Method for extracting rim angle coal and re-extracting after warehouse coal extracting

A technology for edge coal and warehouse, which is applied in ground mining, mining equipment, earthwork drilling, etc., can solve the problems of waste of resources, low work efficiency, and many people, so as to improve the degree of mechanization, improve the recovery rate of resources, and save coal resources. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

[0029] A method for re-mining and scrap coal recovery after coal mining in warehouses, comprising the following processes:

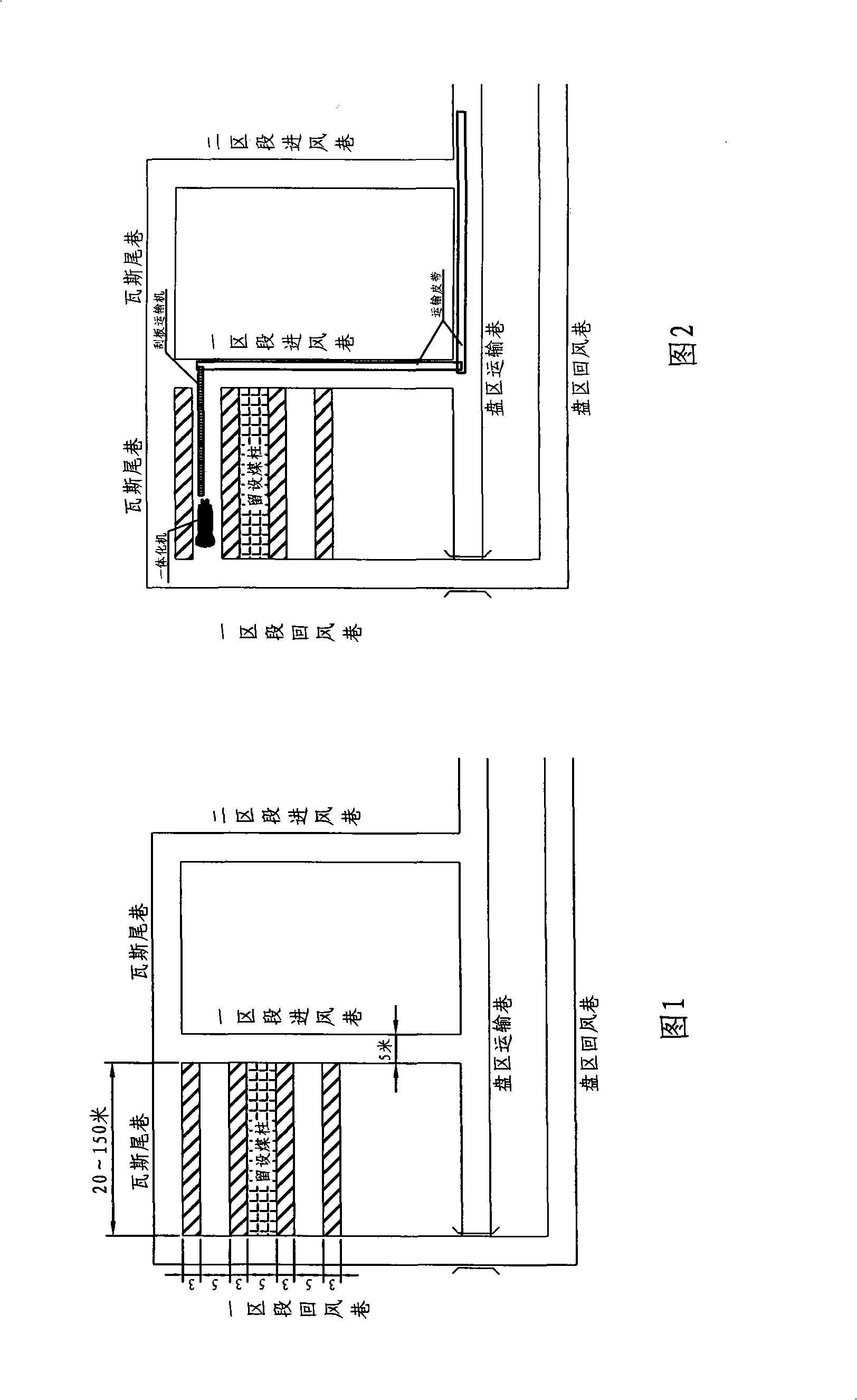

[0030] 1. Roadway layout: Divide several sections in the panel area, and arrange two preparation roadways in the section, one of which is used as the air inlet lane and the other as the return air lane. After mining in the previous section, the air inlet lane in the upper section can be used as the air return lane in the next section. Only one air return lane will be excavated in the next section. In the middle of the two preparation roadways, strip-shaped house pillars are arranged, as shown in Figure 1, which is a schematic diagram of roadway layout of the present invention; The column width is 5+4=9m, and 5m coal column is reserved to ensure that the mining of the next room column is carried out under a smaller roof press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com