Circuit board bearing device and circuit board fixing method

A technology of a bearing device and a fixing method, which is applied in the direction of assembling printed circuits, electrical components, and electrical components with electrical components, can solve the placement error of solder paste printed graphic devices, poor connection between electronic components and circuit boards, and electronic components. Device damage, falling off and other problems, to achieve the effect of large contact surface, excellent placement effect, and warpage prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The implementation of the technical solution will be further described in detail below in conjunction with the accompanying drawings.

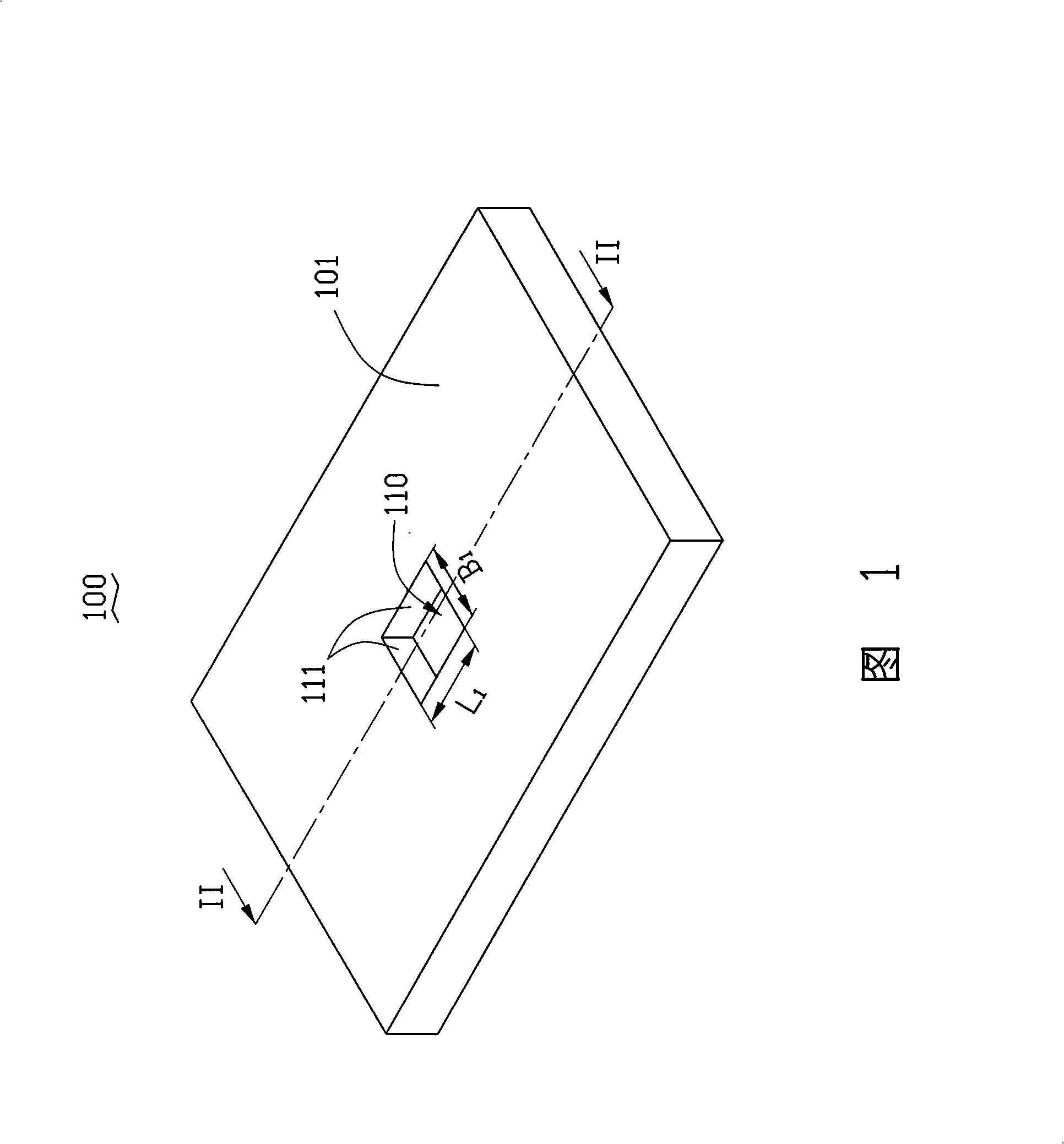

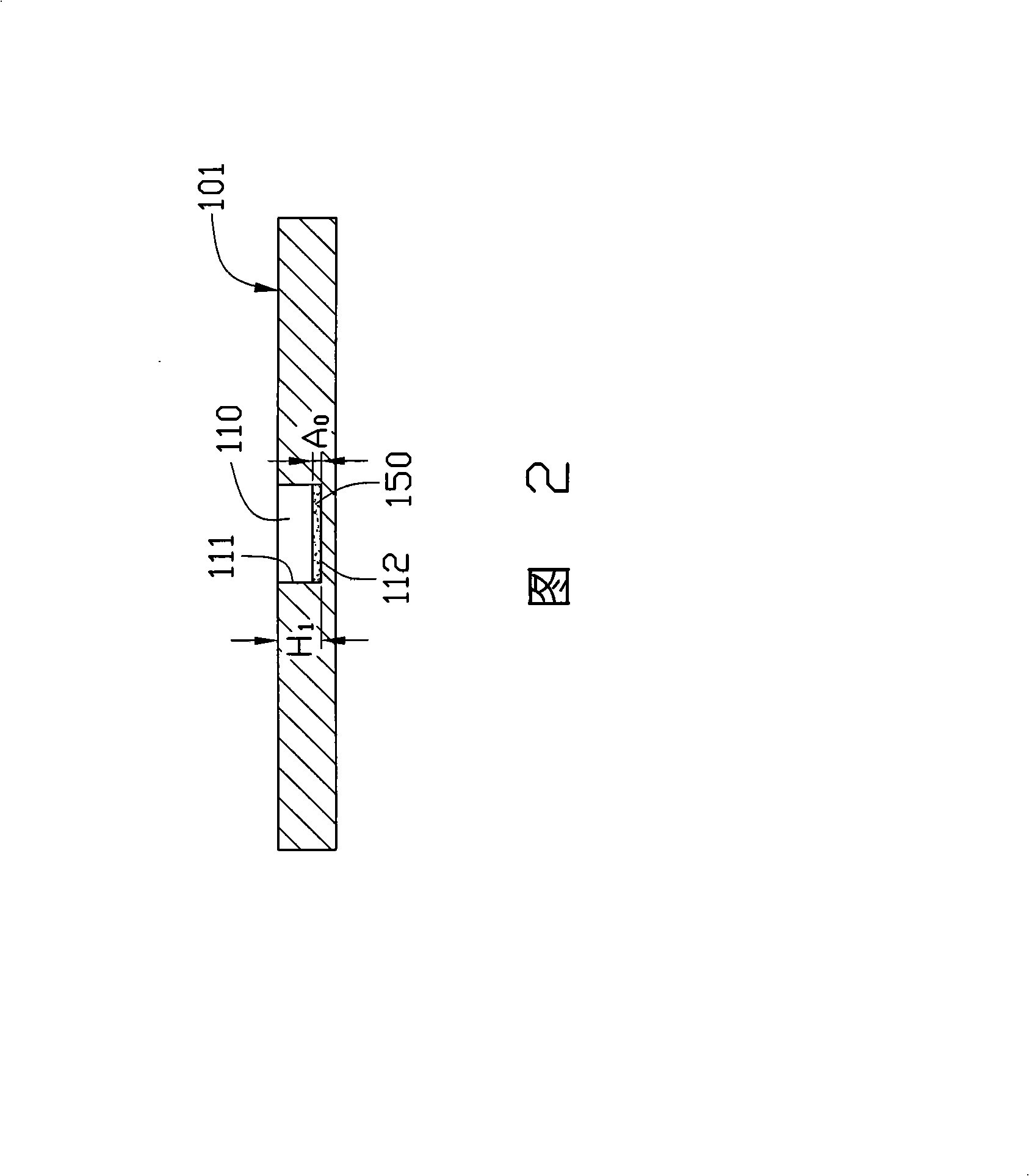

[0023] Please refer to FIG. 1 and FIG. 2 , the circuit board carrying device 100 provided by the first embodiment of the technical solution has a carrying surface 101 for carrying a circuit board. The bearing surface 101 is provided with at least one groove 110, and the groove 110 is used for accommodating electronic components arranged on the first surface of the circuit board. Therefore, the structure of the groove 110 is compatible with the structure of the electronic components. The so-called matching means that the electronic components can be accommodated in the groove 110 exactly. The groove 110 is surrounded by a plurality of side surfaces 111 and a bottom surface 112 . The bottom surface 112 of the groove 110 is provided with an adhesive layer 150 for bonding and fixing the electronic components accommodated in the groove 110 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com