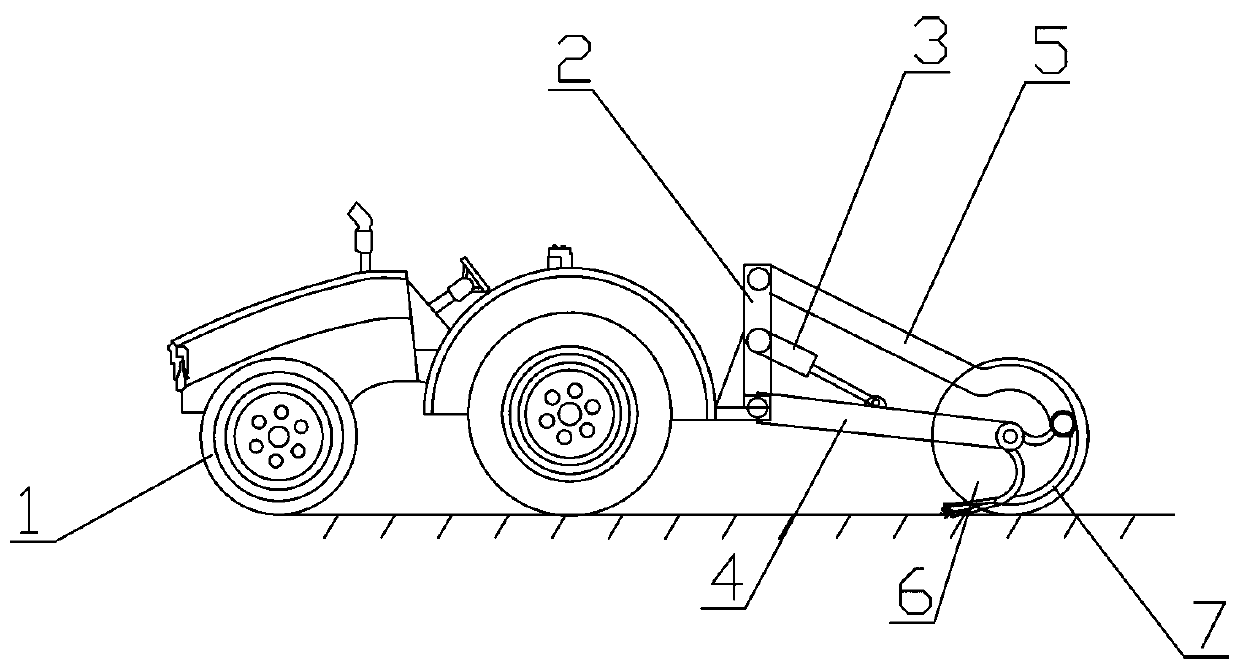

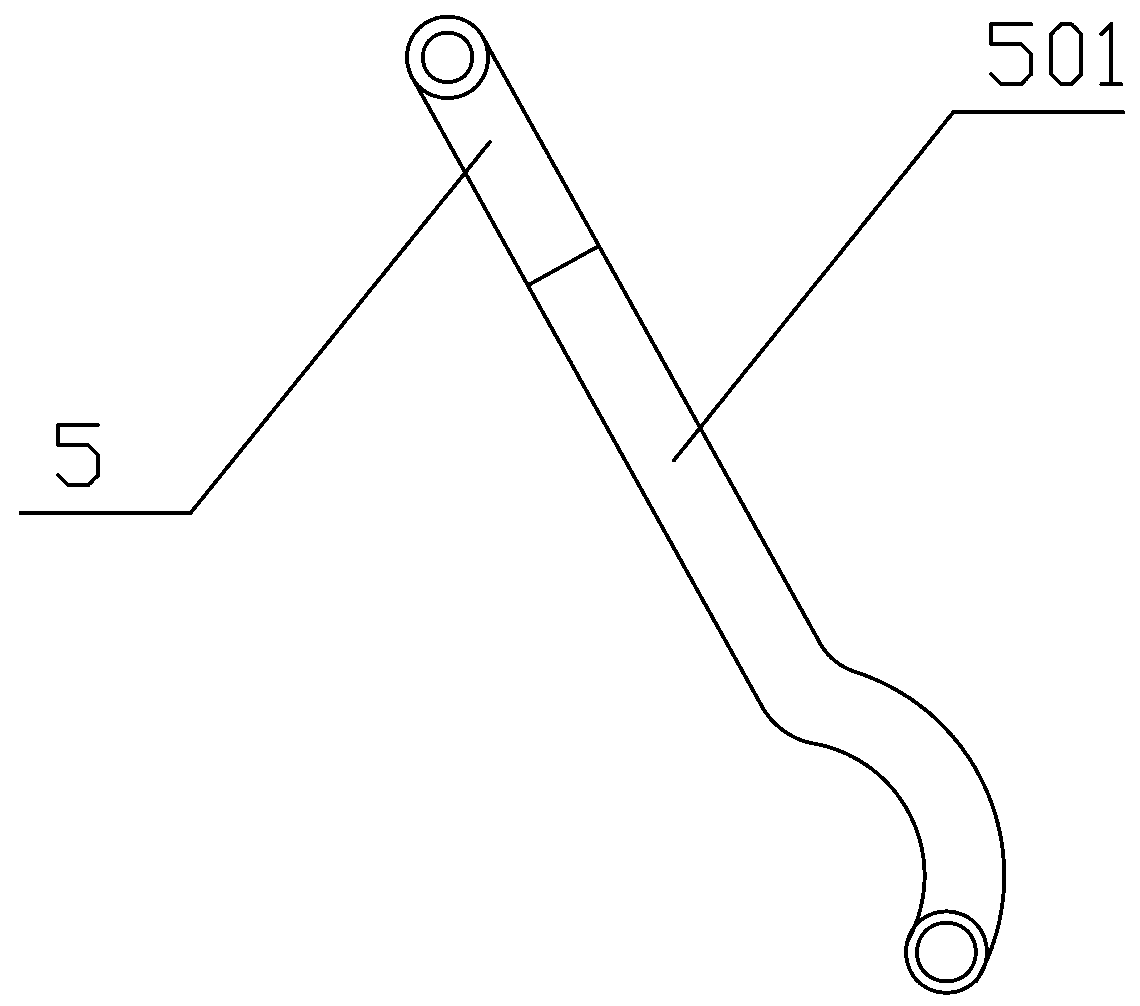

Suspended turf transplanting machine

ActiveCN109511475ASimple structureEasy to operateHops/wine cultivationTurf growingFixed frameControl arm

The invention relates to a suspended turf transplanting machine. The suspended turf transplanting machine comprises a fixing frame, the fixing frame is provided with a turf transplanter, the turf transplanter comprises a connecting rod, a control arm, a running mechanism and knife rests, the front end of the connecting rod is rotatably connected with the fixing frame, the rear end of the connecting rod extends laterally towards two sides to form a hollow first connecting portion, the first connecting portion is connected with the running mechanism for driving the turf transplanter to move, thefront end of the control arm is rotatably connected with the fixing frame, the rear end of the control arm is divided into two symmetrical second connecting portions, the two second connecting portions are respectively provided with the knife rests, every knife rest generally has a sector-shaped shape, a cutting member is clamped between the two knife rests, the cutting member and knife plats areconnected by connecting pieces, a driving mechanism is arranged between the fixing frame and the turf transplanter, and the turf transplanter can be lowered and lifted relative to the fixing frame under the driving of the driving mechanism. The suspended turf transplanting machine can effectively speed up the turf pulling process and improve the greening grass transplanting efficiency.

Owner:SHANGQIU NORMAL UNIVERSITY

Installation device for car rearview mirror

InactiveCN105059191AEnhanced axial fixationAchieve circumferential fixationOptical viewingRear-view mirrorEngineering

Owner:戴万岳

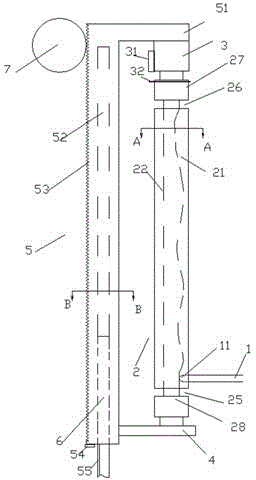

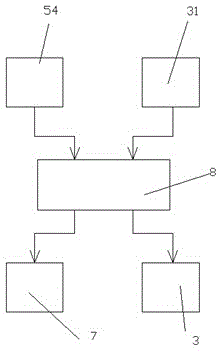

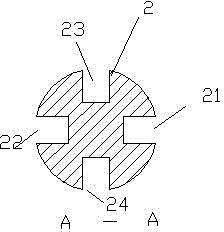

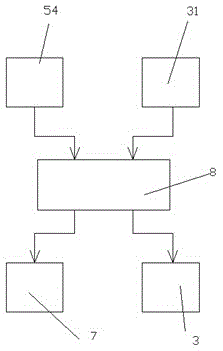

Tool profiling control system

InactiveCN104084845AStable mold changeMachining shape influenceCopying process control systemsControl systemEngineering

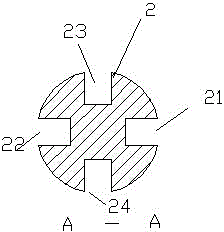

Disclosed is a tool profiling control system. The tool profiling control system comprises a tool profiling device and a control processor (8). The tool profiling device comprises a tool (1) and a profiling column (2), wherein the profiling column (2) is integrally in a cylindrical shape, and both ends of the cylindrical shaped are provided with an upper plug (27) and a lower plug (28); a middle profiling unit is formed between the upper plug (27) and the lower plug (28) and circumferentially and uniformly provided with four longitudinal profiling grooves (21, 22, 23 and 24) which are connected with the connecting end (11) of the tool (1); at least one of the four longitudinal profiling grooves is a return groove (22), the profiling contour of the return groove (22) is of a flat type, the other profiling grooves are curved grooves and are used for performing feeding control on the tool (1), and meanwhile, the curved grooves are different in curved surface shape.

Owner:AIRUI KETE TIANJIN PRECISION METAL TOOL CO LTD

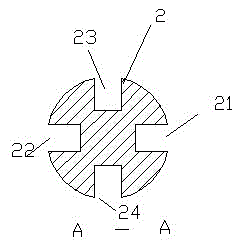

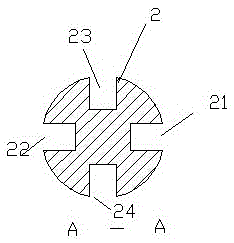

Cutter profiling device

InactiveCN104015102AStable mold changeMachining shape influenceCopying process control systemsEngineeringRisk stroke

The invention discloses a cutter profiling device. The cutter profiling device comprises a cutter (1) and a profiling column (2), wherein the profiling column (2) is cylindrical in the whole; two ends of the cylindrical part are respectively provided with an upper end cap (27) and a lower end cap (28); a middle profiling part is arranged between the upper end cap (27) and the lower end cap (28); four longitudinal profiling grooves (21, 22, 23 and 24) are uniformly distributed on the middle profiling part peripherally; the profiling grooves and a joint end part (11) of the cutter (2) are joined; at least one of the four longitudinal profiling grooves is a return stroke groove (22); the profiling outline of the return stroke groove is plane type; the rest profiling grooves in the four longitudinal profiling grooves are curved surface grooves for controlling feeding quantity of the cutter (1); moreover, the plurality of curved surface grooves have different curved surface shapes.

Owner:深圳市乔本金刚石刀具有限公司

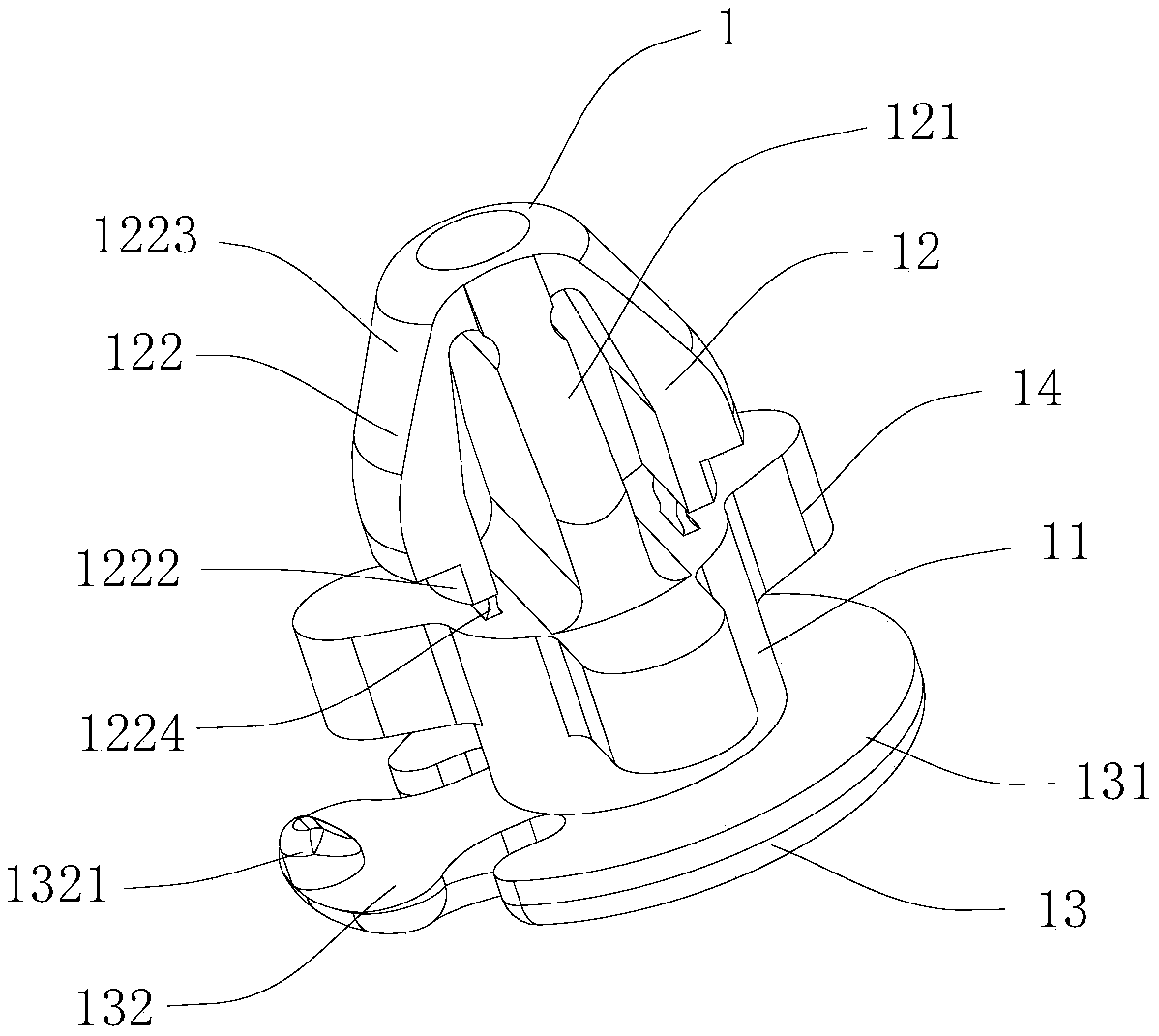

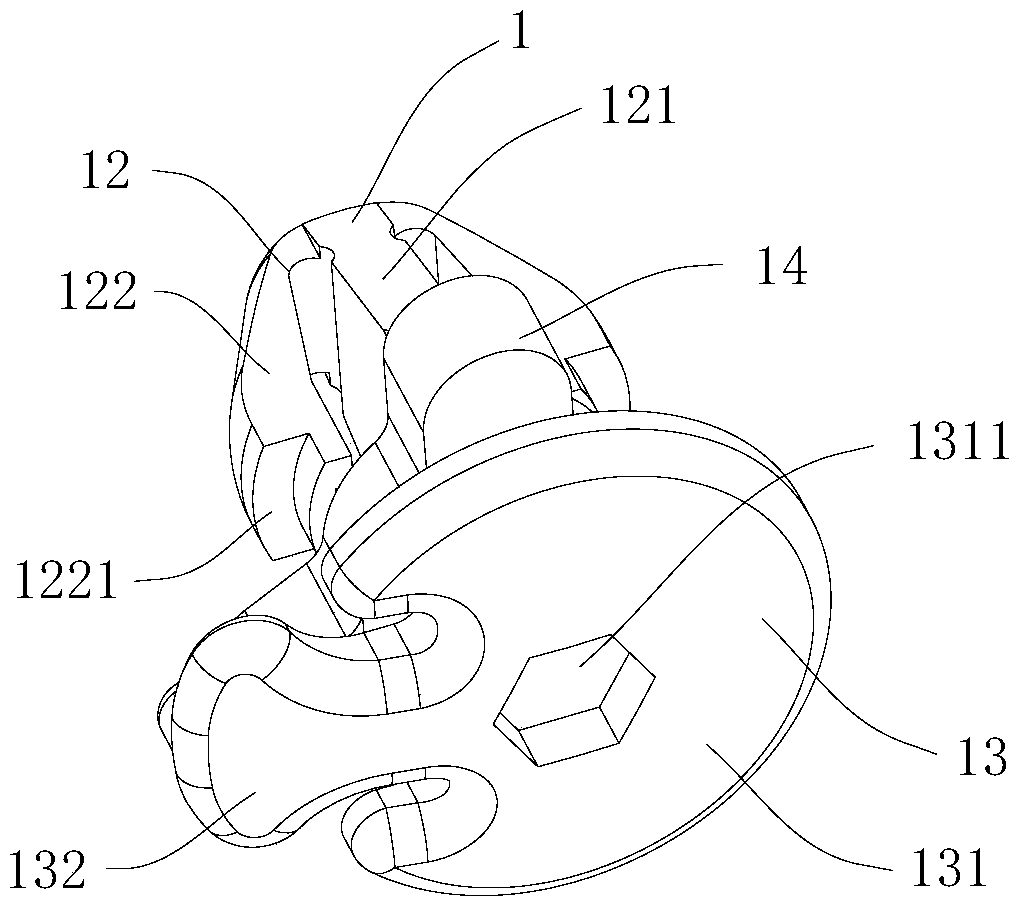

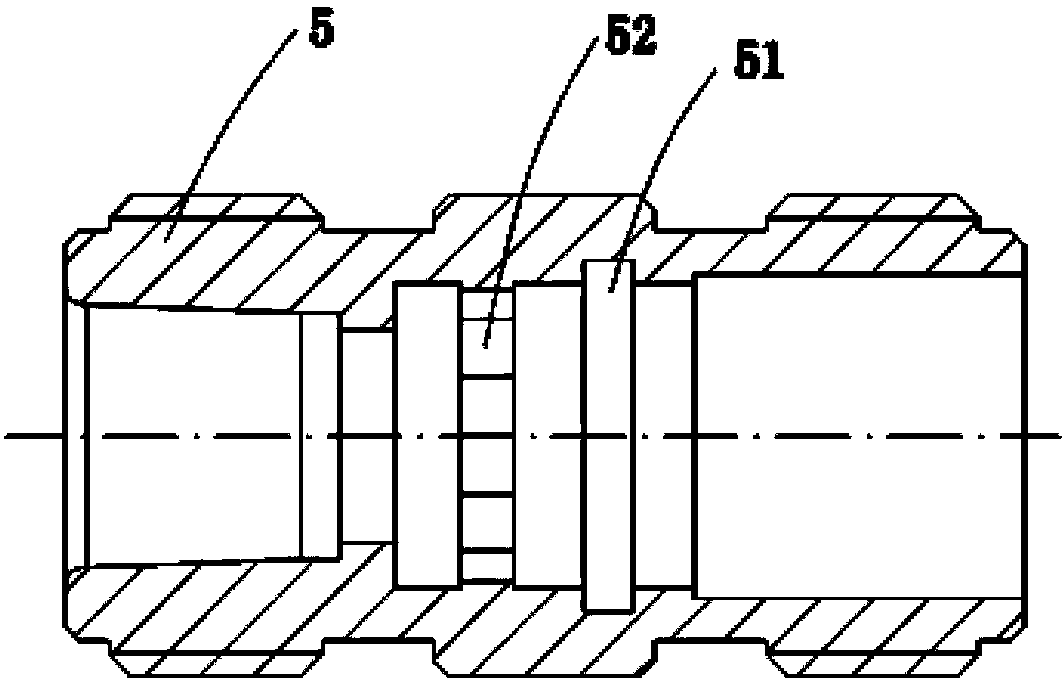

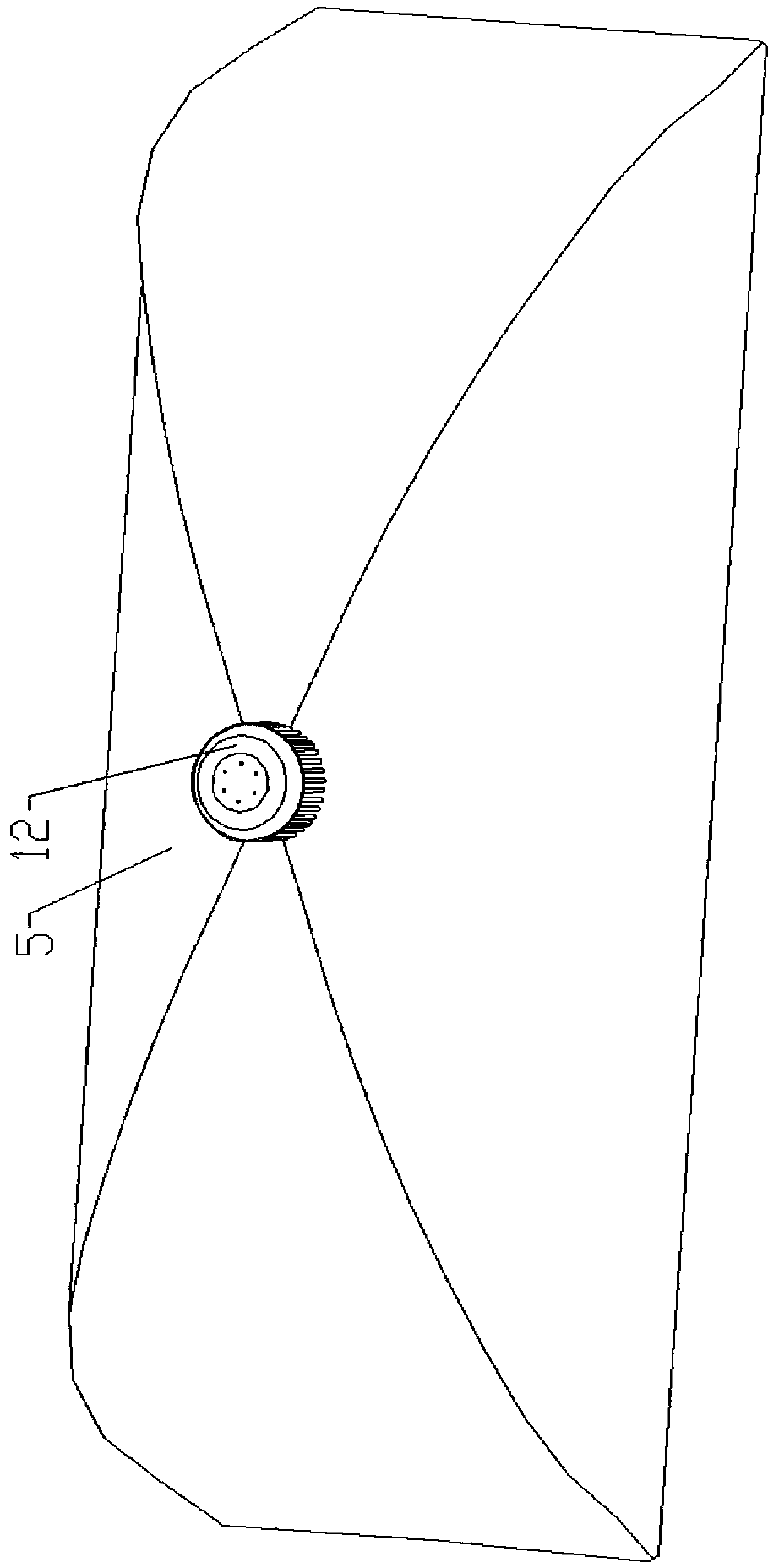

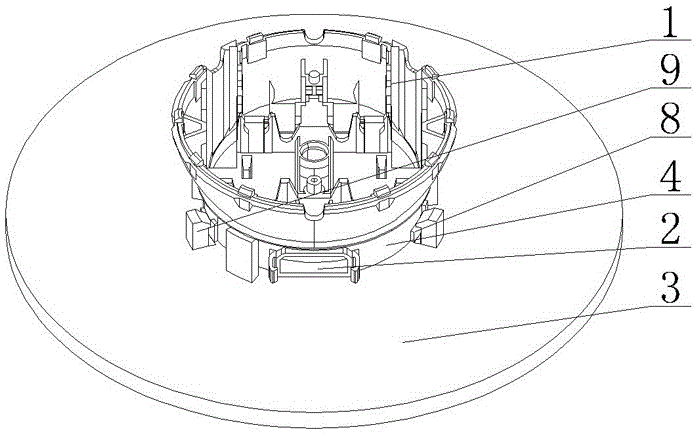

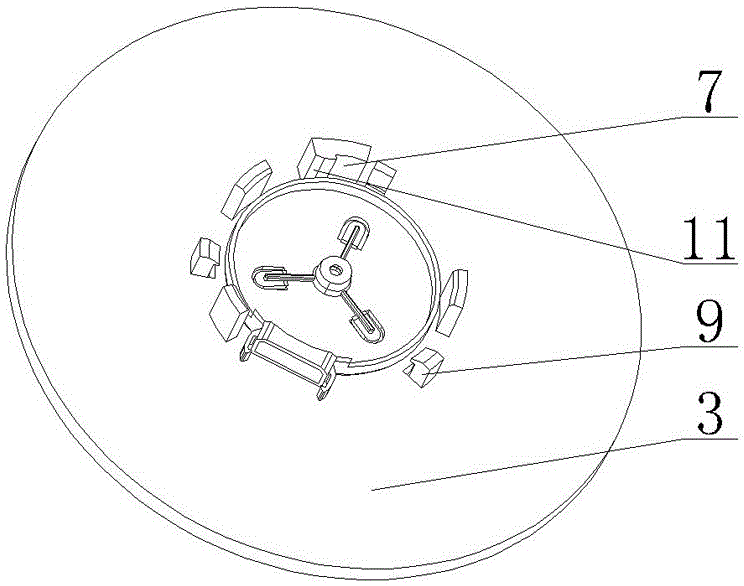

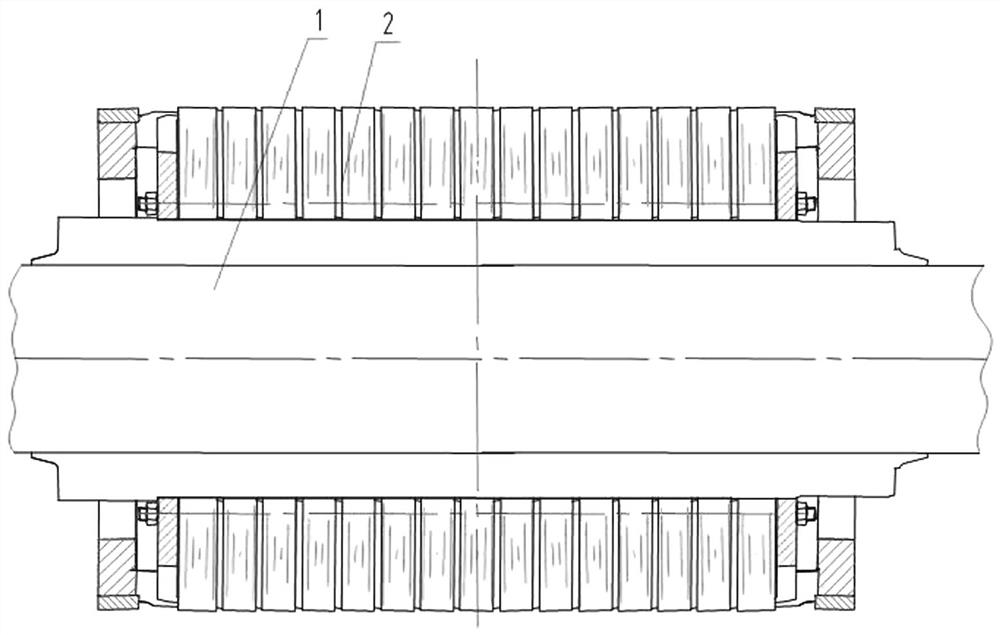

A fully automatic winding die for a skeletonless coil winding

ActiveCN105529178BAchieve circumferential fixationSimple structureInductances/transformers/magnets manufactureWinding machineBobbin

The invention relates to a fully automatic winding die for a skeletonless coil winding, which is characterized in that it comprises a mold core cover (1), the core cover (1) is fixedly connected to a fixed plate (4), and the core cover (1) has an inner hole fixed sleeve The mold mandrel (2), the mold mandrel (2) is circumferentially fixed and axially slidable to cover the sliding sleeve (3), and the sliding sleeve (3) is sleeved in the inner hole of the mold core sleeve (1); the sliding sleeve (3 ) and the core cover (1) are provided with a movable plate (5), and a fastening device is provided between the core cover (1) and / or the fixed plate (4) and the movable plate (5); the core cover (1 ) to connect one end of the winding slider (10) to the inner hole of the mold core sleeve (1), and the inner end of the winding slider (10) is extrusion-fitted with the sliding sleeve (3). After adopting the above-mentioned technical scheme, a full-automatic winding machine can be equipped with a plurality of fully-automatic winding molds for coil windings without skeletons, the efficiency is greatly improved, and batch operation can be performed.

Owner:ANHUI HAOFANG ELECTROMECHANICS

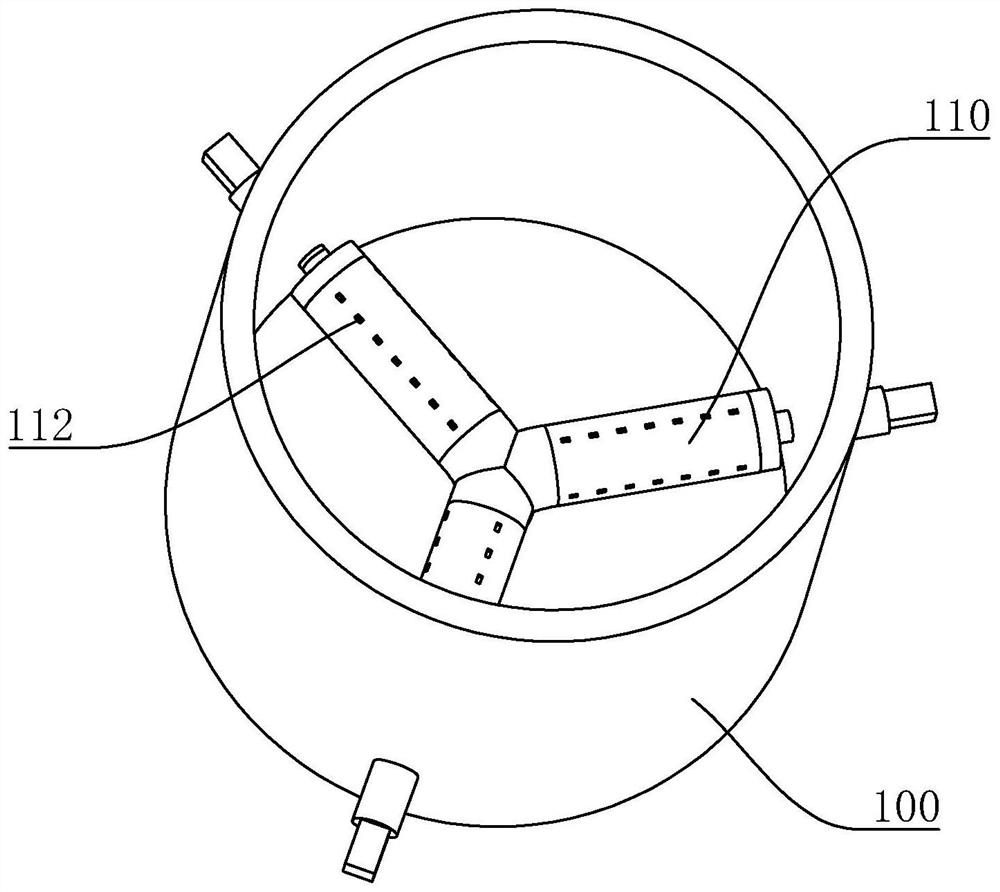

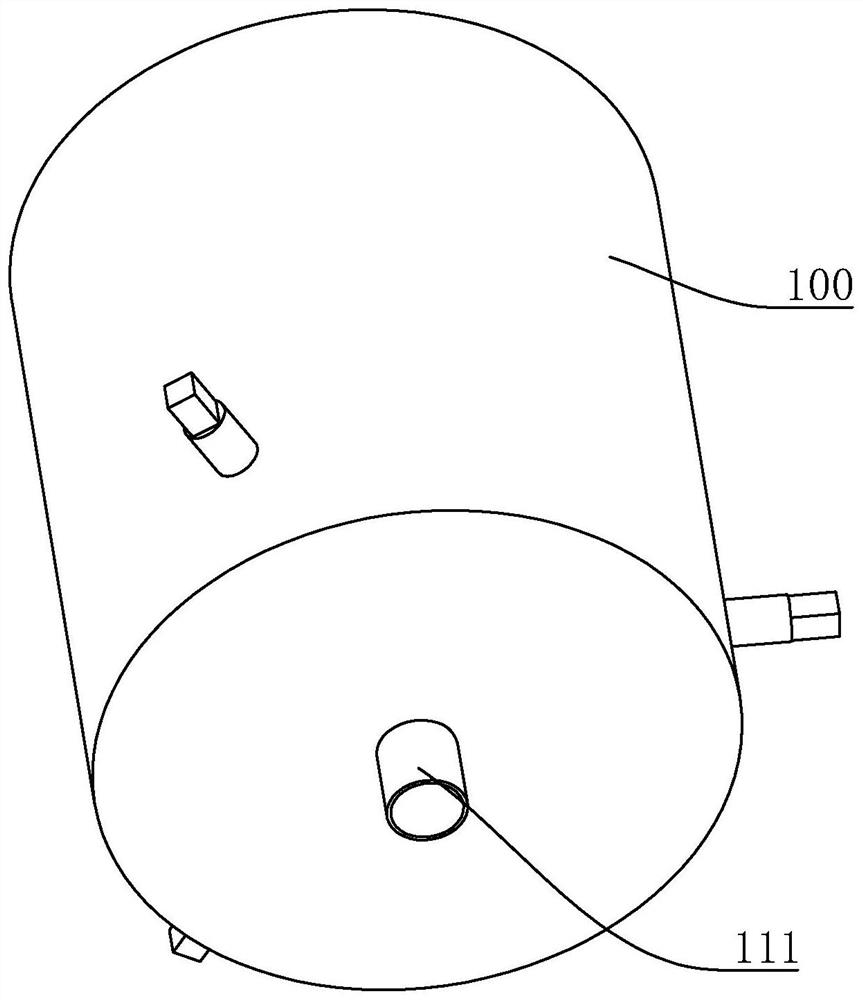

Device and method for preparing polyaluminum chloride water purifying agent

ActiveCN114405360AGuaranteed to workIncrease productivityTransportation and packagingMixersAluminium chlorohydrateEnvironmental engineering

The invention relates to the technical field of preparation of water purifying agents, in particular to a device and a method for preparing a polyaluminum chloride water purifying agent. The polyaluminum chloride water purifying agent preparation device comprises a preparation tank body, a pulse air pipe is arranged in the preparation tank body, a plurality of air holes are evenly distributed in the pulse air pipe, and a dredging assembly is arranged in the pulse air pipe. The dredging assembly comprises a dredging head which is connected to the pulse air pipe in a sliding mode and used for being inserted into the air hole for dredging, and a driving piece used for driving the dredging head to move is arranged in the preparation tank body. The pulse air pipe has the following effects that after the pulse air pipe is used for a period of time, the dredging head is made to move through the driving piece, the dredging head can be inserted into the air hole, the air hole can be dredged in an insertion mode, and therefore normal work of the pulse air pipe is kept.

Owner:绍兴绿嘉环保科技有限公司

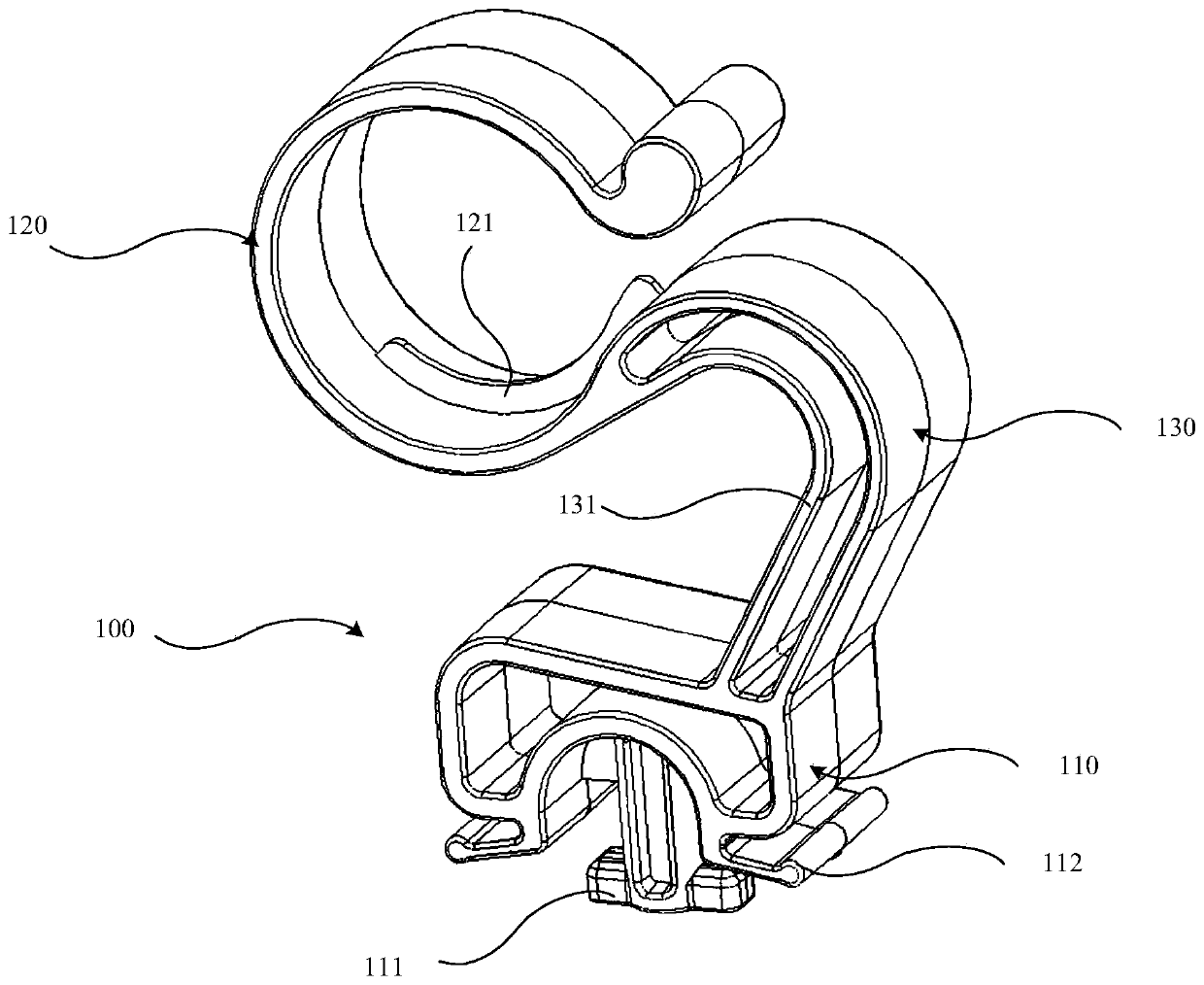

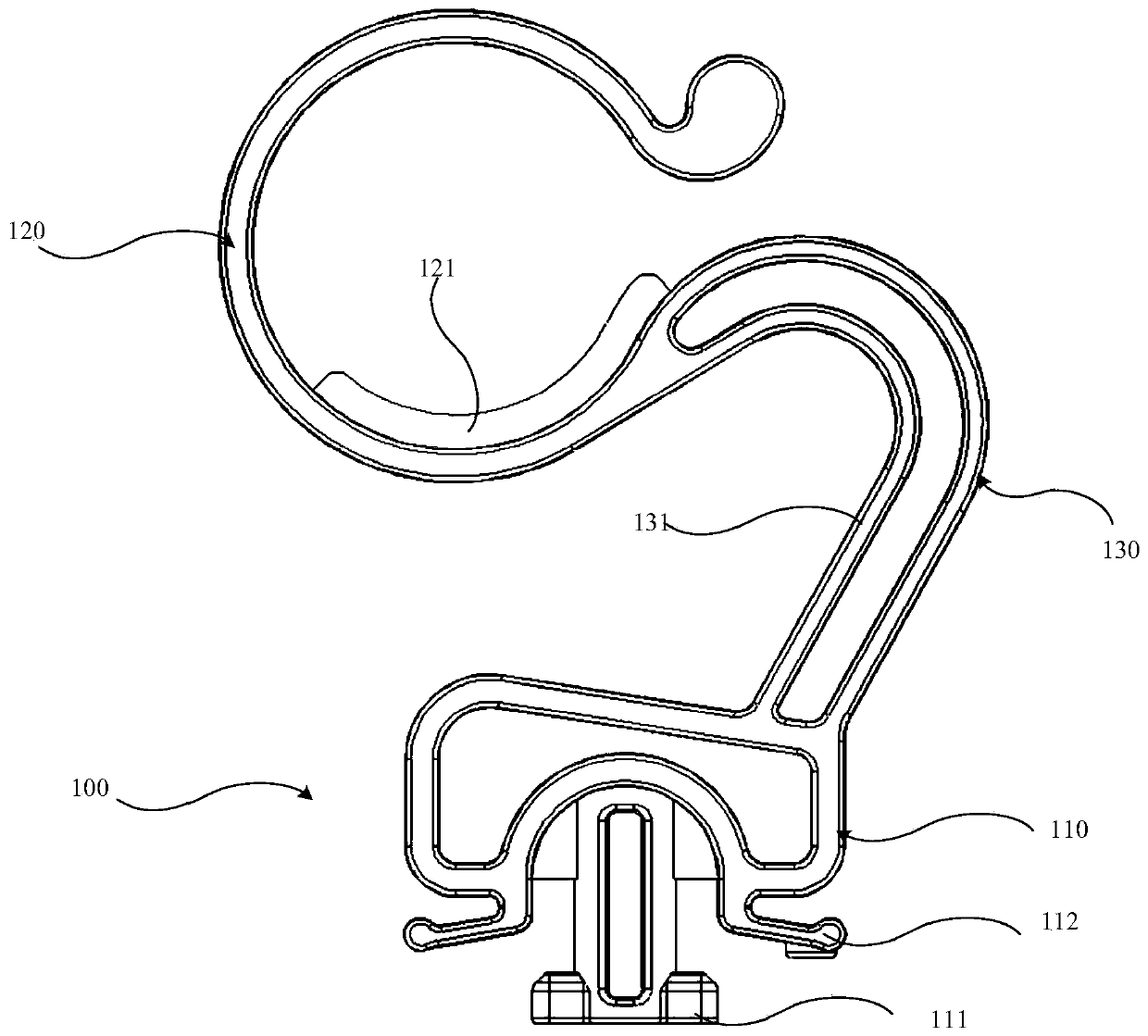

Inner drainage pipe fixing bracket and washing machine

PendingCN110528231AAchieve circumferential fixationAvoid swingingOther washing machinesTextiles and paperPulp and paper industry

The invention relates to the technical field of washing machines, in particular to an inner drainage pipe fixing bracket and a washing machine, and aims at solving the problem of a poor fixing effectwhen a locking belt is adopted for fixing an inner drainage pipe. The provided inner drainage pipe fixing bracket is used for fixing the inner drainage pipe of the washing machine, and comprises a bracket body, wherein a base of the bracket body is detachably connected with a bottom plate of the washing machine, and the top end of the bracket body is provided with a clamping piece; the clamping piece sleeves the inner drainage pipe, and the inner side wall of the clamping piece is also provided with a clamping part used for cooperating with a bulge or groove of the inner drainage pipe.

Owner:QINGDAO HAIER WASHING MASCH CO LTD +1

Tube cutting shaft strengthening and attaching device

InactiveCN108381640AGuaranteed exact dimensionsThe section of the paper tube is neatMetal working apparatusEngineeringPressure transmission

The invention discloses a tube cutting shaft strengthening and attaching device. The device is used for a paper tube cutting machine, and the paper tube cutting machine is provided with a tube cuttingshaft used for sleeving a paper tube; the tube cutting shaft strengthening and attaching device comprises an elastic sleeve, a support, a tip cone, a sleeve, a tip cone moving mechanism and a sleevemoving mechanism, wherein the elastic sleeve sleeves the tube cutting shaft, the side face of the free end of the tube cutting shaft is provided with a conical surface, the end face of the free end ofthe tube cutting shaft is provided with a conical groove, and the tip cone moving mechanism and the sleeve moving mechanism are correspondingly arranged on the support; and the tip cone moving mechanism is fixedly connected with the tip cone so as to drive the tip cone to be inserted into the conical groove of the tube cutting shaft, and the sleeve moving mechanism is fixedly connected with the sleeve so as to drive the sleeve to clamp the conical surface of the tube cutting shaft. According to the device, the sleeve cooperates with the taper of the tube cutting shaft, so that attaching of the tube cutting shaft is easier to achieve; and meanwhile, pressure transmission is carried out, so that the elastic sleeve is enabled to be expanded to realize the circumferential fixation of the paper tube, the accurate size of cutting the paper tube is guaranteed, and the paper tube is neat in section and consistent in size after cutting.

Owner:唐山市晟腾机械制造有限公司 +1

Embedded type anti-loosening back bolt with flexible cladding layer and back bolt assembly of embedded type anti-loosening back bolt

The invention belongs to the technical field of back bolt connection, and relates to an embedded type anti-loosening back bolt with a flexible cladding layer and a back bolt assembly of the embedded type anti-loosening back bolt. The embedded type anti-loosening back bolt comprises a metal body, wherein a connecting cavity which penetrates through the metal body in the axial direction of the metalbody is arranged in the metal body; inner threads which are connected to a back bolt rod are arranged in the connecting cavity; the bottom of the metal body is bulged outwards to form an inverted cone shaped expanding part; the flexible layer is covered on the outer surface of the metal body in a clinging mode; and one end, close to the expanding part, of the flexible layer is bulged outwards along the expanding part to form an inverted cone shape, and one end, with the expanding part, of the metal body is sealed to form a back cover; and the metal body is fixedly connected to the flexible layer. Compared with the prior art, the embedded type anti-loosening back bolt has the advantages of being small in temperature influence, and not liable to crack boards by expanding.

Owner:HANGZHOU STAN NEW MATERIALS TECH CO LTD

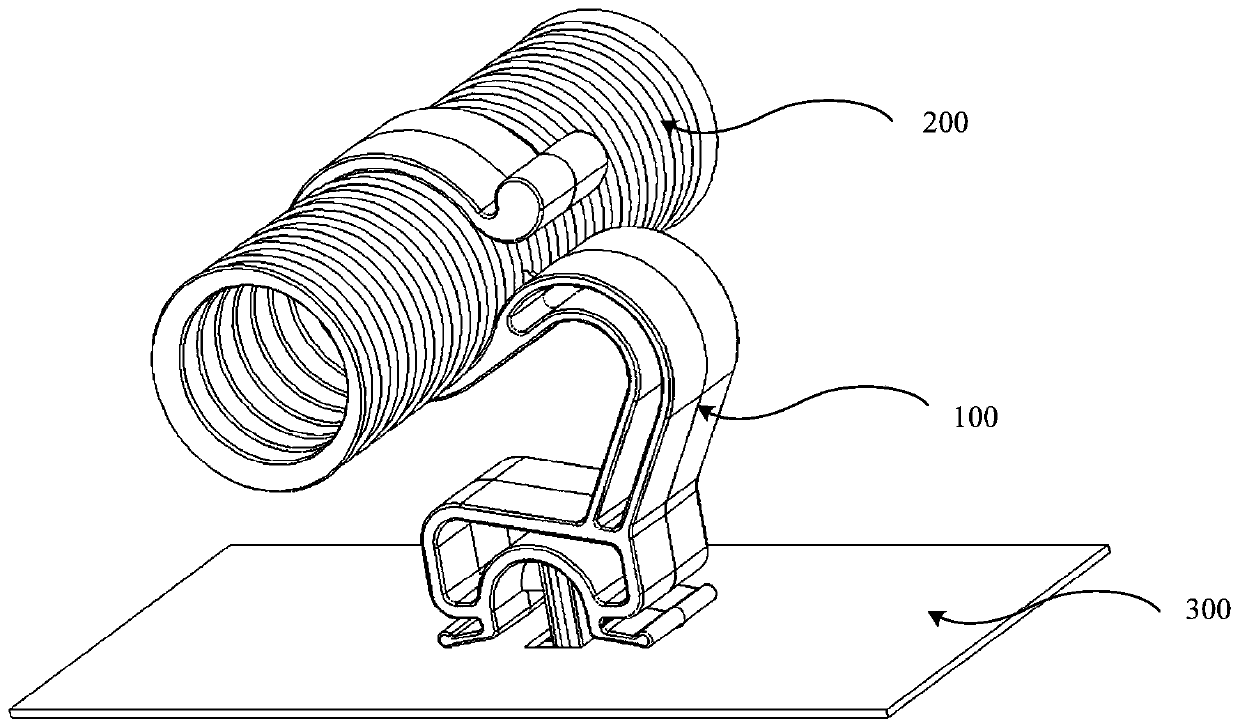

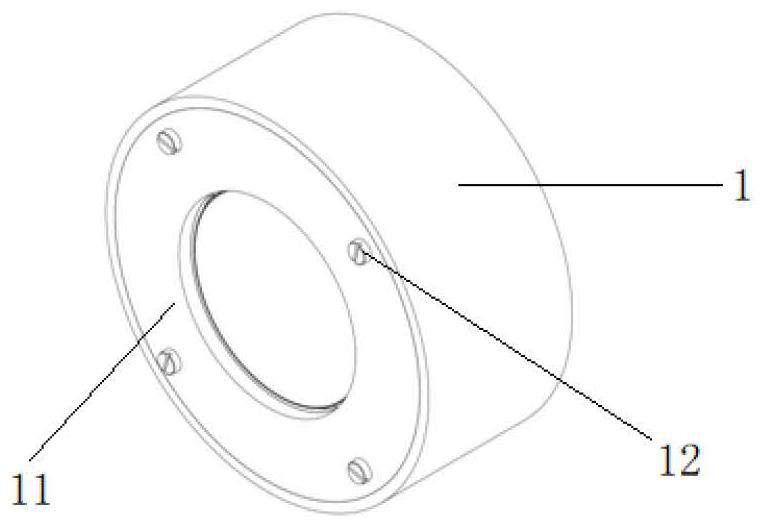

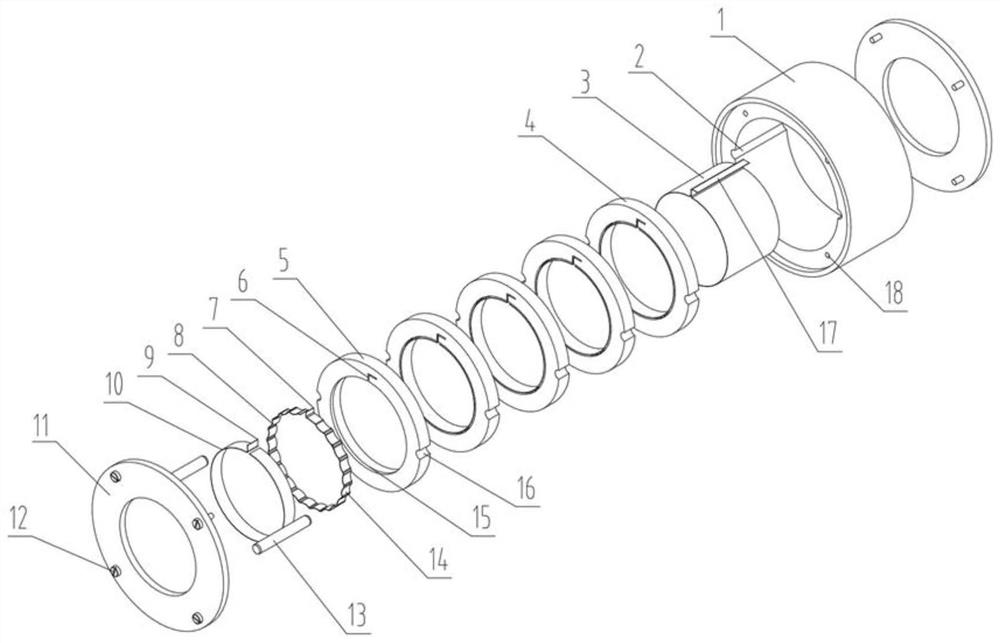

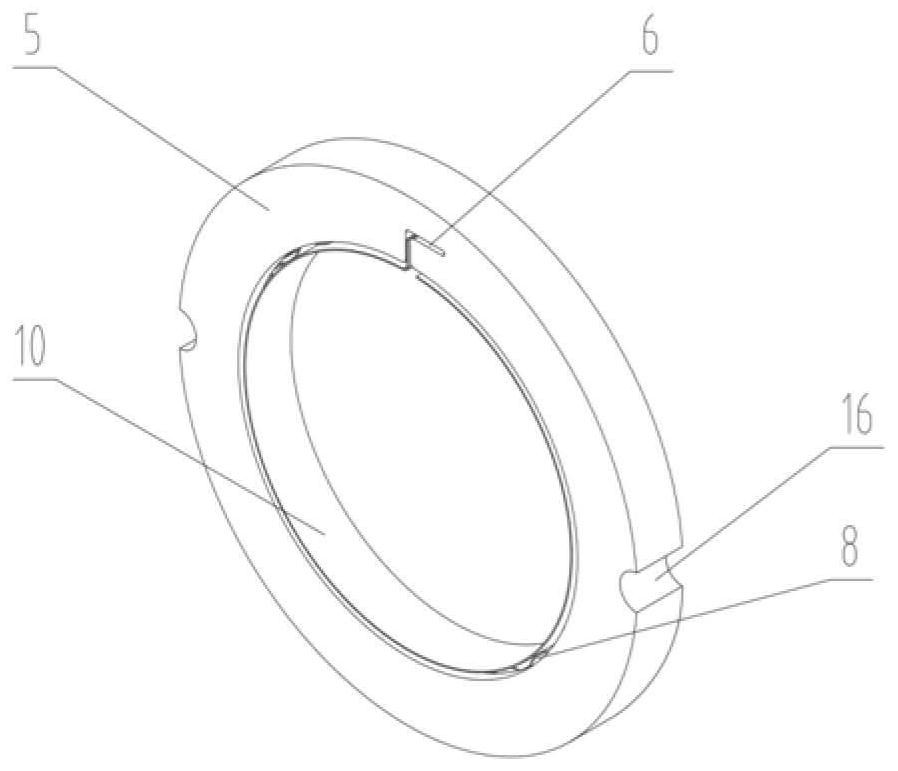

Unit ring combined bump foil type radial air bearing

ActiveCN113494529AEasy to processThe process is easy to implementShaftsBearing componentsAir bearingEngineering

The invention provides a unit ring combined bump foil type radial air bearing. The unit ring combined bump foil type radial air bearing comprises an outer bearing sleeve and end covers located at the two ends of the outer bearing sleeve, wherein a plurality of unit rings are arranged in the bearing sleeve, a top foil is connected in the unit rings in a clamped and closed mode, and the top foil axially extends into all the unit rings. According to the unit ring combined bump foil type radial air bearing, free combination of the unit rings with different waveforms and widths enables the bearing to realize targeted optimization adjustment of the bearing rigidity and the bearing width so as to meet the requirements of specific working conditions; the unit rings are easy to machine, the process is easy to realize, and installation is convenient; and in addition, the unit rings with the small axial widths are combined, the foil structure inclination rigidity can be reduced, compensation for shaft neck deflection is realized, and the impact resistance of a bearing-rotor system is improved.

Owner:SUZHOU CHANGHENG PRECISION METAL DIE CASTING

Tool processing method

InactiveCN104084844AStable mold changeMachining shape influenceCopying process control systemsEngineeringMachine tool

The invention provides a tool processing method. The method is characterized in that a profiling machine tool consisting of a cutter (1) and a cutter profiling device is arranged; the cutter profiling device comprises a profiling column (2) that is generally in a shape of a cylinder; an upper plug (27) and a lower plug (28) are respectively arranged at two ends of the cylinder; a medium profiling part is arranged between the upper plug (27) and the lower plug (27); four longitudinal profiling grooves are uniformly distributed in the medium profiling part along the circumferential direction; the profiling grooves are jointed with a jointing end part (11) of the cutter; at least one of the four longitudinal profiling grooves is a return groove (22); the profiling line of the return groove (22) is a plane; the rest longitudinal profiling grooves are curved grooves and used to control the feed rate of the cutter (1).

Owner:东莞市莱锐精密五金科技有限公司

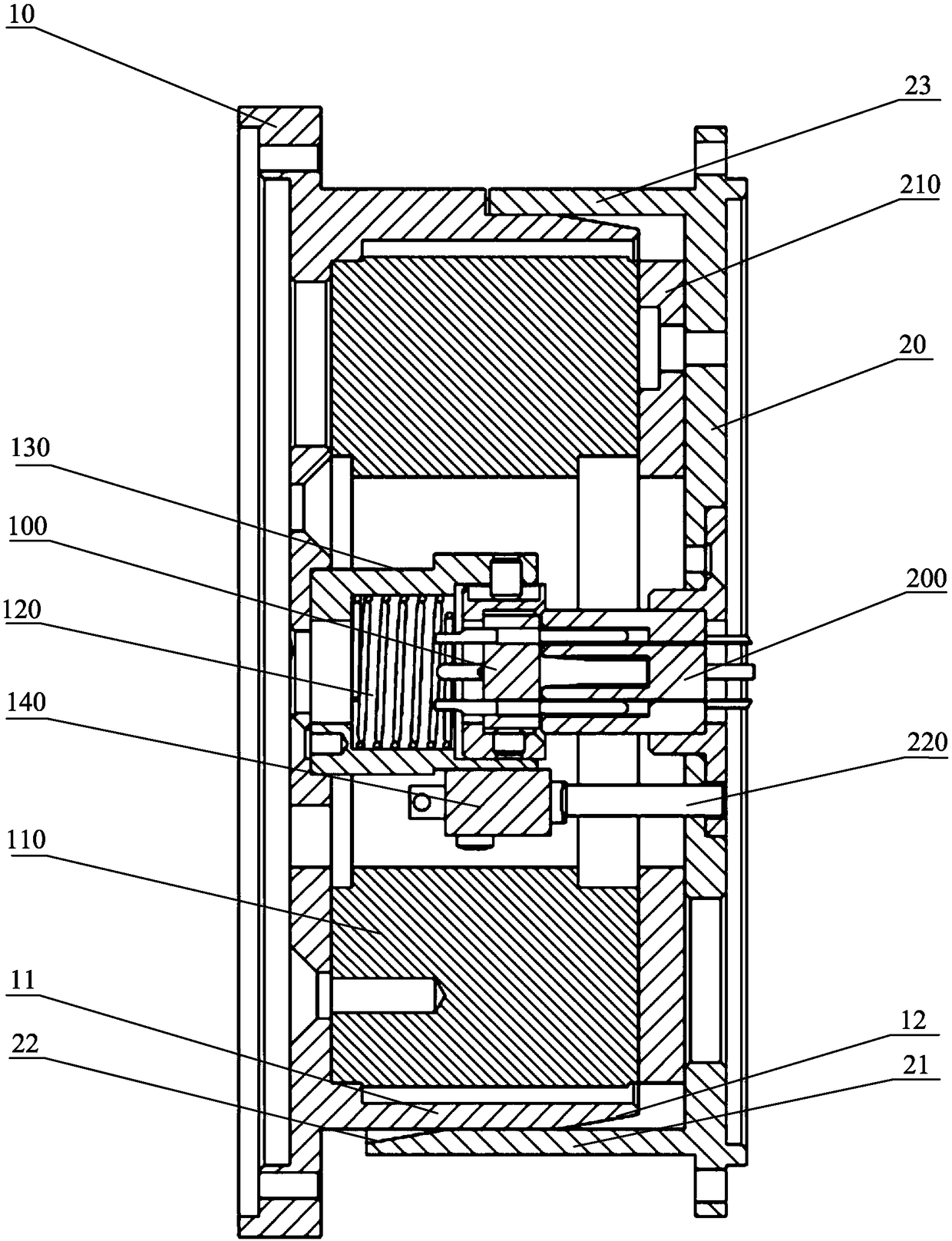

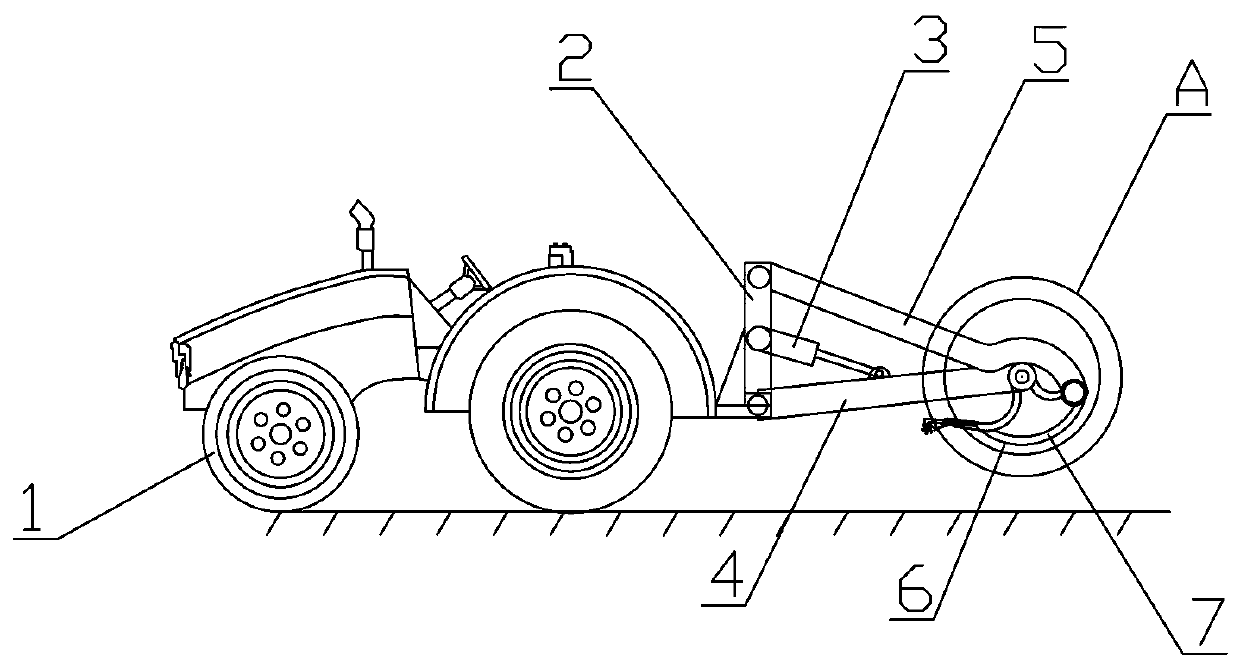

Speed reduction clutch device of mechanical fertilizer applicator

PendingCN112664620AReduced strength requirementsLow costToothed gearingsInterengaging clutchesGear wheelAgricultural engineering

The invention discloses a speed reduction clutch device of a mechanical fertilizer applicator. A main reversing machine and a fertilizer hopper are installed on a support of the speed reduction clutch device, a fertilizer wheel is installed in a wheel type fertilizer application mechanism of a fertilizer outlet of the fertilizer hopper, an intermediate gear and a fertilizer wheel shaft which are connected in a rotating mode are installed on a support, a first speed reduction gear on a power output shaft of the main reversing machine is engaged with the intermediate gear, and a second speed reduction gear is fixedly installed on the intermediate gear. One end of the fertilizer wheel shaft is fixedly connected with the fertilizer wheel, the fertilizer wheel shaft is sleeved with a clutch gear which is fixed in the circumferential direction and connected in a sliding manner in the axial direction, and the clutch gear is located at one side dead point to be engaged with the second speed reduction gear and located at the other side dead point to be separated from the second speed reduction gear. The wheel diameters of the two speed reduction gears are smaller than those of the intermediate gear and the clutch gear. A displacement driving mechanism of the clutch gear is arranged on the support. The device can reduce the speed of the power of a power shaft on a agricultural machine carrier and then transmit the power to the fertilizer wheel shaft, the power is cut off or connected according to needs, the combination rushing impact force during power connection is small, and power transmission is reliable.

Owner:董书银

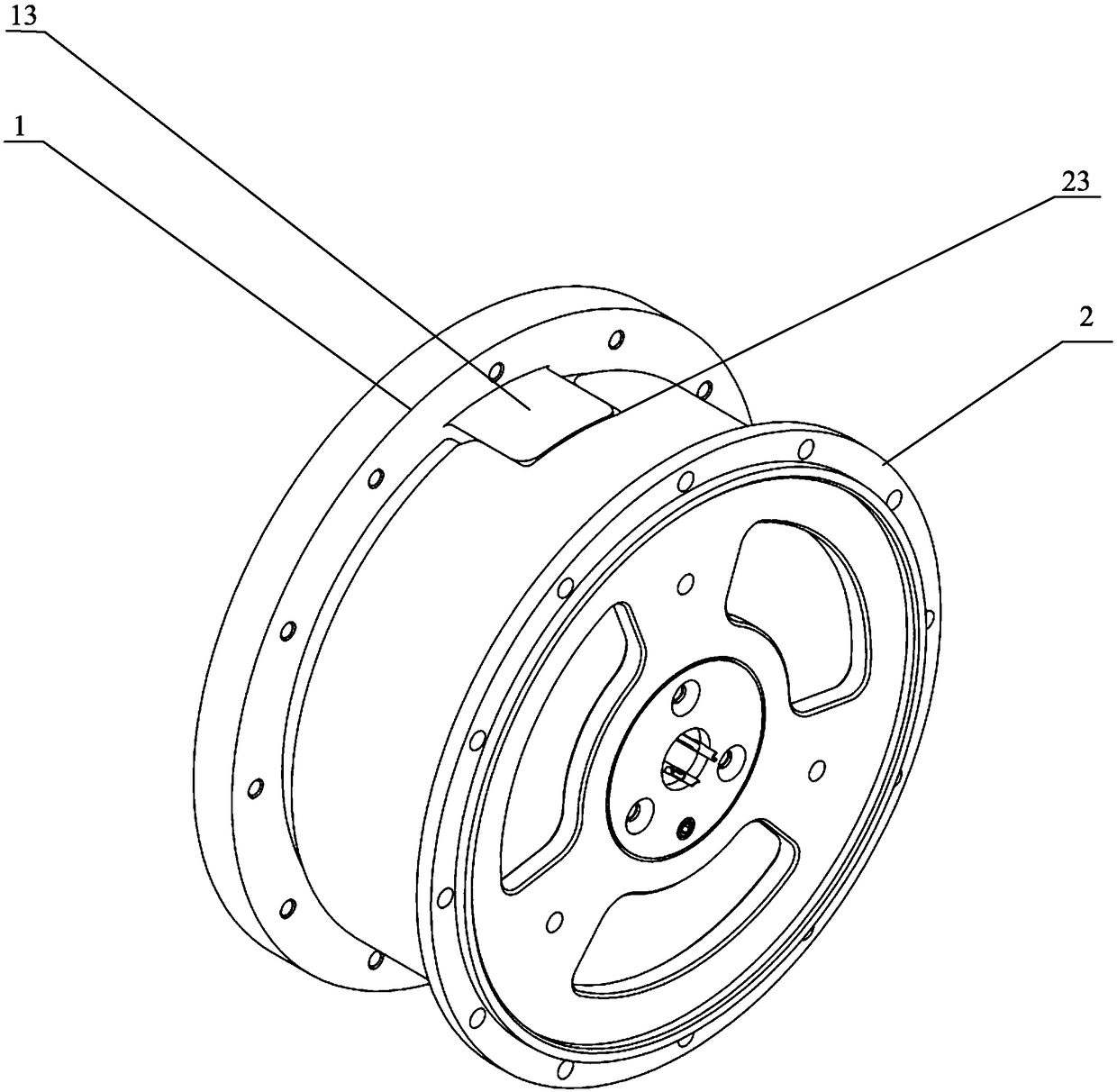

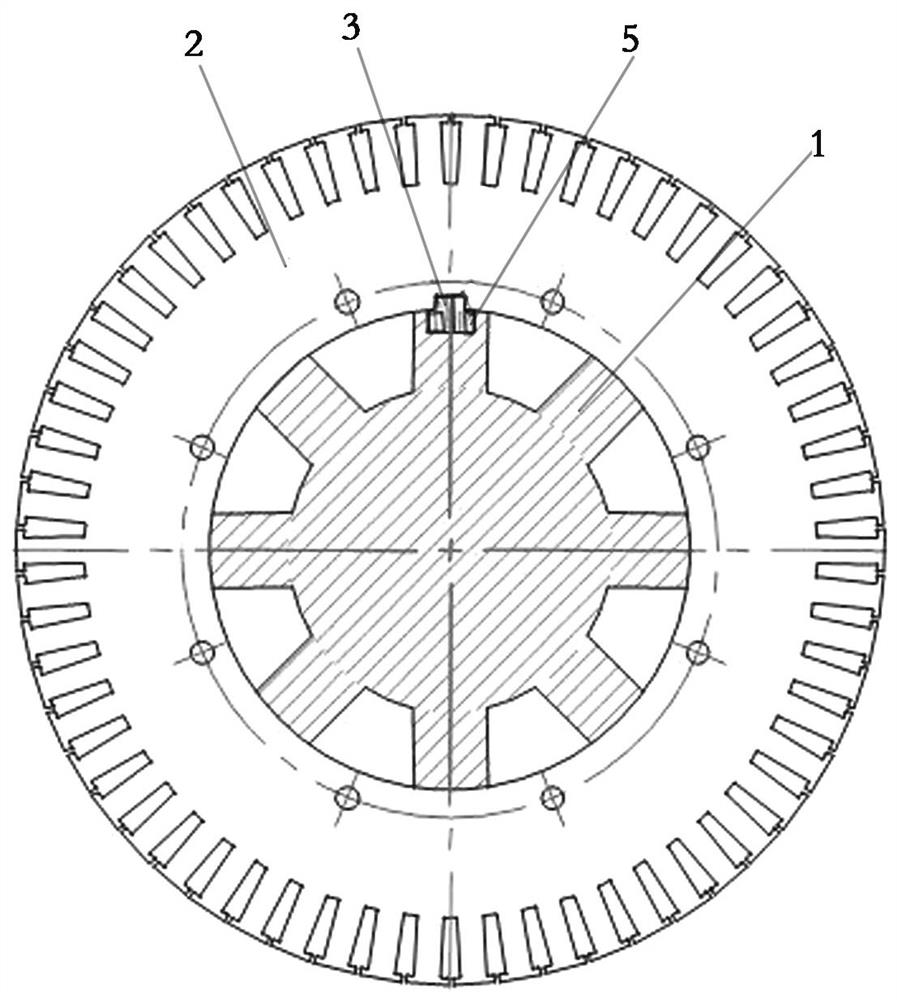

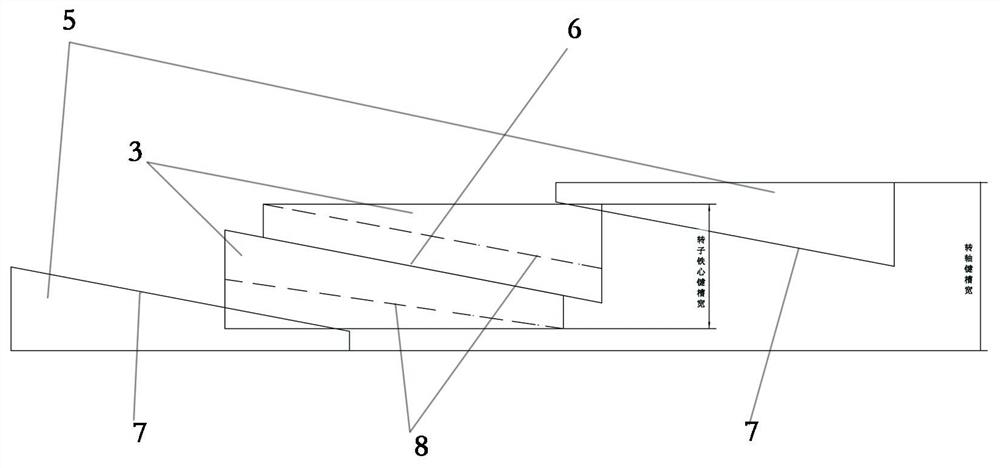

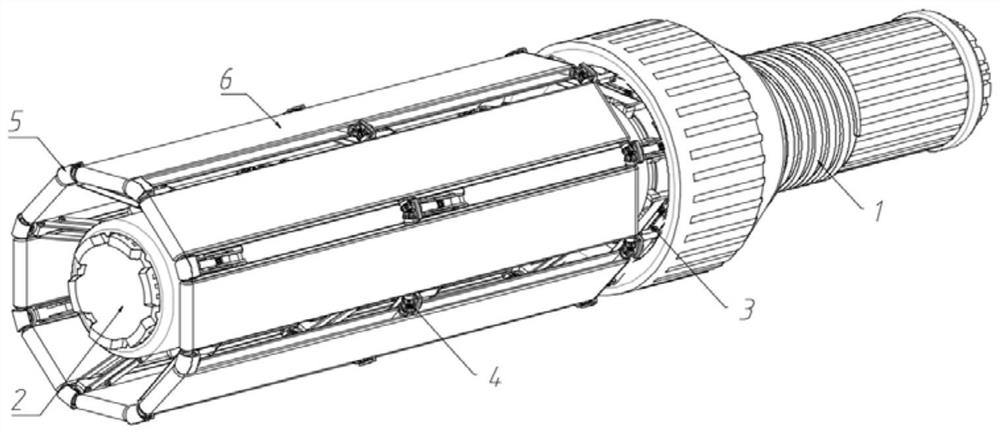

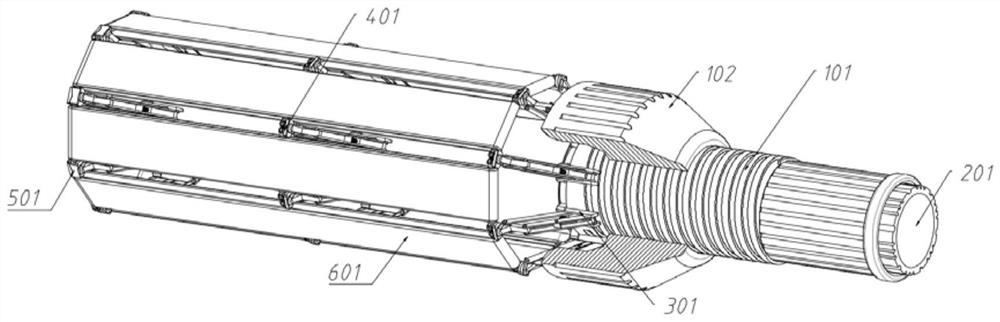

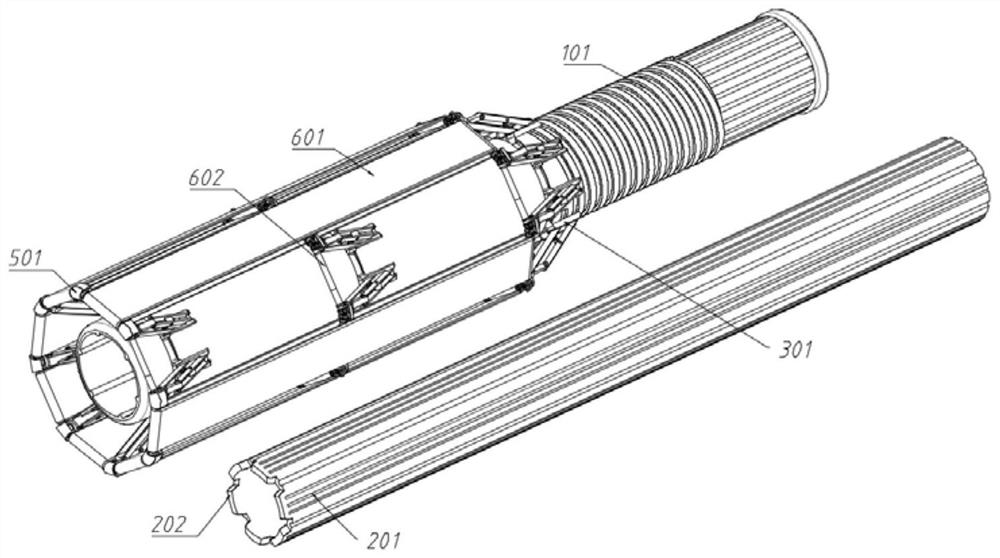

Rotor structure of asynchronous motor

PendingCN114243968AAssembly saves time and effortAchieve circumferential fixationMagnetic circuit rotating partsManufacturing stator/rotor bodiesStructural engineeringControl theory

The invention relates to an asynchronous motor, in particular to a rotor structure of an asynchronous motor, solves the problem that an existing rotor structure of the asynchronous motor is difficult to assemble under the condition that a rotating shaft is long, and provides a novel rotor structure of the asynchronous motor, which comprises the rotating shaft, a rotor core, a first wedge-shaped key and a second wedge-shaped key, the width of a key groove in the rotor iron core is smaller than that of a key groove in the rotating shaft, the first inclined faces of the two first wedge-shaped keys are tightly attached, and the parts, located in the key groove of the rotor iron core, of the right-angle faces of the two first wedge-shaped keys are tightly attached to the groove walls of the two sides of the key groove of the rotor iron core respectively. The two first wedge-shaped keys are respectively provided with a notch with a third inclined face matched with the second inclined faces of the second wedge-shaped keys, and the right-angle faces of the two second wedge-shaped keys are tightly attached to the groove walls of the two sides of the key groove of the rotating shaft respectively. According to the invention, the circumferential fixation of the rotating shaft and the rotor core is realized by ingeniously adopting the cooperation of the four wedge-shaped keys, and the rotor structure is not limited by the length of the rotating shaft during assembly.

Owner:CRRC YONGJI ELECTRIC CO LTD

An adjustable knee brace

ActiveCN104799990BAchieve circumferential fixationEasy to adjust the curvatureFractureThighKnee Joint

The invention belongs to the technical field of medical auxiliary equipment and particularly relates to an adjustable kneecapping joint supporting tool. The adjustable kneecapping joint supporting tool comprises thigh fixing plates and shank fixing plates, wherein the thigh fixing plates are connected through a hook-and-loop fastener belt, the shank fixing plates are connected through a hook-and-loop fastener belt, an angle adjusting mechanism is arranged between the thigh fixing plates and the shank fixing plates and comprises a first turntable, the first turntable is in rotary connection with a second turntable, a locking structure is arranged between the first turntable and the second turntable and comprises a locking groove formed in the first turntable, and the locking groove is evenly distributed in the peripheral direction of the first turntable. A locking block is arranged on the second turntable, the first turntable and the second turntable are oppositely and peripherally fixed when the locking block is inserted into the locking groove, the first turntable is fixedly connected with the thigh fixing plates, and the second turntable is fixedly connected with the shank fixing plates. The adjustable kneecapping joint supporting tool has the advantages of being adjustable in angle and high in flexibility.

Owner:金华德仁康复辅具有限公司

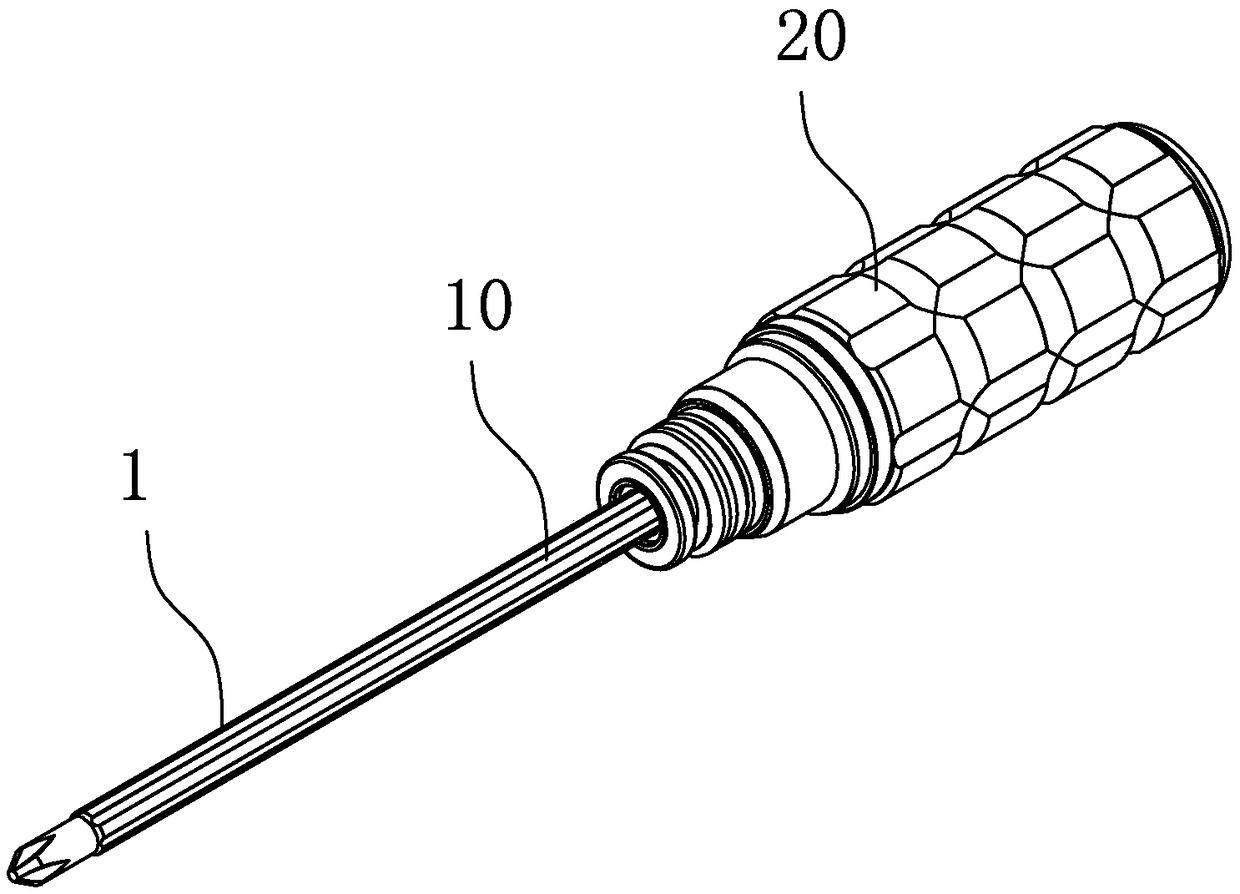

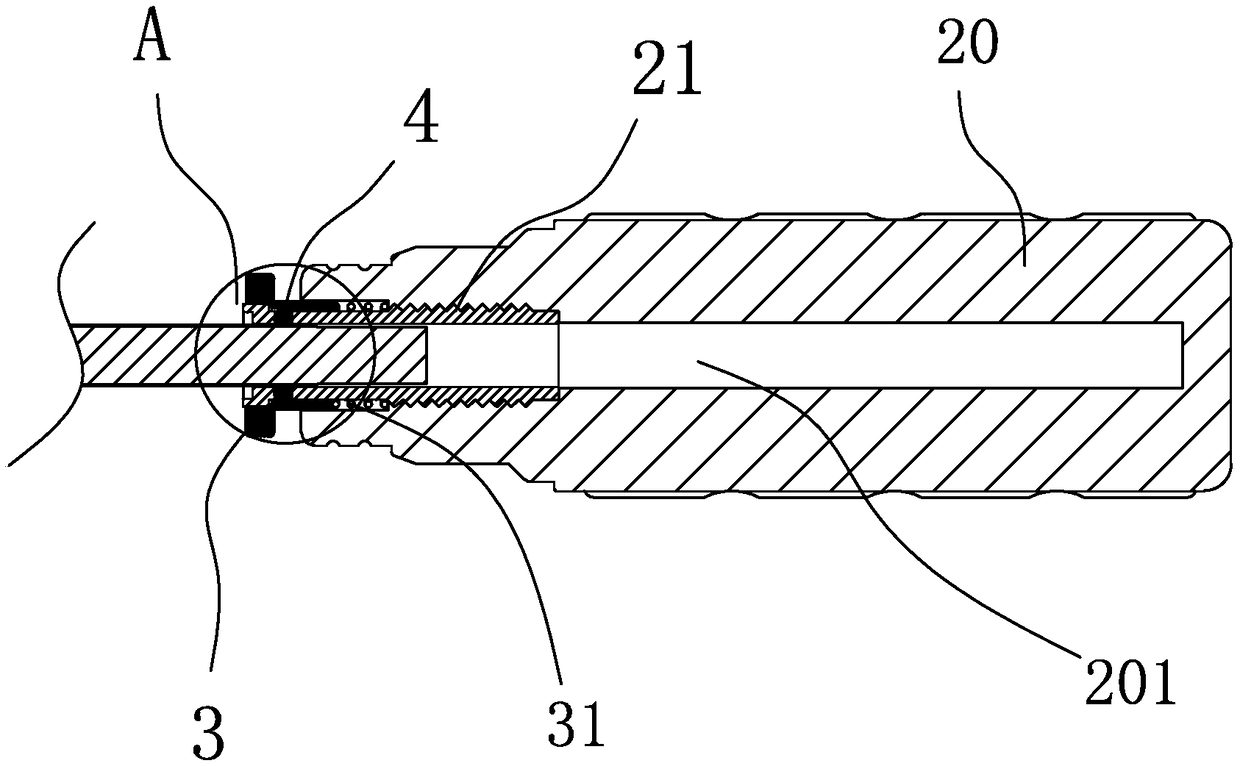

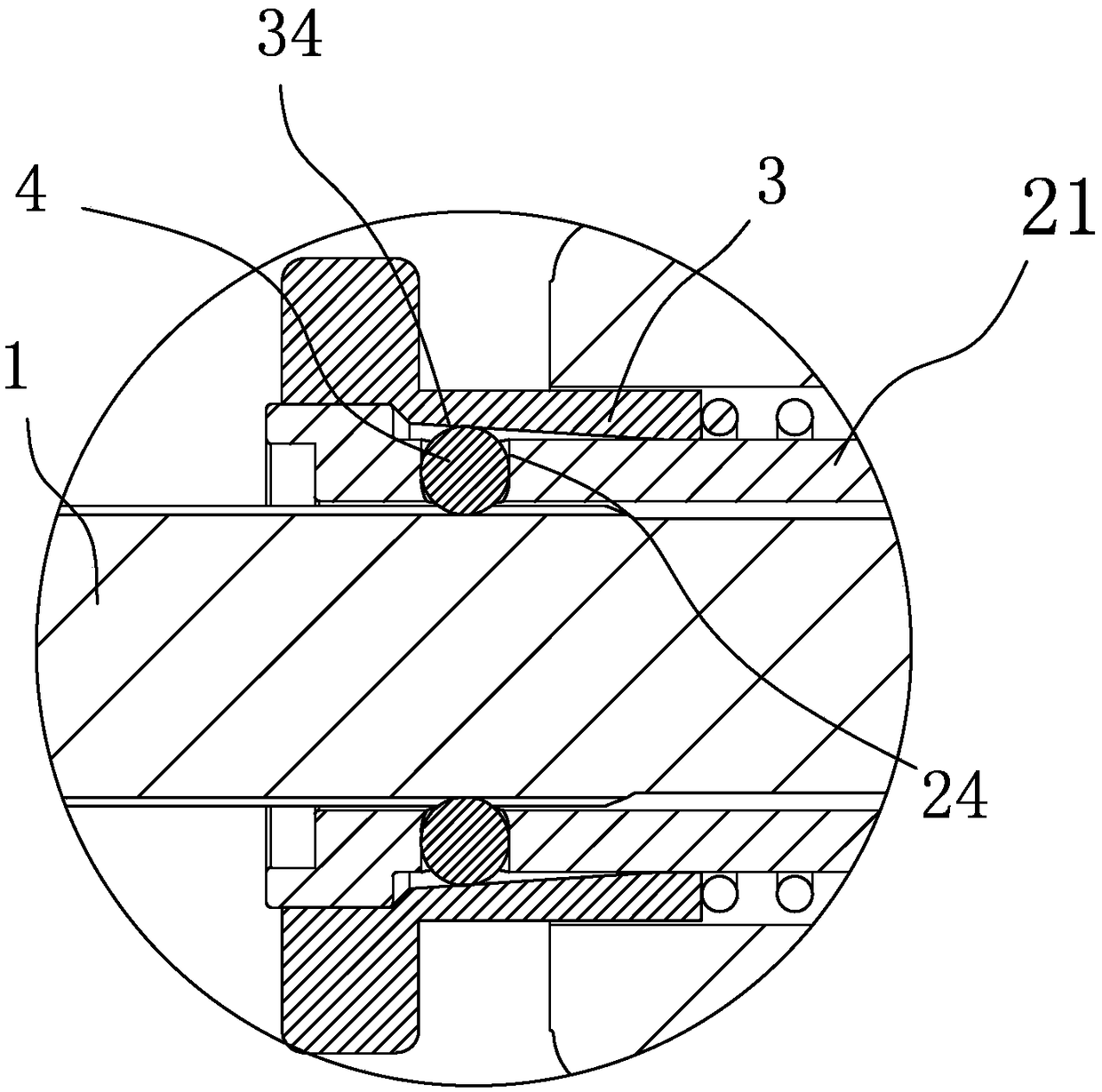

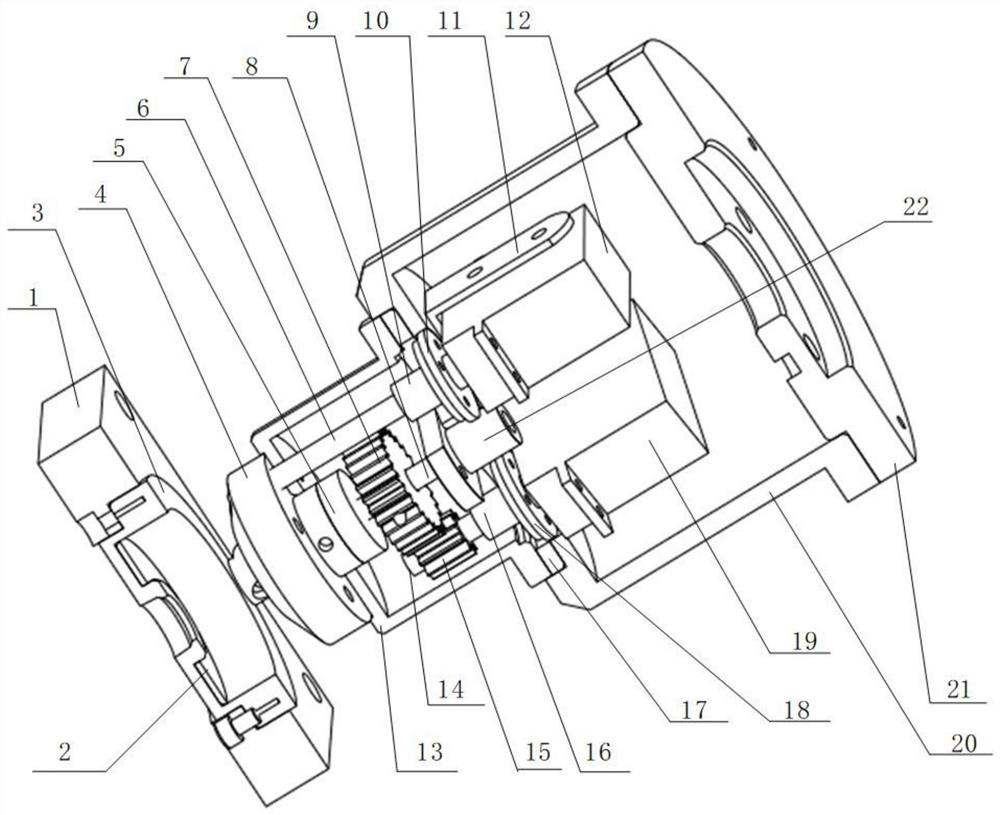

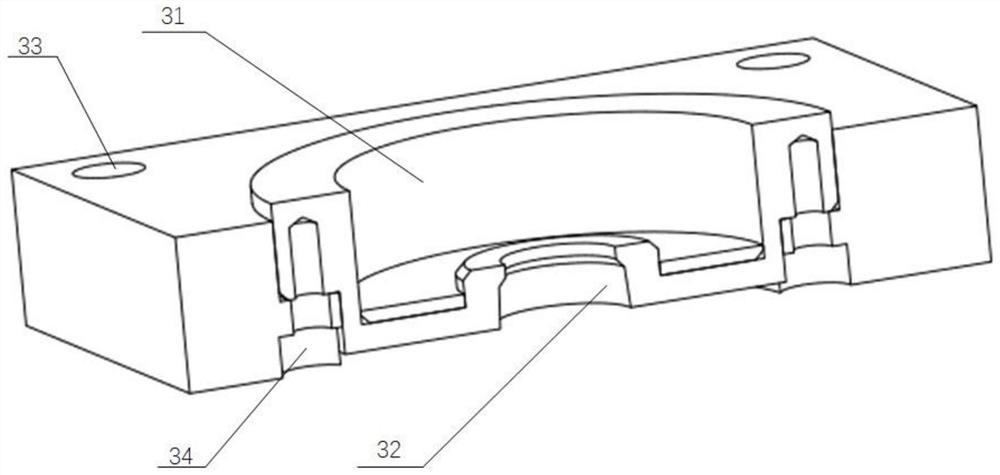

Stepless telescopic mechanism and stepless telescopic screwdriver

PendingCN108994766ARealize reverse self-lockingAvoid accidental disengagementSpannersWrenchesSelf lockingEngineering

The invention relates to a stepless telescopic mechanism and a stepless telescopic screwdriver. Firstly, a containing cavity is formed in a connecting rod and a connecting handle is arranged in the containing cavity so as to form the telescopic mechanism, the connecting handle is arranged in different depth of the containing cavity, so that the overall length adjustment can be realized; secondly,a self-locking body and a self-locking part are arranged, the self-locking body is arranged between the self-locking part and the connecting handle, an inclined abutting surface is arranged on the self-locking body, so that the single-direction pulling can be realized, and meanwhile, in the direction opposite to the pulling direction, the self-locking body is driven by the friction force of the connecting handle, the self-locking body abuts against the inclined and narrowed abutting surface, the reverse self-locking is realized, so that a single-direction locking action force is provided.

Owner:XIAMEN NANCH BIT PRECISION TOOLS

Quick automatic connecting device for mechanical arm end actuator

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Sampling device for early screening of cervical cancer

InactiveCN113616251AEasy to screw inEasy to tightenSurgeryVaccination/ovulation diagnosticsStructural engineeringMechanical engineering

The invention provides a sampling device for early screening of cervical cancer. The sampling device comprises a mounting assembly, an inner pipe structure and connecting assemblies, the inner pipe structure is arranged to be of a cylindrical structure, the mounting assembly sleeves the inner pipe structure, and a supporting device is mounted on the outer wall of the mounting assembly in a surrounding mode; the connecting assemblies are arranged to be of a blocky structure, the connecting assemblies are clamped at the tail end of the supporting device, protective structures are clamped on the outer sides of the connecting assemblies, guiding devices are mounted at the positions between the adjacent connecting assemblies in a winding mode, auxiliary sleeves are mounted on threaded grooves of mounting cylinders in a screwed mode, and when the auxiliary sleeves are screwed down, the auxiliary sleeves and grooves in the outer walls of the mounting cylinders can increase the friction force of the outer wall, so that the auxiliary sleeves can be conveniently screwed down; and when the auxiliary sleeves rotate inwards, the auxiliary sleeves extrude the supporting device, so that the supporting device is shrunk, and the auxiliary sleeves are additionally arranged to assist in controlling the diameter of the outer walls of the guide devices.

Owner:常婧伊

A tool profiling control system

InactiveCN104084845BStable mold changeMachining shape influenceCopying process control systemsControl systemEngineering

Disclosed is a tool profiling control system. The tool profiling control system comprises a tool profiling device and a control processor (8). The tool profiling device comprises a tool (1) and a profiling column (2), wherein the profiling column (2) is integrally in a cylindrical shape, and both ends of the cylindrical shaped are provided with an upper plug (27) and a lower plug (28); a middle profiling unit is formed between the upper plug (27) and the lower plug (28) and circumferentially and uniformly provided with four longitudinal profiling grooves (21, 22, 23 and 24) which are connected with the connecting end (11) of the tool (1); at least one of the four longitudinal profiling grooves is a return groove (22), the profiling contour of the return groove (22) is of a flat type, the other profiling grooves are curved grooves and are used for performing feeding control on the tool (1), and meanwhile, the curved grooves are different in curved surface shape.

Owner:AIRUI KETE TIANJIN PRECISION METAL TOOL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com