The Transformation Method of Motor Never Breaking

A technology for broken bars and motor rotors, which is applied in the manufacture of motor generators, asynchronous induction motors, electromechanical devices, etc., and can solve problems such as no motor broken bars.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

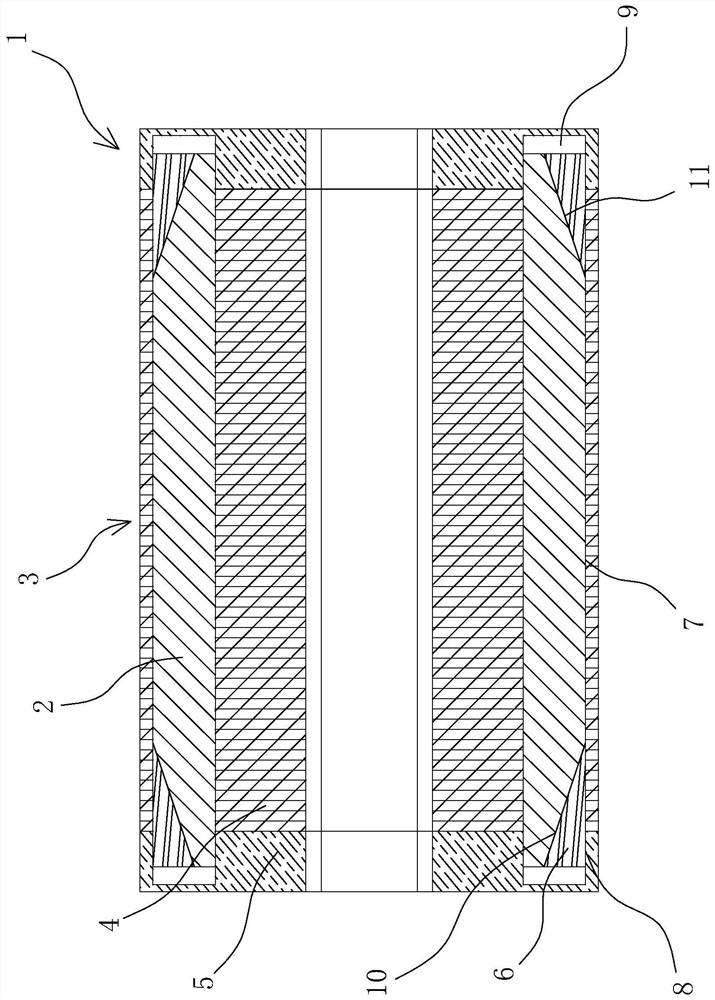

[0039] Such as figure 1 As shown, a method for transforming a motor that is never broken, including a motor rotor 1, includes the following steps:

[0040] Step 1: Order high-precision trapezoidal copper bars as the rotor cage bar 2 according to the design plan. The material is T2 copper. According to the design requirements and size of the motor rotor 1, redesign and customize two end rings 5 and iron core 3. The iron core 3 is made of A number of rotor silicon steel sheets 4 are stacked, and the iron core 3 is provided with a number of high-precision guide grooves 7 that are compatible with the rotor cage 2. The material of the end ring 5 is forged T2 copper, and according to the rotor cage 2 The size of the end, the pool groove 9 is gold-processed on the end ring 5;

[0041] In this embodiment, the rotor cage bar 2 made of trapezoidal copper bar structure can effectively prevent broken bars due to good heat dissipation, effective tensioning of the copper bar, and large s...

Embodiment 2

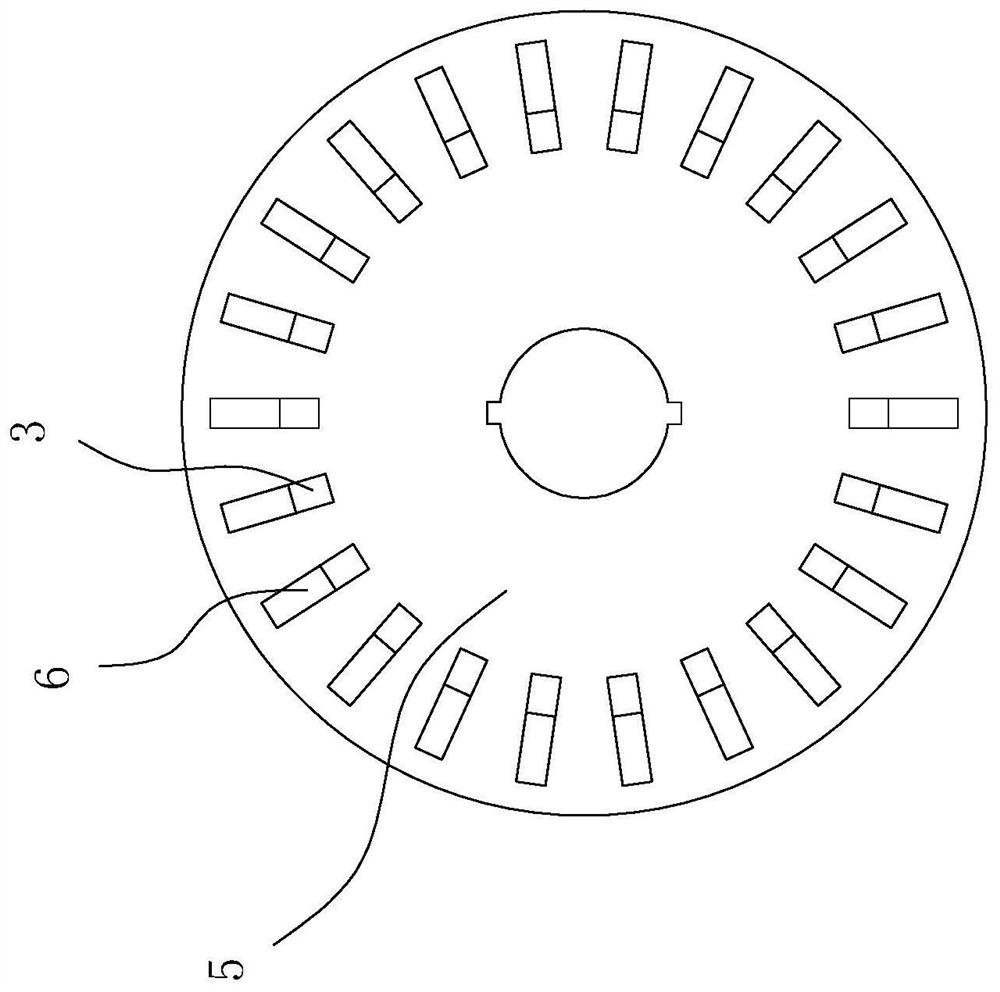

[0069] Wherein, the rotor silicon steel sheet 4 in the step 2 is made through the following steps:

[0070] Step a: Design the rotor silicon steel sheet 4 of the motor rotor 1, design and manufacture the press ring tool according to the required size;

[0071] Step b: design the composite mold for the rotor silicon steel sheet 4 according to the drawing, and draw the construction drawing;

[0072] Step c: Make the mold of the rotor silicon steel sheet 4 according to the figure;

[0073] Step d: Punch the rotor silicon steel sheet 4 on a large punching machine, the material is DW470-50 cold-rolled silicon steel sheet, and paint the rotor silicon steel sheet 4;

[0074] Step e: laminate several rotor silicon steel sheets 4 on a punching machine to form an iron core 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com