Secondary tubular pile tensioning process by prestress and special tensioner

A technology for prestressed pipe piles and tensioning devices, applied in the direction of strengthening and forming, can solve the problems of uneven prestressing of main bars, difficult actual prestressing, high labor intensity, etc., and achieve low manufacturing costs, improve production efficiency, and safety. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

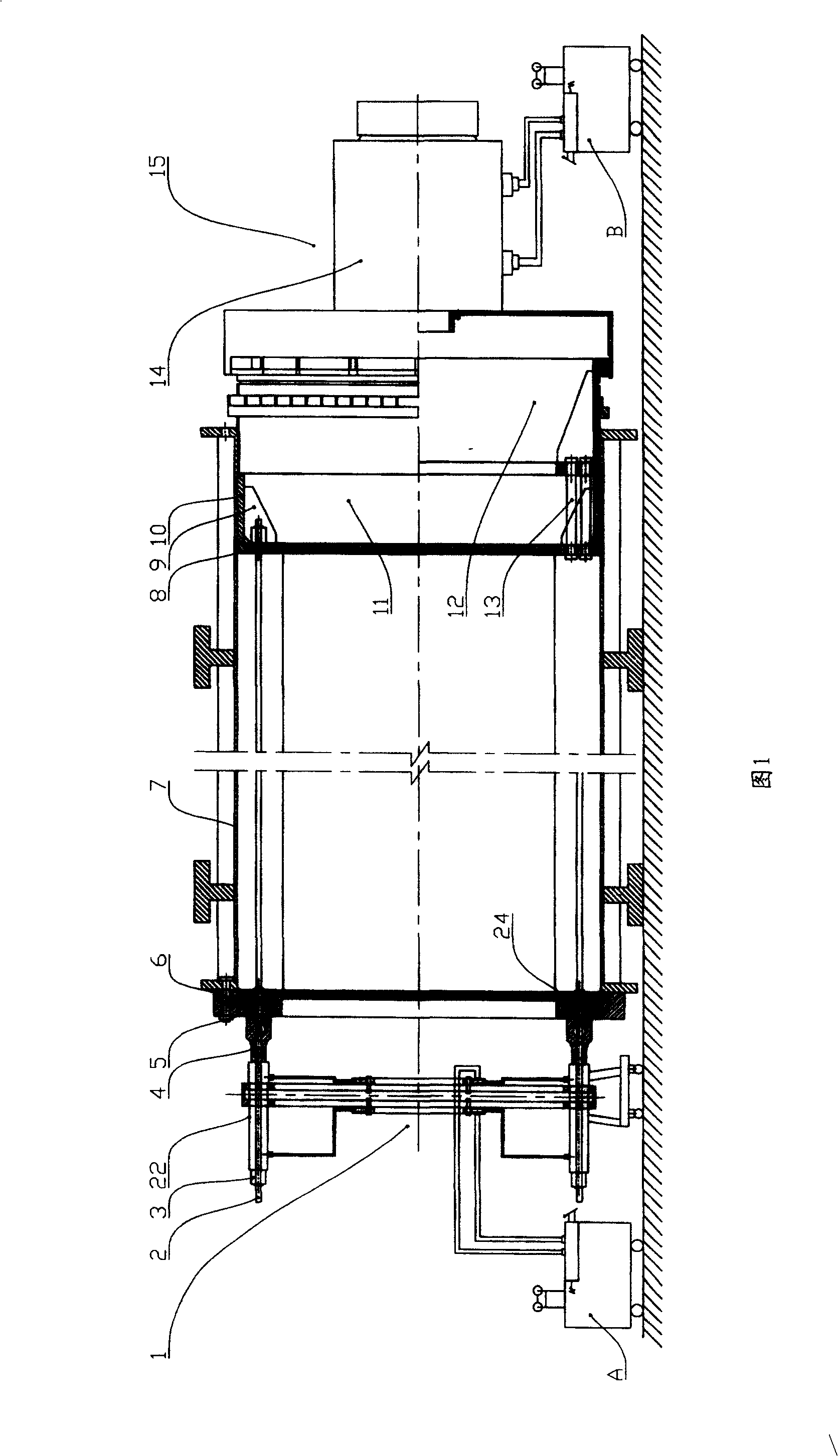

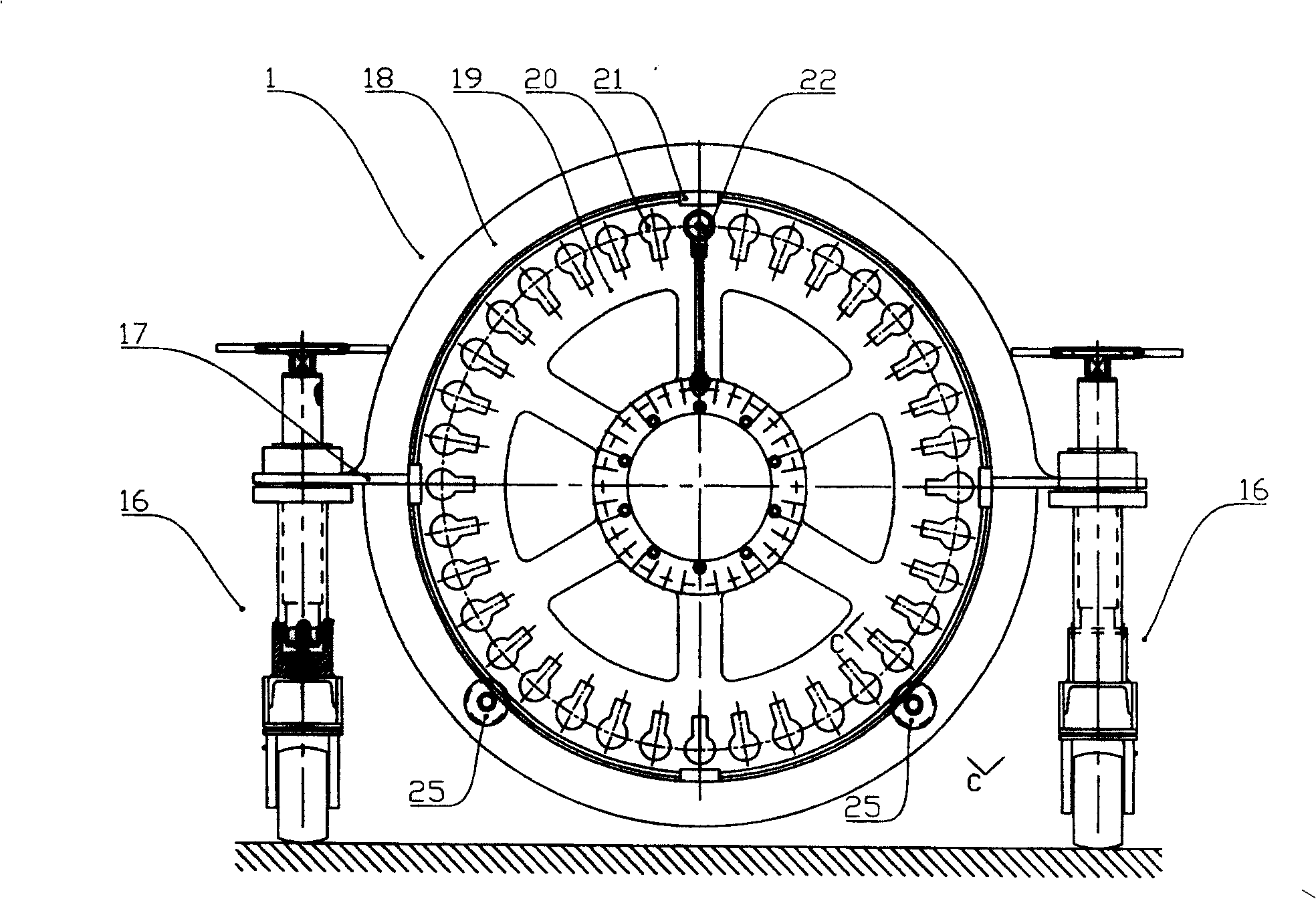

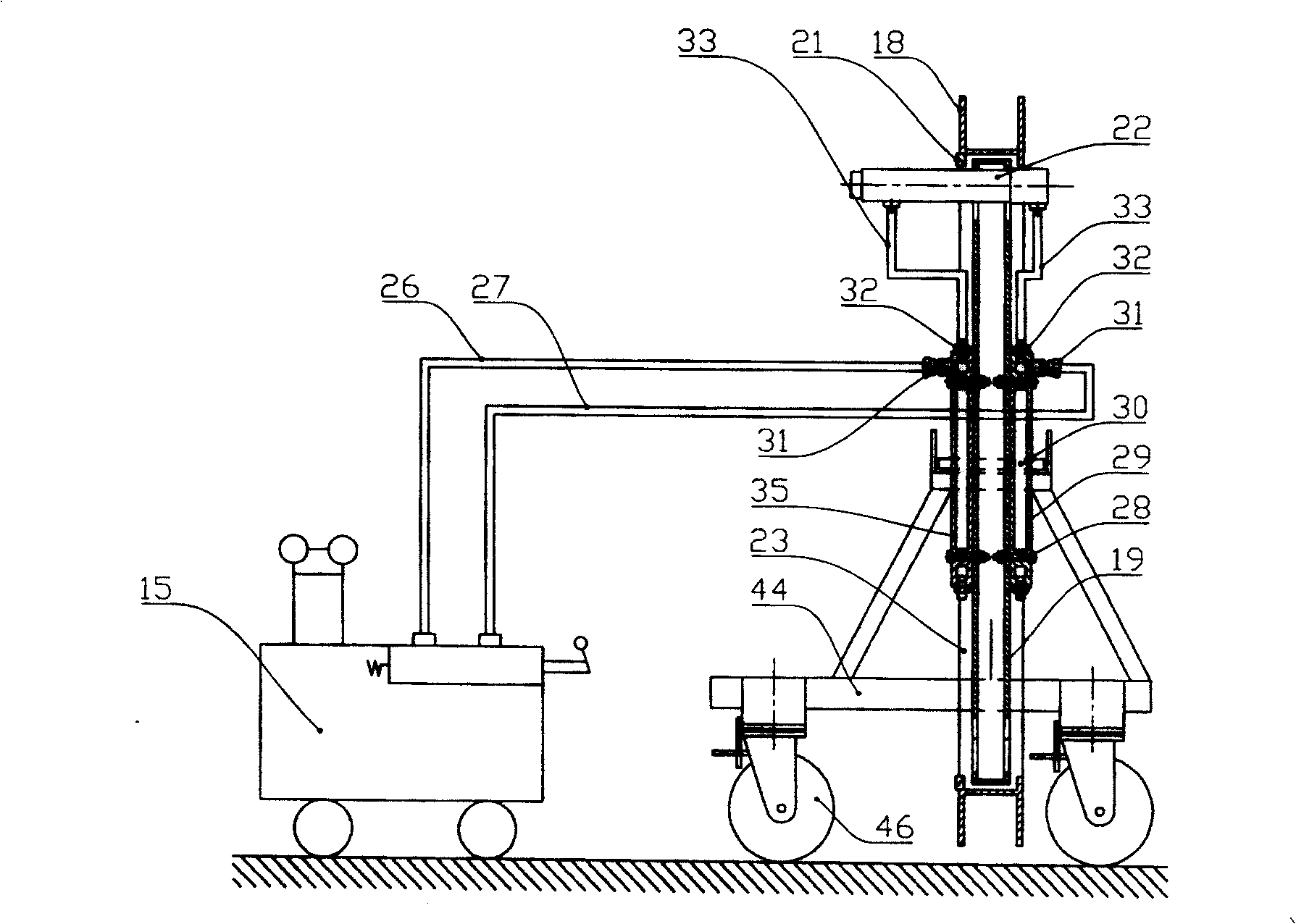

[0021] As shown in Figure 1, when the special tensioning device of the present invention secondly tensions the PHC pile main reinforcement 2, an integral tensioning machine 15 and a hydraulic device B are set at one end of the steel mold 7, and the integral tensioning machine 15 and the jack 14 are tensioned. Pull ring 12 is connected pipe pile end plate 11, and described end plate 11 comprises bottom plate 8 and end 10, and evenly distributes a plurality of stiffening plates 9 between described bottom plate 8 and end head 10 inner walls, and described bottom plate 8 and main bar 2 are formed by Anchors anchor. The tension ring 12 is connected to the bottom plate 8 by bolts 13 . A pre-tensioning machine 1 is established at the other end of the steel mold 7 . The end of the steel mold 7 is fixed with a support plate 5 by bolts 6, and all the main bars 2 of the steel cage pass through the support plate 5 through the stretching holes 24 provided at the corresponding positions of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com