Aircraft and propeller fast disassembly device thereof, fast-disassembly propeller and propeller base component

A propeller and quick-release technology, applied to aircraft, unmanned aircraft, rotorcraft, etc., can solve problems such as structural damage, and achieve the effect of improving mechanical strength and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

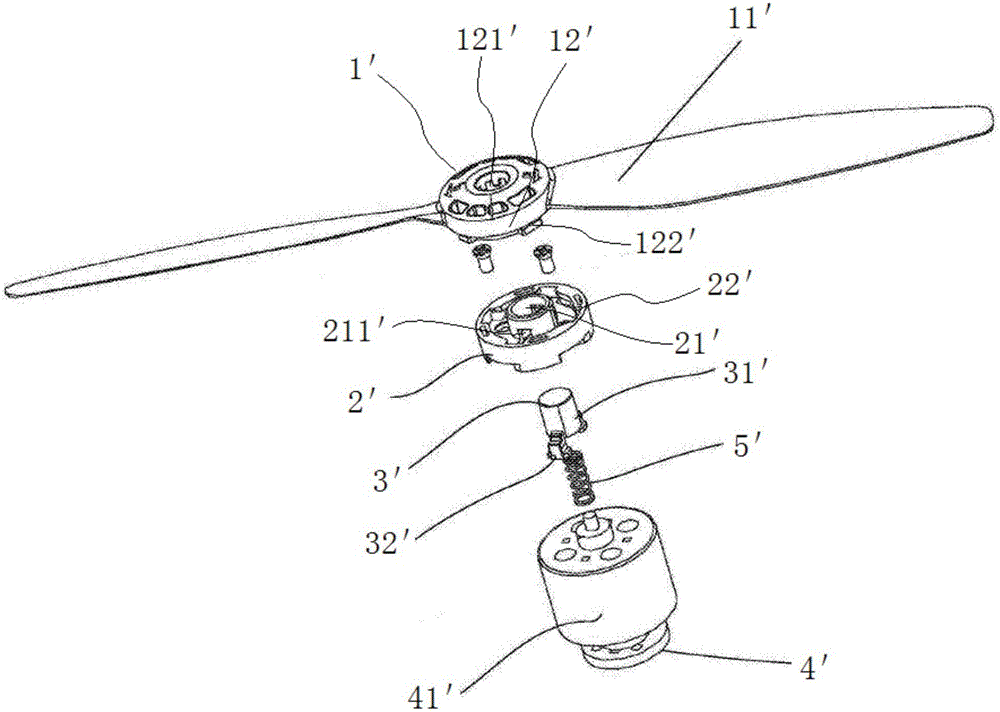

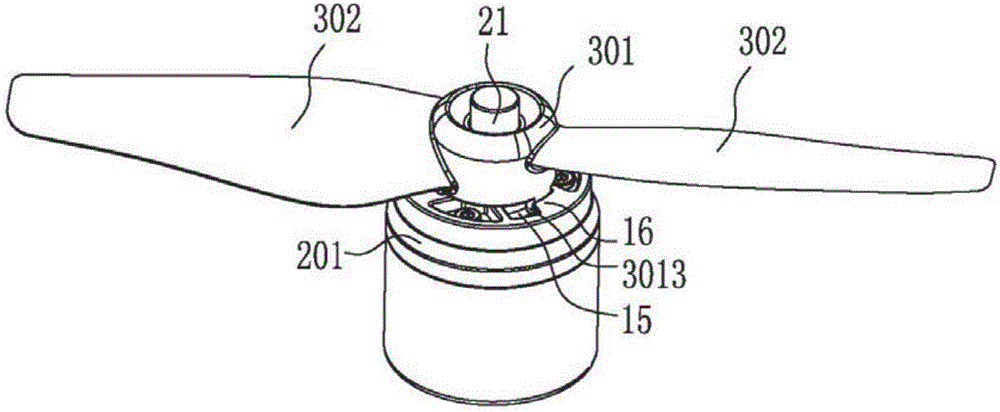

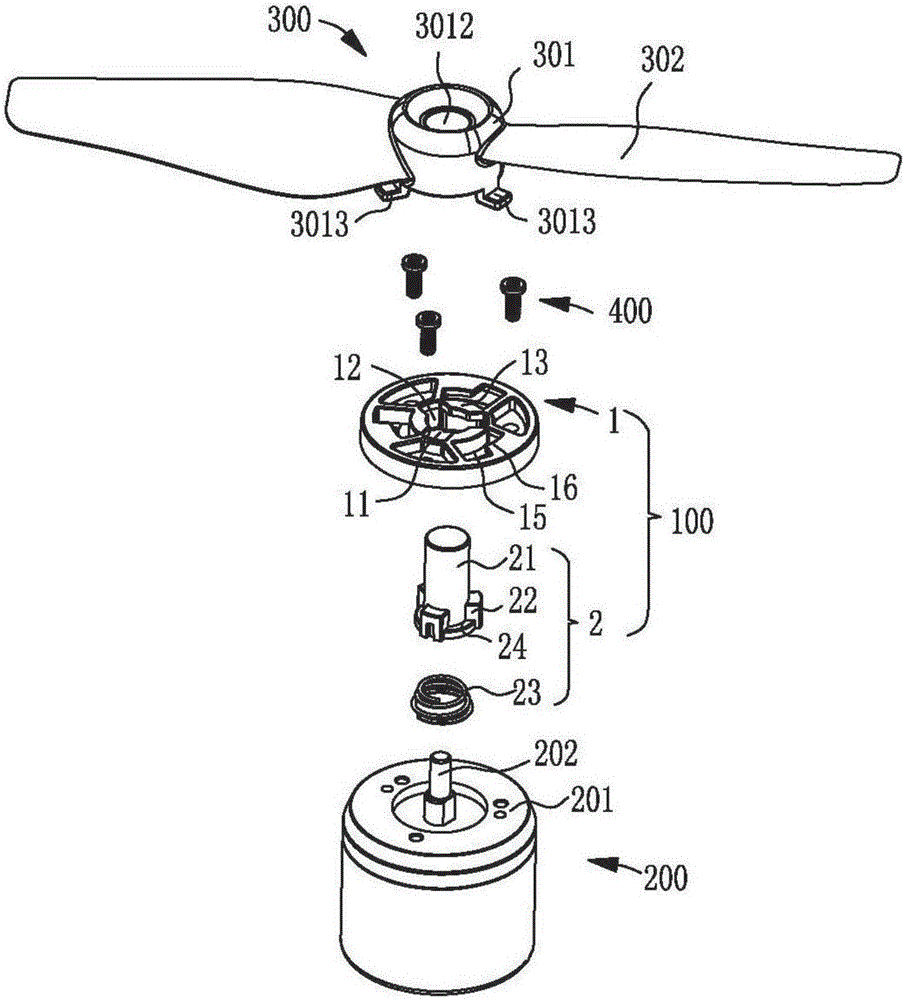

[0056] like Figure 2 to Figure 4 A specific implementation of the propeller quick-release device shown includes a propeller base assembly 100 as a connection base and a quick-detachable propeller 300 as a connection accessory.

[0057] Wherein, the quick-detachable propeller 300 includes a seat body 301 and at least two blades 302 that are evenly distributed in the circumferential direction on the seat body 301. The seat body 301 is formed with a positioning structure on the side facing the propeller base assembly 100 (not shown in the figure). ), the positioning structure is restricted by the propeller base assembly 100 toward the protruding part of the seat body and blocks the rotation of the seat body 301 relative to the propeller base assembly 100;

[0058] The propeller base assembly 100 includes a fixed seat 1 and a key switch 2, the fixed seat 1 is fixedly connected to the rotating part 201 of the driving device 200, and an engaging mechanism ( Not marked in the figur...

Embodiment 2

[0070] This embodiment provides an aircraft (not shown in the figure), including a fuselage and any one of the propeller quick release devices described in Embodiment 1.

[0071] The above-mentioned aircraft has the advantages described in any one of Embodiment 1 due to the adoption of the above-mentioned propeller quick release device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com