Ink drying device applied to newspapers

A drying device and ink technology, applied in the general parts of printing machinery, printing, printing machines, etc., can solve the problems of increased time cost, poor control of the degree of ink moisture removal, etc., to increase the uniformity and improve the uniformity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

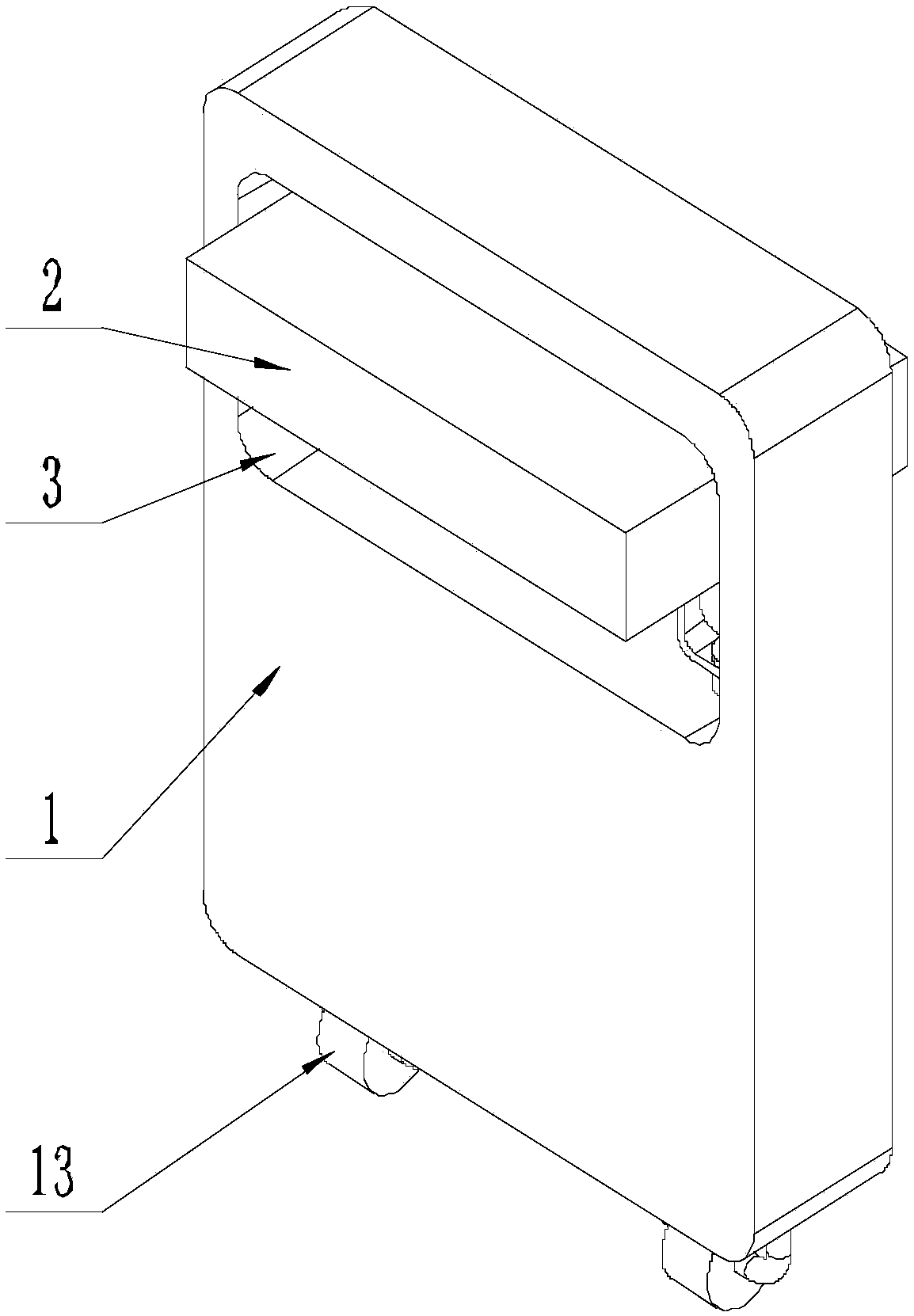

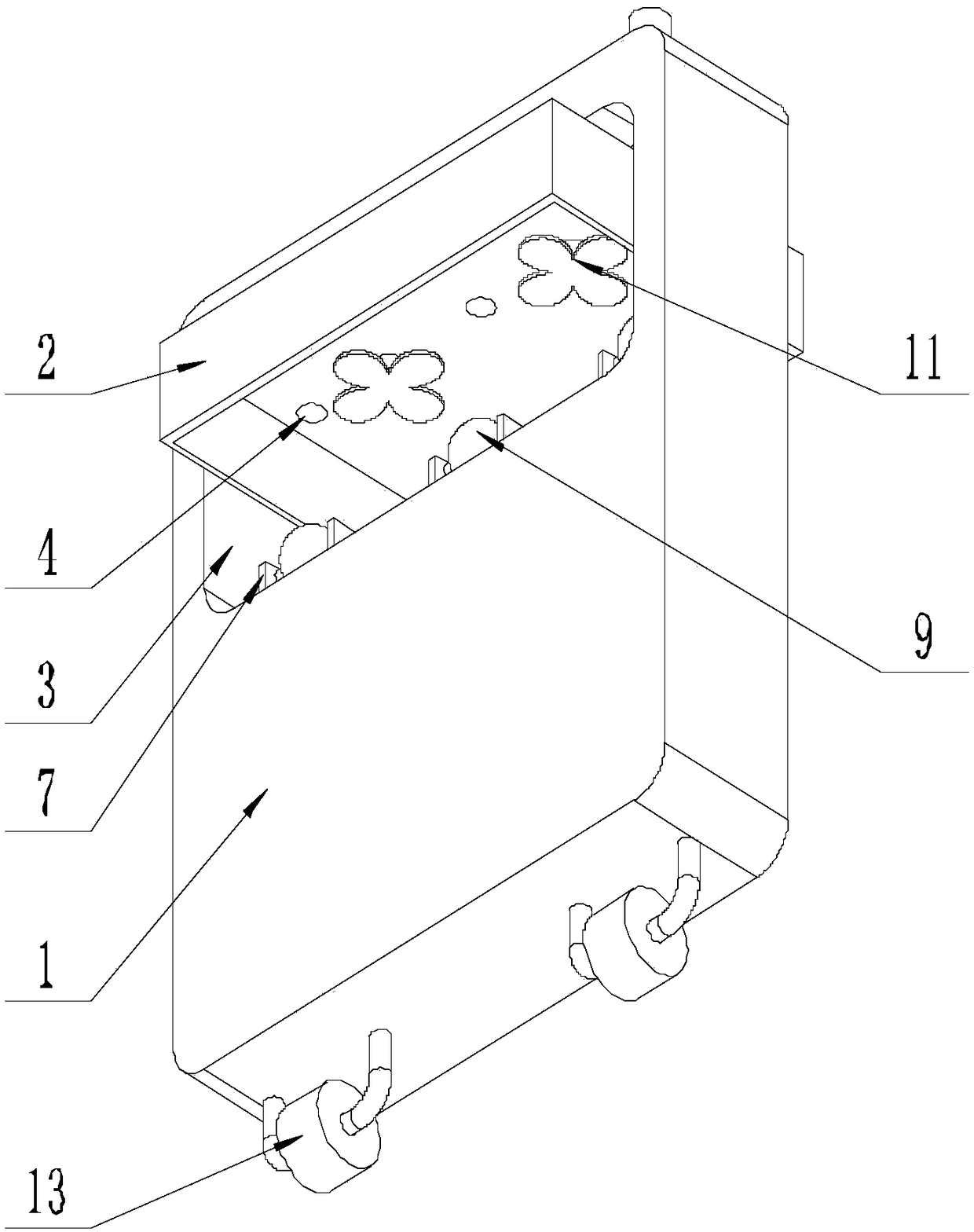

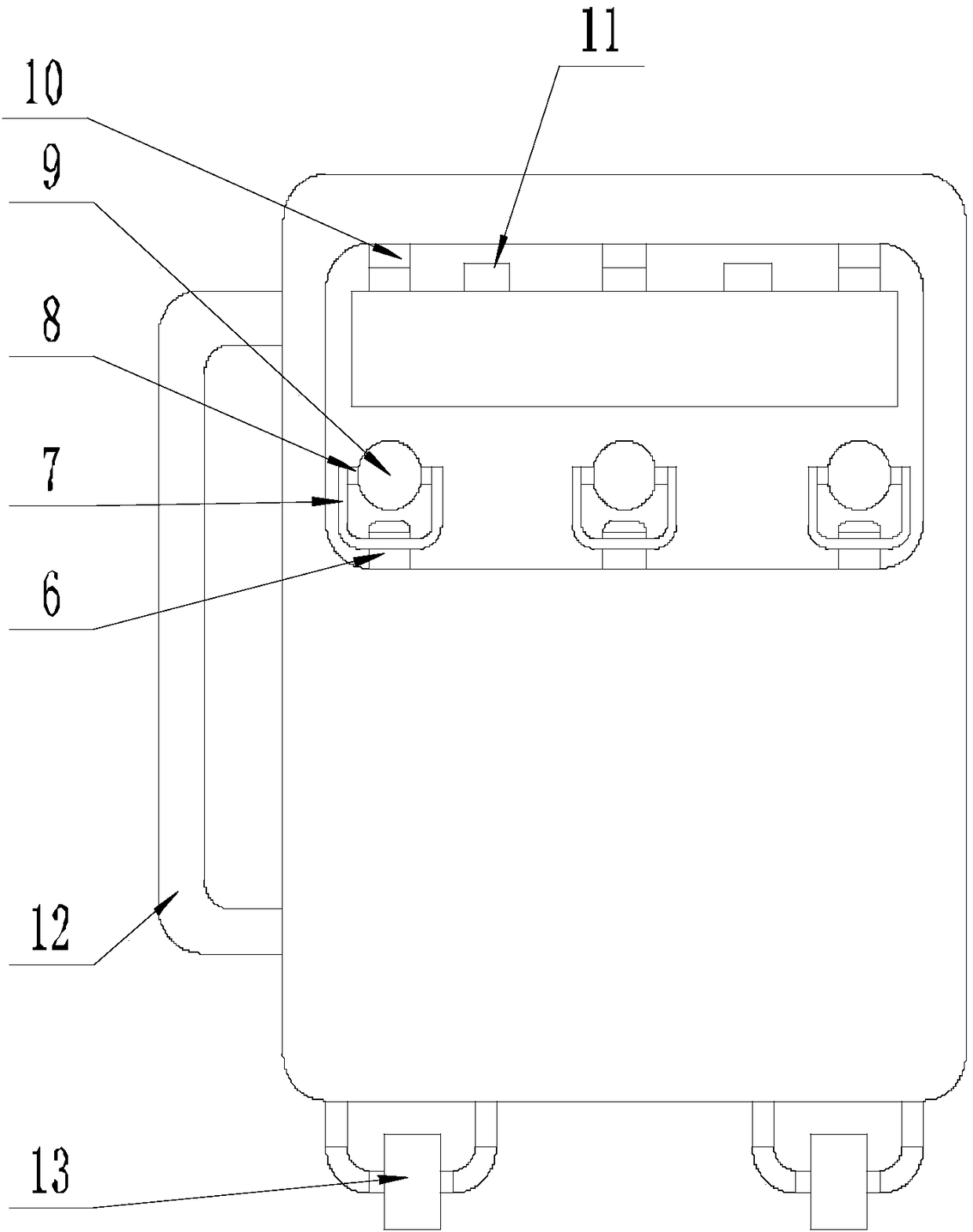

[0039] Such as Figure 1-Figure 4 As shown, the present invention is applied to an ink drying device for newspapers, including a support block 1, a support cover 2 and several elastic guides, and a strip hole 3 is provided on the side wall of the support block 1, and the strip hole 3 is Through hole, the plane where the long side is located in the cross section is parallel to the ground, on the hole wall of the strip hole 3, one end near the ground is provided with several mounting holes, the axes of the mounting holes are perpendicular to the ground, and the mounting holes are respectively Cooperate with a guide piece each;

[0040] The guide includes an elastic rubber strip 5, a moving shaft 6, a connecting arm 7, a supporting shaft 8 and a ball 9 connected in sequence, the ball 9 is sleeved on the supporting shaft 8, and the two ends of the supporting shaft 8 are respectively Connect with one end of the moving shaft 6 through a connecting arm 7, the other end of the moving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com