Electric main shaft supported by hydrostatic integrated gas bearing

A gas bearing, dynamic and static pressure technology, applied in the direction of large fixed members, metal processing machinery parts, maintenance and safety accessories, etc., can solve the problems of complex structure of electric spindle, continuous gas supply, etc., and achieve low friction and gas-saving supply , Strengthen the effect of supporting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

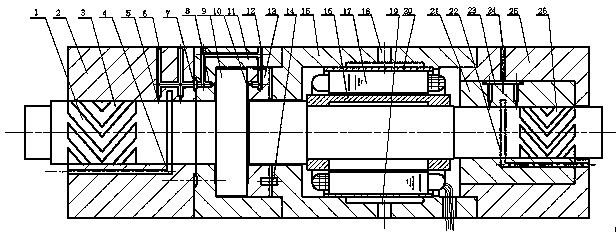

[0020] see figure 1 , the electric spindle supported by the gas bearing integrated with dynamic and static pressure includes rotating shaft 1, front radial dynamic and static pressure integrated gas bearing 2, front thrust gas bearing 11, front air hole 12, front exhaust hole 4, thrust plate 9, rear Thrust gas bearing 13, fastening bolt 14, housing 15, motor rotor 16, motor stator 17, water inlet 18, water outlet 19, cooling water tank 20, rear radial dynamic and static pressure integrated gas bearing 21, sealing ring 23, rear inlet Air hole 24, rear exhaust hole 22, rear end cover 25. It is characterized in that: the motor rotor 16 of the electric spindle is nested on the rotating shaft 1 and rotates together with the rotating shaft 1; the motor stator 17 is fastened and nested on the housing 15; the front and rear ends of the rotating shaft 1 are separated by the front The radial dynamic and static pressure integrated gas bearing 2 and the rear radial dynamic and static pre...

Embodiment 2

[0022] see figure 2 , 3 , 4, 5, the present embodiment is basically the same as Embodiment 1, and the special features are as follows:

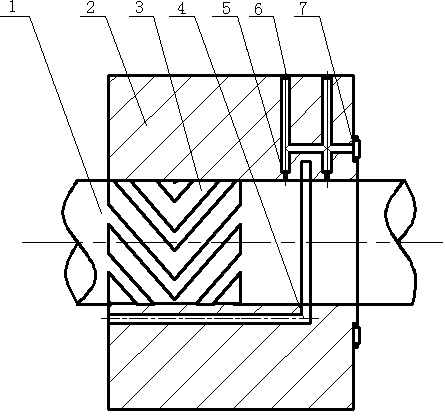

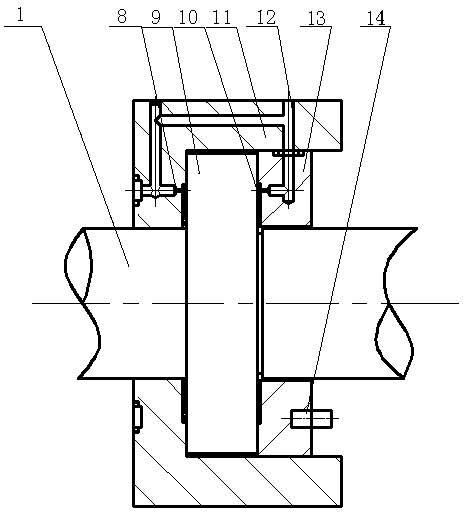

[0023] The electric spindle supported by the dynamic and static pressure integrated gas bearing is characterized in that: the front thrust gas bearing 11 and the rear radial dynamic and static pressure integrated gas bearing 21 are respectively processed with air intake holes 12 and 24 to assist the formation of the gas bearing The air film will float the rotating shaft; the part of the rotating shaft 1 that cooperates with the front radial dynamic and static pressure integrated gas bearing 2 and the rear radial dynamic and static pressure integrated gas bearing 21 is processed with spiral grooves 3 and 26 to strengthen the dynamic pressure bearing. The dynamic pressure effect can make the dynamic pressure effect more significant under high-speed working conditions; the front radial dynamic and static pressure integrated gas bearing 2 and t...

Embodiment 3

[0025] see figure 1 , the second embodiment is basically the same, and the special features are as follows:

[0026] The front radial dynamic and static pressure integrated gas bearing 2 is equipped with a plug 6 at the outer end of the processing gas path to prevent air leakage and affect the formation of the gas film; the front air inlet 12 and the rear air inlet 24 are respectively connected to the front and rear radial dynamic Sealing rings 7, 23 are installed at the joints of the pressure-integrated gas bearings 2, 21 to ensure the smoothness and stability of the whole gas circulation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com