Valve box, tank container and box door mounting structure

A valve box and box door technology, which is applied in the field of valve boxes, can solve the problems of increasing the number of welds in the tank, theft of the transport medium, and the increased risk of tank failure, so as to improve the anti-prying ability, prevent damage, and ensure the structure The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

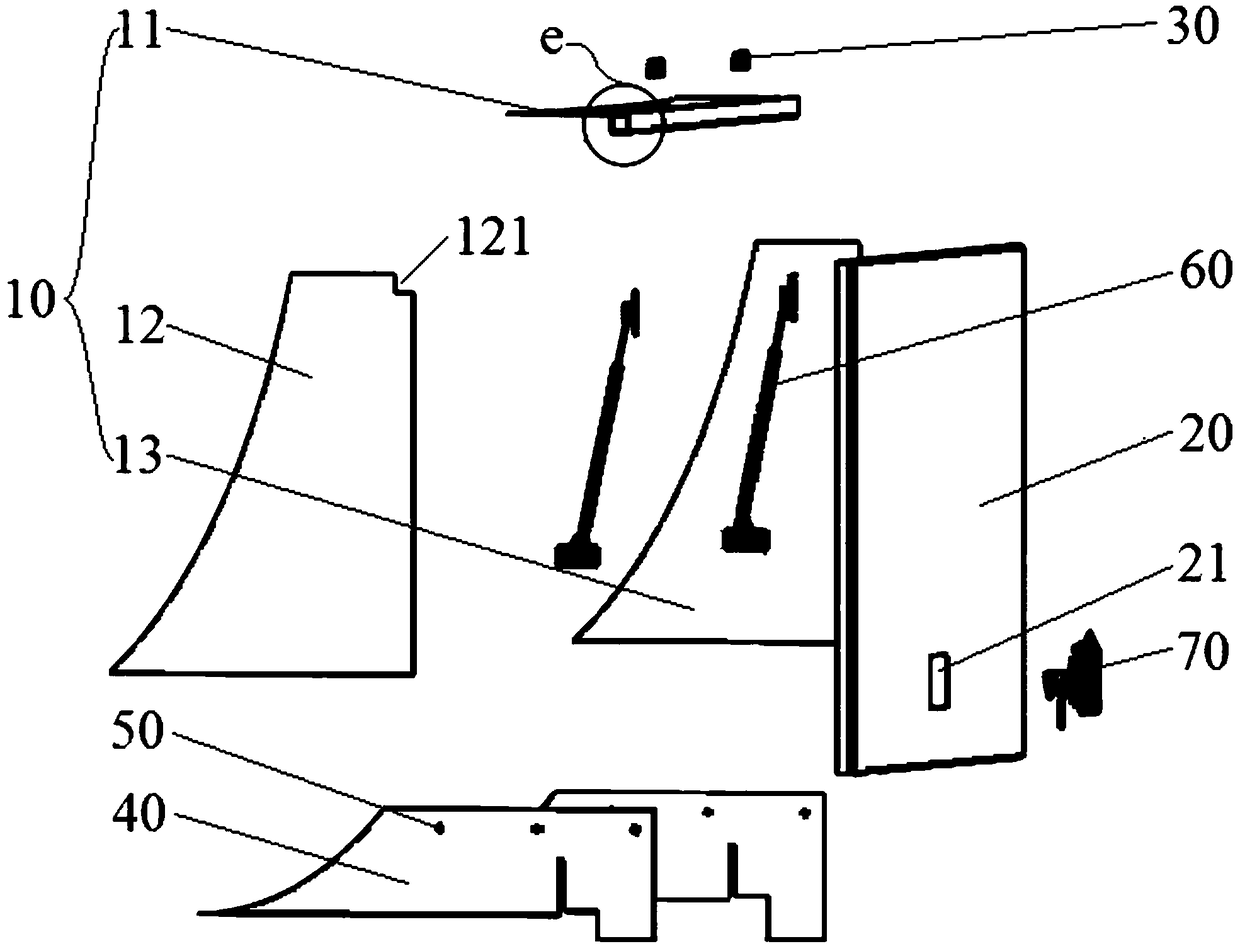

[0057] see figure 1 , a valve box, including a box body 10, a box door 20 and a support device 40, the support device 40 is located below the box body 10, and the box body 10 is installed on the support device 40.

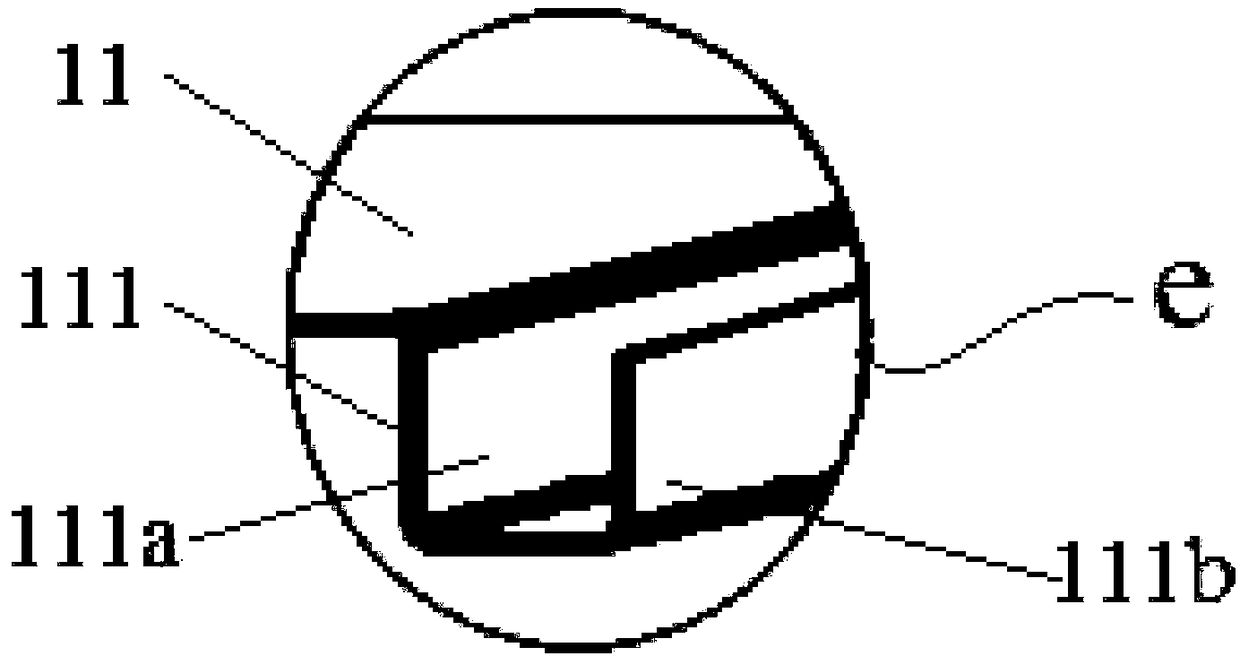

[0058] The box body 10 includes a top board 11 , a left side board 12 and a right side board 13 , and the box door 20 is hinged to the top board 11 through a hinge member 30 . The inner side of the box door 20 and the position of the top plate 11 for installing the box door 20 are all provided with hinged positions; the two hinged positions are opposite to each other, and jointly define a sinking hinged area, the height of which is not higher than the top plate 11 The upper surface; the hinged part 30 is installed in the hinged area, between the door 20 and the top plate 11, and the hinged part 30 is respectively connected with two hinged positions.

[0059] In the embodiment of the present invention, the box body 10 has no bottom plate, and is composed of a top p...

Embodiment 2

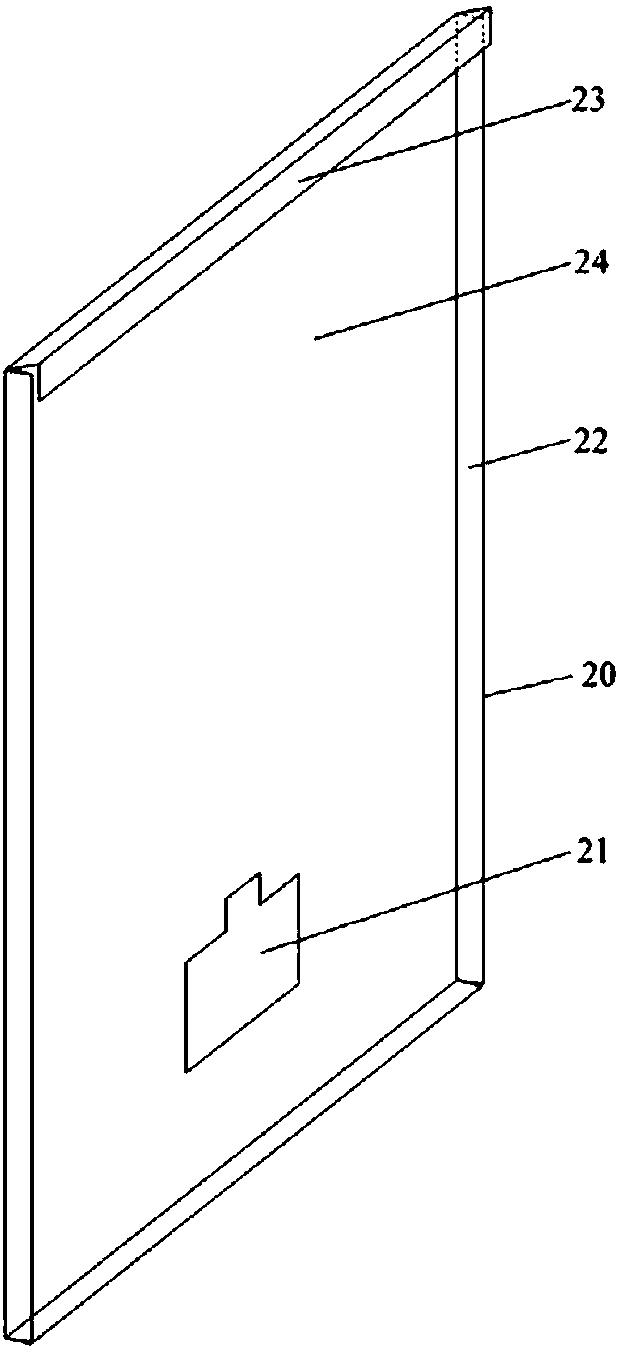

[0068] see Figure 5 , a valve box, comprising a box body 10 and a box door 20, the box body 10 includes a top plate 11, a left side plate 12 and a right side plate 13; the box door 20 is hinged with the top plate 11 through a hinge part 30, and the length of the top plate 11 is in the box The door installation side is slightly shortened, avoiding the space for the installation of the hinged parts 30; the length of the left side panel 12 and the right side panel 13 is lengthened, and its bottom just rests on the frame of the tank container after installation.

[0069] see Figure 6 , the inside surface of the box door 20 and the position of the top plate 11 for installing the box door 20 are provided with hinged positions 91, 92, wherein the box door hinged positions 91 are two pieces welded on the inner surface of the box door 20 and distributed at intervals The top plate hinged position 92 is two plates welded on the lower surface of the top plate 11 and distributed at inte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com