A multi-point active loading aircraft panel prestressed shot peening tooling and shot peening method

A technology of aircraft siding and prestressing, which is applied in the field of prestressing shot peening tooling and shot peening of aircraft siding, which can solve the problems of poor prebending effect, distortion, and few prestressing force points, so as to avoid local distortion, Guarantee the effect of prestressing and uniform prestressing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

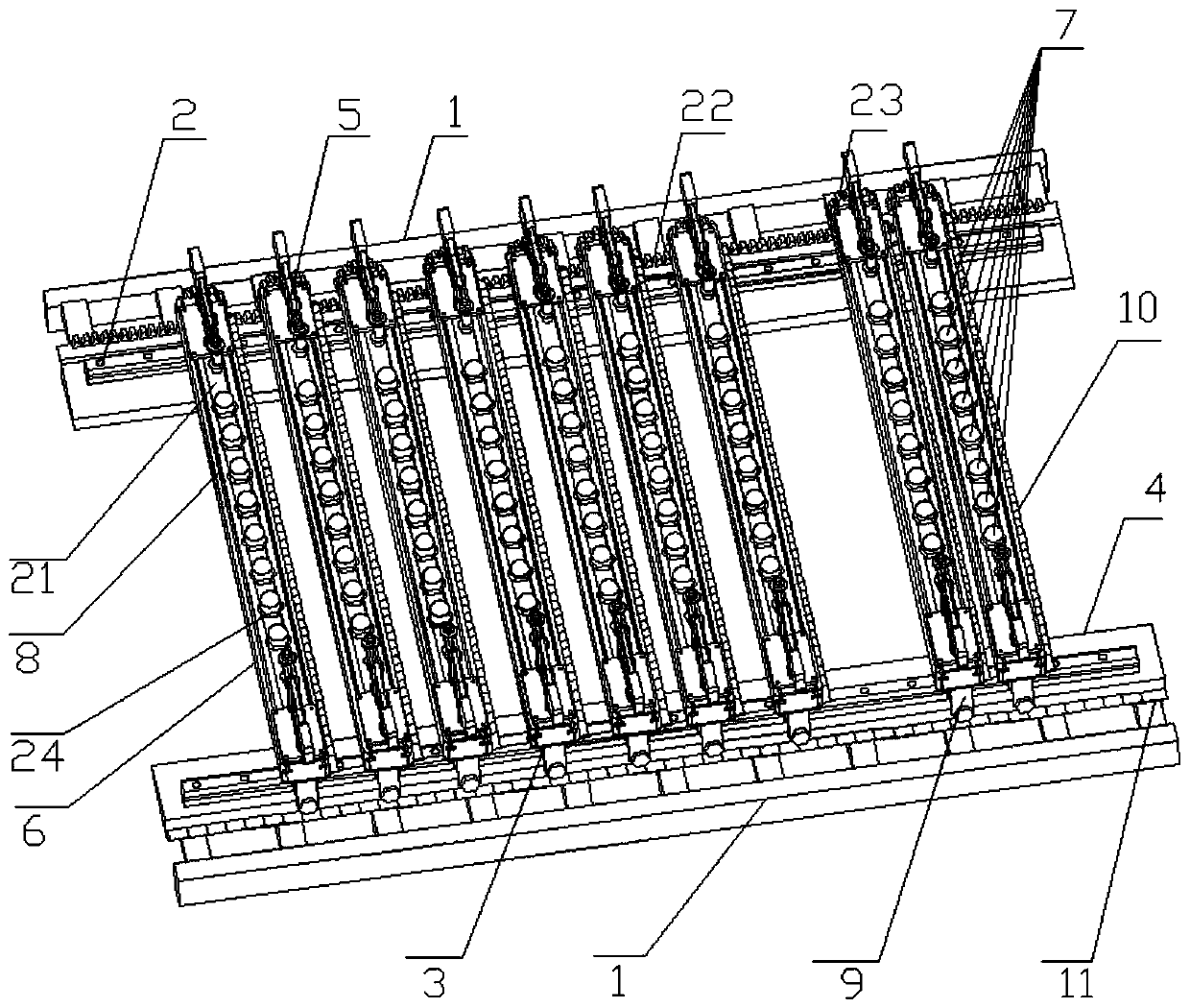

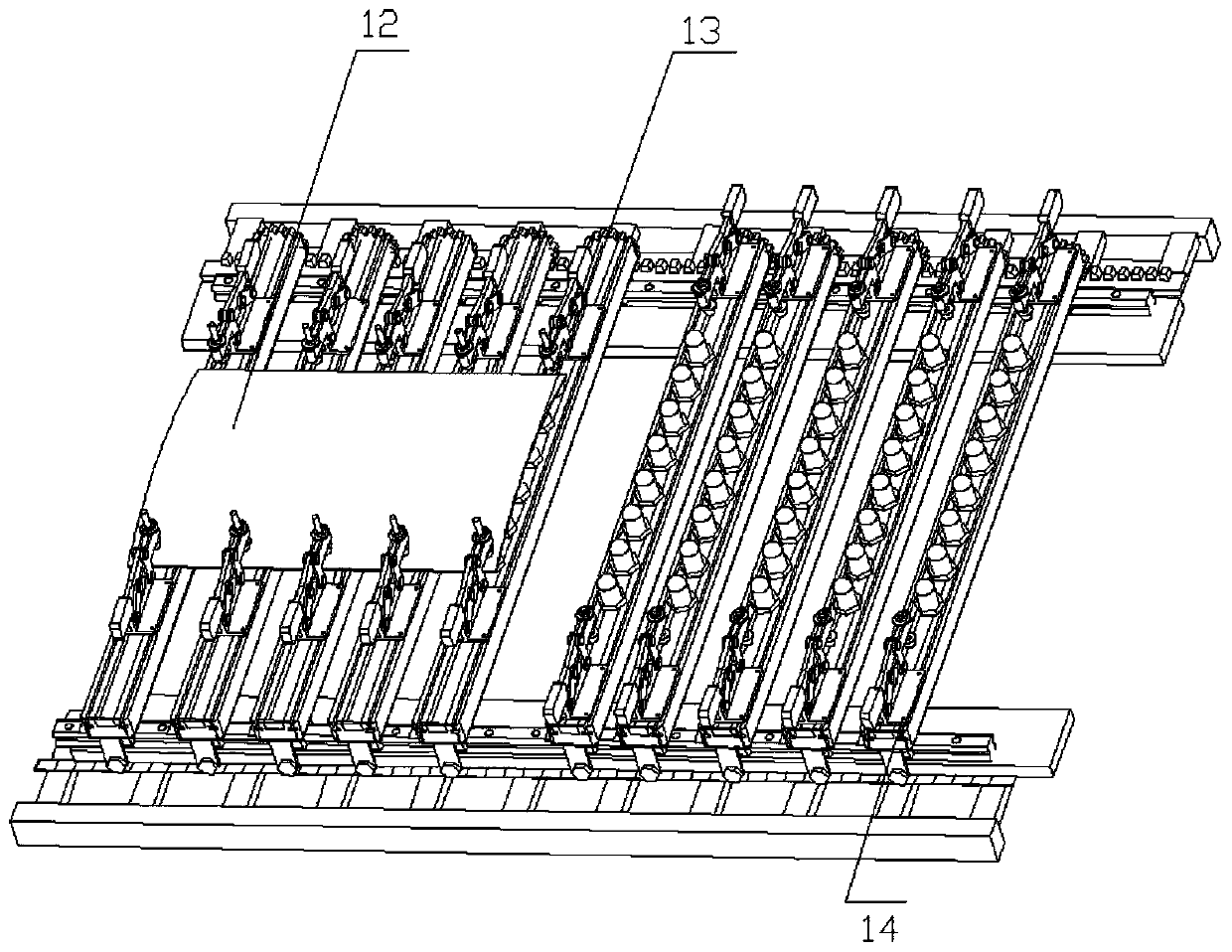

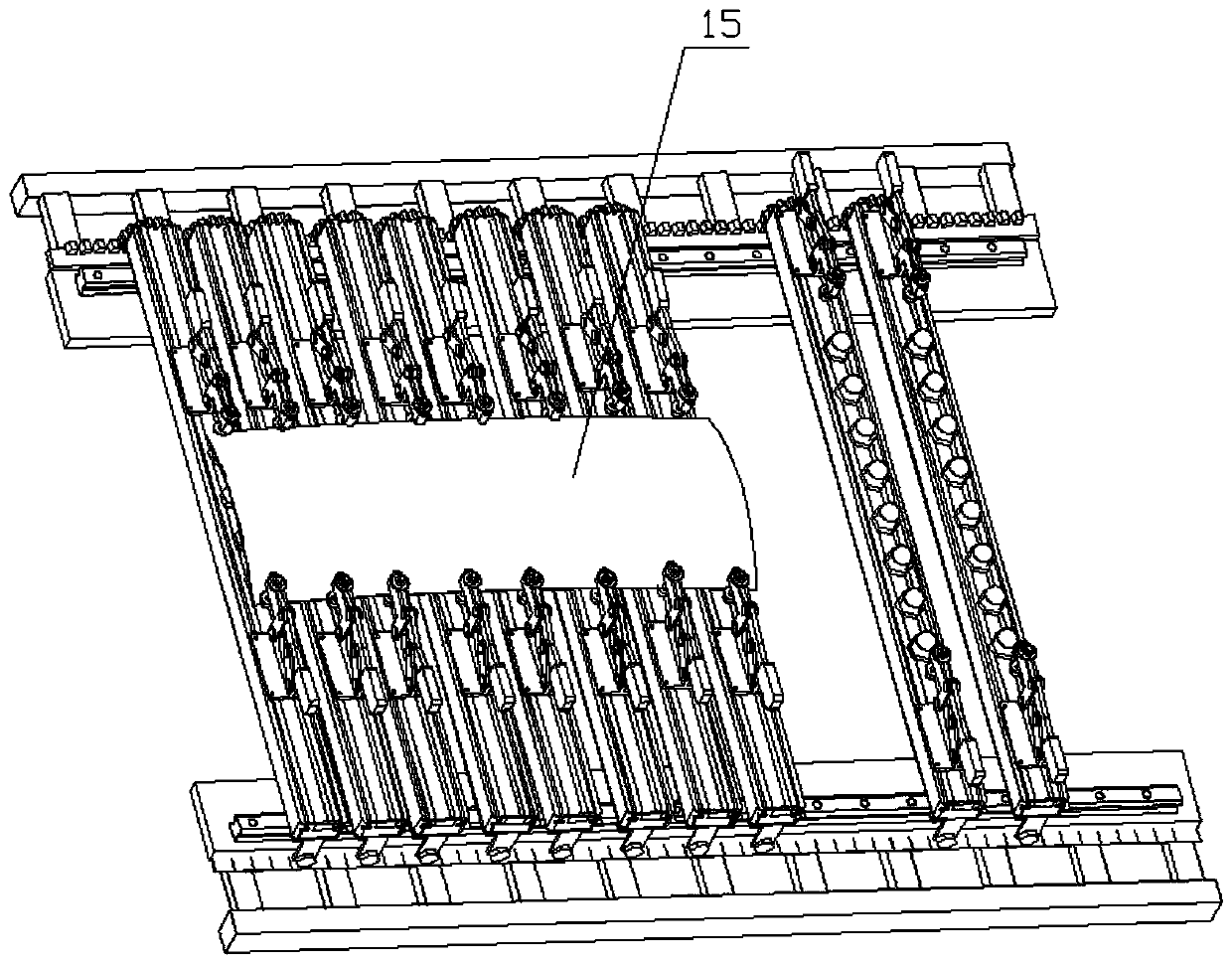

[0026] refer to figure 1 , figure 2 , image 3 , a multi-point active loading aircraft panel prestressed shot peening tooling, the tooling includes a joint slider 3, a compression clamp 5, a multi-point punch system 7, a rack and pinion transmission mechanism, two rigid frames 1, two Two guide rail bases 4, two linear guide rails 2 and multiple longitudinal beams 6; two described guide rail bases 4 are fixed on two rigid frames 1; two described guide rail bases 4 are installed with two Linear guide rail 2; the two ends of multiple longitudinal beams 6 are respectively connected with the joint slider 3, and one end is equipped with a locking mechanism 9, and the other end is equipped with a rack and pinion transmission mechanism; the joint slider 3 Slidingly matched with the linear guide rail 2, the joint slider 3 can drive the longitudinal beam 6 to reciprocate on the linear guide rail 2. The purpose of the movement is to adjust the position of the longitudinal beam 6 accor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com