A kind of in-situ thermoplastic forming lining pipe and its construction technology

A technology for thermoplastic molding and lined pipes, which is applied in the field of lined pipes, can solve problems such as lined pipe breakage, breakage, and poor pipeline conditions, and achieve the effect of avoiding stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The invention will be described in detail below in conjunction with the accompanying drawings.

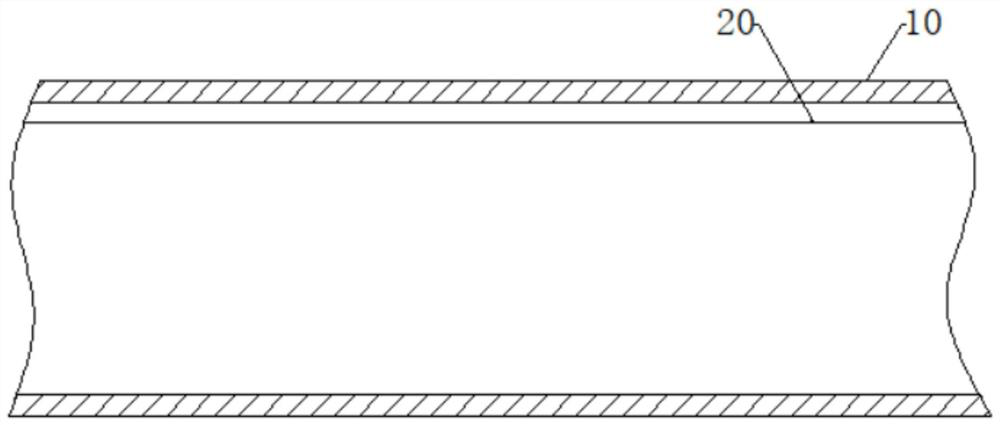

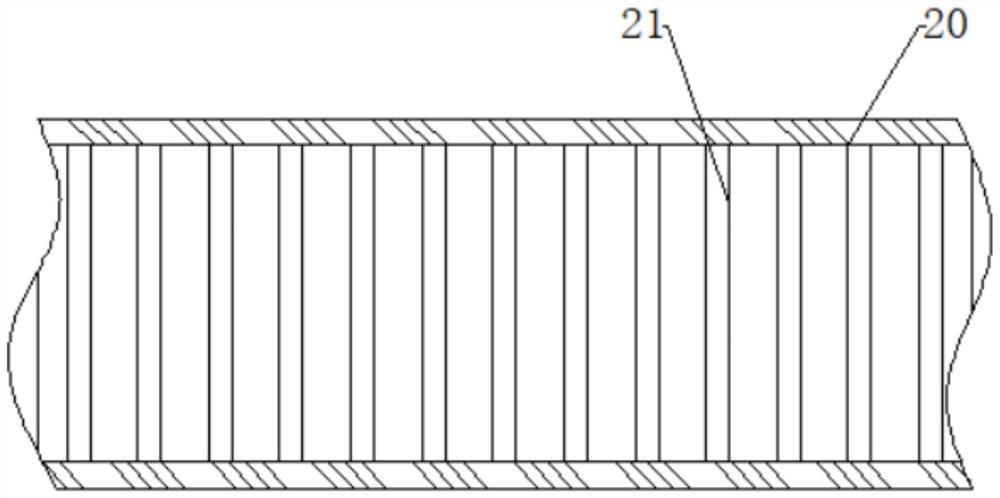

[0031] Such as Figures 1 to 6 As shown, an in-situ thermoplastically formed liner pipe includes an outer pipe, and is characterized in that the outer pipe includes a barrier layer 10 and a support layer 20;

[0032] The barrier layer 10 is located on the outside of the support layer 20 and is used for waterproofing and anticorrosion. Thermosetting PVC or thermosetting resin (unsaturated polyester (UP)) can be used. The thickness of the barrier layer 10 is relatively thin, within the range of 0.2-0.8mm. ;

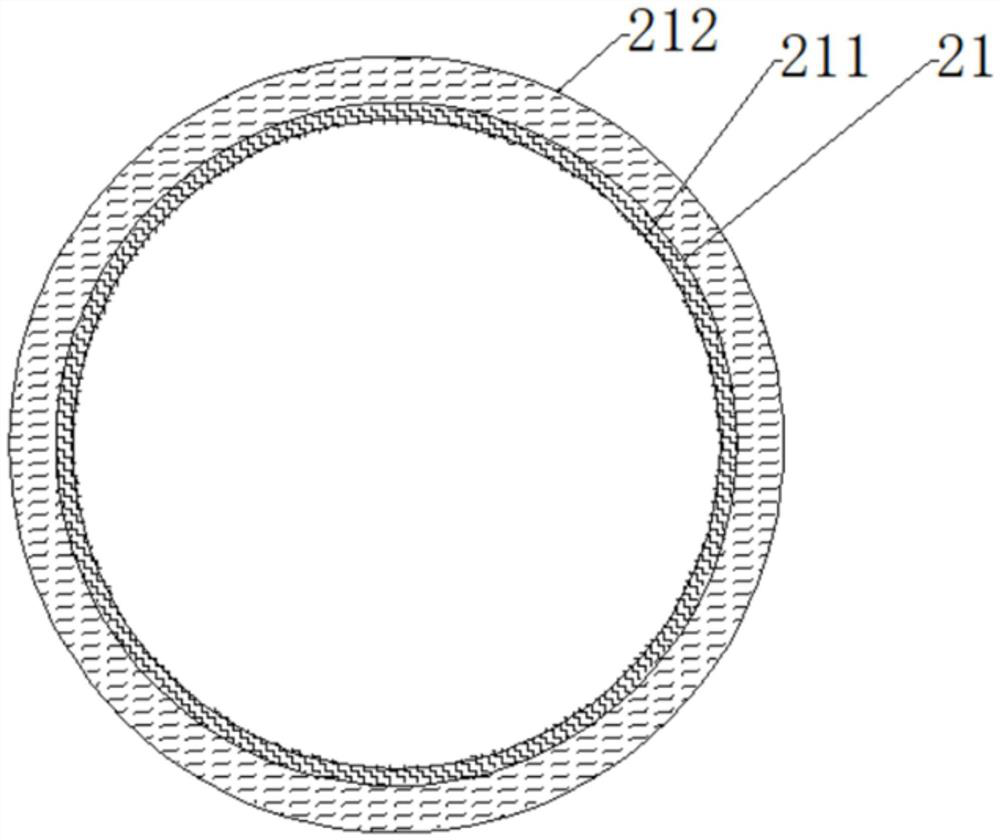

[0033] The support layer 20 includes a fiber reinforced layer, the fiber reinforced layer contains a fiber net 22 and a thermosetting resin, the fiber net 22 is located in the thermosetting resin, the thickness of the fiber reinforced layer is in the range of 3-15mm, and the mesh of the fiber net is rhombus, which The acute angle in the apex angle is in the range of 60-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com