Heat-preservation color steel sandwich corner plate adopting straw for foaming and manufacturing technology thereof

A manufacturing process, color steel technology, applied in the direction of building components, buildings, building structures, etc., can solve the problems of weak connection at the corners of color steel sandwich panels, affecting the service life of the plates, and insufficient use of straw, etc., to achieve improved Convenience and flexibility, reduced production costs, time-saving and labor-saving assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

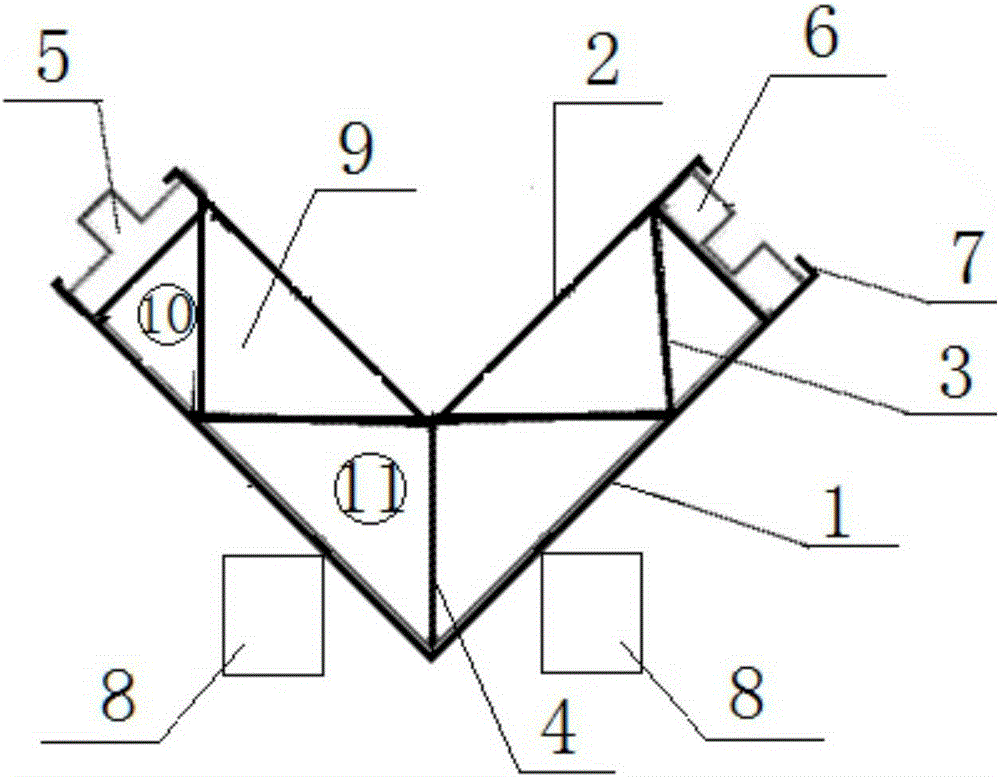

[0061] In this example, a heat-insulating color-steel sandwich corner plate using straw foaming includes V-shaped plates, long plates 4 and heat-insulating sandwich materials 9. The angle of the V-shaped plates is 90 degrees, and the left and right symmetrical structures have three types. They are V-shaped plate Ⅰ1, V-shaped plate Ⅱ2 and V-shaped plate Ⅲ3 respectively, and their side widths are a, b and c respectively, and the relationship between the width and size is a=b+c / √2, b=√2×c; long plate The width of 4 is c; there are two V-shaped plates III3; the corner of the V-shaped plate II2 is fixedly connected with one long side of the long plate 4 to form a left-right symmetrical structure with a Y-shaped cross section, and the other long side of the long plate 4 and The corners of the V-shaped plate Ⅰ1 are connected, so that the V-shaped plate Ⅰ1 and the V-shaped plate Ⅱ2 are assembled into a V-shaped thermal insulation color steel sandwich corner plate with the long plate 4 ...

Embodiment 2

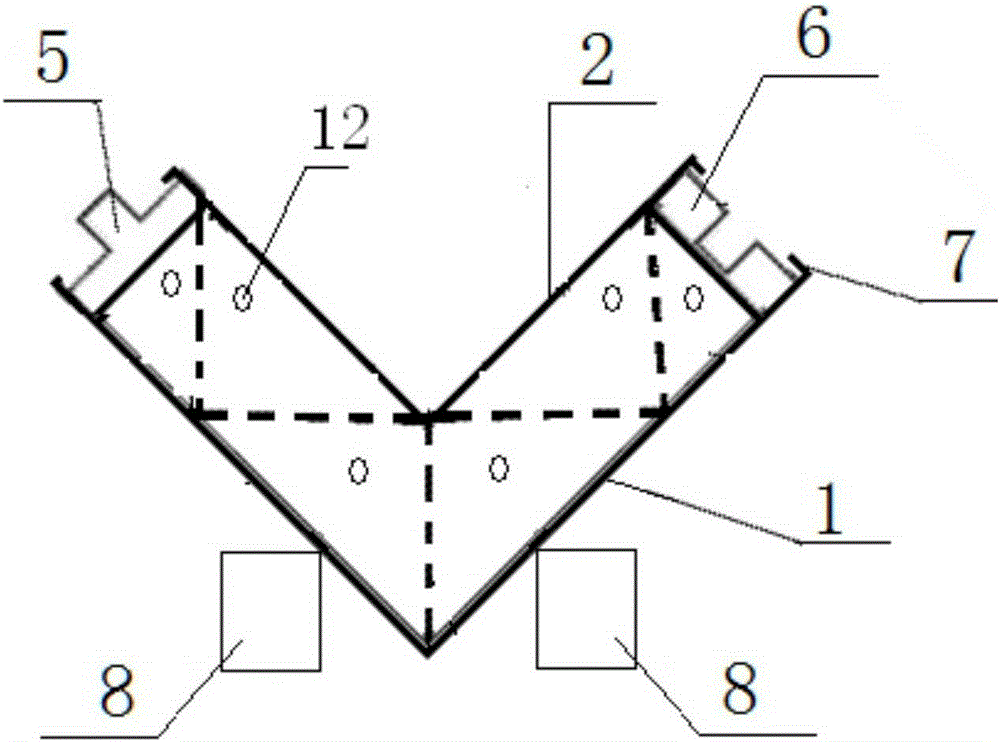

[0074] In this embodiment, a thermal insulation color steel sandwich corner plate using straw foaming, the basic structure is the same as that of embodiment 1, and the improvement is that the V-shaped plate is made of V-shaped color steel plate, such as figure 1 As shown, it also includes a tenon joint device arranged at the two top ends of the heat-insulation color steel sandwich corner plate, the tenon joint device is a groove plate 6 and a bump plate 5 arranged in cooperation; A top end is provided with an inner chamfer 7 which is opposite and clamps the mortise joint device.

[0075] In this embodiment, a production process of heat-insulating color-steel sandwich corner panels using straw foaming, the basic steps are the same as in Embodiment 1, and the improvement is that: material A and material B are respectively combined polyether and isocyanate. Steps to perform experiments and calculations before proceeding to Step A:

[0076] -2A. Test the mixing ratio of polyether...

Embodiment 3

[0090] The heat-insulating color steel sandwich corner panel using straw foaming in this embodiment has the same basic structure as that in Embodiment 2, except that the mortise joint device is replaced by a clamping device, and the clamping device is a male card and a female card. Material A and B are combined basic phenolic resin and low-boiling alkane respectively; combined basic phenolic resin includes basic phenolic resin and emulsifier; low-boiling alkane is preferably normal pentane, isopentane, normal hexane, cyclopentane 1. One or more of petroleum ether, most preferably n-pentane-isopentane body, the present embodiment selects n-pentane-isopentane body;

[0091] In this embodiment, a production process of a heat-insulating color steel sandwich corner panel using straw foaming, the basic steps are the same as in Embodiment 2, except that:

[0092] -2A. Mixing ratio of test combination alkaline phenolic resin and n-pentane-isopentane body and expansion coefficient afte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com