Hydraulic tensioner

A tensioning device and hydraulic technology, applied in the direction of transmission, belt/chain/gear, machine/engine, etc., can solve the problems of high cost and achieve the effect of reducing manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

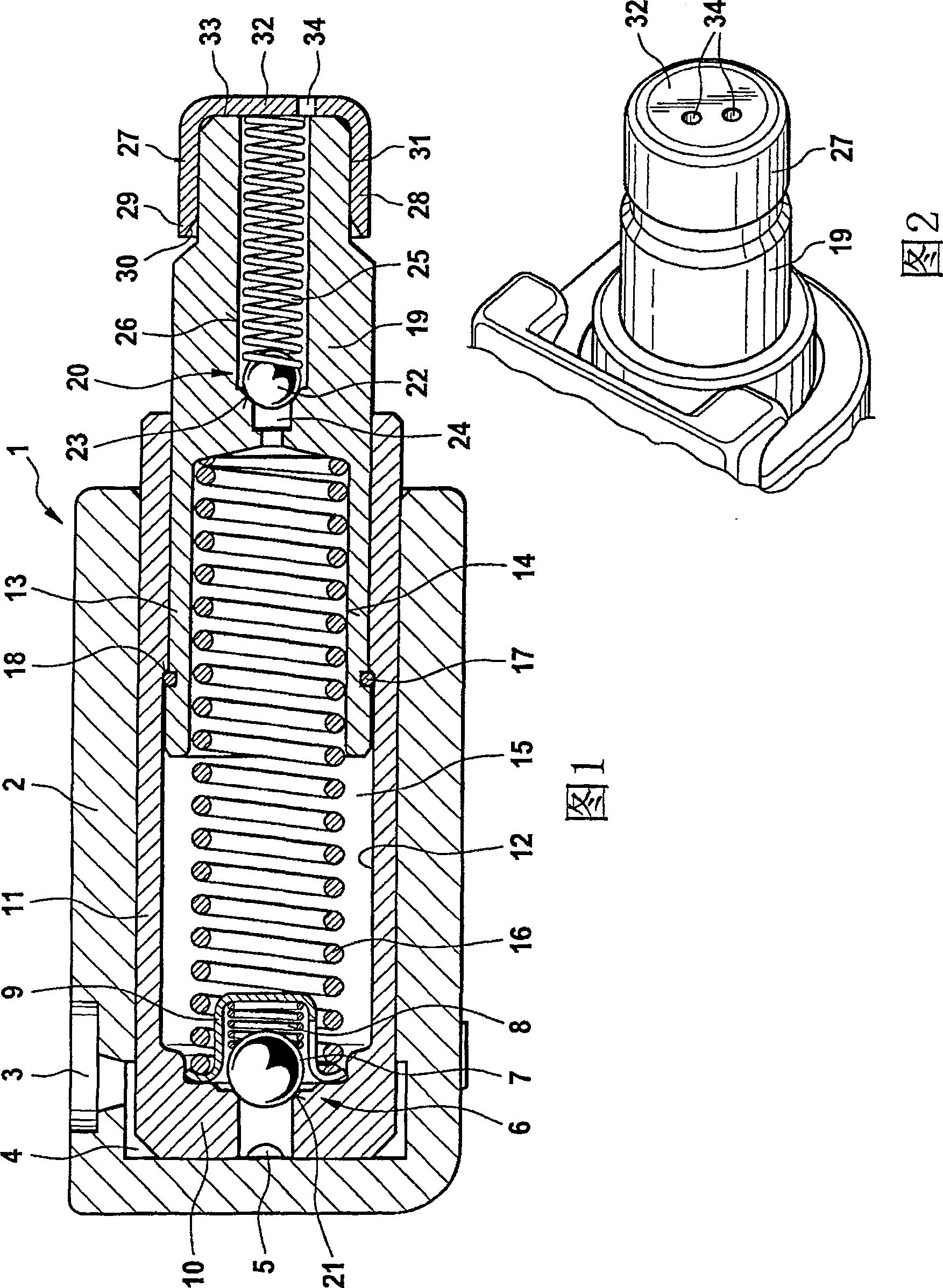

[0026] FIG. 1 shows a longitudinal section through a hydraulic tensioning device 1 with a protective housing 2 . The protective casing 2 is connected to the engine casing, not shown. It has a pressure oil port 3, and lubricating oil from the pressure oil port 3 reaches the valve 6 through the annular space 4 and the transverse groove 5. The valve 6 is located at the bottom 10 of a box 11 which is arranged in the protective case 2 with a sealing clearance. The valve 6 includes a valve ball 7 , a valve seat 21 , a valve spring 8 and a valve sleeve 9 .

[0027] The housing 11 has a blind bore 12 into which a tensioning piston 13 is introduced with sealing play. The tensioning piston 13 contains a blind bore 14 . The blind holes 12 , 14 surround a high-pressure chamber 15 in which a compression spring 16 is arranged. The compression spring 16 acts via the tensioning piston 13 on a not shown tensioning and pulling mechanism. The stroke of the tensioning piston 13 is limited by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com