Rotor structure of asynchronous motor

A rotor structure, asynchronous motor technology, applied in the manufacture of motor generators, stator/rotor body, magnetic circuit shape/style/structure, etc., can solve problems such as assembly process difficulties, save time and labor in assembly, and reduce process difficulty Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

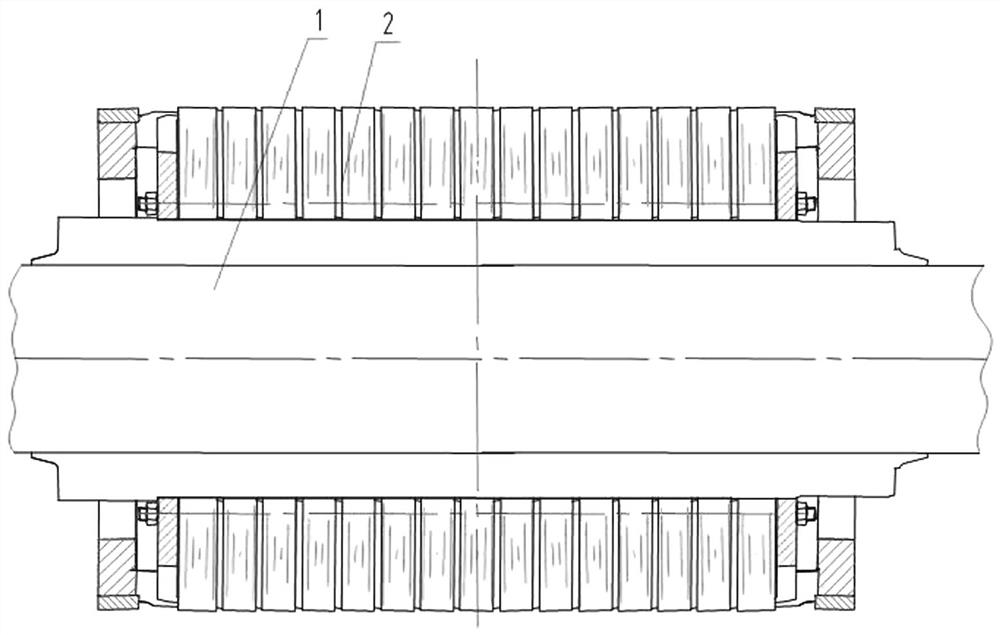

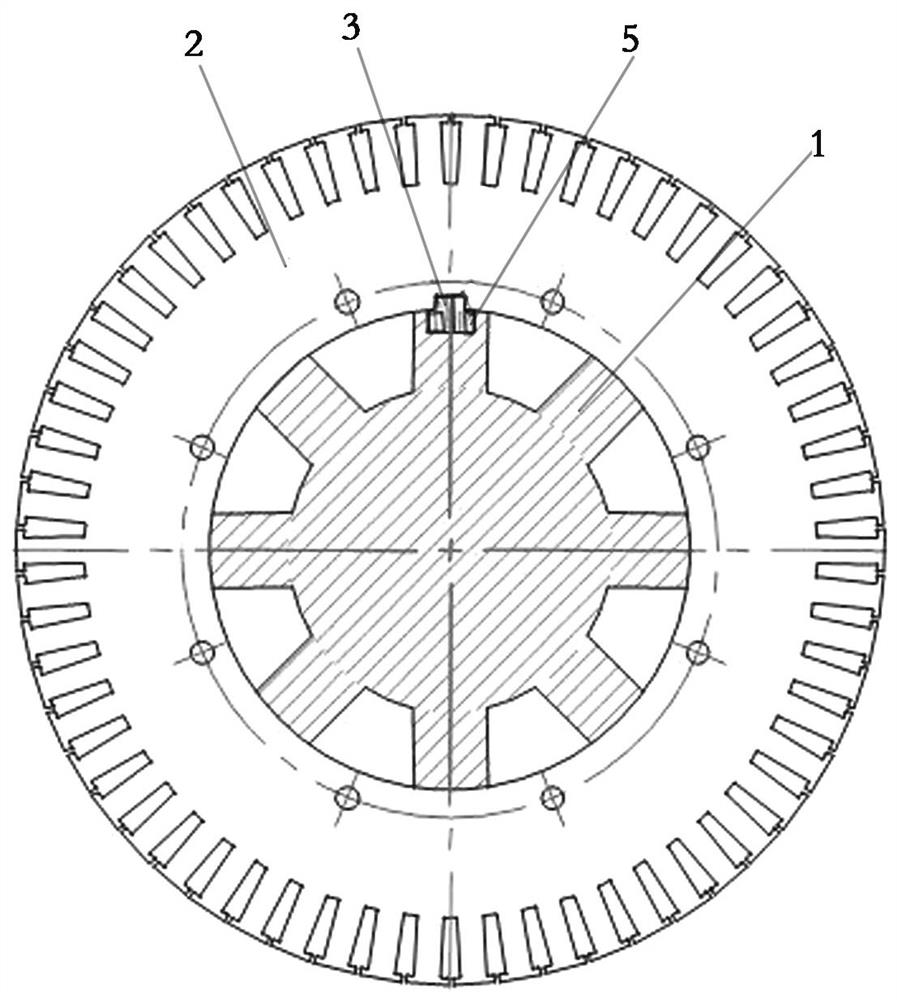

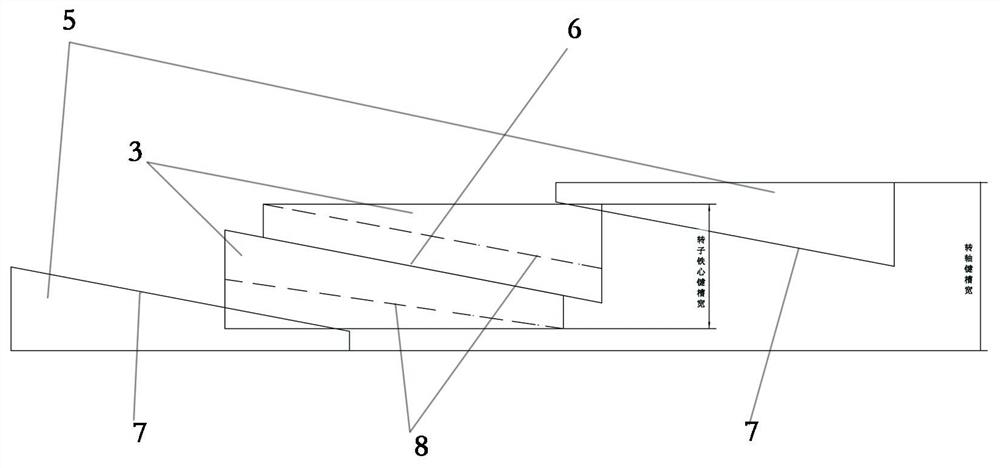

[0020] Embodiment one: if Figure 1 to Figure 7 As shown, an asynchronous motor rotor structure includes a rotating shaft 1 and a rotor core 2. Both the rotor core 2 and the rotating shaft 1 are provided with axially penetrating key grooves, and the width of the key groove on the rotor core 2 is smaller than that on the rotating shaft 1. It includes two first wedge-shaped keys 3 located in the space formed by the key groove of the rotor core 2 and the key groove of the rotating shaft 1 and a second wedge-shaped key 5 located in the key groove of the rotating shaft 1. The two first wedge-shaped keys 3 and the second wedge-shaped key The height directions of 5 are all arranged axially along the rotating shaft 1. The height direction is arranged axially along the rotating shaft 1, that is, the arrangement direction of the height of the first wedge-shaped key 3 is consistent with the axial direction of the rotating shaft 1 and its cross-section is a right-angled trapezoid. The firs...

Embodiment 2

[0026] Embodiment two: if Figure 4 to Figure 7As shown, a rotor structure of an asynchronous motor includes a rotating shaft 1 and a rotor core 2. Both the rotor core 2 and the rotating shaft 1 are provided with axially penetrating key grooves. The width of the key groove on the rotor core 2 is greater than that on the rotating shaft 1. It includes two first wedge-shaped keys 3 located in the space formed by the key groove of the rotor core 2 and the key groove of the rotating shaft 1 and a second wedge-shaped key 5 located in the key groove of the rotor core 2. The two first wedge-shaped keys 3 and the second wedge-shaped key The height direction of the keys 5 is arranged axially along the shaft 1. The height direction is arranged axially along the shaft 1, that is, the arrangement direction of the height of the first wedge-shaped key 3 is axially consistent with the shaft 1 and its cross-section is a right-angled trapezoid. The first wedge-shaped key 3 Including the first b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com