Unit ring combined bump foil type radial air bearing

A technology of air bearings and unit rings, applied in the direction of bearings, bearing components, shafts and bearings, etc., can solve the problem of difficult axial positioning of the free end of wave chaff, affecting bearing capacity and rotor system operation stability, interference and even misalignment, etc. problems, to avoid axial interference and misalignment, to achieve the effect of easy process and simple processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

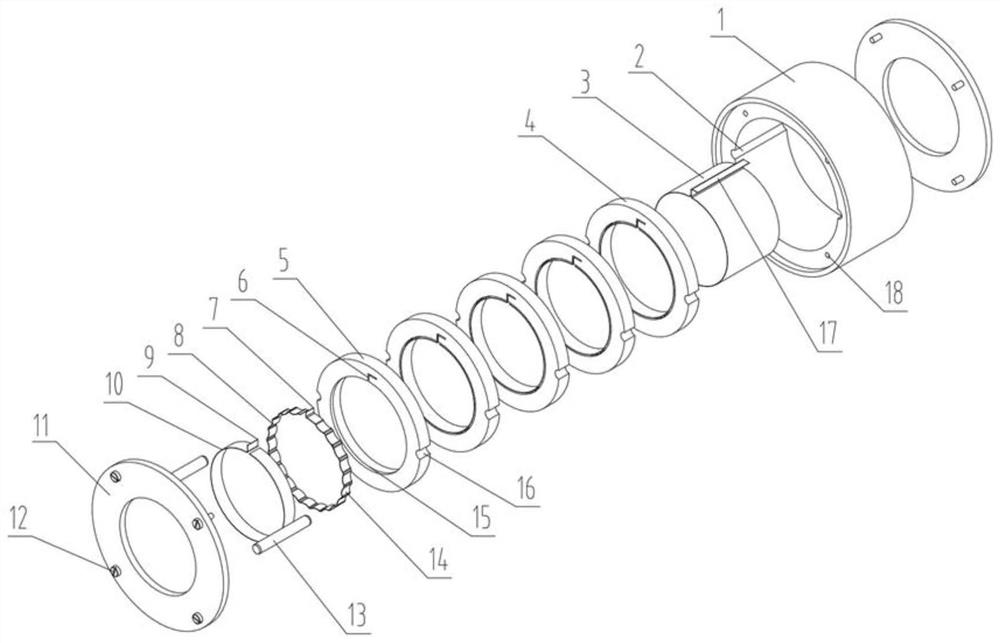

[0034] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

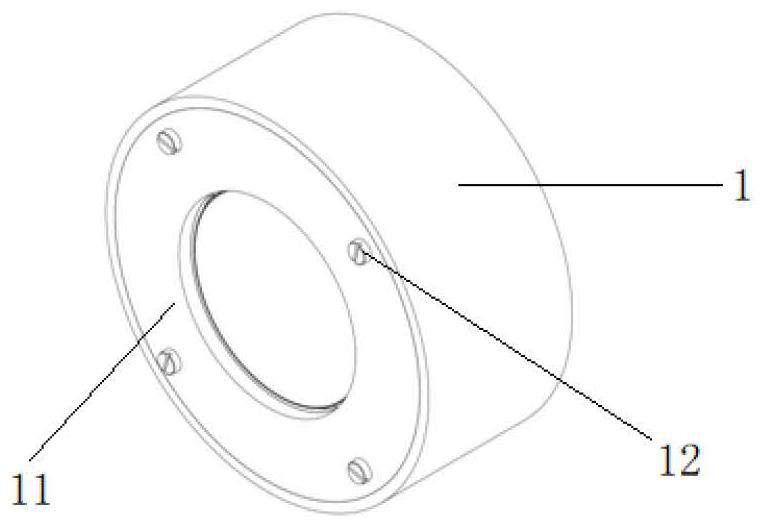

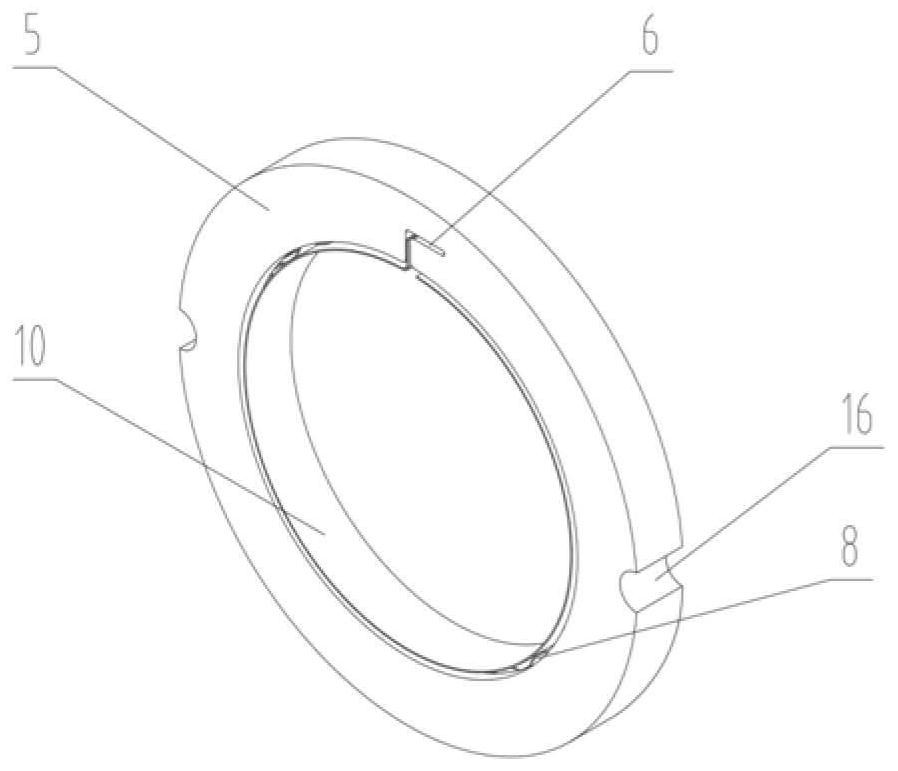

[0035] Such as figure 1 , figure 2 As shown, the present invention proposes a unit ring combined wave foil type radial air bearing, which includes an outer bearing sleeve 1, end covers 11 located at both ends of the outer bearing sleeve 1, and the front and rear end covers 11 are passed through circumferentially evenly distributed screws 12 The threaded hole 18 on the outer bearing sleeve 1 and the light hole on the end cover 11 achieve axial fixation, thereby restricting the axial movement of the unit ring 4 and the top foil 3 . The fixing method of the screw connection is convenient for installation and disassembly, and avoids the influence of welding on the mechanical properties of the fixed end of the foil, thereby improving the stability of the process.

[0036] The ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com