Natural gas hydrate rotary pressure maintaining coring device

A hydrate and rotary technology, applied in the field of drilling, can solve problems such as short service life, inability to maintain pressure, and small application range, and achieve the effects of simple and convenient operation, improved coring success rate, and fast and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

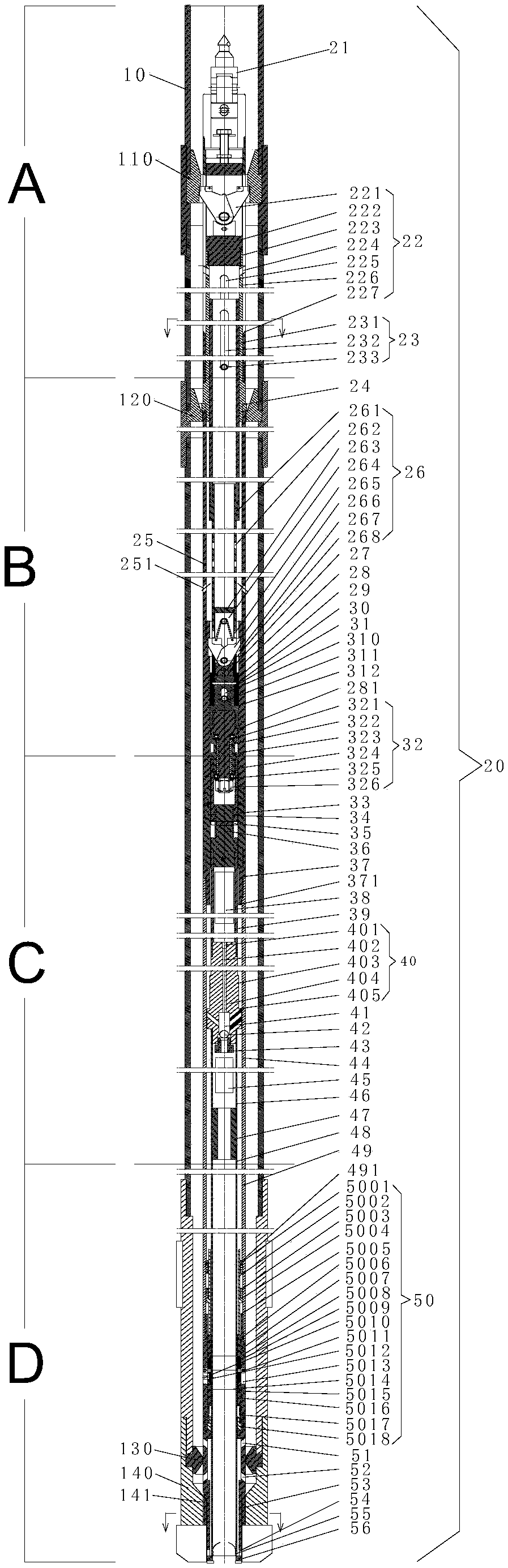

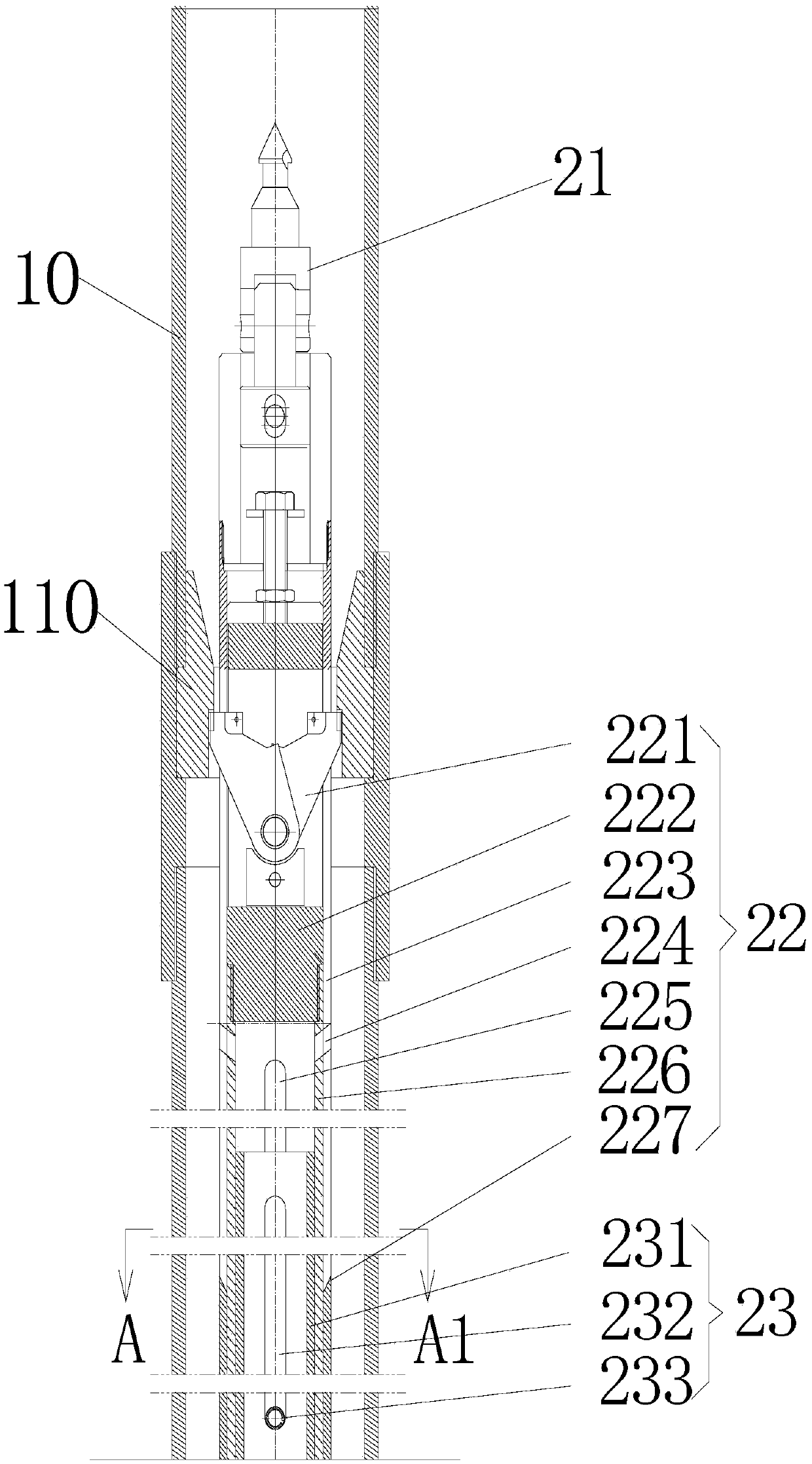

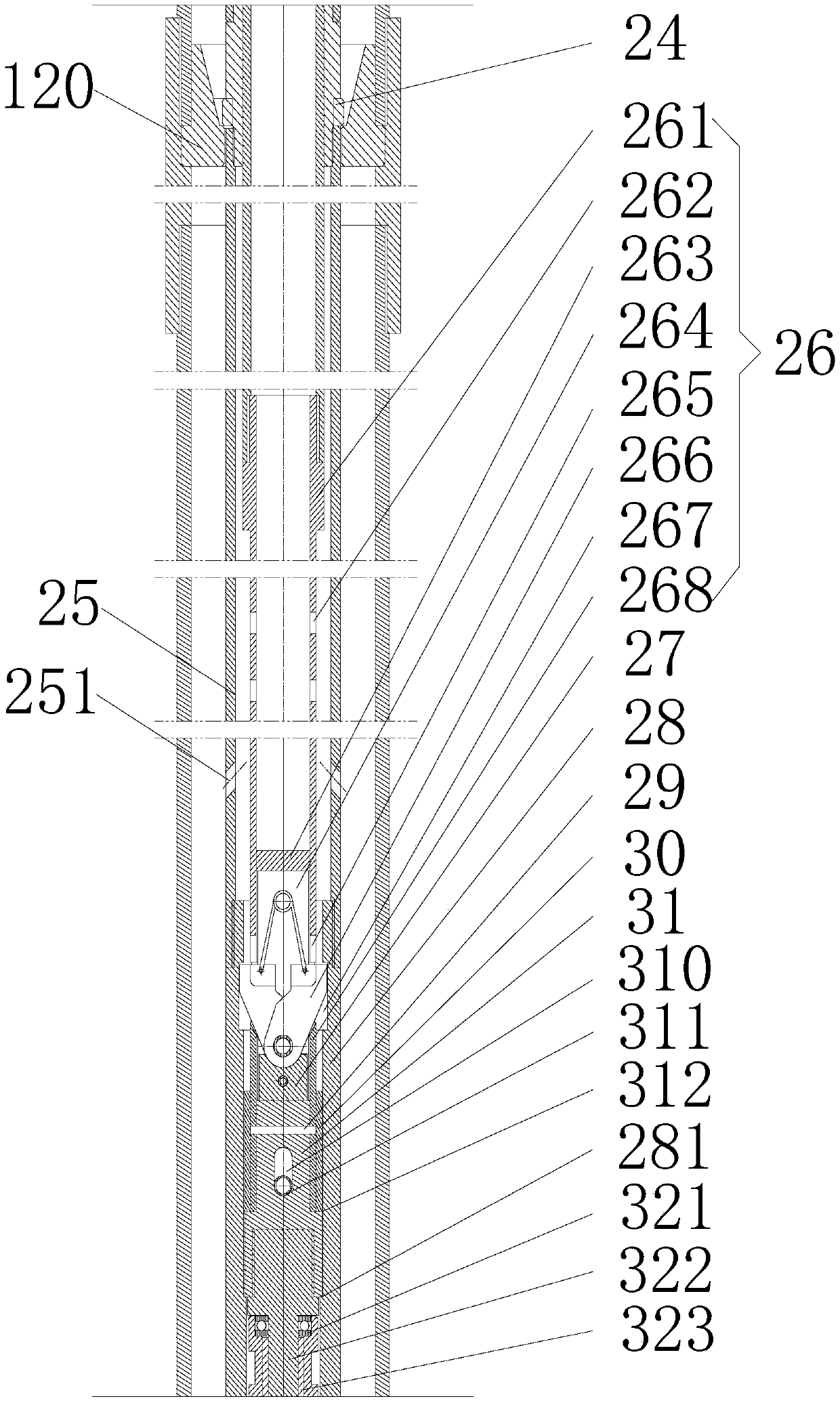

[0054] like Figures 1 to 21 As shown, a natural gas hydrate rotary pressure-maintaining coring device includes an outer pipe assembly 10 and an inner pipe assembly 20 installed inside the outer pipe assembly 10, and the inner wall of the outer pipe assembly 10 is sequentially arranged from top to bottom An ejection chamber 110, a seat ring 120 and a centering ring 130 are provided, and a drill bit 140 is provided at the bottom of the outer tube assembly 10;

[0055] The inner tube assembly 20 includes an inner tube assembly a 201 and an inner tube assembly b 202, the inner tube assembly b 202 is installed inside the inner tube assembly a 201 and can be axially aligned with the inner tube assembly a 201 Moving, the inner pipe assembly a 201 includes the salvage spearhead 21, the ejection mechanism 22, the matching long pipe 25, the middle pipe nipple 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com