Hollow coil winding jig

A technology of hollow coils and winding fixtures, which is applied in the manufacture of electrical components, inductors/transformers/magnets, circuits, etc., can solve problems such as high energy consumption, poor practicability, and burns, and achieve reduced processing difficulty, reduced costs, and energy saving The effect of the design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0092] The following are specific embodiments of the invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

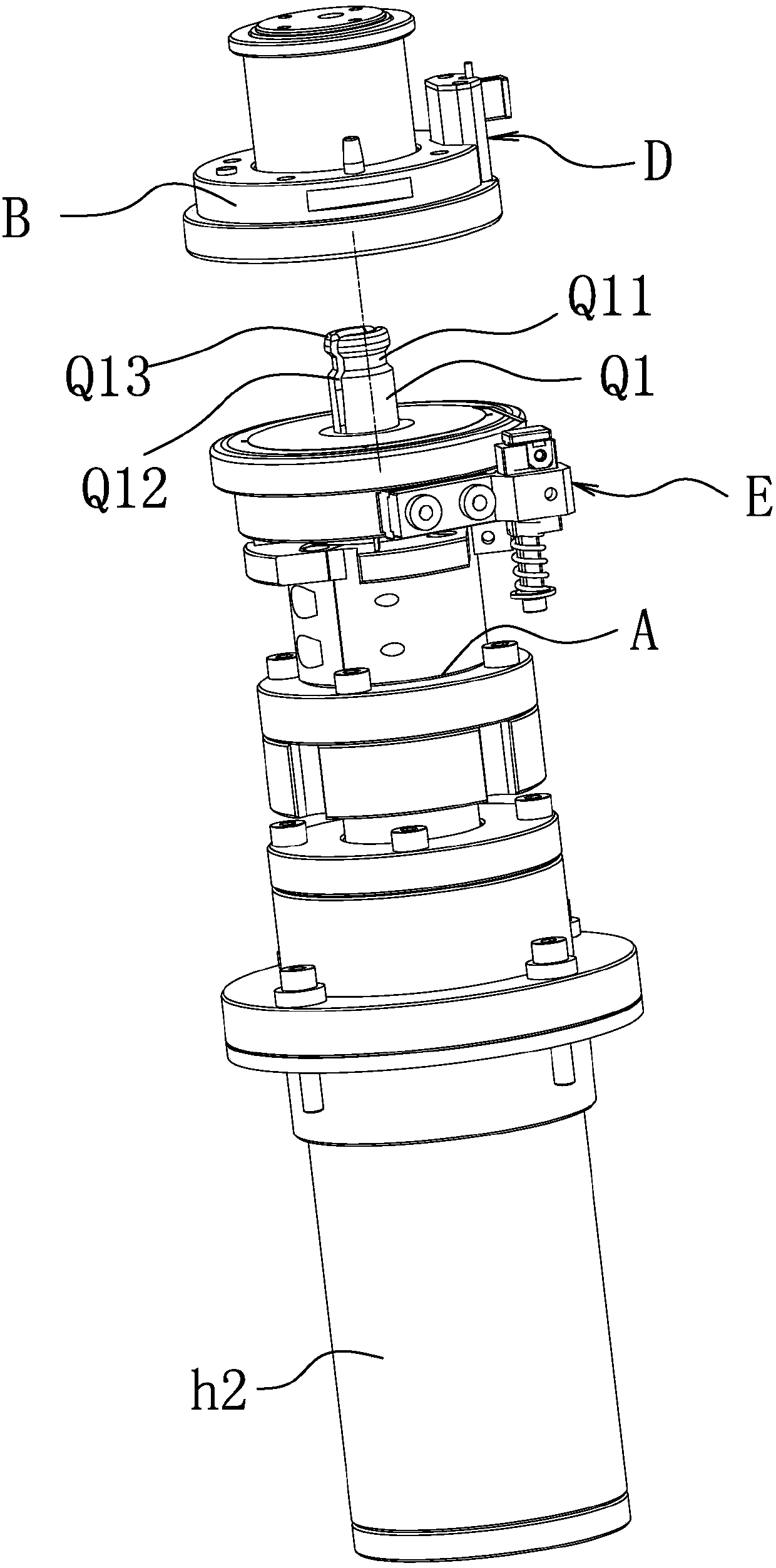

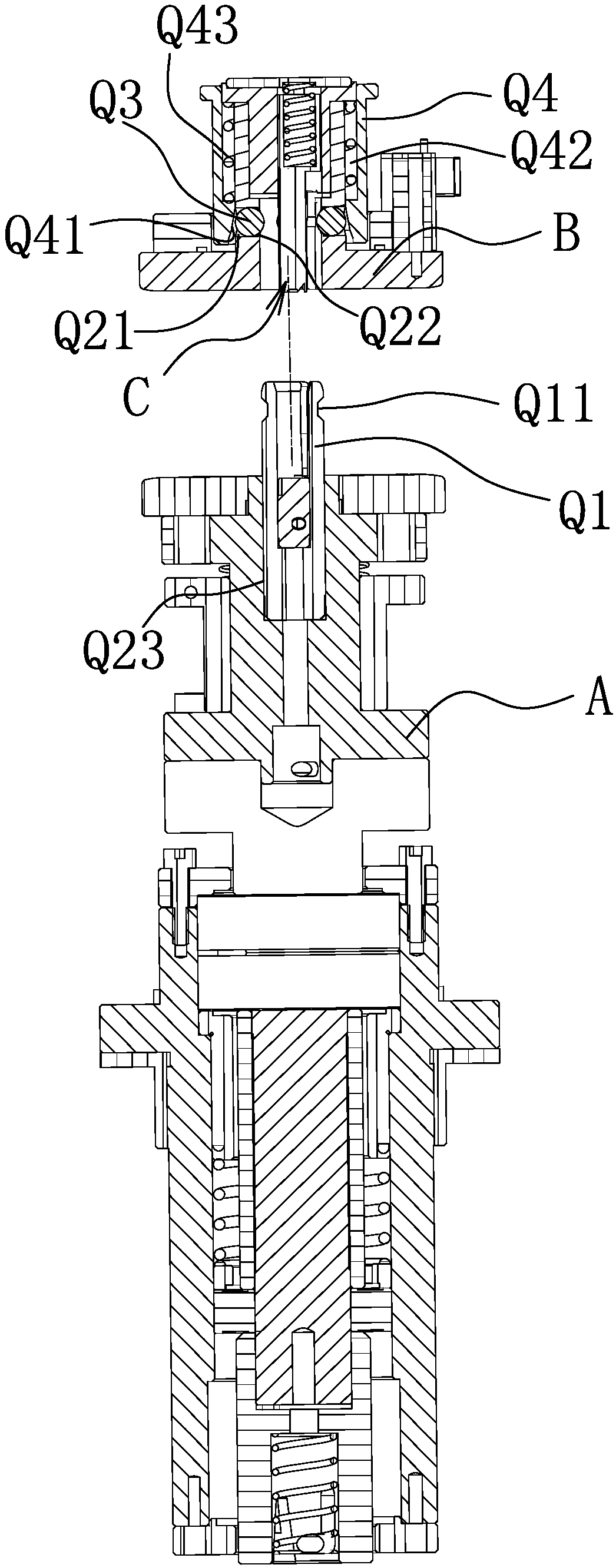

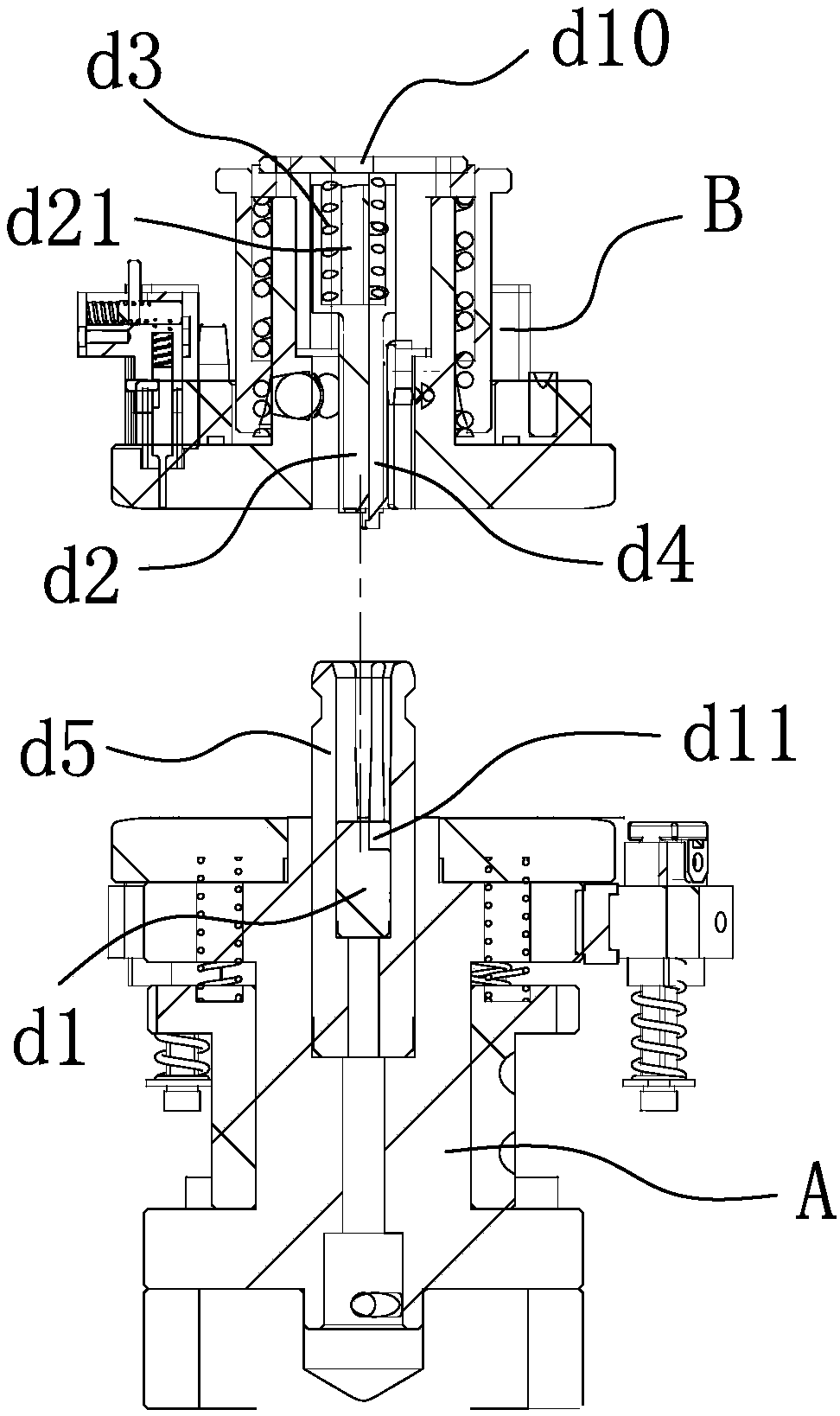

[0093] Such as Figure 1-2 and Figure 20 As shown, the hollow coil winding jig includes an upper jig B and a lower jig A located below the upper jig B. Between the upper jig B and the lower jig A, there is a The pierced inner wire head clamps the piercing mechanism C, and the outer edge of the upper jig B is provided with an outer wire end bending mechanism D that can force the outer wire end of the hollow coil to bend inward when the hollow coil is wound. The jig A or the upper jig B is provided with an outer wire end clamping and piercing mechanism E capable of clamping and piercing the outer wire end of the hollow coil.

[0094] Specifically, such as Figure 3-7 As shown, the internal thread end clamping and piercing mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com