600 microns thin-specification 250 MPa high-phosphorus IF steel stable rolling method

A 250mpa, thin gauge technology, applied in the production process of thin gauge high-strength deep-drawing steel in the metallurgical industry, can solve the problems of inability to guarantee the quality of the plate shape, the fluctuation of the thickness of the steel strip, and the aging of the shearing edge, so as to avoid cold working brittle cracking. , The effect of inhibiting grain boundary segregation and reducing the deformation resistance of strip steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

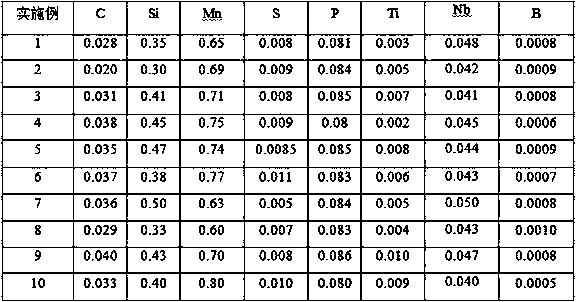

[0045]Smelting process: a total of 10 furnaces were smelted, and the chemical composition of the steel is shown in Table 1.

[0046] Table 1 Chemical composition (mass percentage wt%)

[0047]

[0048] Hot-rolling process: The hot-rolled strip steel is prepared according to the specification of 2.5-2.6mm, and all adopt post-stage cooling. Hot-rolled coil numbers 1-10 correspond to heats 1-10 respectively.

[0049] Table 2 Hot rolling process parameters

[0050]

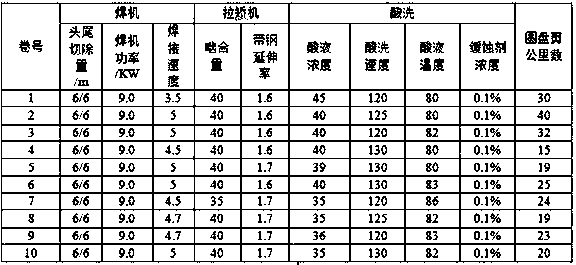

[0051] Continuous acid rolling process: coil numbers are 1 to 10, corresponding to 10 furnace components respectively.

[0052] The specific acid rolling process is as follows:

[0053] Table 3 Acid rolling process-1

[0054]

[0055] Table 4 Acid rolling process-2

[0056]

[0057] Table 5 Acid rolling process-3

[0058]

[0059] The final mechanical properties of the strip shape and strip steel in acid rolling:

[0060] Volume numbers are 1 to 10, corresponding to 10 batches of ingredients.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com