Motor package aluminum rotor structure

A technology of rotor structure and aluminum cladding, applied in the direction of magnetic circuit shape/style/structure, mechanical equipment, machine/engine, etc., can solve problems such as centrifugal inertia force can not offset each other, accelerate bearing wear, shorten mechanical life, etc., to achieve saving The time to adjust the direction of the fan blades, ensure the dynamic balance, and reduce the overall vibration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

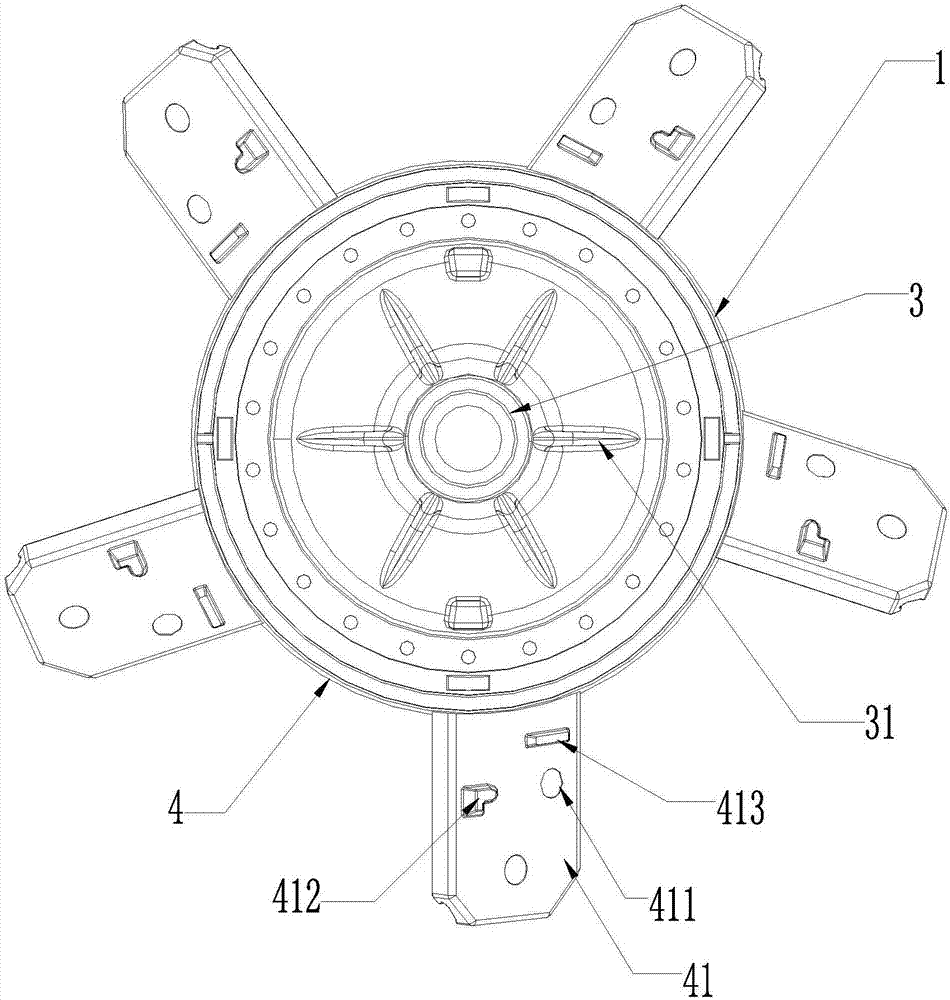

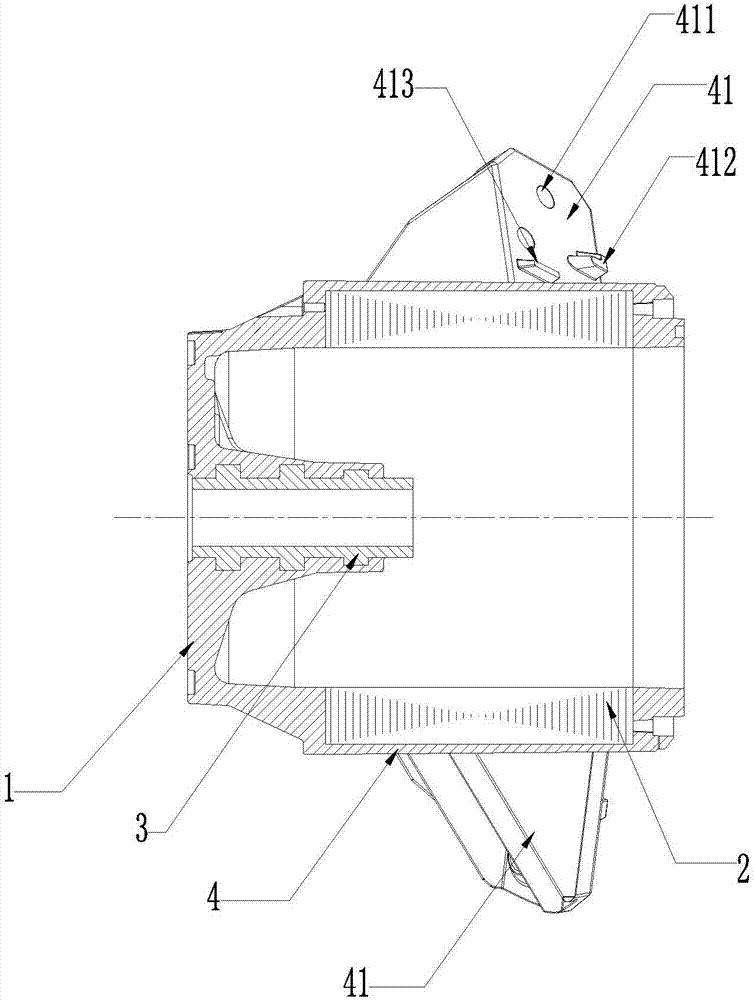

[0029] Such as Figure 1-5 As shown, in order to achieve the above purpose, the technical solution adopted by the present invention is as follows: The present invention discloses an aluminum-clad rotor structure for a motor, including a rotor body 1 and a flange structure 41, and the flange structure 41 is evenly and symmetrically arranged on the rotor body On the side wall of the outer circle 4 of 1, the flange structure 41 is used to disassemble and fix the fan blade 5, and the rotor body 1 and the flange structure 41 are integrally formed by a die-casting process. The rotor structure is produced through an integrated die-casting molding process. The rotor structure is an integral structure, which minimizes the beating problem caused by the interference fit of the steel ring to the outer circle of the rotor body, and at the same time solves the air hole problem on the surface of the rotor structure.

[0030] Such as figure 1 with 6 As shown, in the first embodiment of the ...

no. 2 example

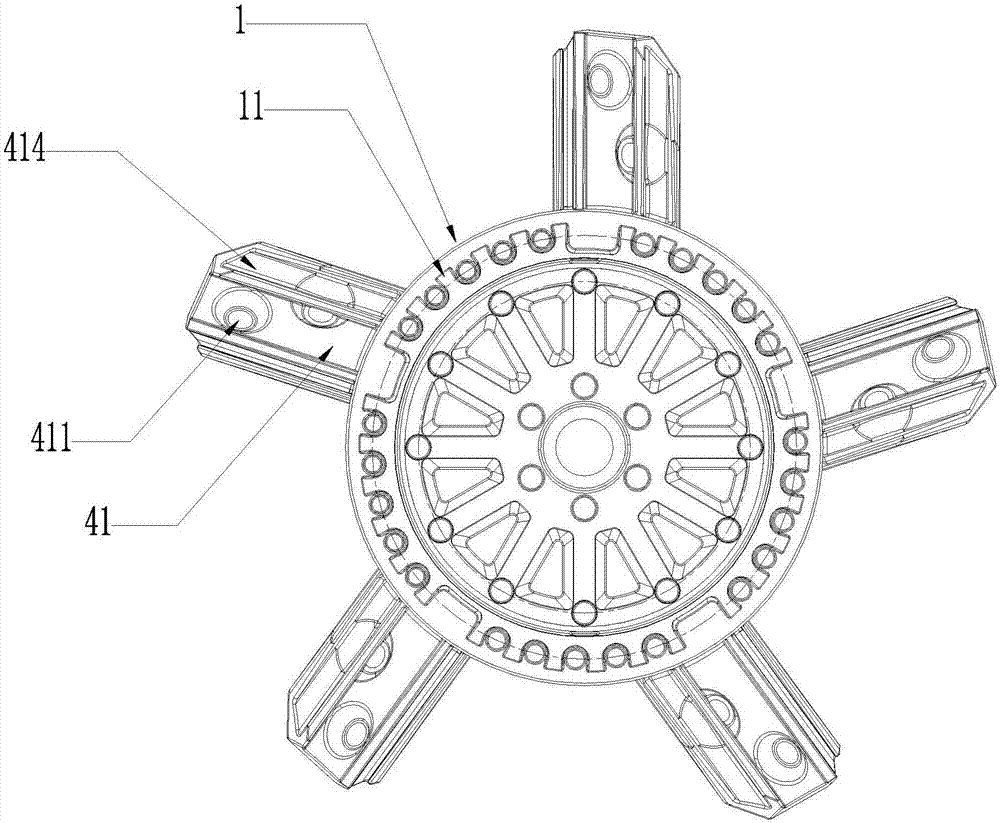

[0036]This embodiment only describes the difference from the above embodiment, and other technical features are the same as the above embodiment. In the second embodiment of the present invention, the mounting area on the front of the flange structure 41 is provided with several positioning holes and threaded holes 411 for positioning and fixing the fan blade 5 . Several positioning protrusions and threaded through holes 511 are provided on the mounting surface 51 of the fan blade 5 mounted on the rotor structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com