Modification method of fan-shaped section phi280 roller system of continuous casting machine

A continuous casting machine segment and roll system technology, which is applied in the field of continuous casting equipment, can solve problems such as increasing equipment repair and maintenance costs, affecting equipment accuracy levels, and overheating of roll bodies, so as to ensure technical performance and equipment accuracy levels, reduce Maintenance and repair costs, effectiveness of addressing water leakage hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

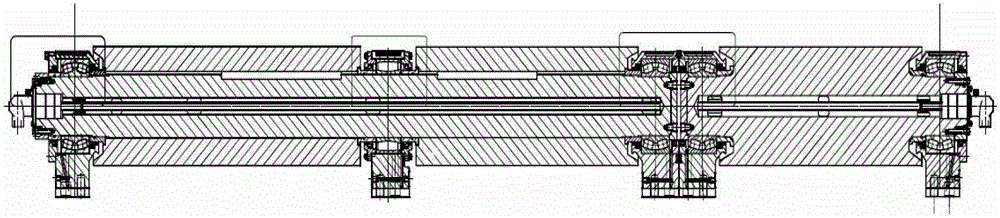

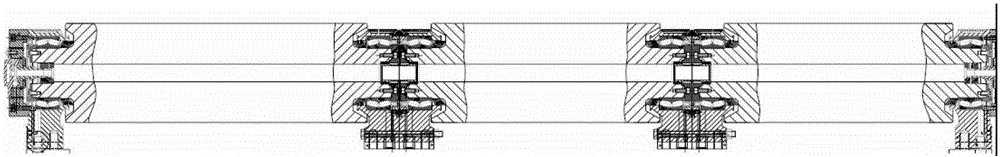

[0015] 1. Transformation of the roll system: change the three-section roll structure of the φ280 roll system in the sector section of the continuous casting machine into a two-section three-section roll structure. Among them, the segmented roll with a roll length of 850mm is set independently, and the two rolls with a length of 720mm are set independently. The segmented roll is changed to an integral two-segmented roll, and the two self-aligning bearings (original) in the middle of the two segmented rolls with a length of 720mm are changed to one CARB bearing, and the two sides are still self-aligning bearings;

[0016] 2. Cooling water transformation: Change the segmented roll with a roll length of 850mm and the two segmented rolls with a roll length of 720mm in the φ280 roll system of the continuous casting machine to independent cooling, and the cooling water of the bearing seats on both sides and the The cooling water of the roll body is separated; at the same time, the wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com