Warp knitting machine

A warp knitting machine and machine body technology, applied in the field of warp knitting machines, can solve problems such as increasing repairs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

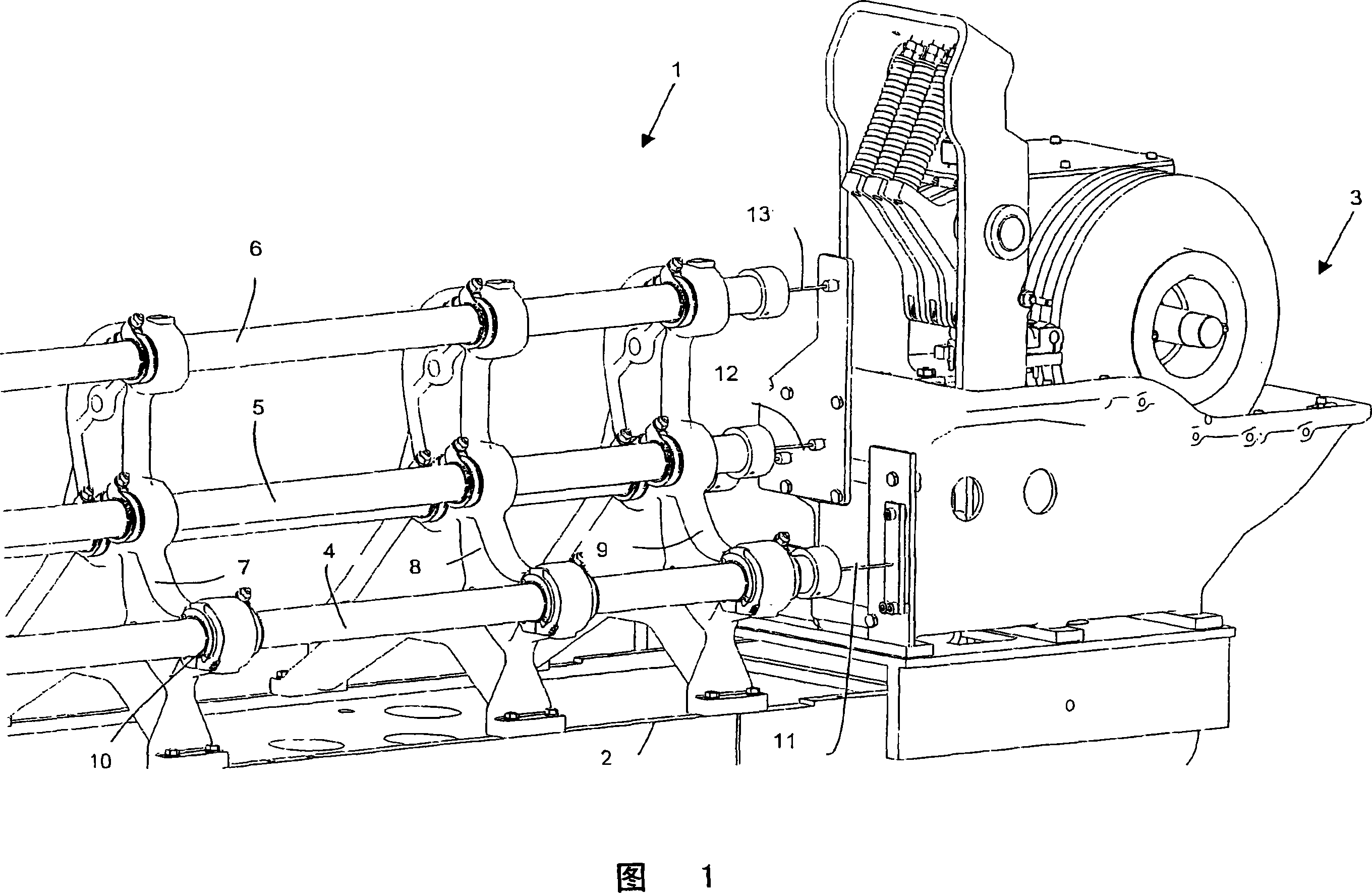

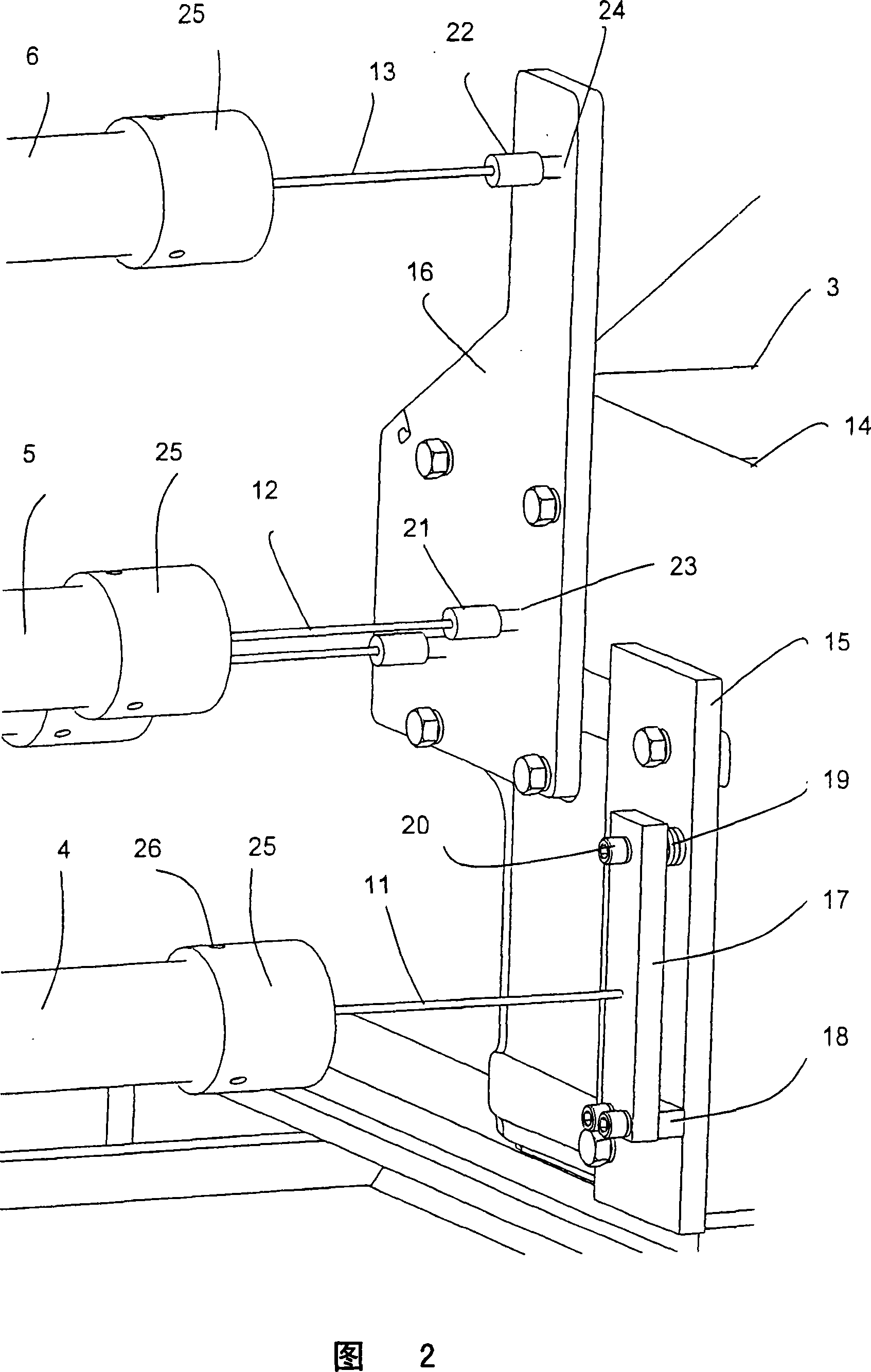

[0025] FIG. 1 shows a partial view of a warp knitting machine 1 having a body 2 . At an axial end of the warp knitting machine 1, a jacquard drive or jacquard device 3 is provided, which makes the not shown knitting tool bar, such as the bar, move back and forth according to the desired pattern of a knitted fabric. .

[0026] The warp knitting machine has a plurality of bearing shafts 4, 5, 6, which are supported in wall panels 7, 8, 9, which are connected to the machine body 2, for example by means of screws. The support shafts 4, 5, 6 are supported in the wall plates 7, 8, 9 by means of bearings 10 which allow the rotational movement of the support shafts 4, 5, 6, but not the support shafts 4, 5, 6 in their axial direction towards Wall panels 7, 8, 9 support.

[0027] The above-mentioned, not shown, comb bars are connected to the support shafts 4, 5, 6 via looping tool bars. If the bearing shafts 4, 5, and 6 are rotated, the corresponding knitting tool bars are swung. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com