Method for controlling occurrence rate of strip-shaped chromatic aberration on surface of pickled low-carbon aluminum killed steel

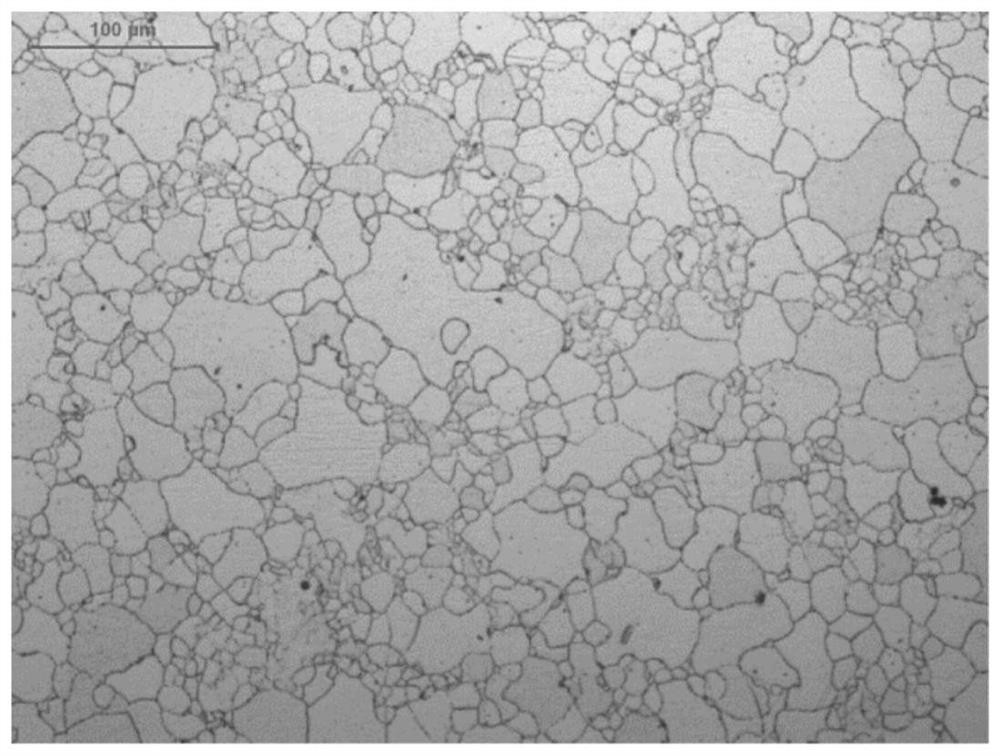

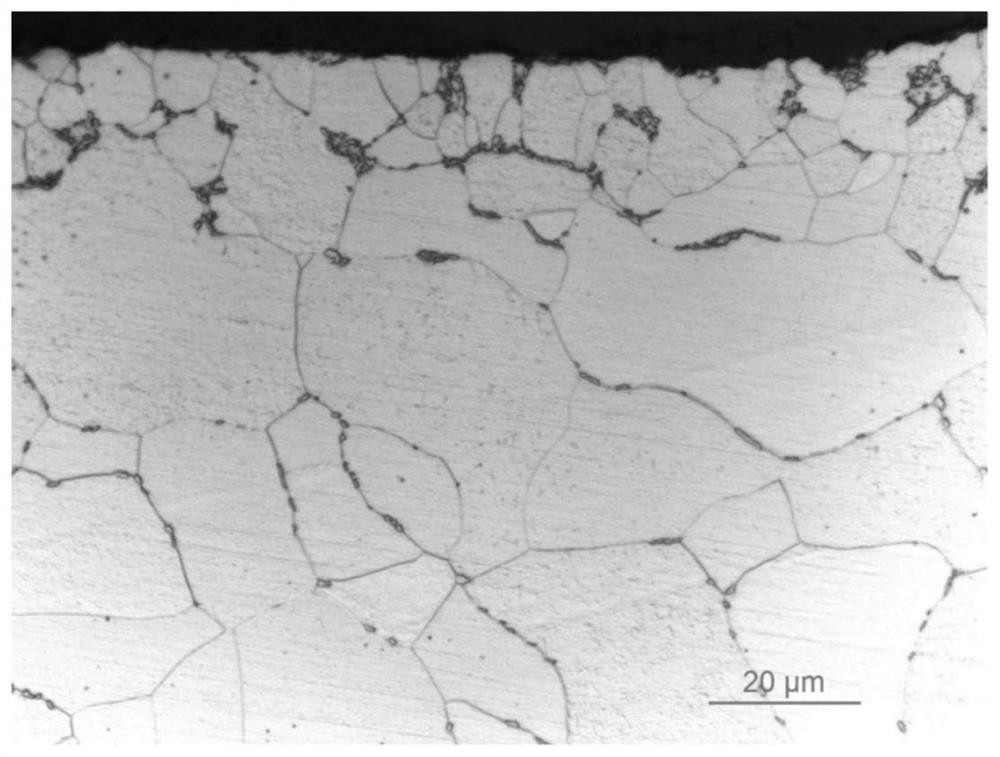

An aluminum-killed steel acid and rear surface technology, applied in metal rolling and other directions, can solve problems such as strip-shaped chromatic aberration, and achieve the effects of controlling grain coarsening, reducing the generation of mixed grain structure, and increasing the melting range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0081] This embodiment is a method for controlling the occurrence rate of banded color difference on the surface of low-carbon aluminum-killed steel after pickling, which specifically includes:

[0082] (1) Molten steel smelting: The mass fractions of C, Al, Mn, Si and B in molten steel obtained from smelting are respectively:

[0083] C: 0.03%, Al: 0.02%, Mn: 0.2%, Si: 0.05%, B: 0.005%.

[0084] (2) Continuous casting of molten steel: During the continuous casting process, the insertion depth of the nozzle is 100-150cm, and the casting speed of the casting machine is 1.5-1.7m / min;

[0085] The mass fraction of C in continuous casting mold flux is 2.7-3.3%, Na 2 The mass fraction of O is 7-8%, the melting range of the mold flux is 45-60° C., and the thickness of the liquid slag layer of the mold flux is 4-5 mm.

[0086] (3) Surface cleaning: the slab obtained in step (2) is surface-cleaned, and the cleaning depth of the surface cleaning is 2-3mm to ensure that there is no ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com