Construction method for cold-bent thin-wall light steel structure building

A technology of light steel structure and construction method, applied in the direction of construction, building components, building materials, etc., can solve the problems of mud wall crack resistance, poor waterproof and sealing performance, weak ability to resist rain erosion, poor adhesion, etc. , achieve good waterproof effect, good thermal insulation effect, and improve the effect of safeguard measures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

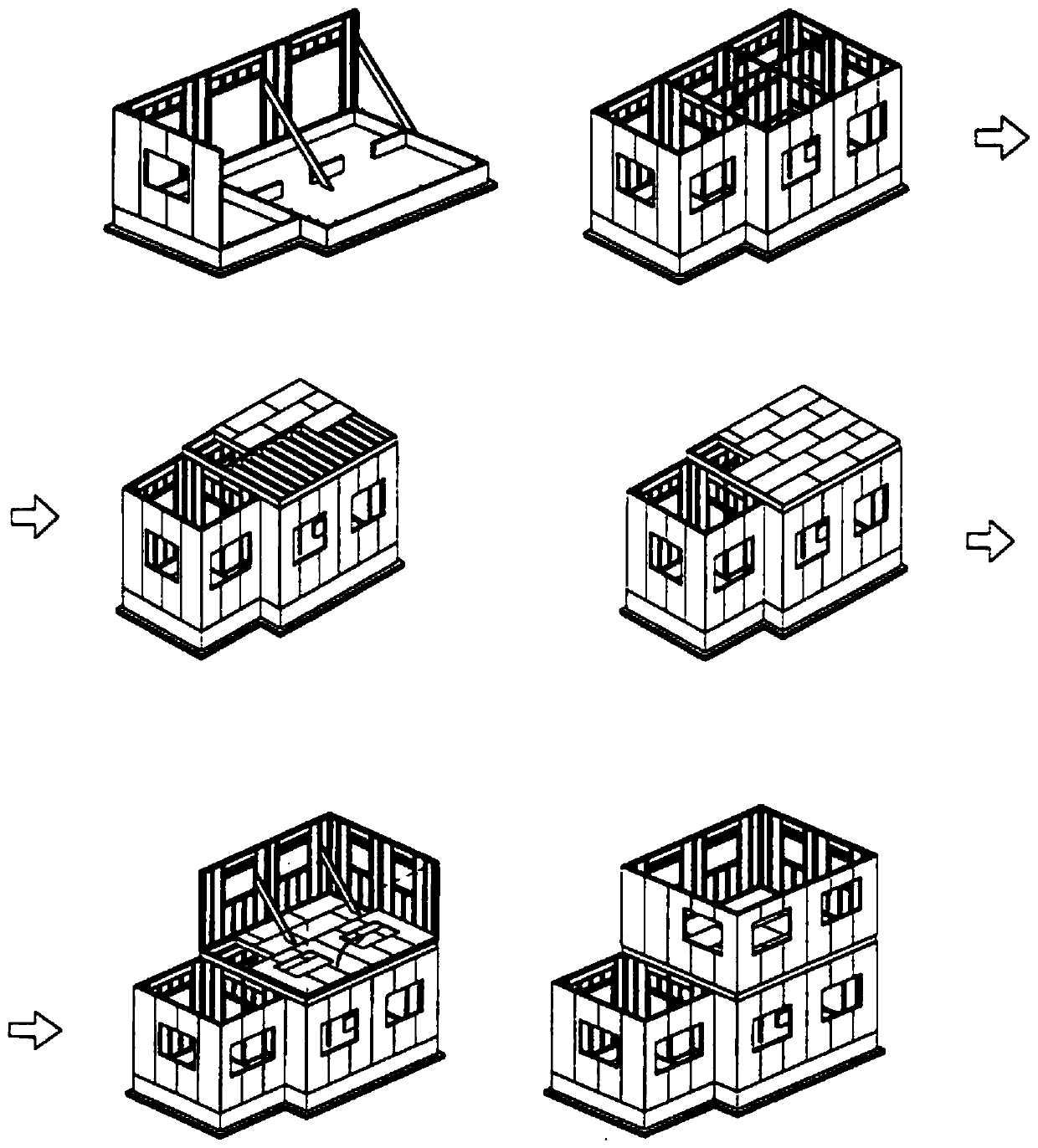

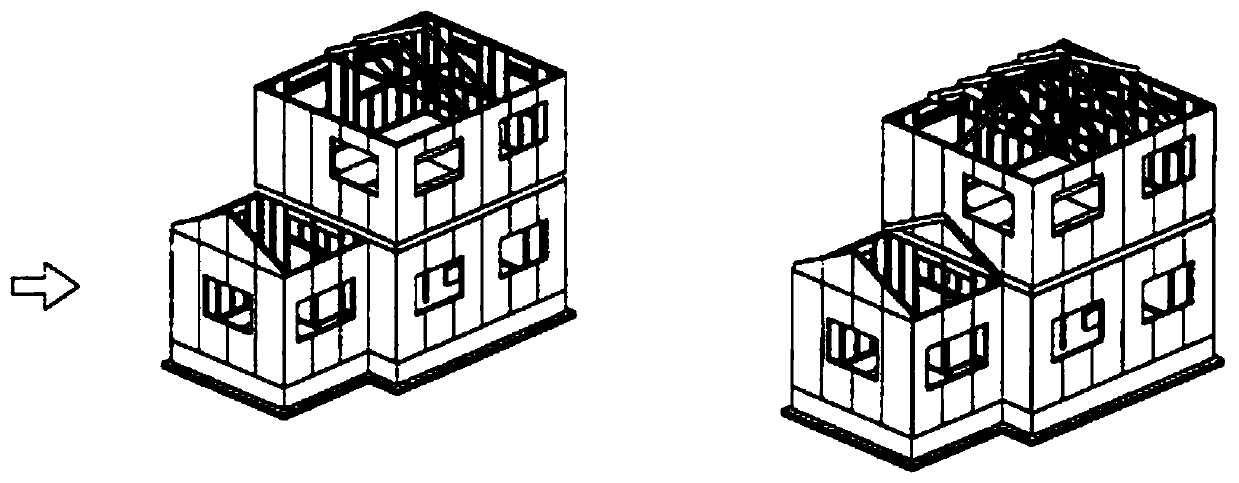

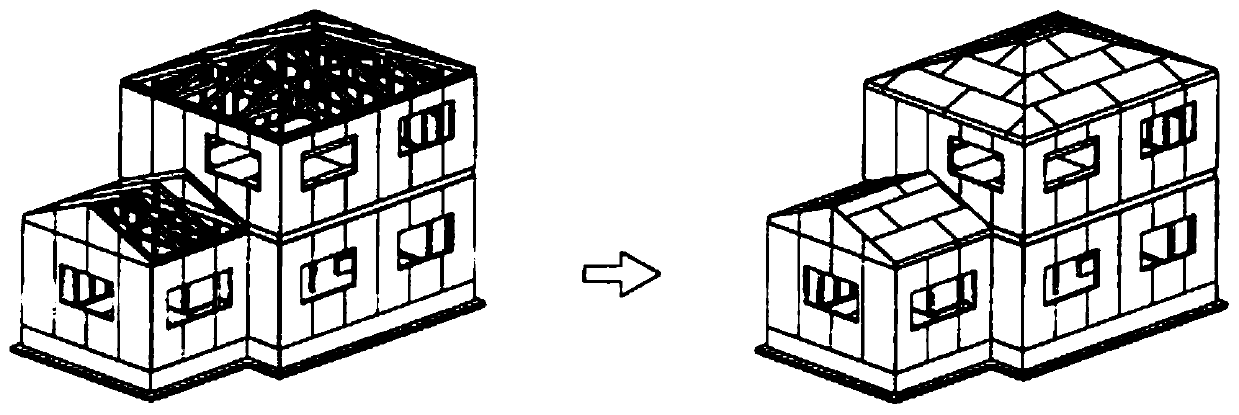

[0053] A construction method of a cold-formed thin-walled light steel structure building, comprising the following steps,

[0054] S1. Main component construction

[0055] After the light steel main components are manufactured in the processing plant, they are transported to the construction site for assembly and hoisting. Among them, the light steel main components are light steel keels formed by cold bending of galvanized steel strips. Preparatory work before installation: provide the structure manufacturer with a list of components entering the site and a timetable for components entering the site, recheck the important dimensions of component appearance quality, component number and component quantity, pop up the relevant lines of components, recheck the strength of the concrete foundation and pop up the axis. Check the performance of all hoisting equipment and the reliability of safety protection products, and determine the construction section of each shift to ensure the...

Embodiment 2

[0093] This embodiment is further improved on the basis of Embodiment 1. The construction method also includes the construction of the yellow mud wall, including the following steps: laying steel wire mesh sheets and asbestos nets in sequence on the outside of the wall, and fixing them with fixtures, and then installing them on the asbestos nets. Apply exterior wall mortar on the outside.

[0094] Specifically, the yellow mud wall is installed on the outer wall insulation board of the light steel structure building. Its function is to increase the aesthetic feeling of the appearance, which is pastoral, and the overall layout of the building is good. The steel wire mesh and asbestos net are laid to make all parts of the yellow mud wall evenly stressed, which is more conducive to the attachment of each part, and the effect of preventing the yellow mud wall from falling and cracking is achieved. The distance between several fixing parts is 0.8-1m, which achieves the effect of kee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com