Discharge lamp

A technology for discharge lamps and discharge vessels, which is applied in the manufacture of high-pressure discharge lamps, discharge tubes/lamps, and parts of gas discharge lamps, and can solve problems such as damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The same reference numerals are used below to designate the same or the same type of features.

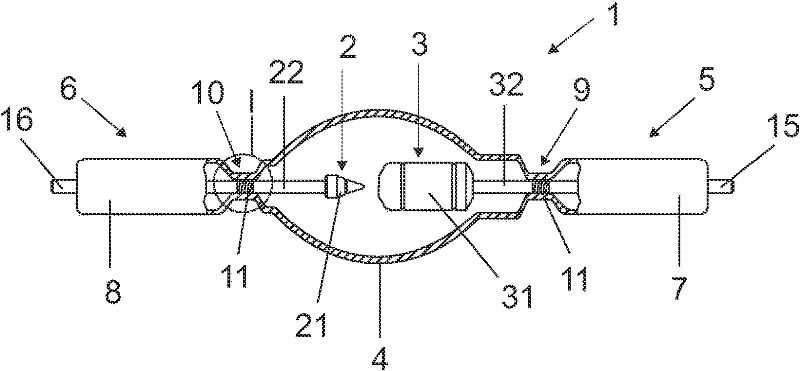

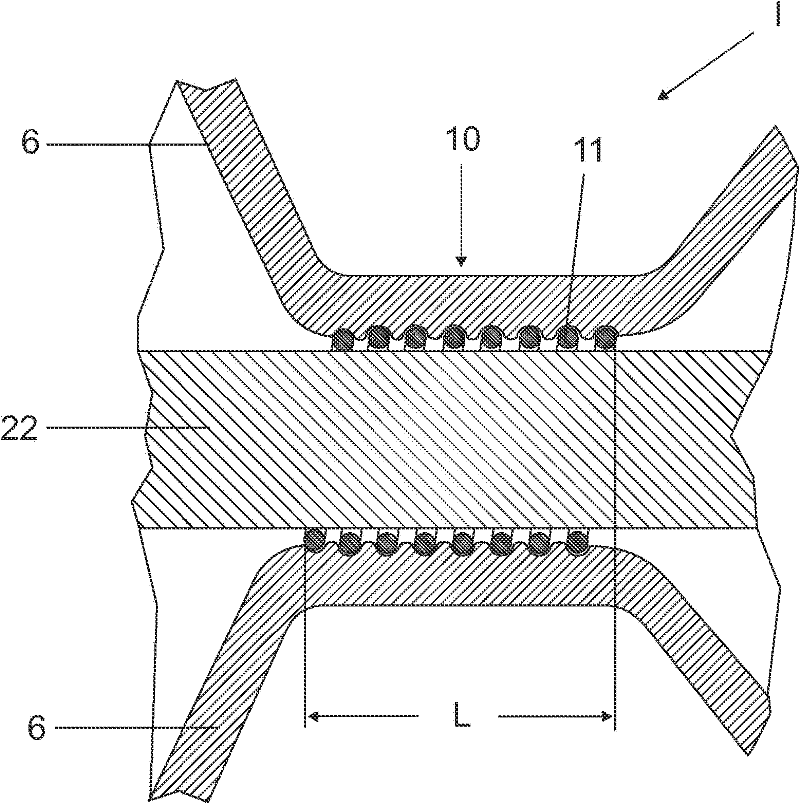

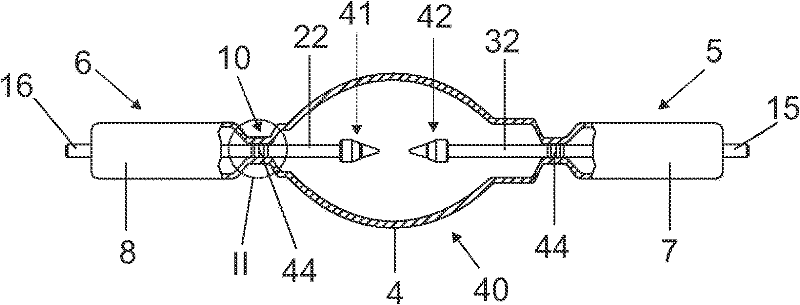

[0019] figure 1 A first embodiment of a short-arc discharge lamp 1 according to the invention is shown in the schematic diagram, which lamp is designed for projection purposes and has an output power of 4000 W. This refers to an inert gas short-arc discharge lamp filled with xenon gas. The lamp 1 is designed for DC operation and has a cathode 2 and an anode 3 for this purpose. The two electrodes 2 , 3 are arranged opposite each other at a distance of approximately 7 mm in an essentially ellipsoidal discharge vessel 4 made of quartz glass and thus define a longitudinal axis A of the lamp. Cathode 2 and cathode 3 each have an electrode tip 21 or 31 and an electrode rod 22 or 32 . The electrode head and the electrode rod are here each separate parts inserted into one another, but can also be produced from a single part. The electrode rods 22 , 32 extend into a respective su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com