Cloth cover tightening mechanism of full automatic automobile cover

A fully automatic, cloth-covered technology, applied in the direction of movable outer sheath, vehicle parts, transportation and packaging, etc., can solve the problems of being blown away by the wind, the cloth cover is separated from the body, and the cloth cover is easy to bulge, etc., to prevent The effect of bulging, compact and reasonable structure, and small space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings.

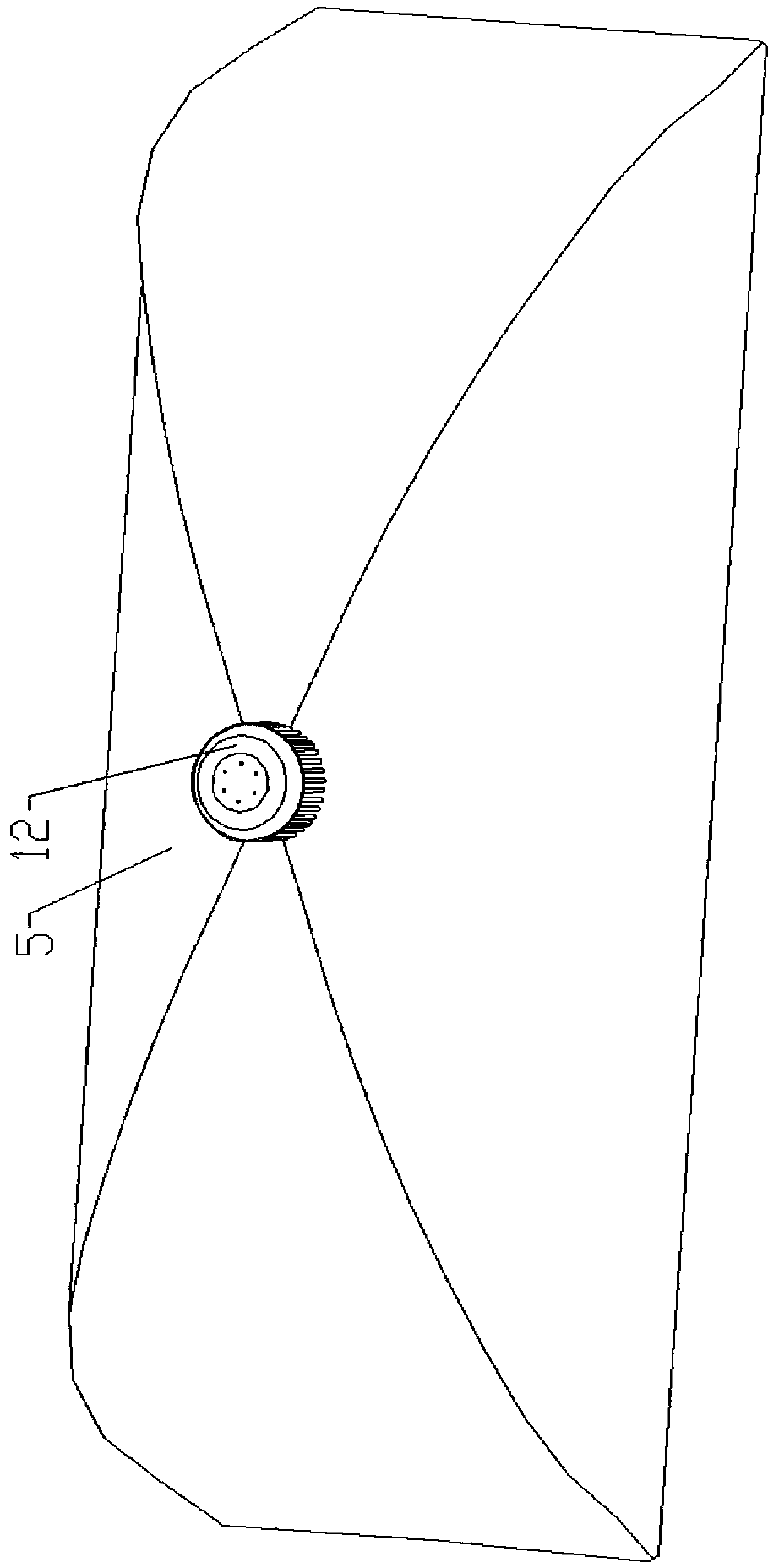

[0022] The cloth cover tightening mechanism of the present invention is additionally provided on the basis of the cloth cover opening mechanism of the fully automatic automobile cover, and can be tightened in time only with the help of parts on the cloth cover opening mechanism, namely the rotating turntable and the fixed seat The lower end of the cloth cover can independently have the function of tightening the cloth cover.

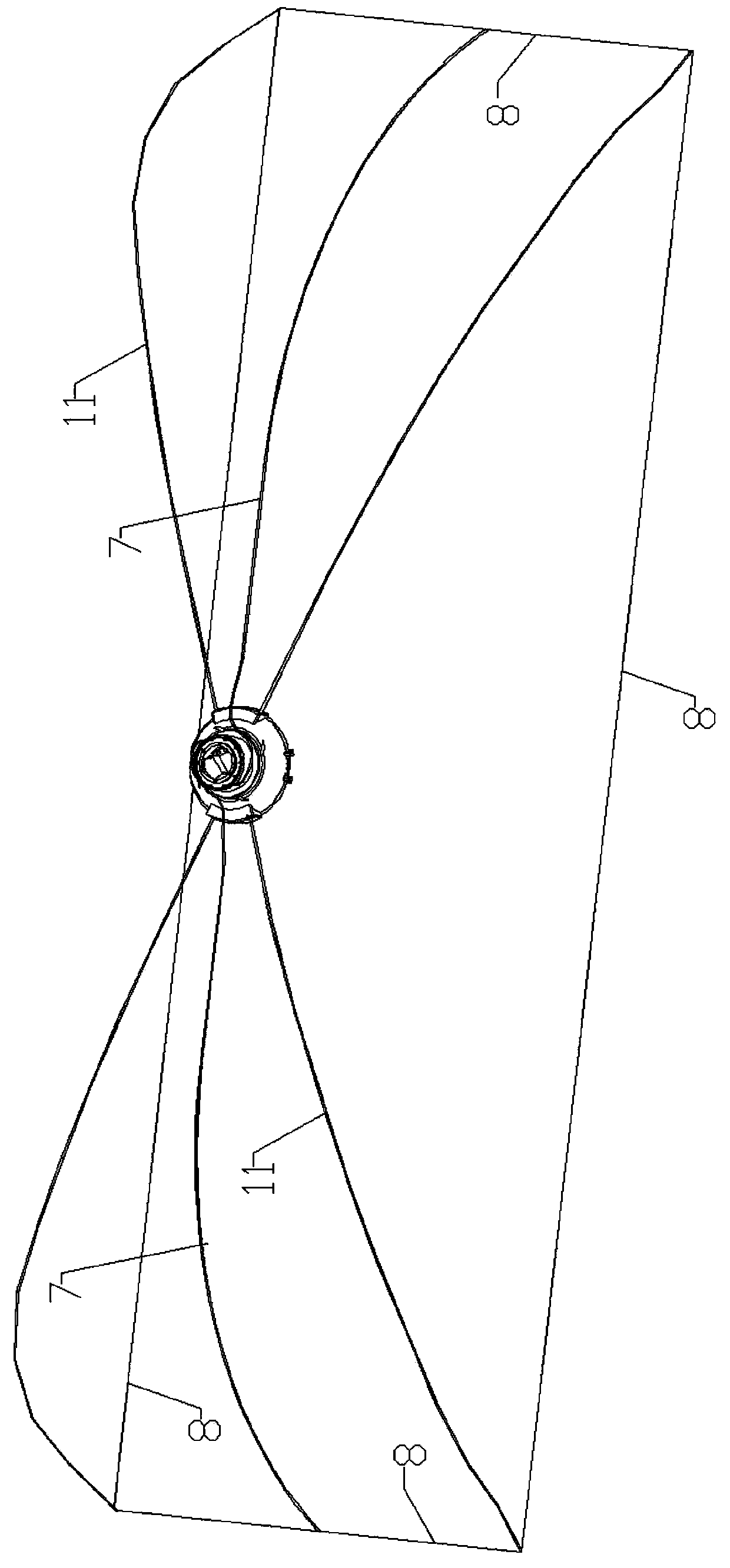

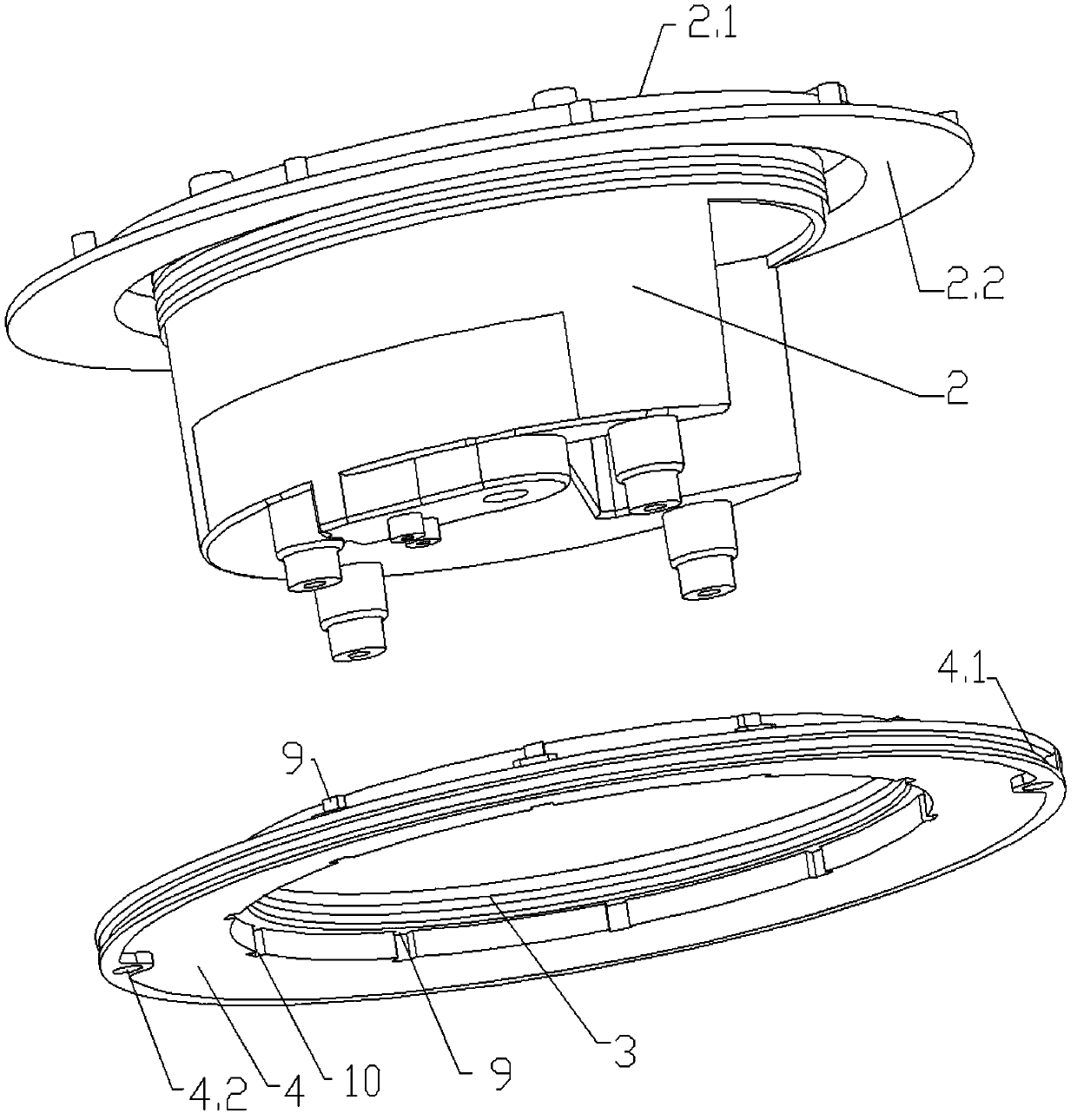

[0023] As shown in the figure, the cloth cover tightening mechanism of the fully automatic car cover of the present invention includes a fixed seat 2, an adjustment ring 3, a transmission ring 4, a tightening rope 8 and at least one hose 7 in number. exist figure 2 Among them, the adjustment ring 3 and the transmission ring 4 are blocked by the upper edge 2.2 of the fixed seat 2, so the adjustment ring 3 and the transmission ring 4 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com