Prefabricated web through type concrete-filled steel tubular column and steel beam connecting joint

A technology for concrete-filled steel tubular columns and connecting nodes, which can be applied to buildings, building structures, etc., can solve problems such as stress concentration and failure of connecting nodes, and achieve the effects of excellent seismic performance, increased longitudinal shear force, and increased area of the connecting area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

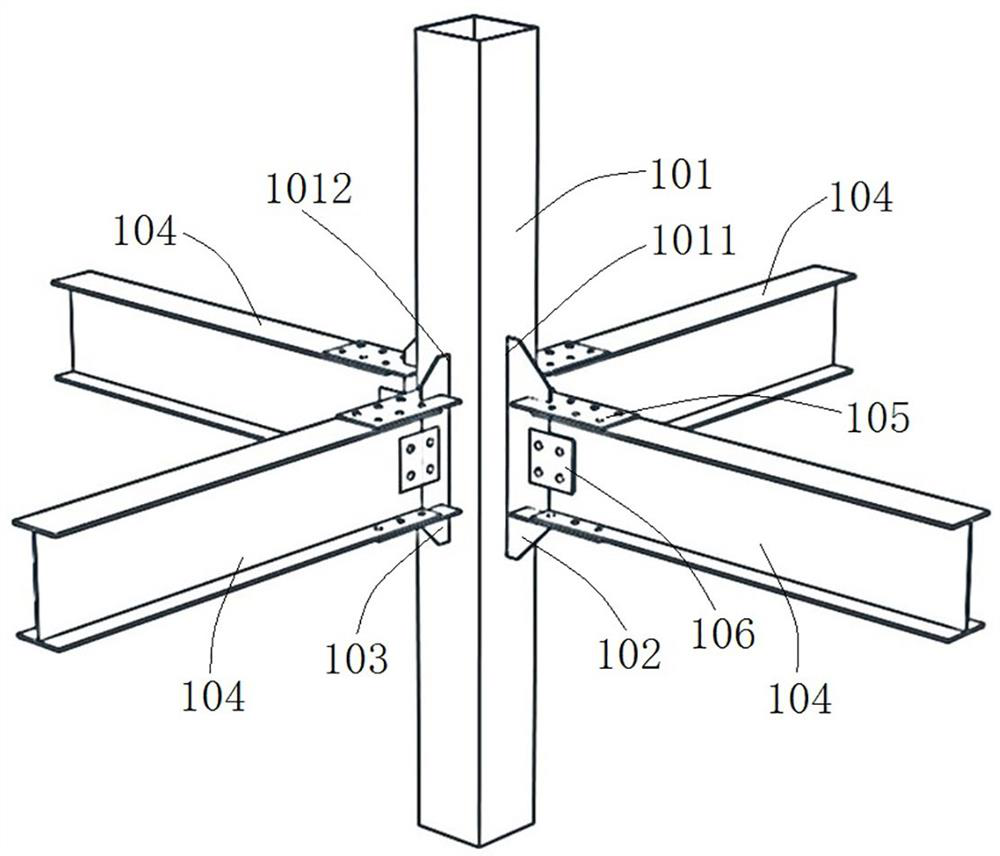

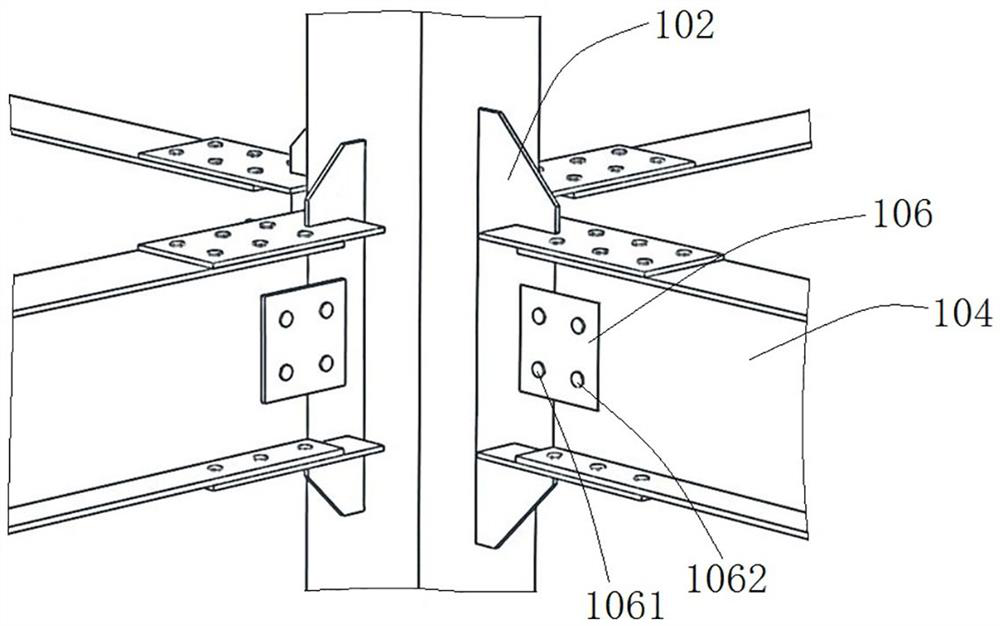

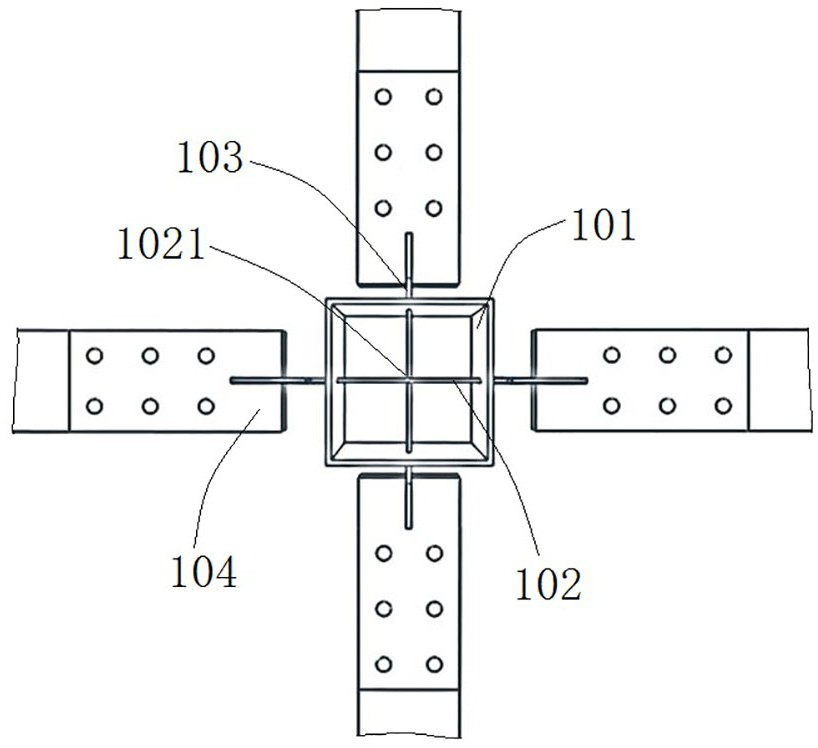

[0053] like Figure 1 to Figure 6 As shown, the connection node between the prefabricated web through-type concrete-filled steel tube column and the steel beam (hereinafter referred to as the connection node) includes a steel tube concrete column 101 and four steel beams connected to the steel tube concrete column 101. The steel beams here are engineering The beams 104 and the concrete-filled steel tube columns 101 extend vertically, and the I-beams 104 extend horizontally. The four I-beams 104 are arranged crosswise in the shape of a "ten". The concrete-filled steel tube column 101 in this embodiment is a square concrete-filled steel tube column with a rectangular cross section.

[0054] like figure 1 As shown, in order to connect the steel tube concrete column 101 and four I-beams 104, the first node plate 102 and the second node plate 103 are penetrated in the steel tube concrete column 101, and the plates of the first node plate 102 and the second node plate 103 The plan...

specific Embodiment 2

[0062] like Figure 7 to Figure 9 As shown, the difference from Embodiment 1 is that in this embodiment, a slot 206 is opened at the end of the first gusset plate 202 facing the I-beam 204 , and the slot 206 here can be used for the I-beam 204 The web 2041 and the flange are inserted and then fixed. Specifically, such as Figure 8 As shown, a first gusset plate connection hole 207 is opened on the first gusset plate 202, as Figure 9 As shown, a web connection hole 2042 is opened on the web 2041, and the first gusset plate 202 and the web 2041 are connected together by bolts. The connection mode between the wing plate 205 and the first gusset plate 202 is the same as that in Embodiment 1, and will not be described in detail here. It should be noted that, in this embodiment, the slot on the wing 205 corresponds to the slot 206 . The connection mode between the second gusset plate 203 and the I-beam 204 is consistent with that in Embodiment 1, and the connection mode between...

Embodiment 1

[0065] In Example 1, bolts are used to fix the two cover plates, the web plate and the gusset plate. In this embodiment, one of the web plate and the gusset plate is connected to the cover plate by welding, and the other is connected to the bolts, or both are connected by welding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com