Belt conveyer and roller supporting assembly for same

A technology for belt conveyors and supporting components, which is applied in the direction of conveyors, transportation and packaging, etc. It can solve the problems of uneven force between the central area and the edge area, the ineffective contact of the conveyor belt with the rollers, increased operation difficulty and maintenance time, etc. To achieve the effect of easy disassembly and effective tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

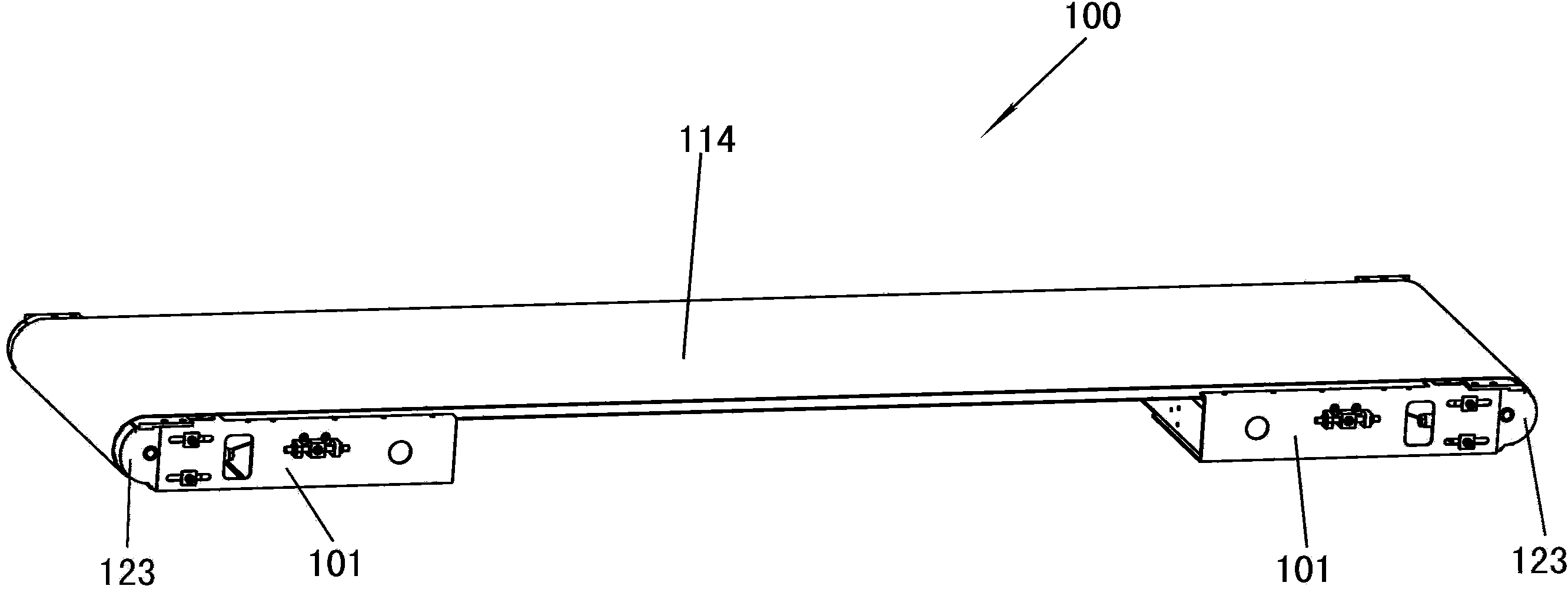

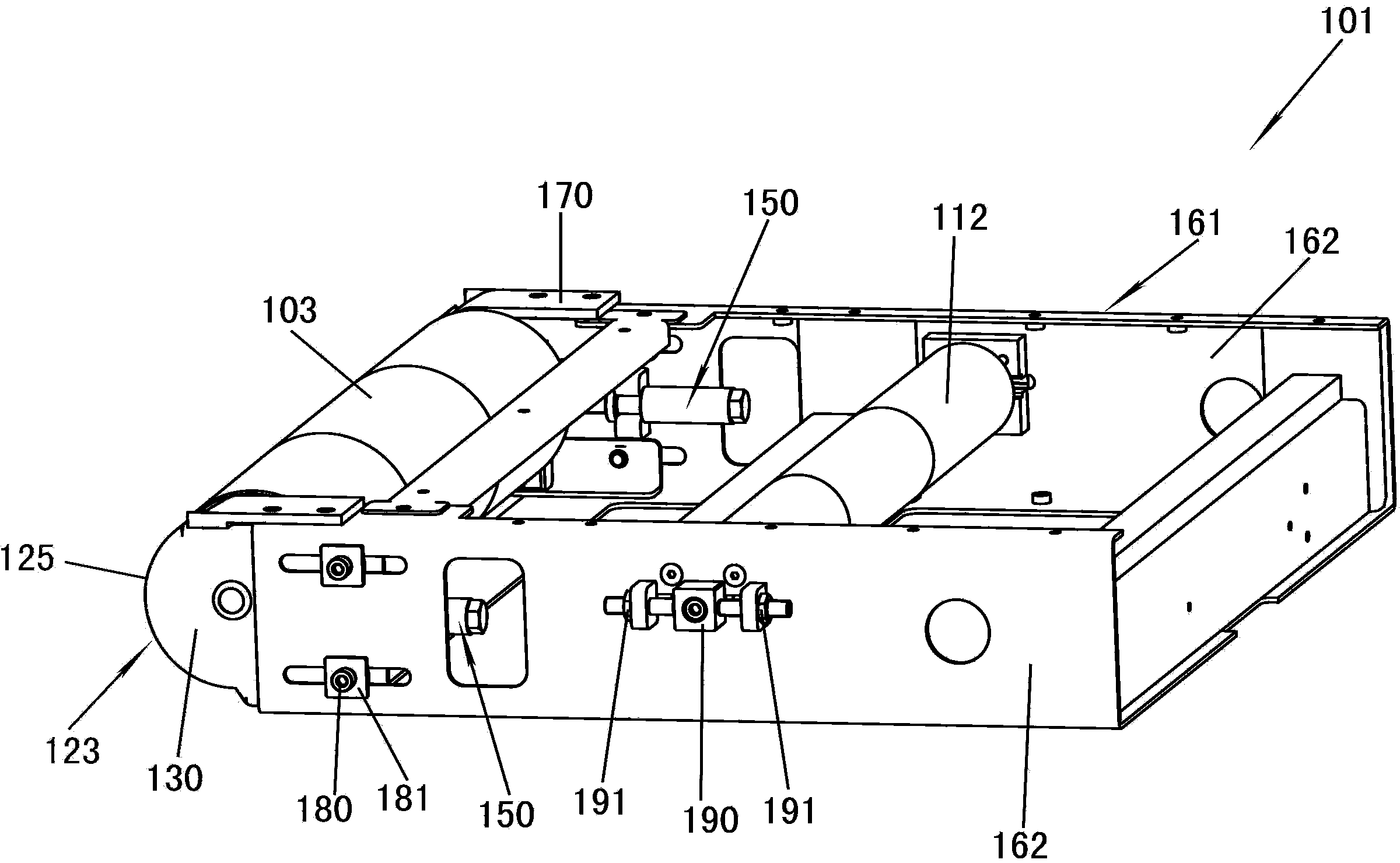

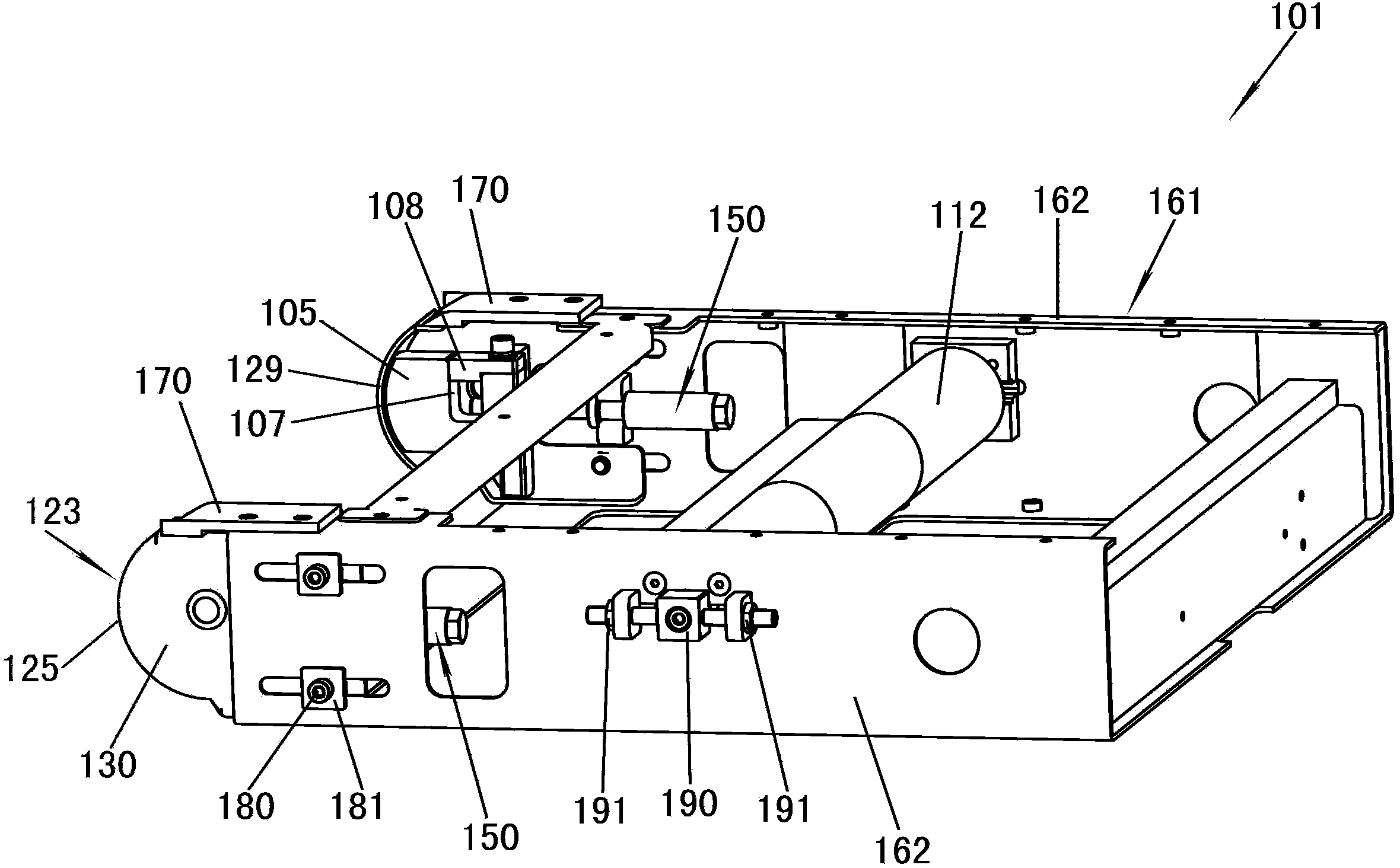

[0024] Such as Figures 1 to 4 As shown, the belt conveyor 100 according to the embodiment of the present invention comprises: a roller support assembly 101; a conveyor belt 114; 105 in the groove 107. In addition, the belt conveyor 100 also includes one or more idler rollers 112 . The belt conveyor 100 according to the embodiment of the present invention can be applied to luggage security inspection equipment. During baggage security inspection, the baggage is placed on the conveyor belt 114, and the conveyor belt 114 transports the baggage through the security inspection channel of the equipment. The conveyor belt 114 is installed on the equipment channel by the rollers at both ends and the roller support assembly 101 . At least one of the two drums 103 may be a motorized drum.

[0025] Such as figure 2 , 3 , 4, the roller supporting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com