Side plate structure of novel drawer slide rail

A side panel and drawer technology, which is applied to drawers, furniture parts, household appliances, etc., can solve the problems of scrapping the overall structure of the side panel, complex shell structure, structural damage, etc., to save material costs, reduce overall weight, and improve service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

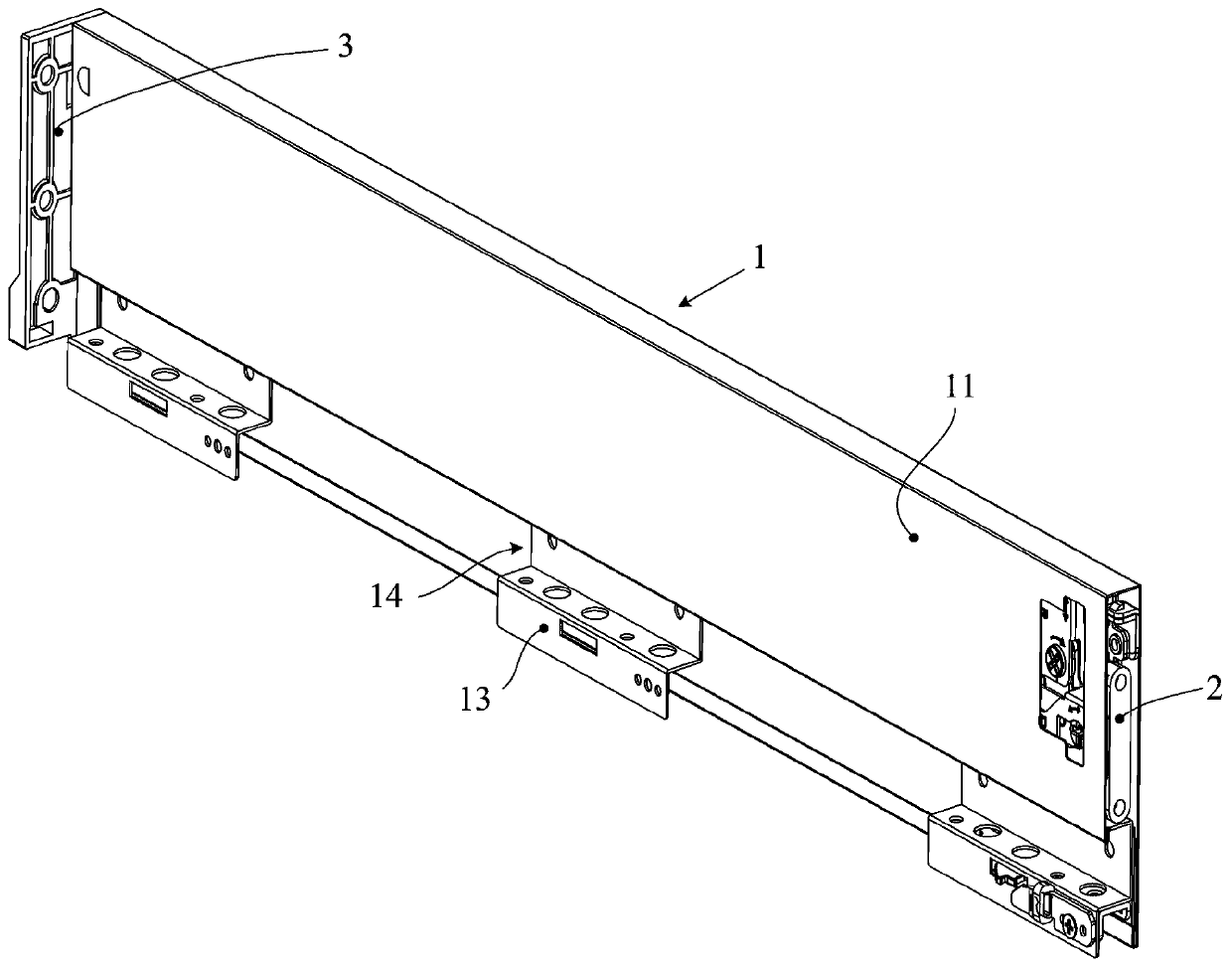

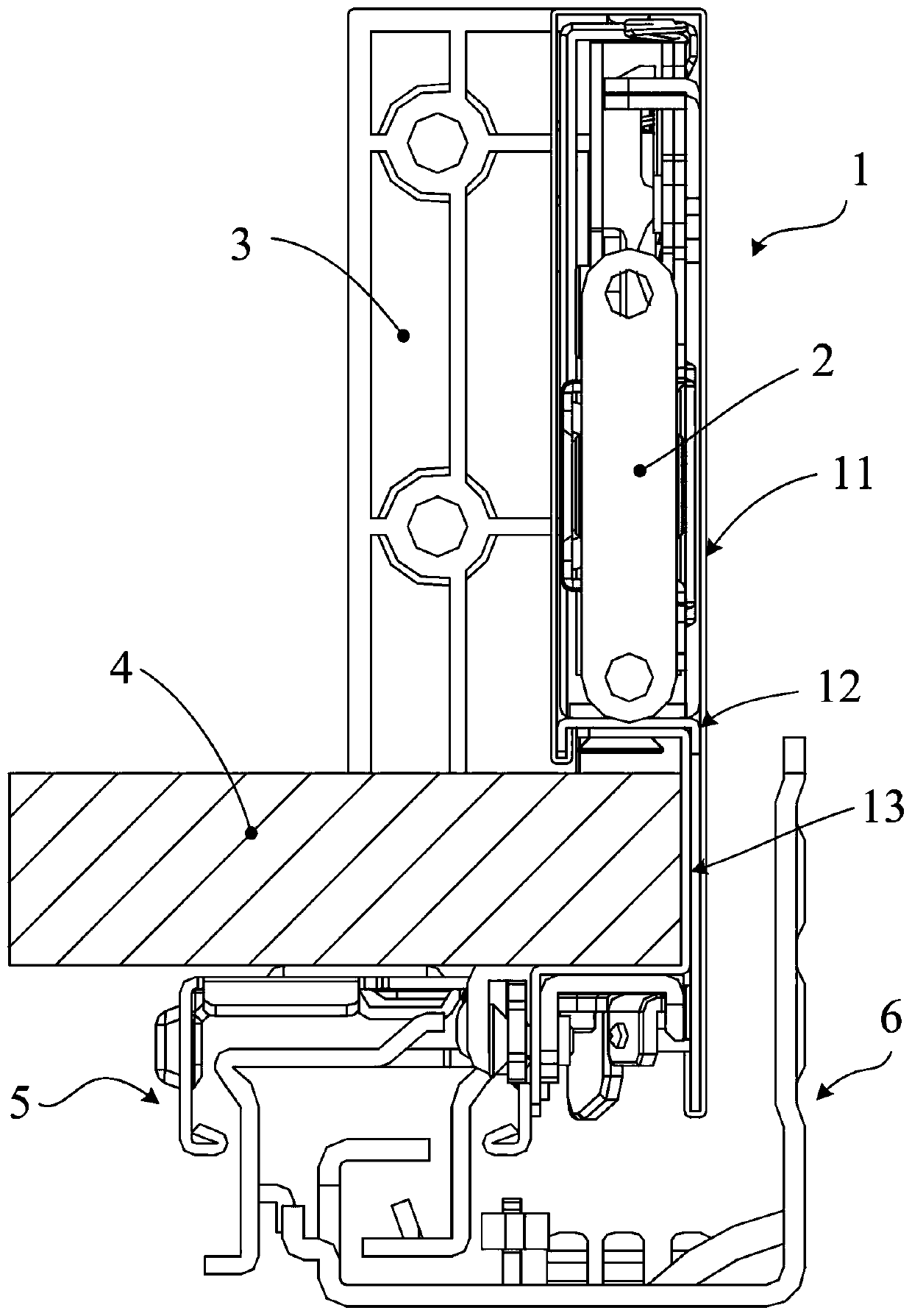

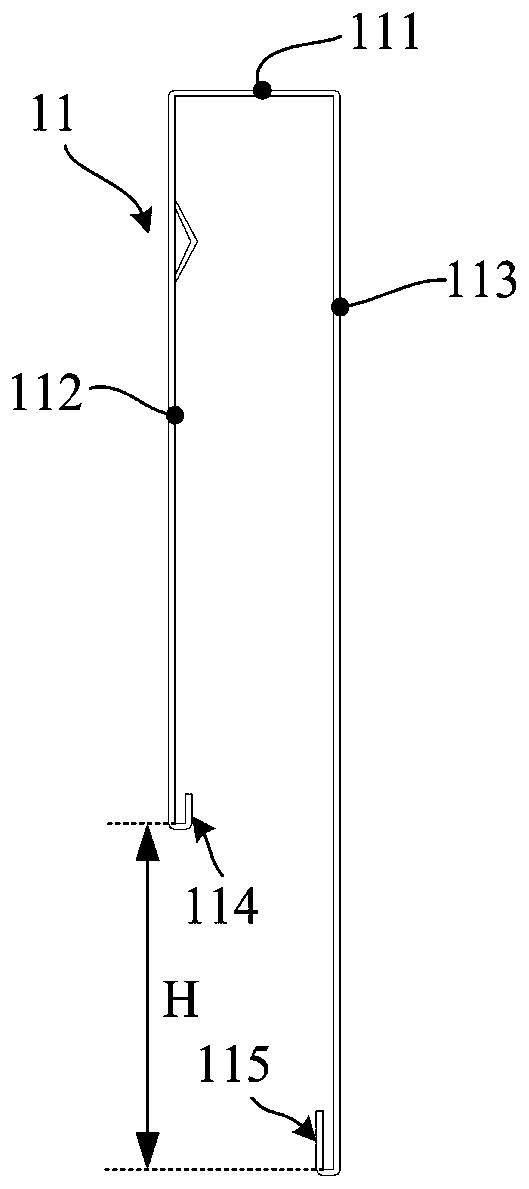

[0034] See Figure 1 to Figure 6 The side plate structure of the novel drawer slide rail of the embodiment of the present invention includes a side plate 1 arranged along the drawer pulling direction, the front part of the side plate 1 is provided with a front connecting piece 2 connected with the front panel, and the rear part of the side plate is provided with a rear The connector 3 is connected to the back panel, and the side panel 1 of this embodiment is composed of a side panel shell 11, an upper side panel frame 12 and a lower side panel frame 13, and the lower part of the side panel shell 11 is at least provided with an inward bending portion and an upper side panel. The bending part of the plate frame 12 is connected by plugging. The lower side plate frame 13 is provided with at least one horizontal part and the upper side frame 12 to form the installation groove 14 for installing the drawer bottom plate 4. The lower side plate frame 13 and the movable slide rail of the...

Embodiment 2

[0041] See Figure 7 , The present embodiment has the following distinguishing technical features from Embodiment 1: elastic members 125 are provided on the concave bottom surface of the first inner curved portion 114 and the concave bottom surface of the second inner curved portion 115. Preferably, the elastic member 125 of this embodiment can be a wedge-shaped block, and the ends of the first vertical support portion 122 and the second vertical support portion 123 are provided with an inclined portion 124 to cooperate with the wedge-shaped block, and the inclined portion and the wedge-shaped The elastic parts of the block are misplaced and matched with each other, so that the mutual cooperation between the vertical support part and the inner bending part is not easy to loosen, and the elastic part is set, and the elastic deformation of the elastic part can compensate the side plate shell and the upper side plate frame. Due to manufacturing errors, when the two are matched, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com