Full-automatic winding die for frameless coil winding

A technology of skeletonless coils and winding molds, which is applied in the manufacture of electrical components, inductors/transformers/magnets, circuits, etc., can solve the problems of low finished product rate of windings without skeleton coils, shorten the mass production cycle, disassemble The effect of convenient installation and improved pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to further explain the technical solutions of the present invention, specific examples are given below to illustrate in detail.

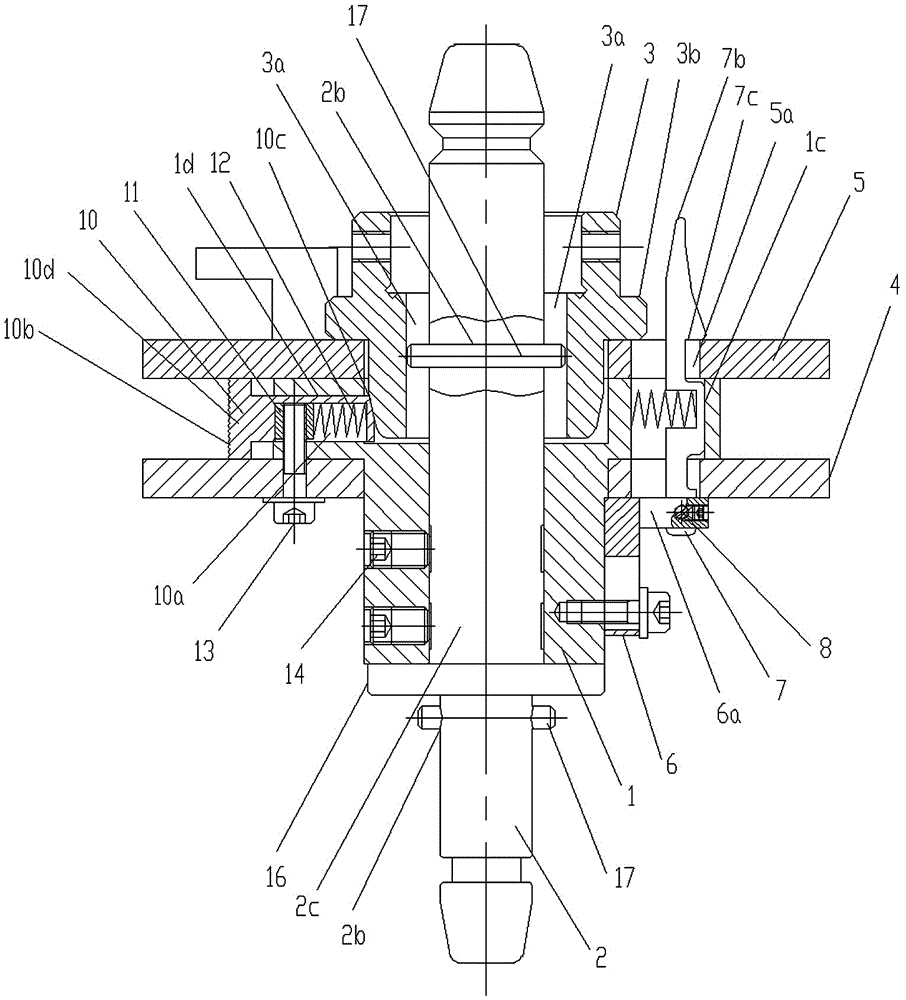

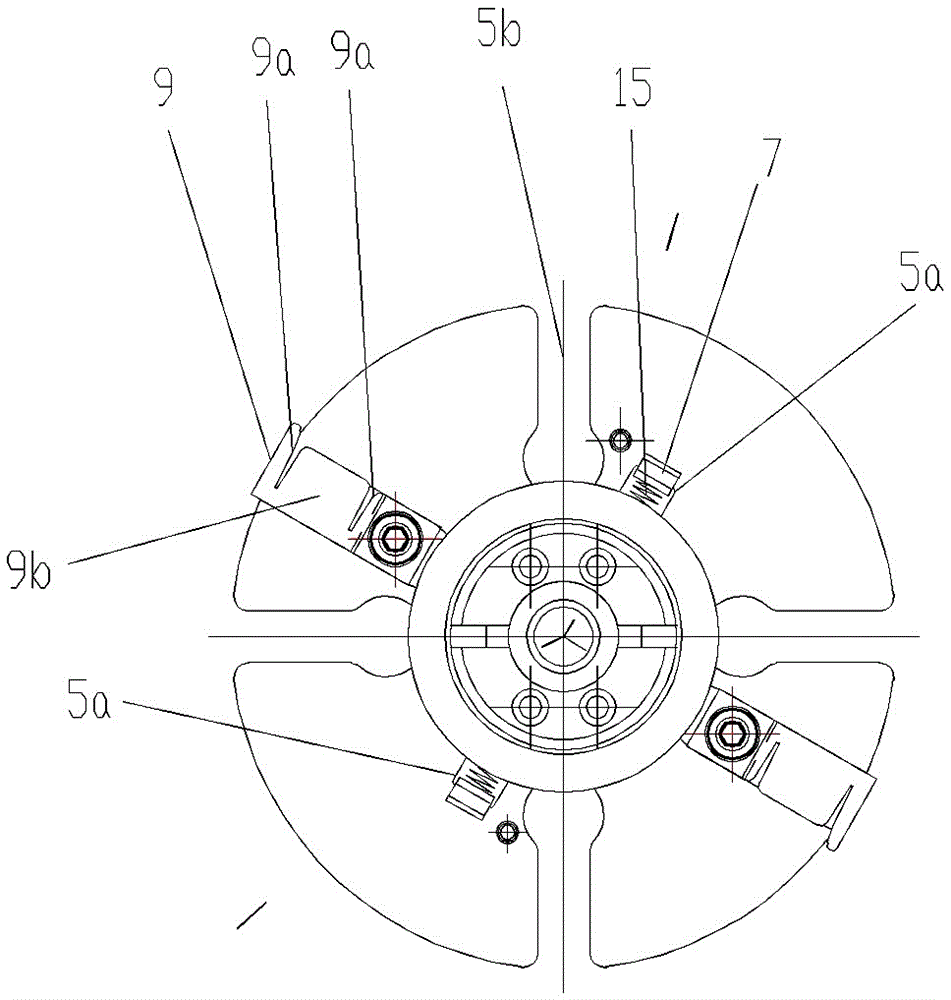

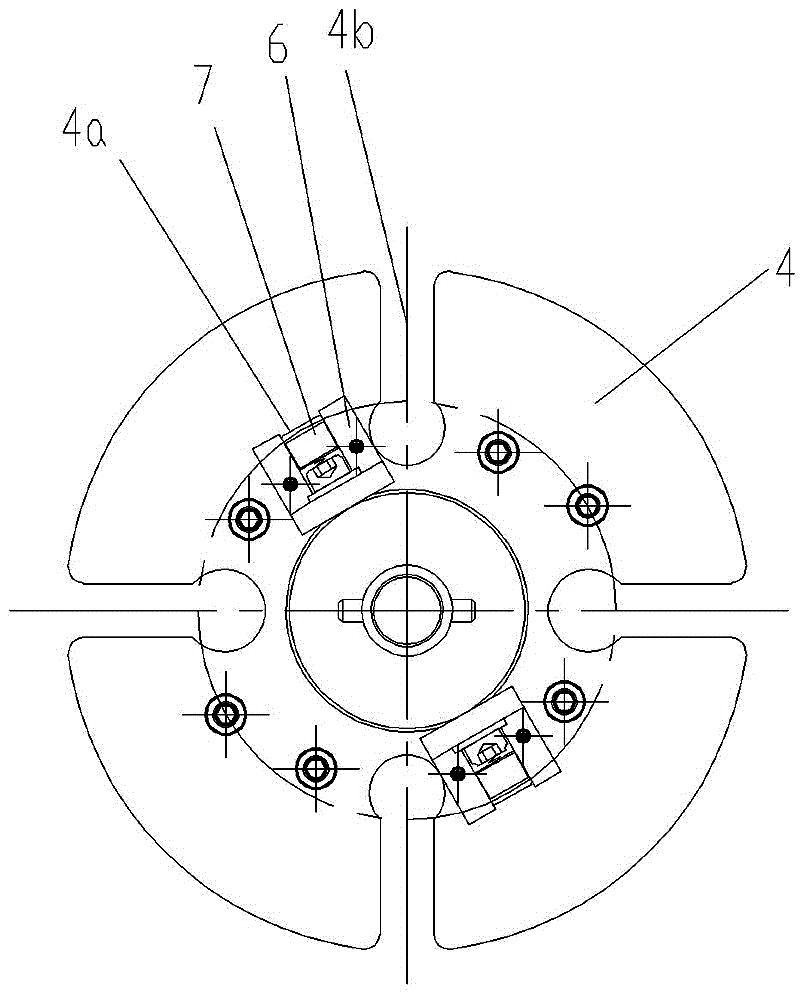

[0029] A fully automatic winding mold for a skeletonless coil winding, comprising a mold core cover 1, such as Image 6 Figure 7 and Figure 8 As shown, the core sleeve 1 is provided with a flange 1f at one end. An axial core hole 1a is provided at the center of the core sleeve 1, and a sliding sleeve hole 1b communicating with the core hole 1a is provided at the center of the flange plate 1f. The wall of the mold core sleeve 1 is provided with tightening screw holes 1g uniformly distributed along the circumferential direction, and the tightening screw holes 1g are arranged in two circles, 4 in each circle. Four radial square wire groove holes 1d uniformly distributed in the circumferential direction are arranged on the flange plate 1f, and each wire groove hole 1d communicates with the sliding sleeve hole 1b. A pair of symmetri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com