Lighthouse lifting device

A technology for lifting devices and lighthouses, applied in the direction of lighting devices, lighting auxiliary devices, lighting device components, etc., can solve problems such as bending deformation of hollow rods, safety impact, uneven force on hollow rods, etc., to achieve uniform force , prolong service life, improve stability and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

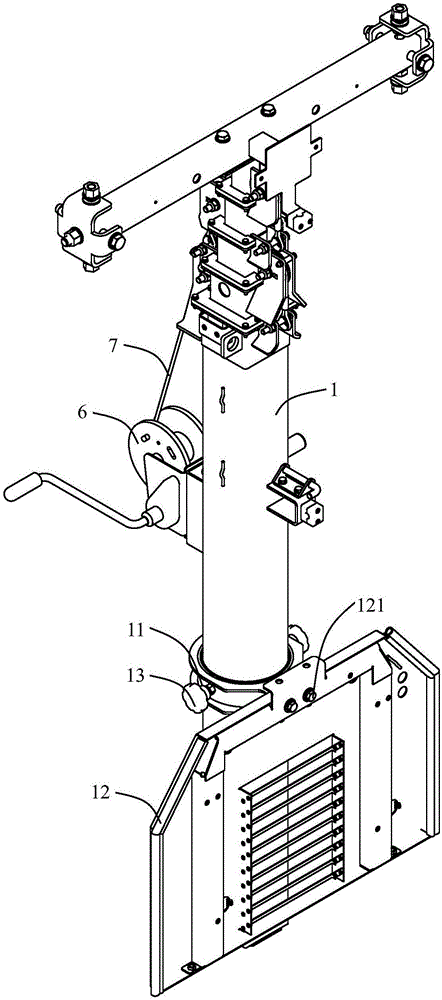

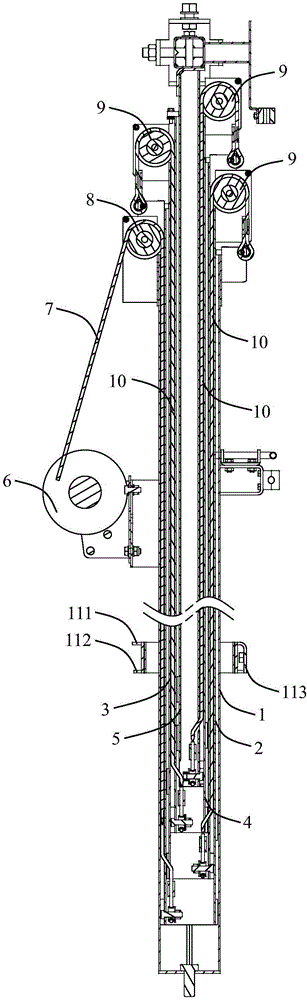

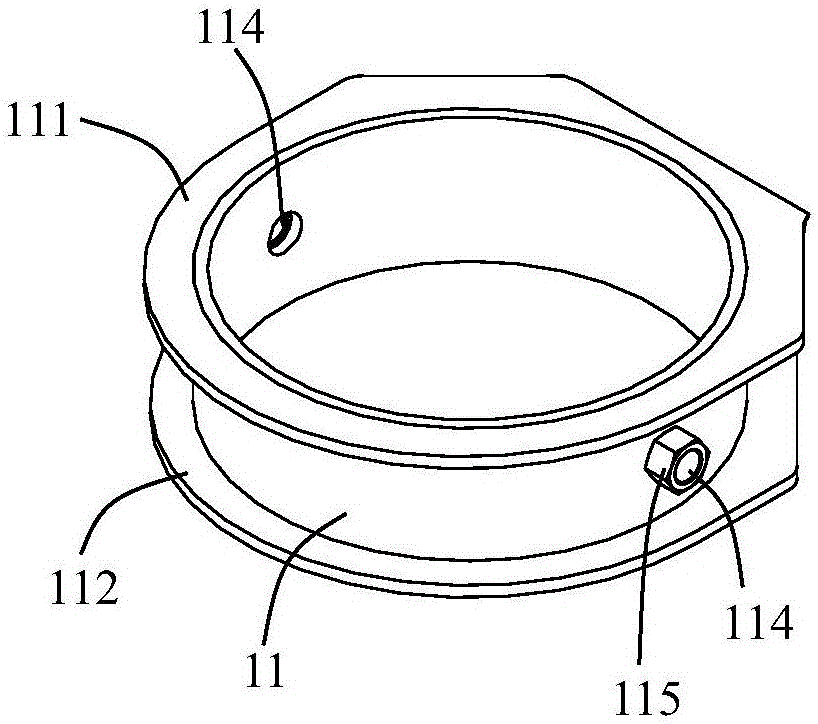

[0031] Below, the structure and working principle of the present invention will be further described in conjunction with the accompanying drawings.

[0032] see figure 1 , figure 2 , the light tower lifting device of the present invention is installed on a movable vehicle frame (not shown in the figure), and the device includes several hollow rods 1, 2, 3, 4, 5 that are sequentially socketed, and the inner hollow rods are placed outside In the cavity of the hollow rods, adjacent hollow rods can slide relative to each other, the outermost hollow rod 1 is fixed on the movable vehicle frame, and the top of the innermost hollow rod 5 is connected to the lamp. The lighthouse lifting device realizes the lifting of the position of the lamp through the relative sliding between the hollow rods.

[0033] Specifically, as figure 2 As shown, the outside of the hollow rod 1 is provided with a driving mechanism, the top is provided with a first pulley 8, and the first pulley 8 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com