Installation device for car rearview mirror

A technology of an automobile rearview mirror and an installation device, which is applied in the field of automobile rearview mirrors, can solve the problems of high cost, inconvenient installation, complicated structure of rearview mirror components, etc., and achieves the effect of improving the axial fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

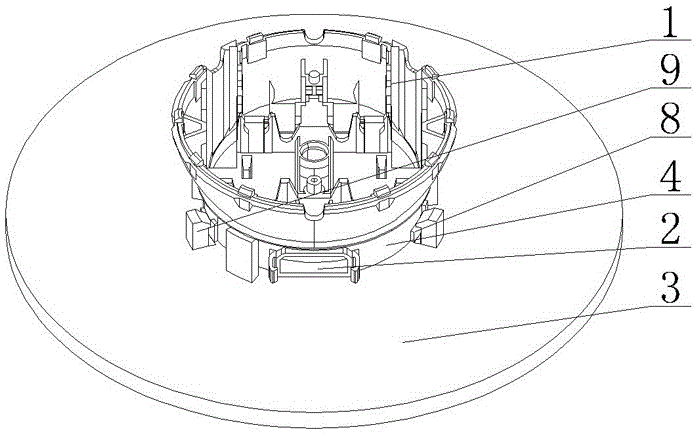

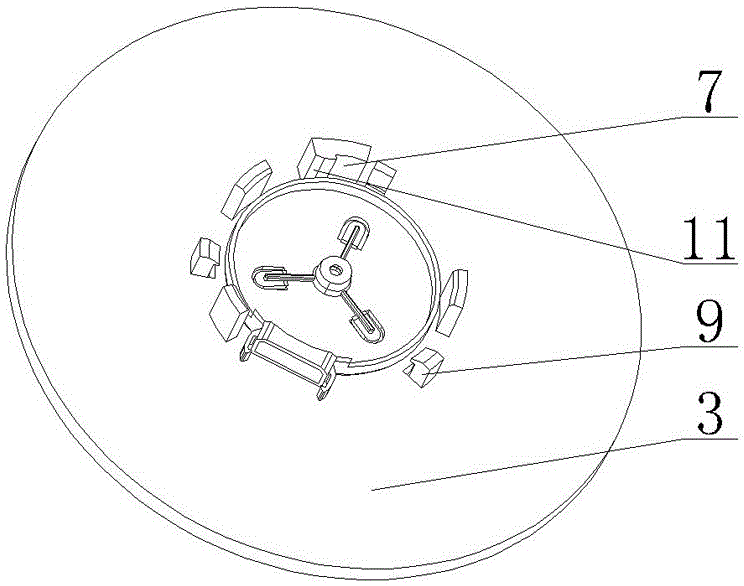

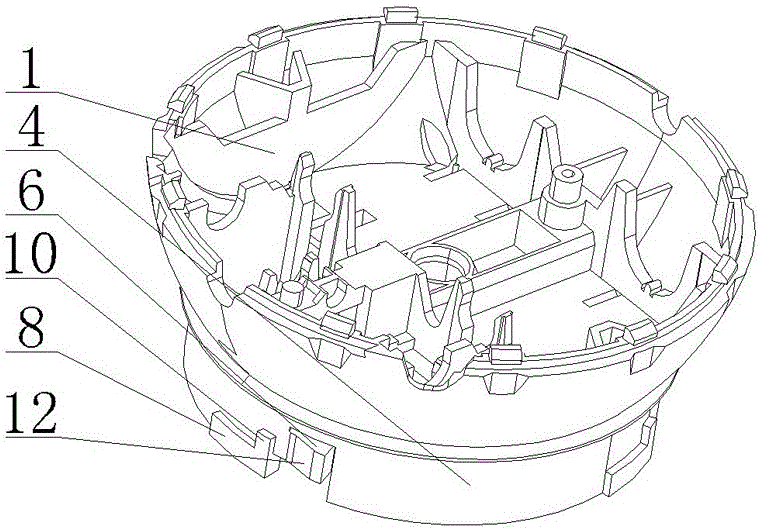

[0017] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the automobile rearview mirror mounting device provided by the present invention comprises a steering gear 1, a bottom cover 2 and a carrier 3, the steering gear 1 lower end is provided with an outer cover 4, and the inner side of the outer cover 4 is provided with a bottom cover installation groove, and the bottom cover 2 is arranged in the installation groove of the bottom cover, the bottom cover 2 and the outer cover 4 are arranged coaxially, the elastic member 5 is provided on the lower end surface of the bottom cover 2, the elastic convex part 6 is provided on the outer cover 4, and the supporting part 3 is provided with a The buckle 7 that is engaged with the elastic protrusion 6 has a first slope 11 inside the buckle 7, and a second slope 12 that matches the first slope 11 on the outside of the elastic protrusion 6. When the elastic protrusion 6 and the buckle 7 are engaged , the elastic member 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com