Manufacturing method and device of optical fiber intelligent carbon fiber sensor belt

An optical fiber intelligence and a technology for making devices, which are applied in measurement devices, measurement and instruments by measuring the changing force of optical properties of materials when they are stressed, can solve the problems of lack of path planning and low accuracy of optical fiber paths, and reduce the Complexity, good extraction effect, uniform prestress effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

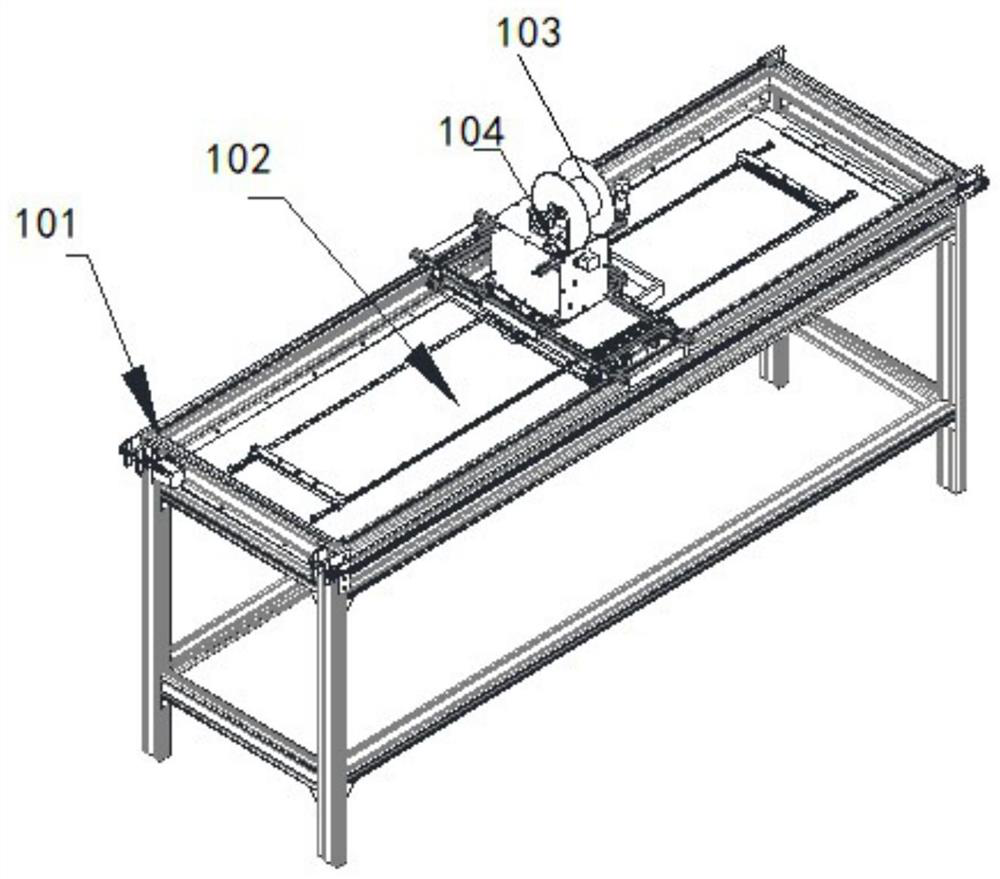

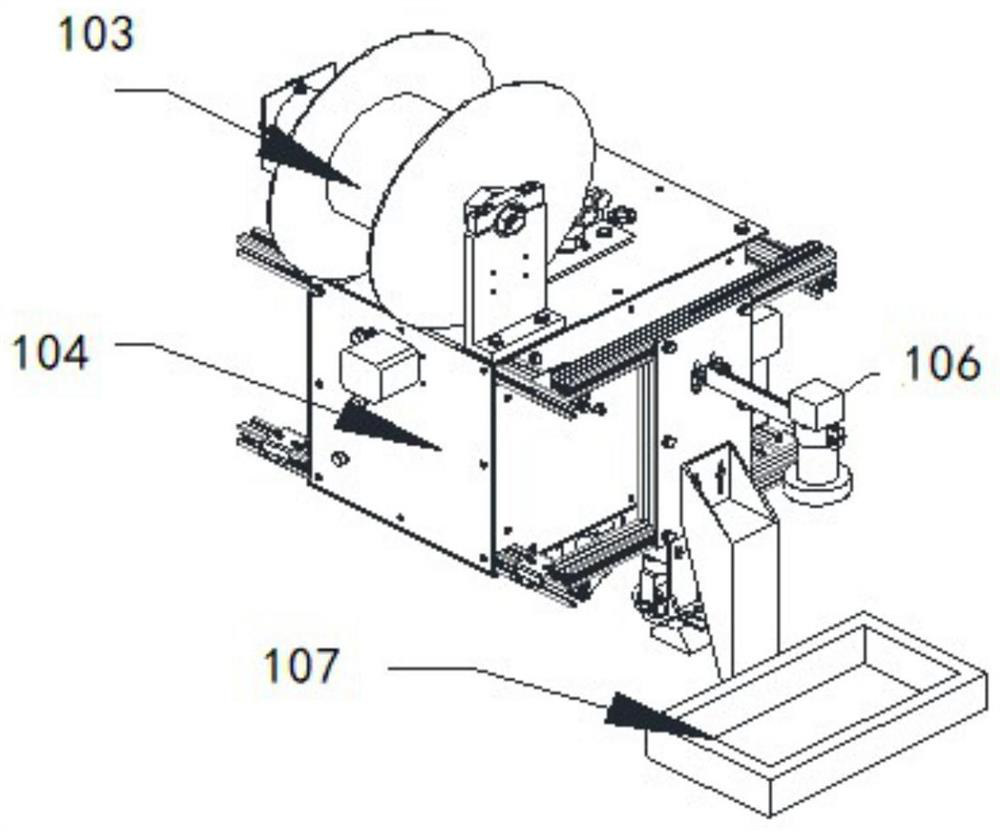

[0054] refer to Figure 1-Figure 3, the present embodiment provides a manufacturing device for an optical fiber smart carbon fiber sensor belt, including a frame 101, a workbench 102, an optical fiber drum 103, a laying head assembly 104, a servo device, an image acquisition device 106, and a processor;

[0055] The workbench 102 is fixed on the frame 101 for laying carbon fiber prepreg;

[0056] An optical fiber is wound on the optical fiber drum 103, and the servo device is used to drive the movement of the placement head assembly 104, so as to lay the optical fiber on the carbon fiber prepreg according to a preset path;

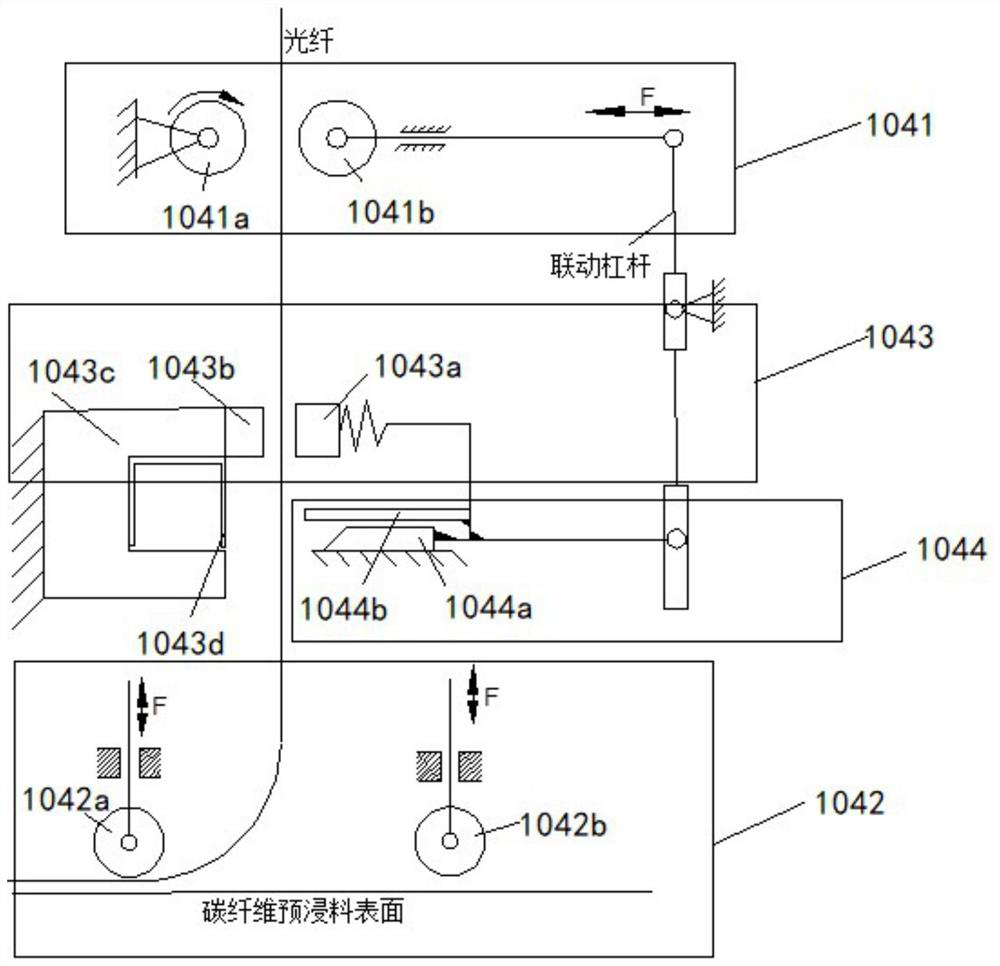

[0057] The placement head assembly includes a re-sending module 1041, a compacting module 1042, a clamping module 1043, and a shearing module 1044. The re-sending module 1041 is used to transport the optical fiber, and the compacting module 1042 is used to press the optical fiber to the carbon fiber prefab according to a preset path. On the dipping materi...

Embodiment 2

[0074] The present embodiment provides a kind of manufacture method of optical fiber smart carbon fiber sensing belt, refer to Figure 1-Figure 6 , using the manufacturing device of the optical fiber smart carbon fiber sensing belt provided in embodiment one to make, the method includes:

[0075] Step S101, fixing the carbon fiber prepreg on the workbench;

[0076] Step S102, transporting the optical fiber wound on the optical fiber drum to the carbon fiber prepreg through the re-feeding module;

[0077] Step S103, driving the laying head assembly to move along a preset path through the servo device;

[0078] Step S104, pressing the optical fiber onto the carbon fiber prepreg according to a preset path through the re-feeding module and the pressing module;

[0079] Step S105, after the optical fiber laying is completed, the clamping module clamps the optical fiber, and the cutting module cuts the optical fiber;

[0080] Step S106, the image acquisition device acquires the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com