Patents

Literature

52results about How to "Prevent affecting welding quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

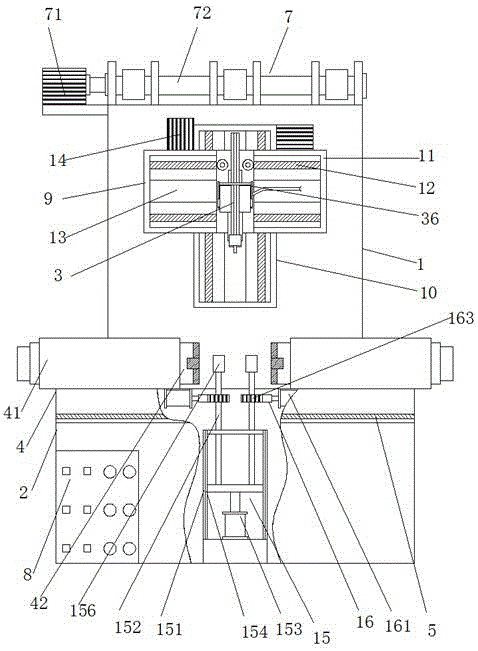

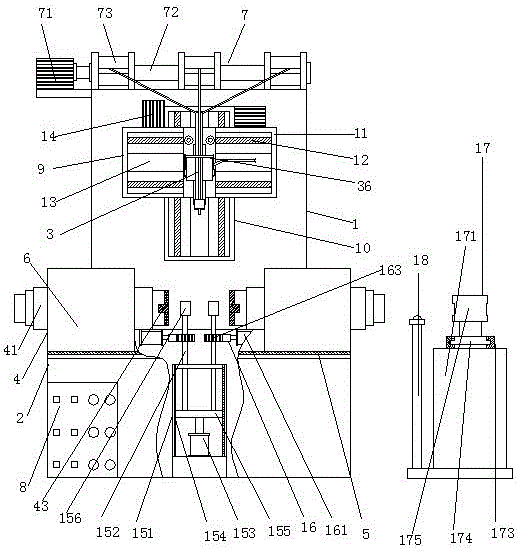

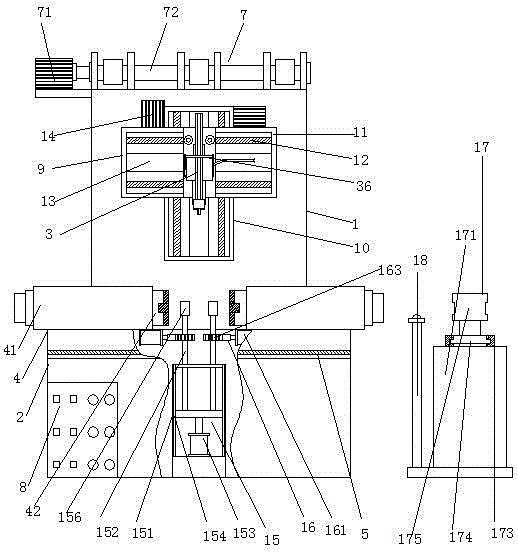

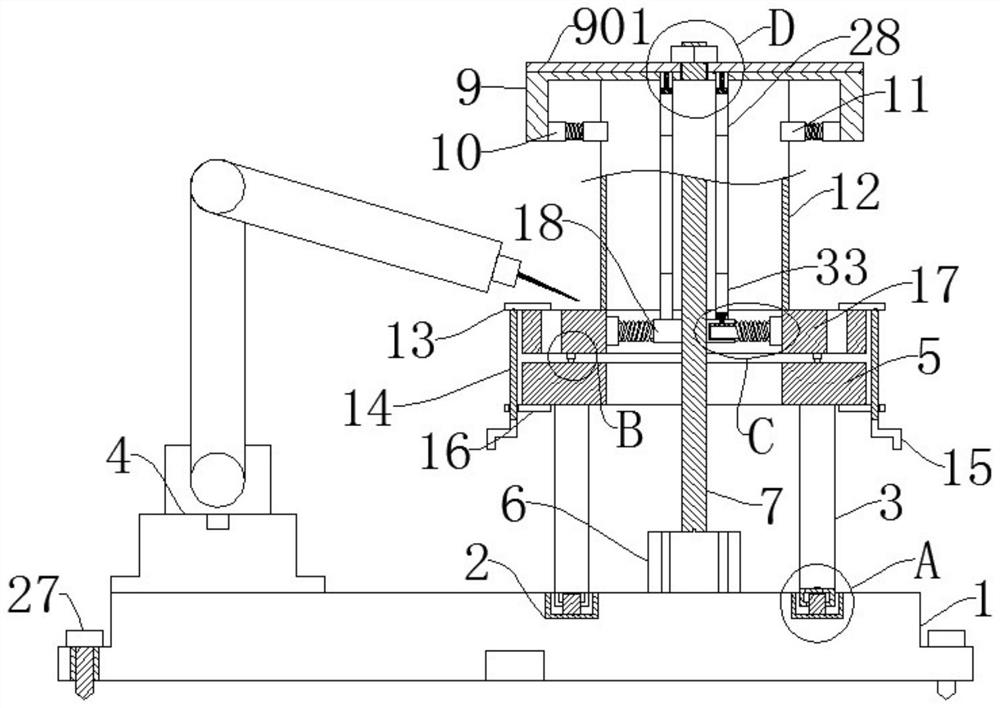

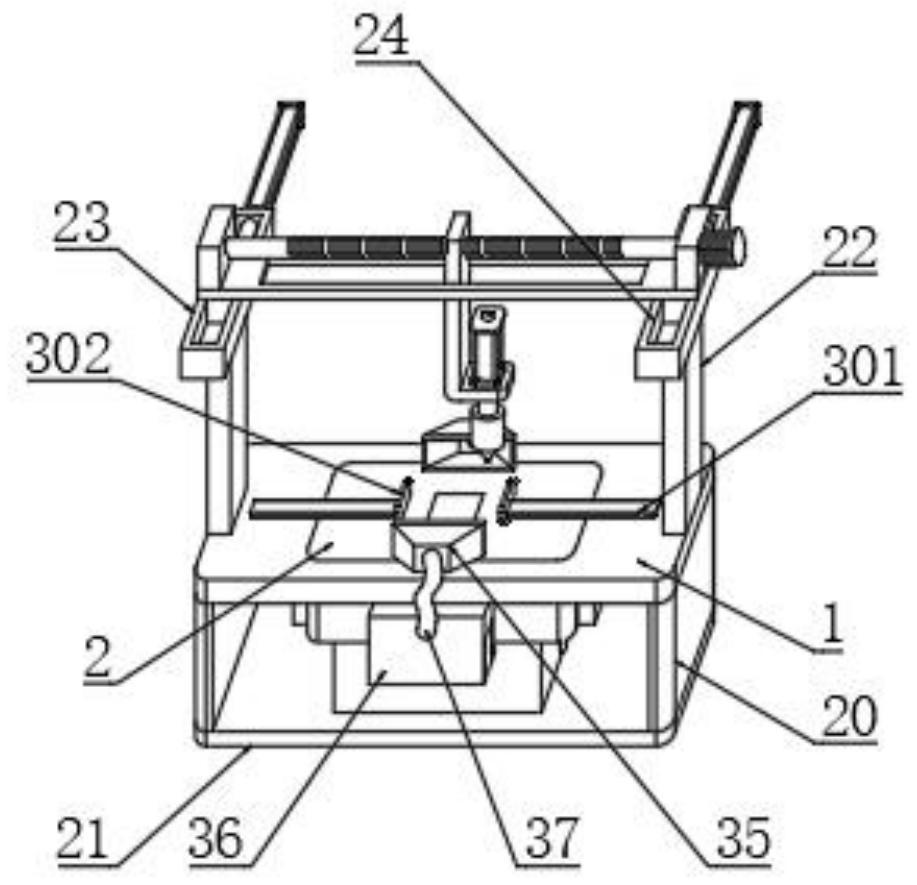

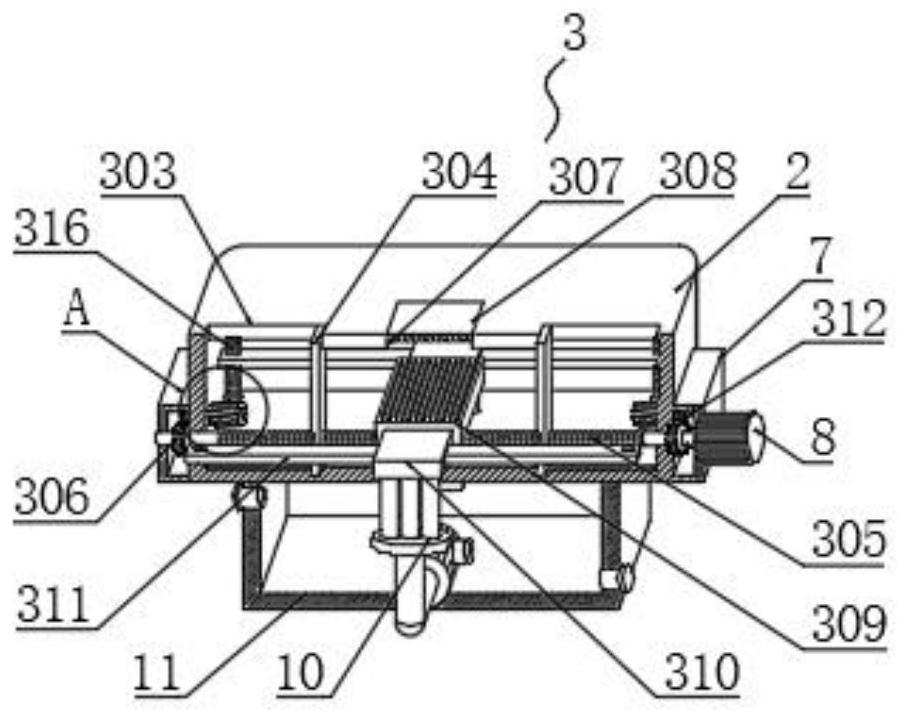

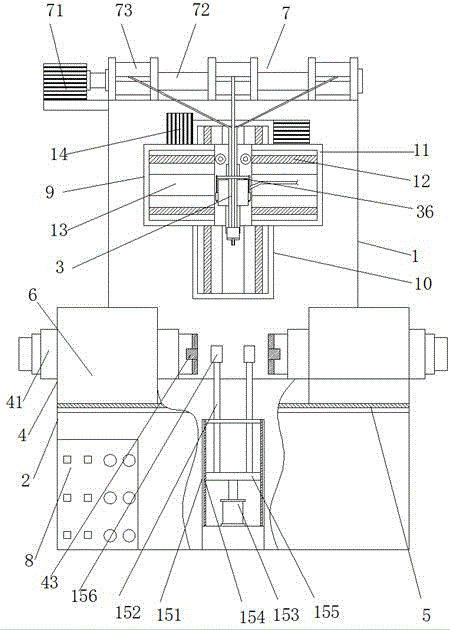

Laser splice welding system for high-strength steel structure thin plates

ActiveCN107363405AIncrease the pressing forcePrevent workpiece deformationLaser beam welding apparatusElectric arcPortal frame

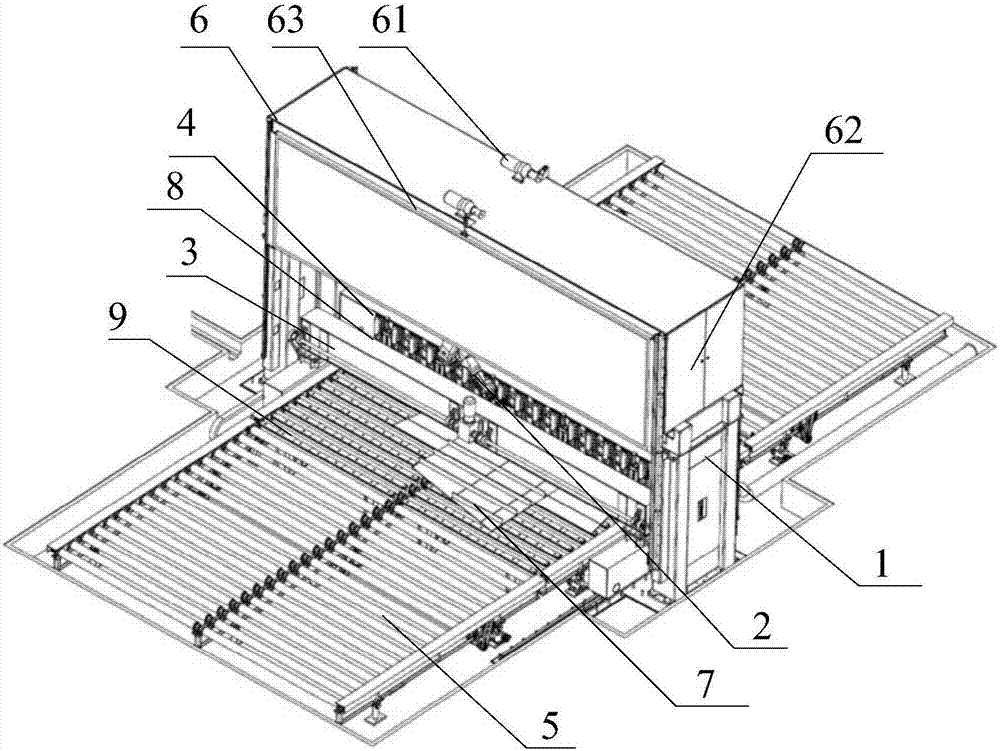

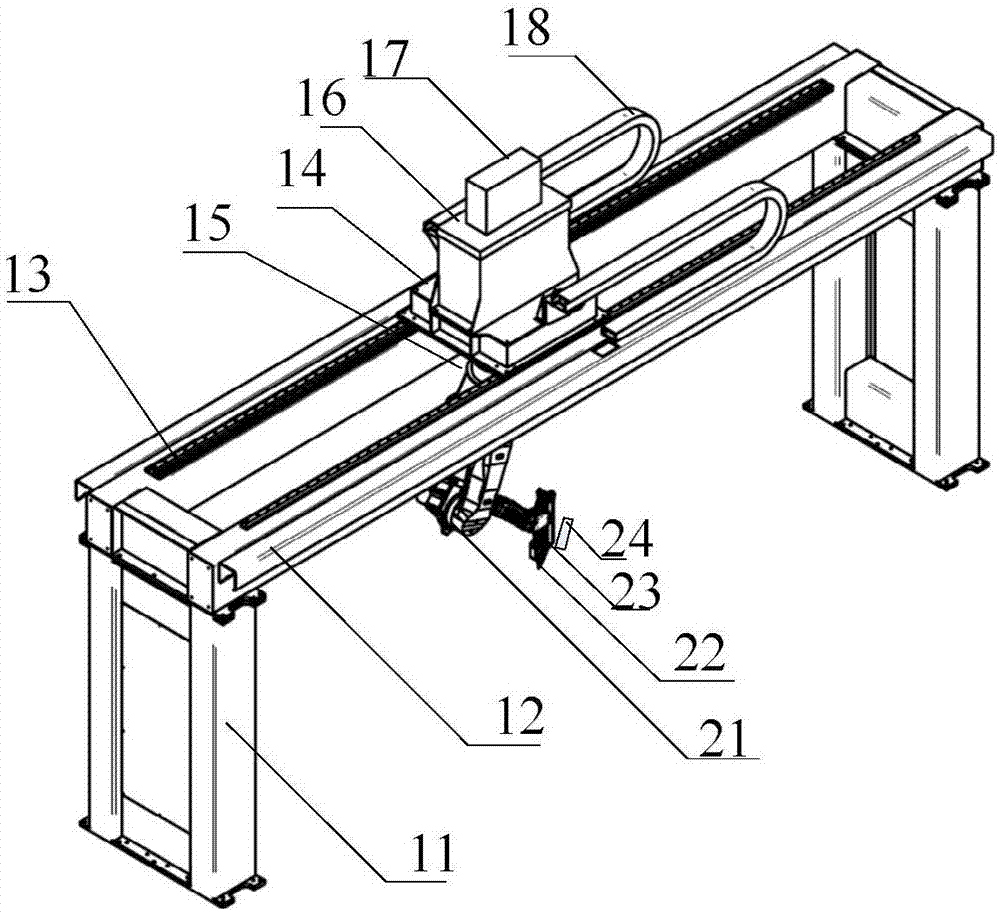

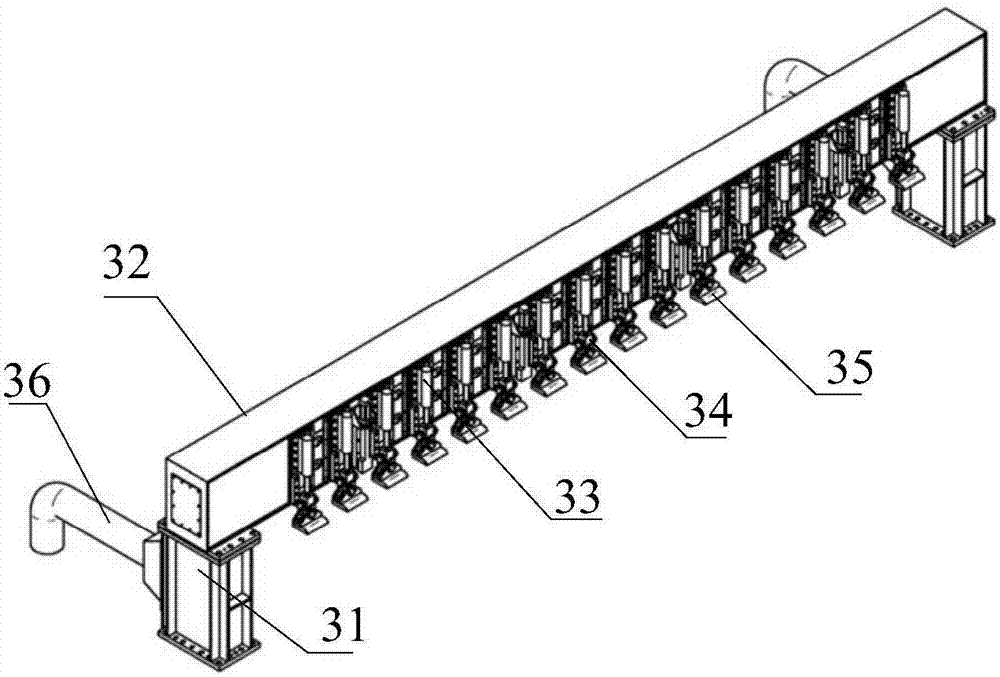

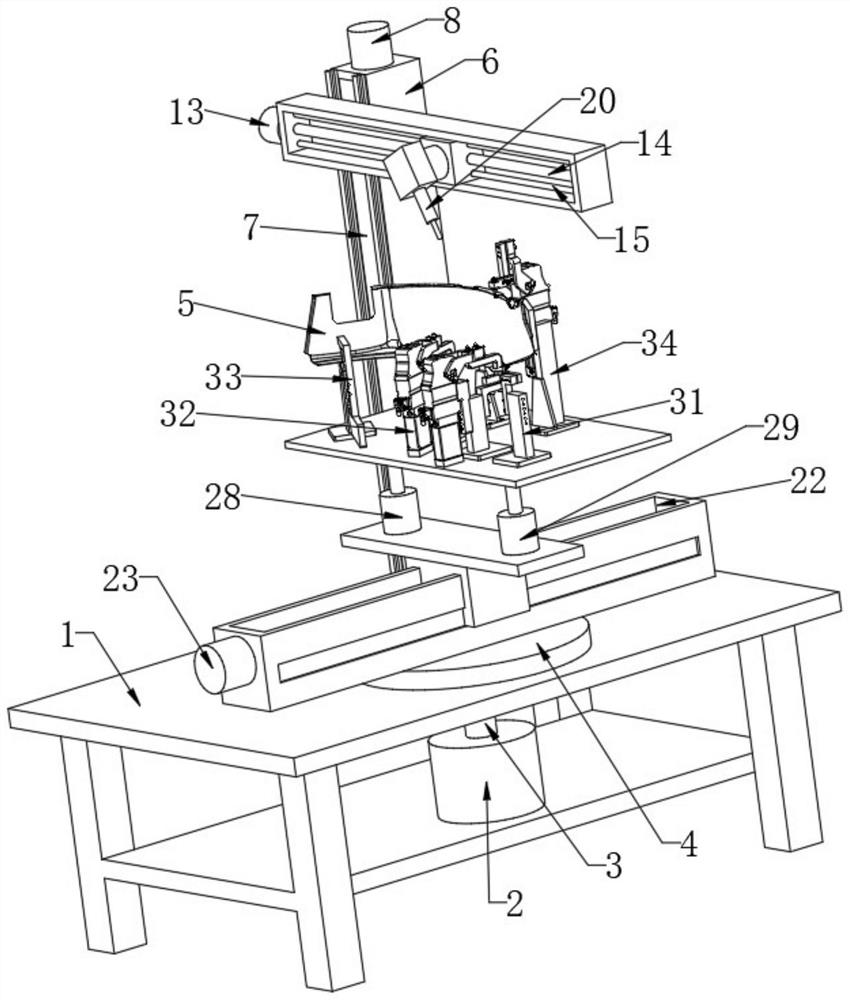

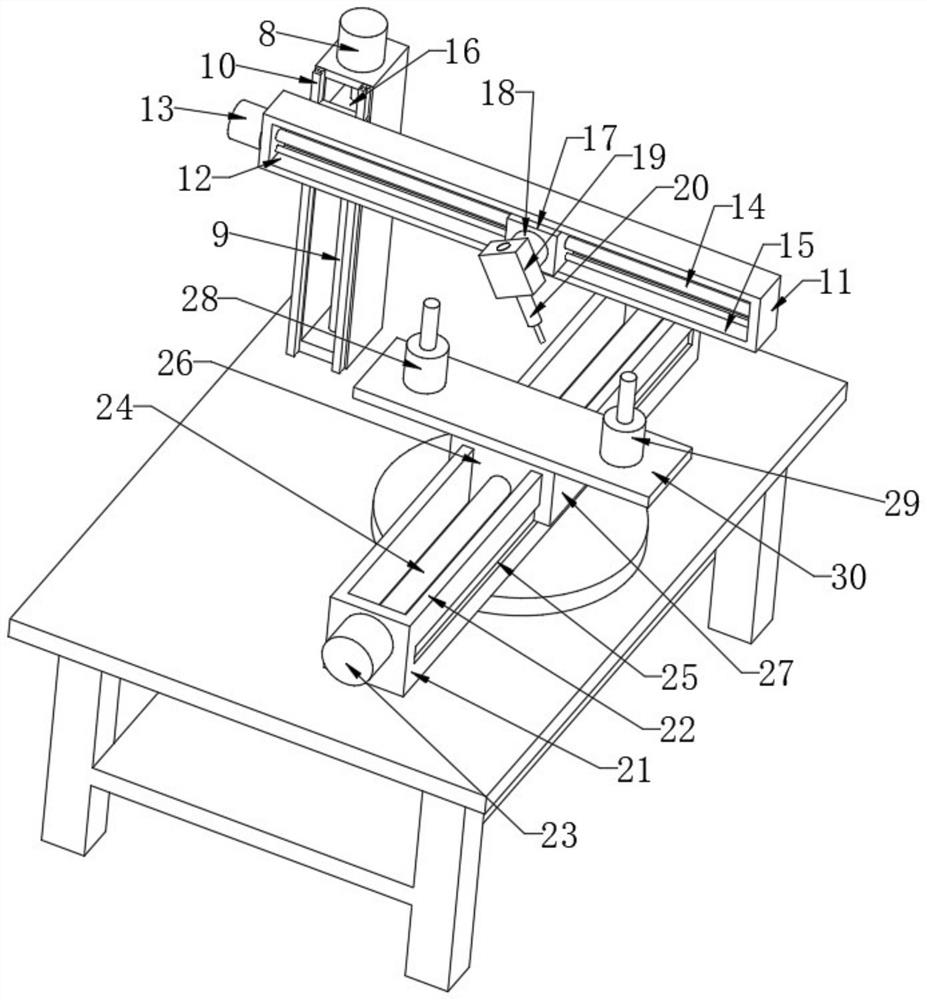

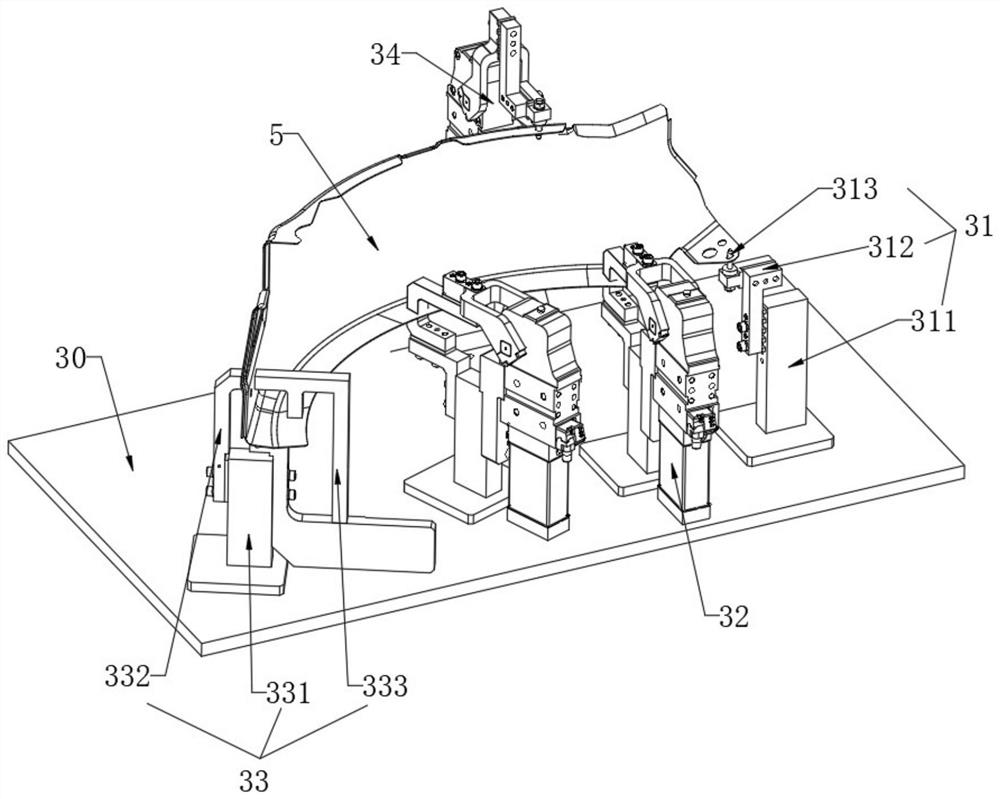

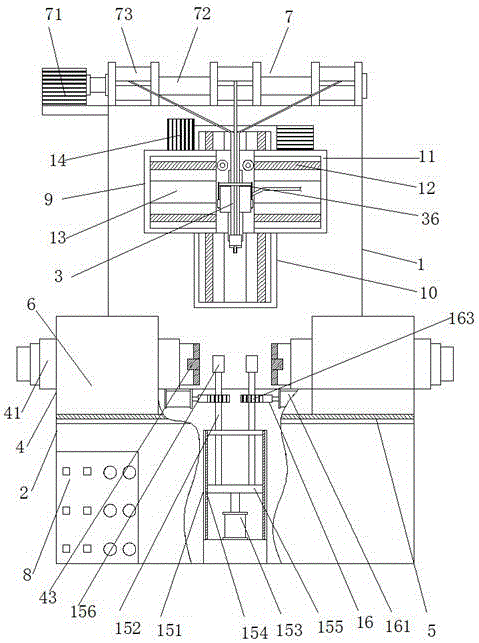

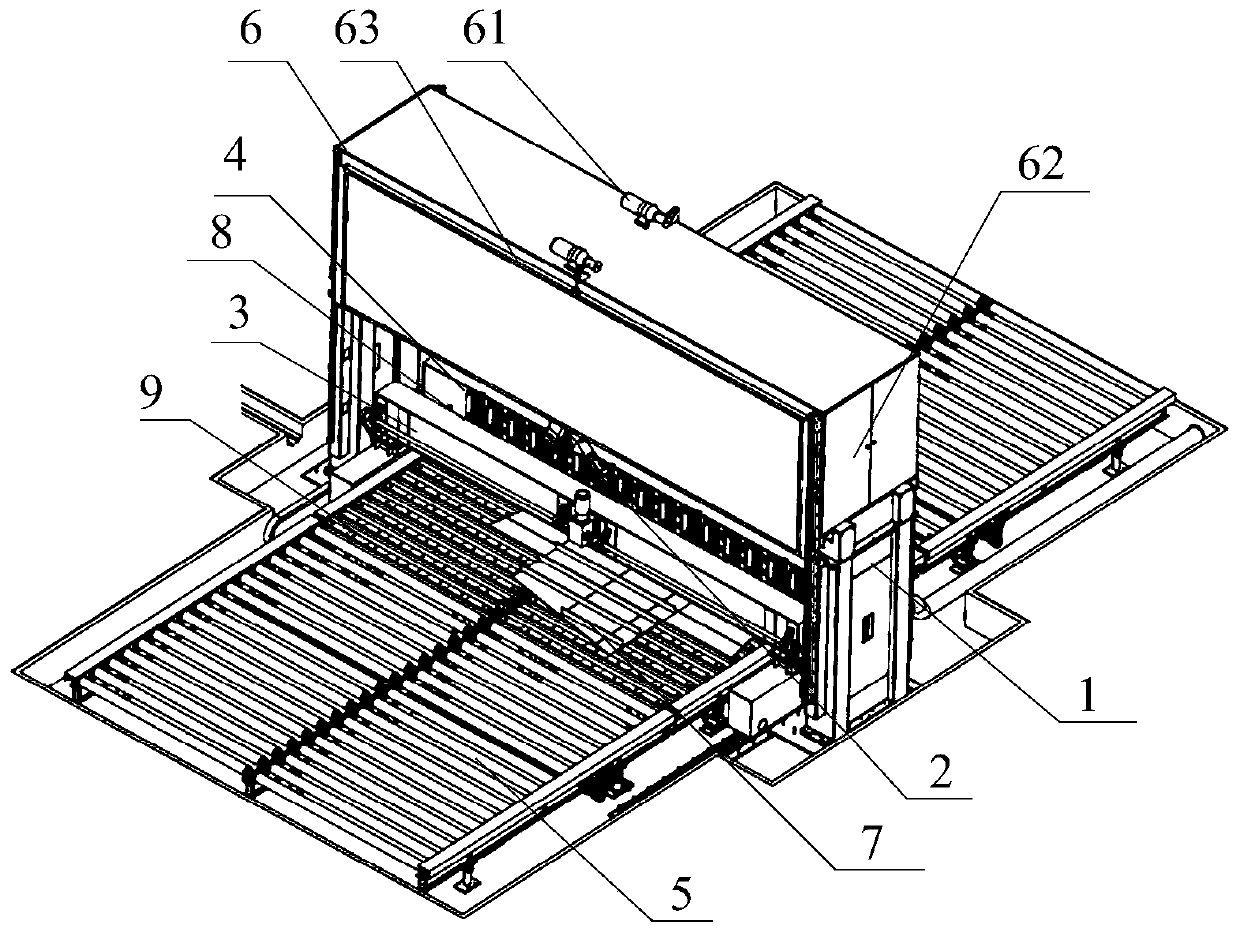

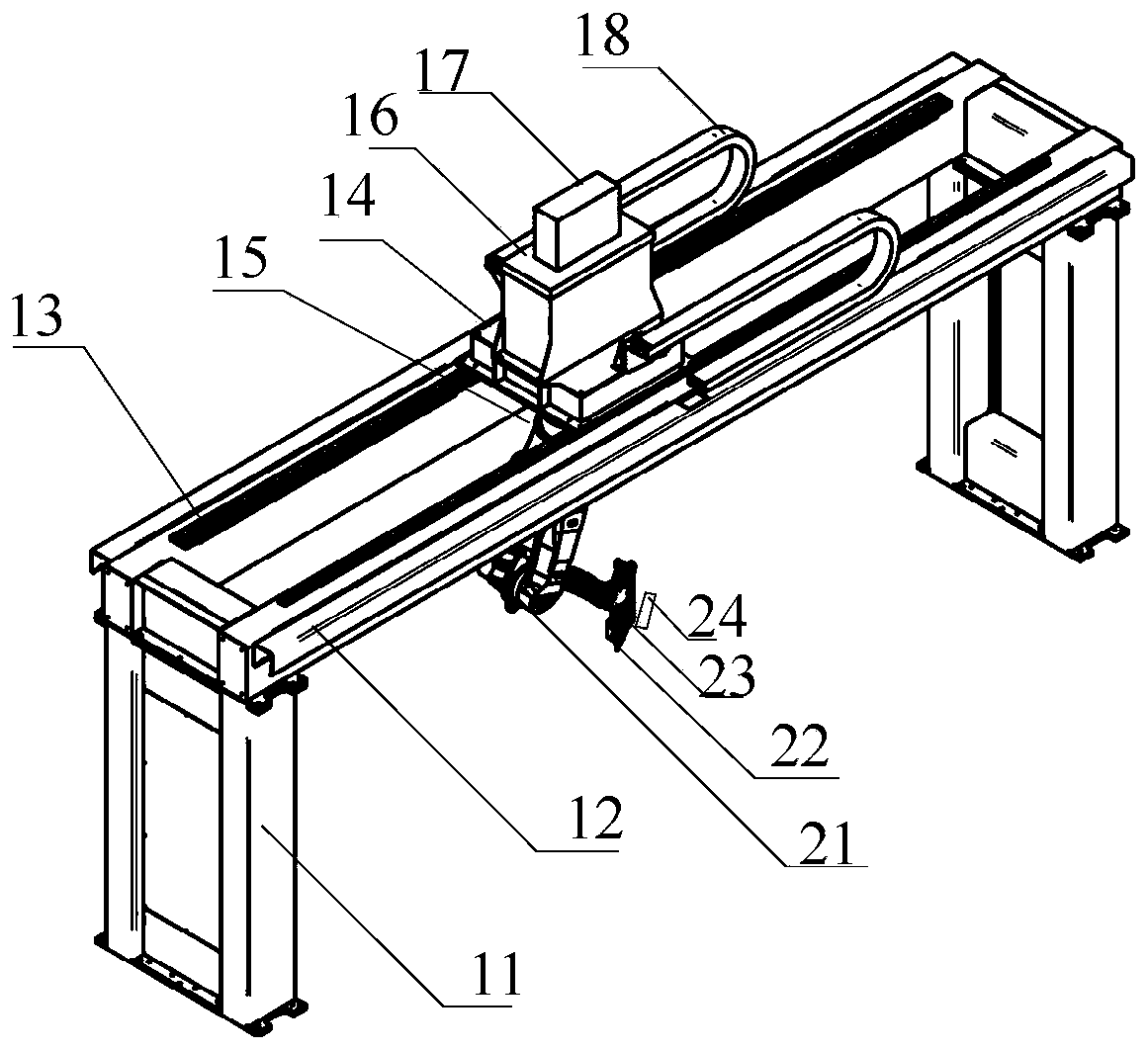

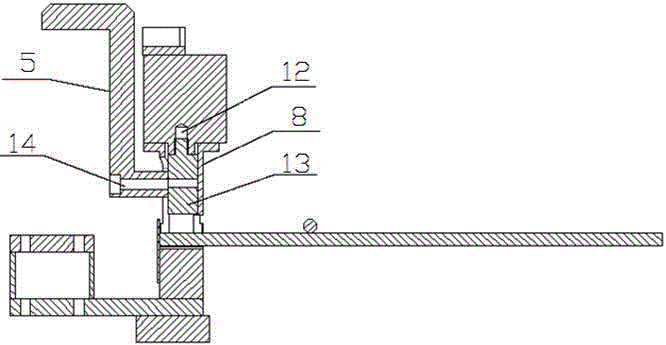

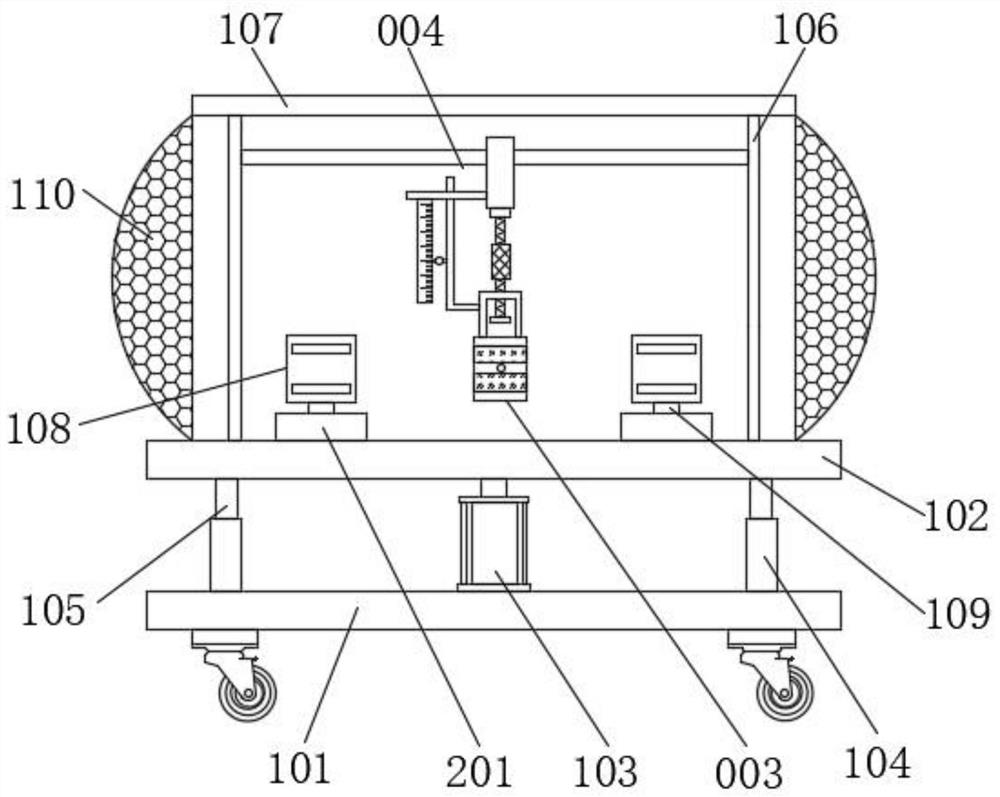

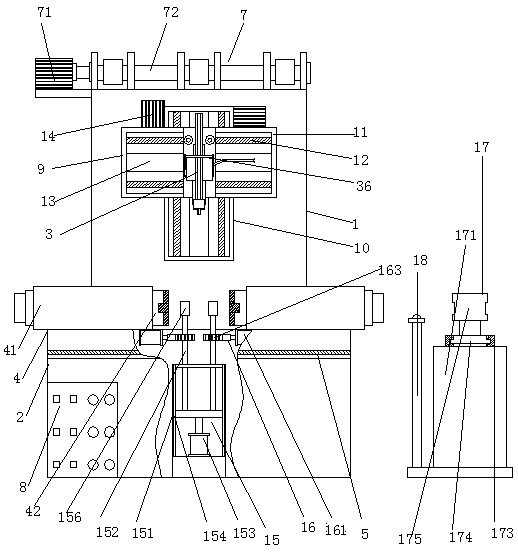

The invention provides a laser splice welding system for high-strength steel structure thin plates. The laser splice welding system comprises a welding portal frame and the like. A fixed pressing device, a movable pressing device and a welding platform are all located below the welding portal frame. The fixed pressing device and the movable pressing device are located on the two sides of the workpiece welding platform correspondingly. A transversely-moving trolley is arranged on the welding portal frame, a robot level laser composite welding system is fixed to the position below the transversely-moving trolley, and a workpiece transferring device is located on the side faces of a front welding material frame and a rear welding material frame. The welding portal frame is sleeved with a laser protective door, and the front welding material frame and the rear welding material frame are located below one side of the fixed pressing device. According to the laser splice welding system for the high-strength steel structure thin plates, the diversified welding methods such as self-fusible welding, laser filler wire welding and laser electric-arc hybrid welding can be achieved, automatic locating can be conducted before welding; and in the welding process, real-time tracing of welding joints can be achieved, the welding technological parameters are adjusted in real time according to slope gap and misalignment changing, and self-adaptation filling of welding wires is achieved. According to the laser splice welding system, teaching programming is easy, and operating is convenient.

Owner:SHANGHAI JIAO TONG UNIV +2

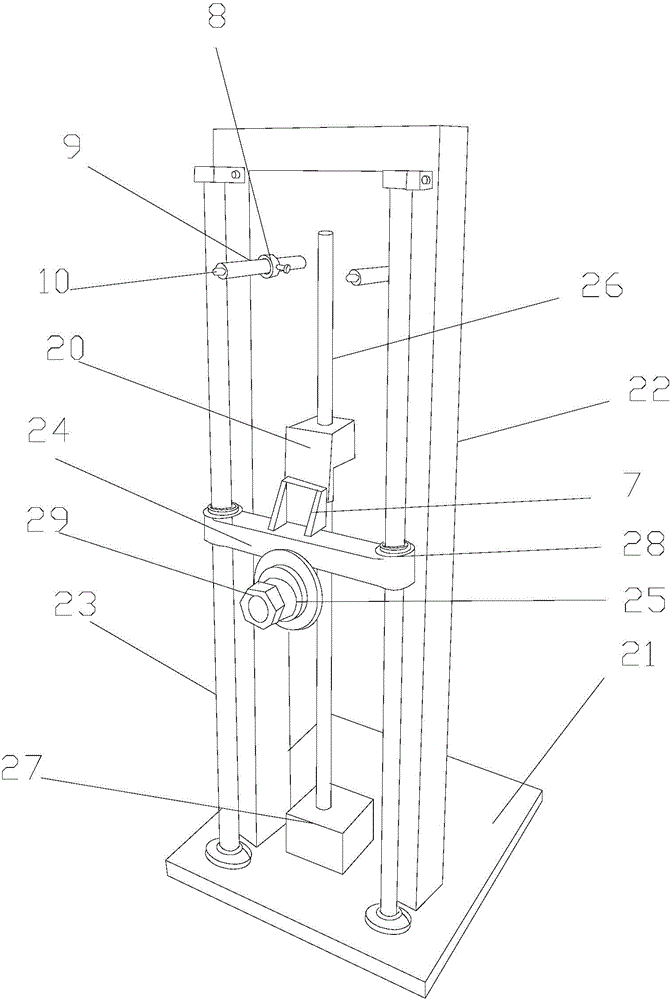

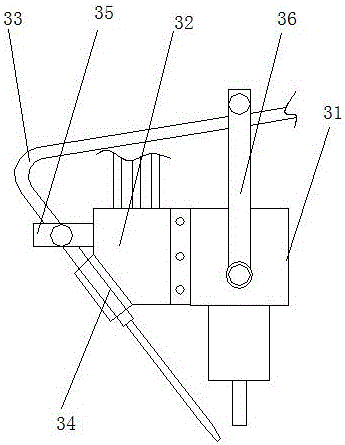

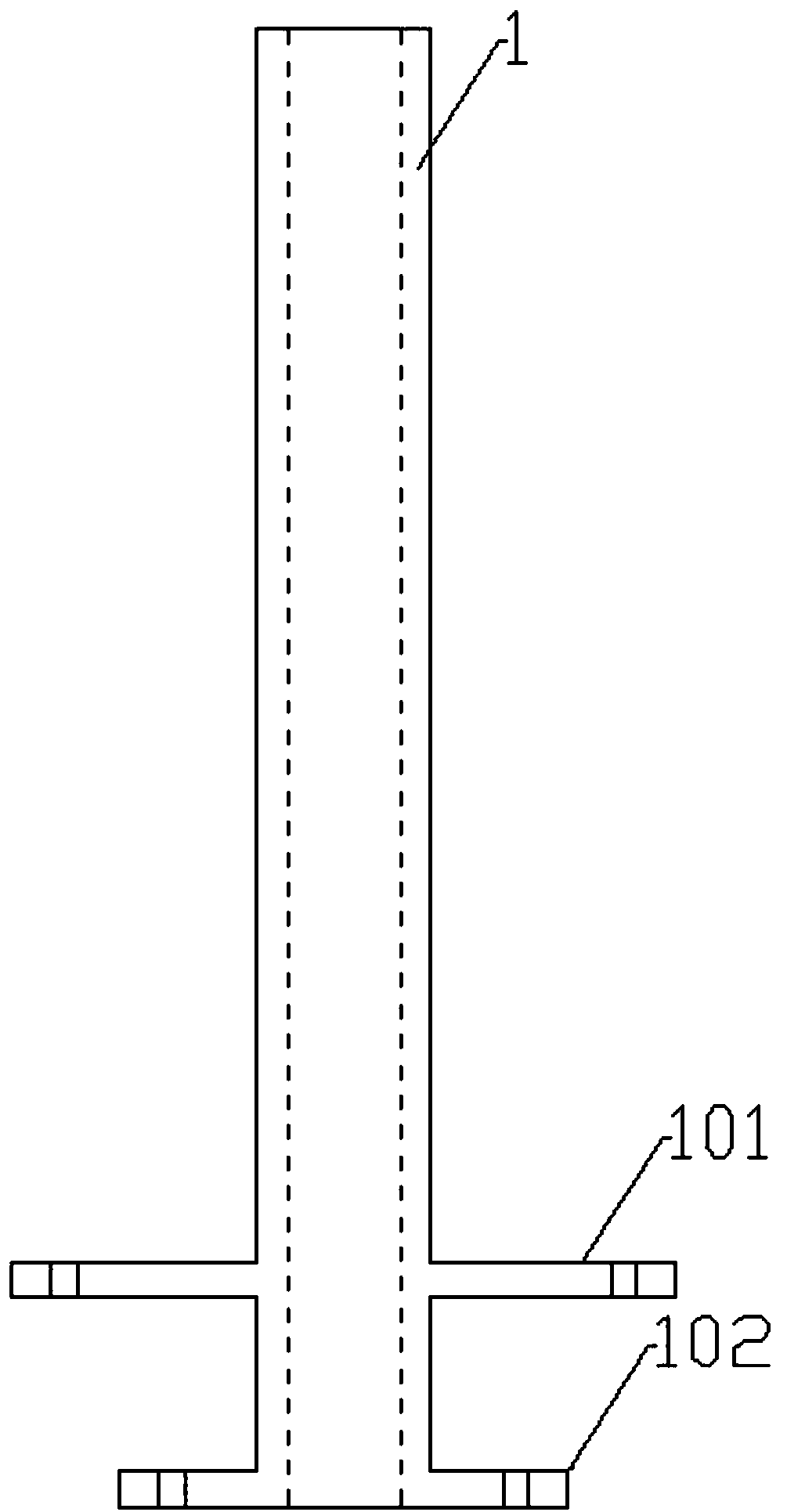

Guide mechanism for reinforcing bar mesh welding

ActiveCN105269205AMeet welding needsPrevent affecting welding qualityWelding/cutting auxillary devicesAuxillary welding devicesEngineeringRebar

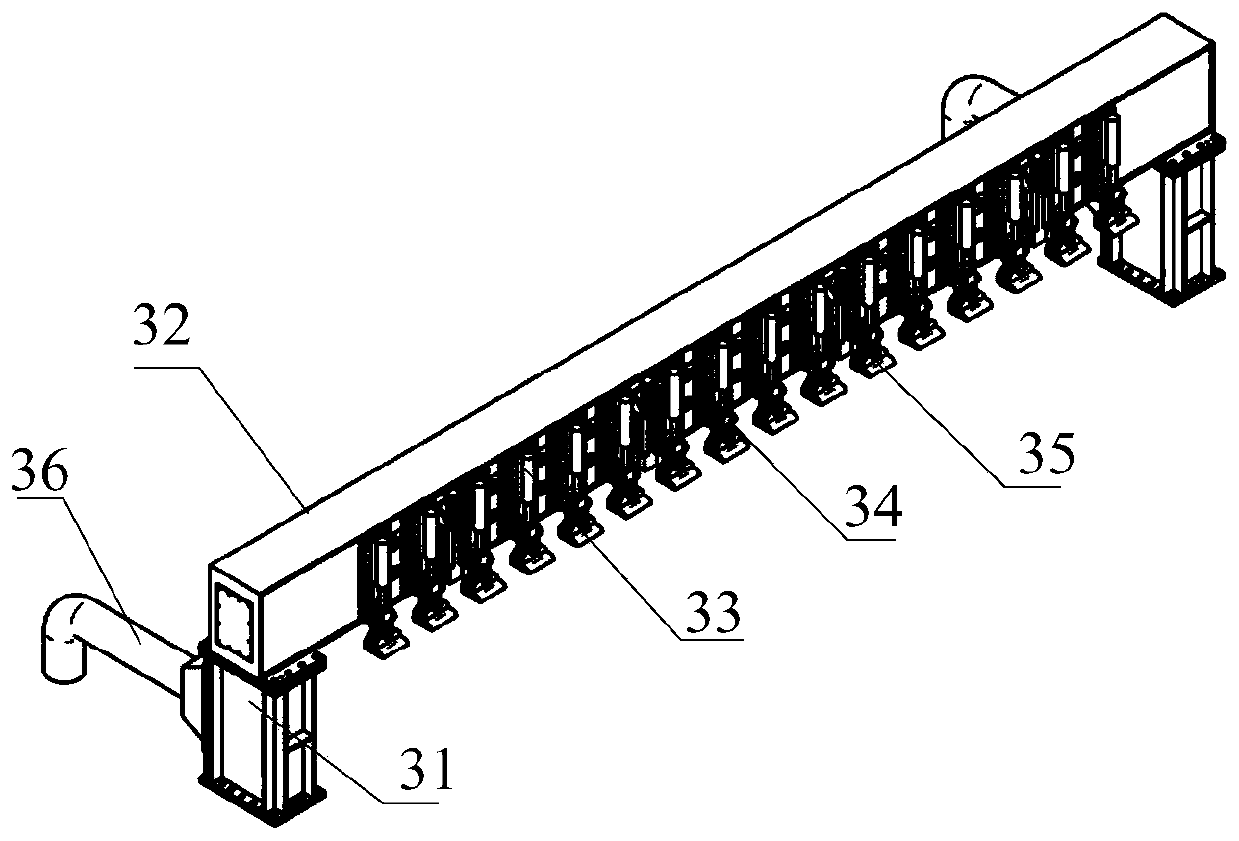

The invention discloses a guide mechanism for reinforcing bar mesh welding. The guide mechanism comprises a guide base, a limiting base, a fixed beam, roller wheels and a guide base fixing base, wherein the guide base is in sliding connection with the fixed beam; the roller wheels capable of freely rotating are arranged above the guide base; a vertical reinforcing bar is placed on the roller wheels; the limiting base is fixed above the guide base; and a transverse reinforcing bar clings to one side of the limiting base. The guide mechanism can position and guide reinforcing bars in a reinforcing bar mesh welding process, prevents reinforcing bars from inclining in the welding process to affect welding quality, is simple to operate, and convenient to use.

Owner:JINAN HUAXIN AUTOMATION ENG

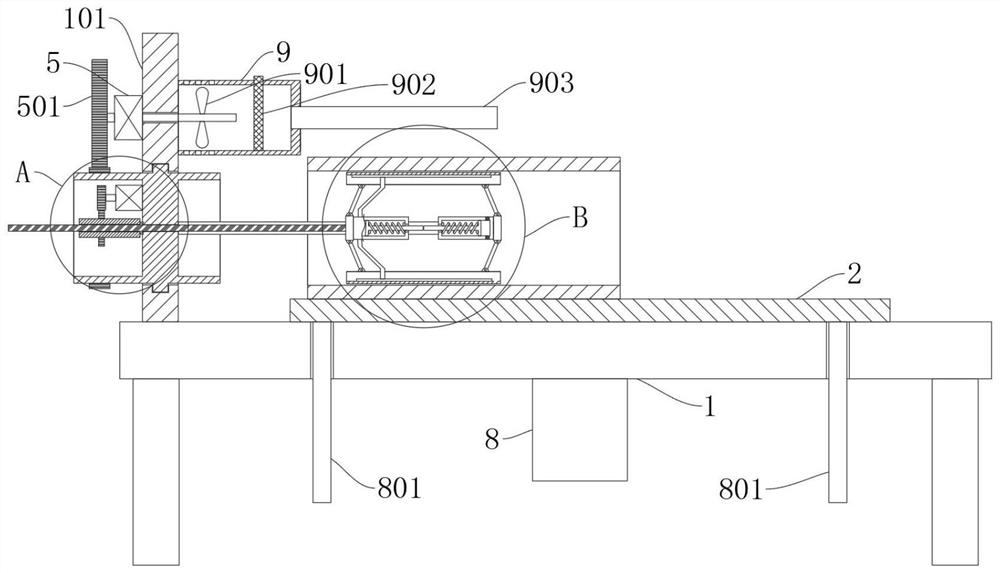

Welding device of saw blade

ActiveCN104476060AAvoid contactAvoid burnsMetal sawing tool makingWelding/cutting auxillary devicesManufacturing technologyCircular saw

The invention relates to the technical field of stone manufacture, and in particular relates to a welding device of saw blade. The welding device of saw blade comprises an induction heating device, a circular saw blade fixing mechanism and a welding piece fixing mechanism, the induction heating device is fixed on the circular saw blade fixing mechanism, the welding piece fixing mechanism is mounted at the top of the circular saw blade fixing mechanism; the circular saw blade fixing mechanism comprises a pedestal, a protal frame, a first sliding shaft, a sliding support plate, a saw blade fixing shaft, a first screw and a motor; the first sliding sleeves are respectively fixed at two sides of the sliding support plate, a fastening nut is connected to the saw blade fixing shaft, a first screw sleeve is fixed at one side of the sliding support plate; the welding piece fixing mechanism comprises a vertical plate, a horizontal plate, a pressing block, a horizontal adjusting plate and an adjusting wheel. The large scale circular saw blade can be fixed through the welding device of saw blade and the diameter of the welding device is 2-3m, the welding quality is impacted, the circular saw blade is rotated for welding the next welding piece and the work efficiency is greatly raised.

Owner:天下石仓(天津)有限公司

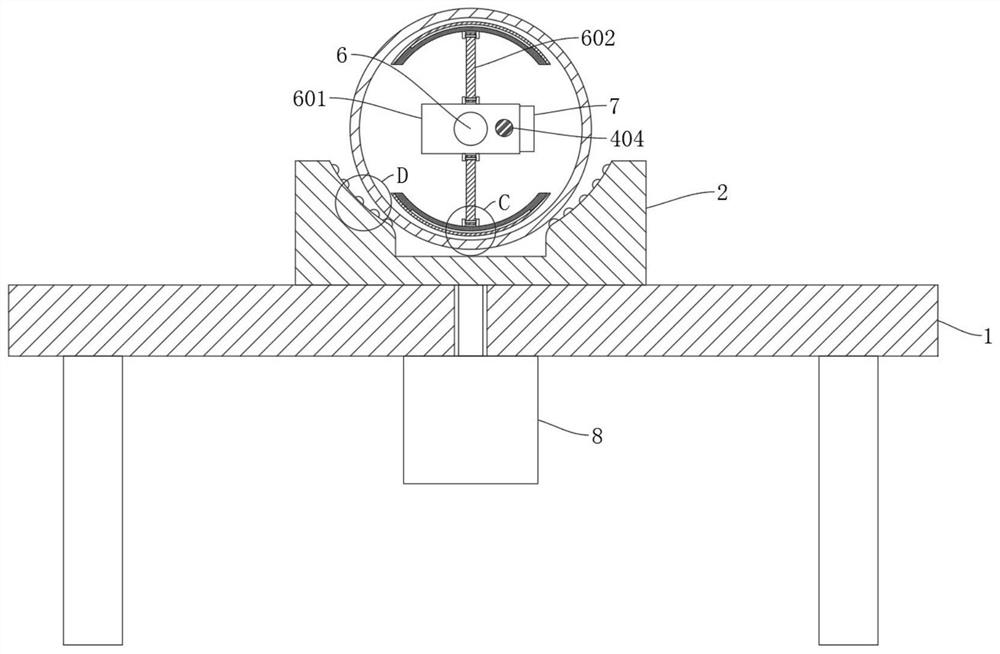

Multi-angle non-dead-angle welding device and using method thereof

InactiveCN113732580AAchieve weldingRealize multi-angle welding without dead angleWelding/cutting auxillary devicesAuxillary welding devicesElectric machineryEngineering

The invention discloses a multi-angle non-dead-angle welding device and a using method thereof, and relates to the technical field of welding. The multi-angle non-dead-angle welding device comprises a workbench; a first motor is installed at the bottom of the workbench; a rotating rod is fixedly connected to the output end of the first motor; the rotating rod penetrates through the workbench; a rotating disc is fixedly connected to the output end of the rotating rod; a workpiece is arranged on the surface of the rotating disc; a riser is fixedly connected to the surface of the workbench; a first groove is formed in the side wall of the riser; a second motor is installed at the upper end of the riser; a first screw rod is fixedly connected to the output end of the second motor; the first screw rod penetrates through the riser; a first moving plate is in threaded connection to the outer wall of the first screw rod; the first moving plate is slidably connected into the first groove; the surface of the first moving plate is connected with a welding gun through a first supporting plate; and the position of the welding gun in the Z-axis direction can be adjusted by controlling the second motor, and the angle of the workpiece in the X-Y plane can be adjusted by controlling the first motor, so that multi-angle welding of the workpiece is implemented.

Owner:南京领易科技有限公司

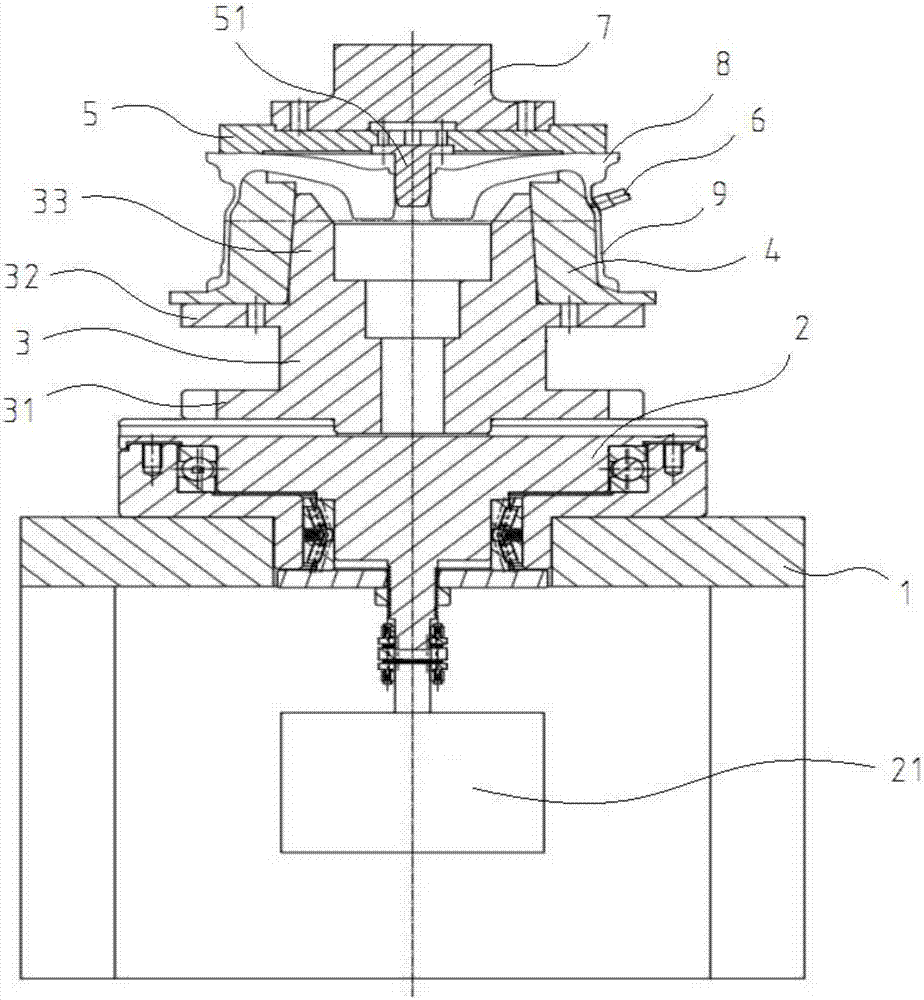

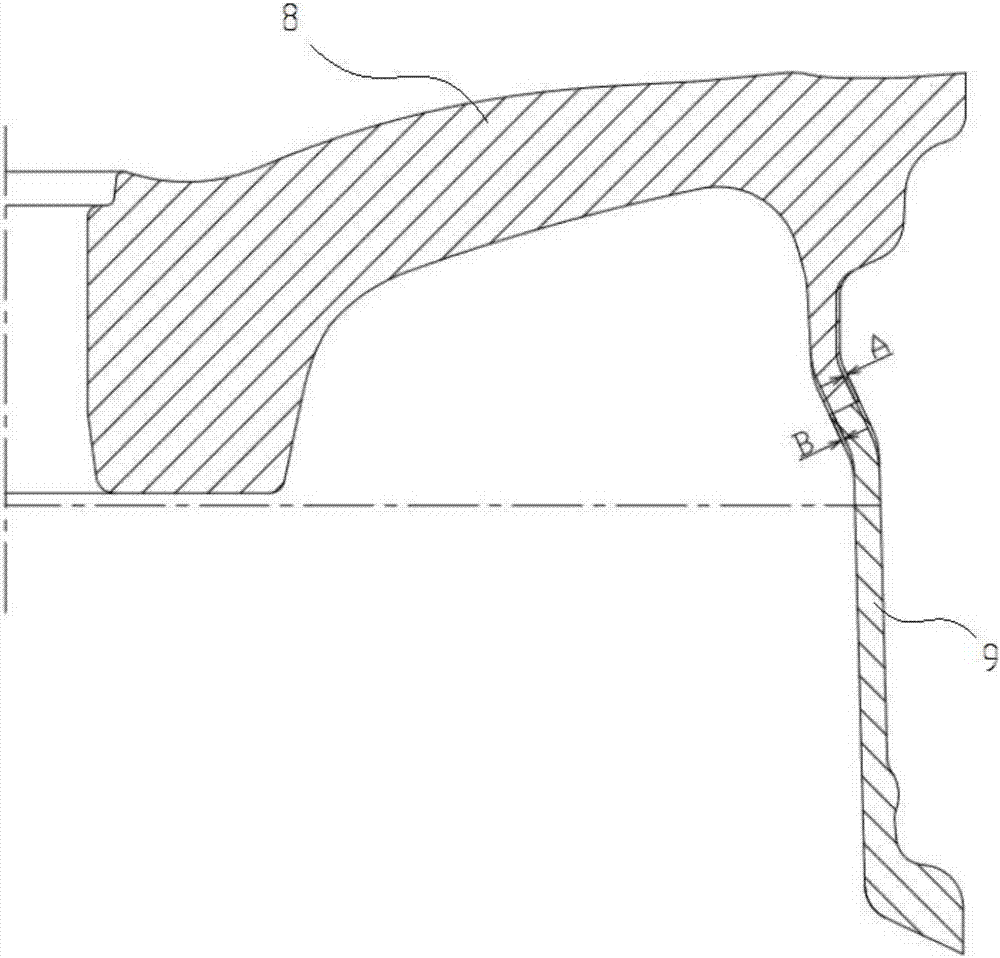

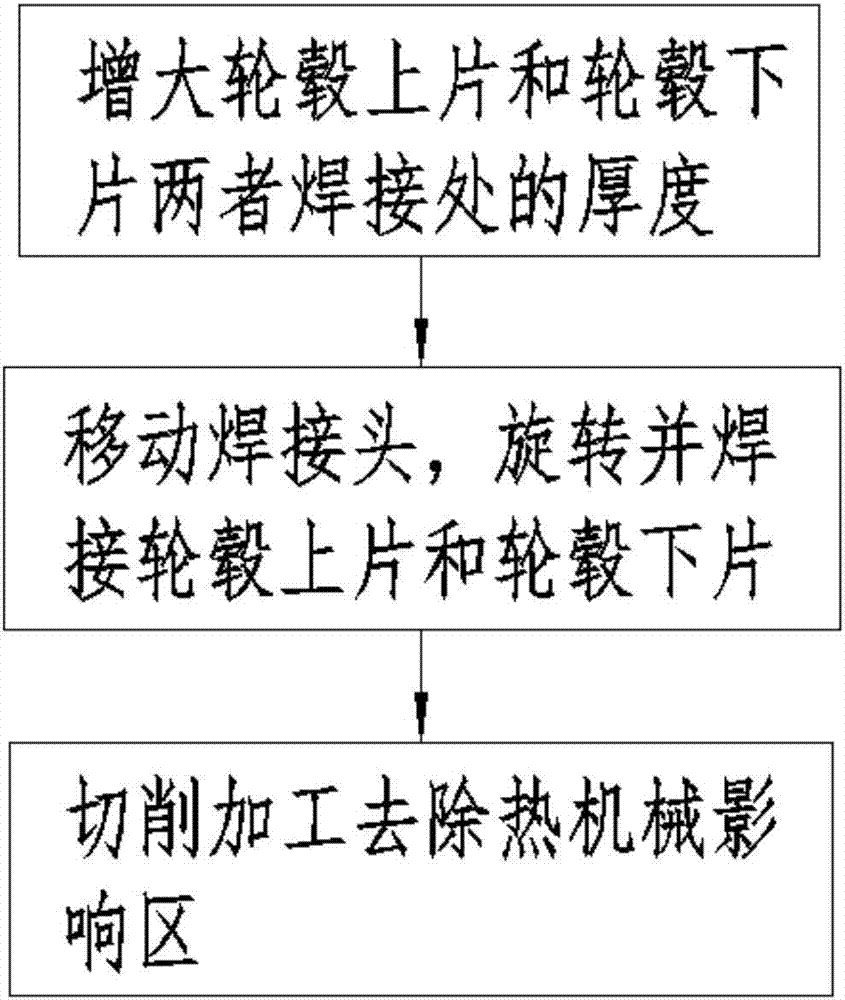

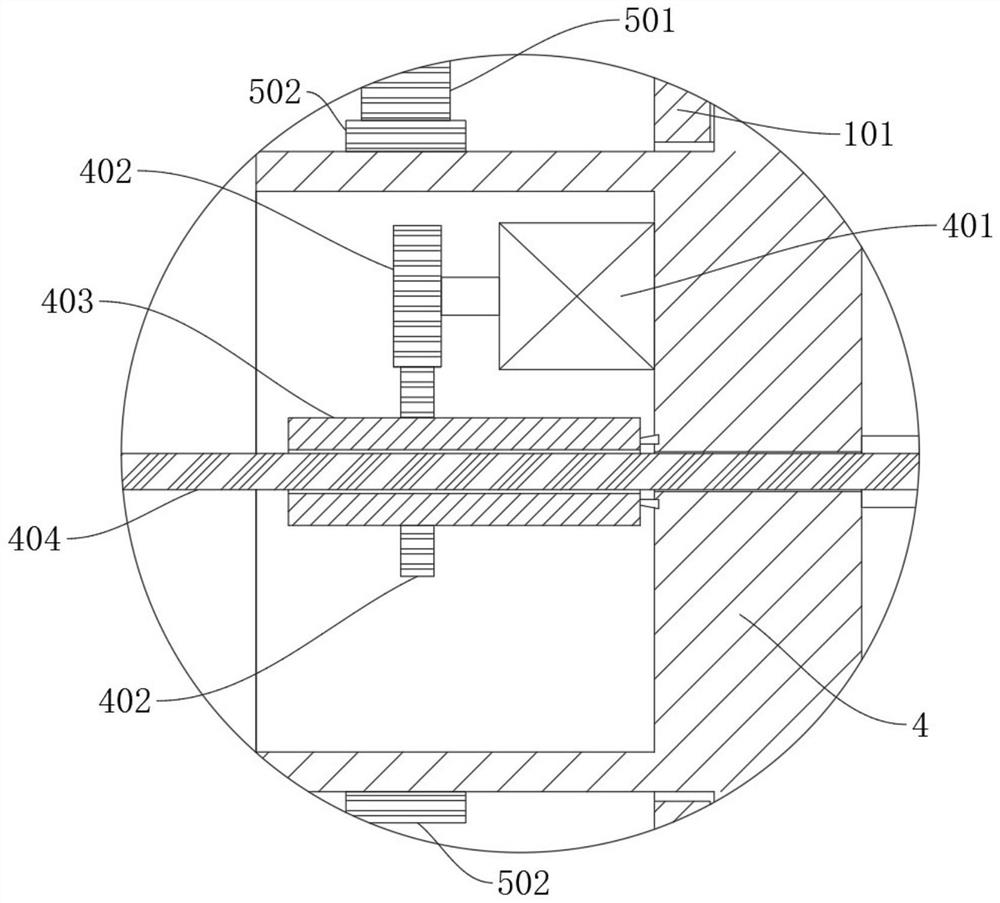

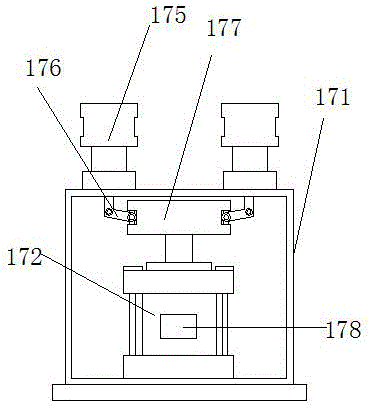

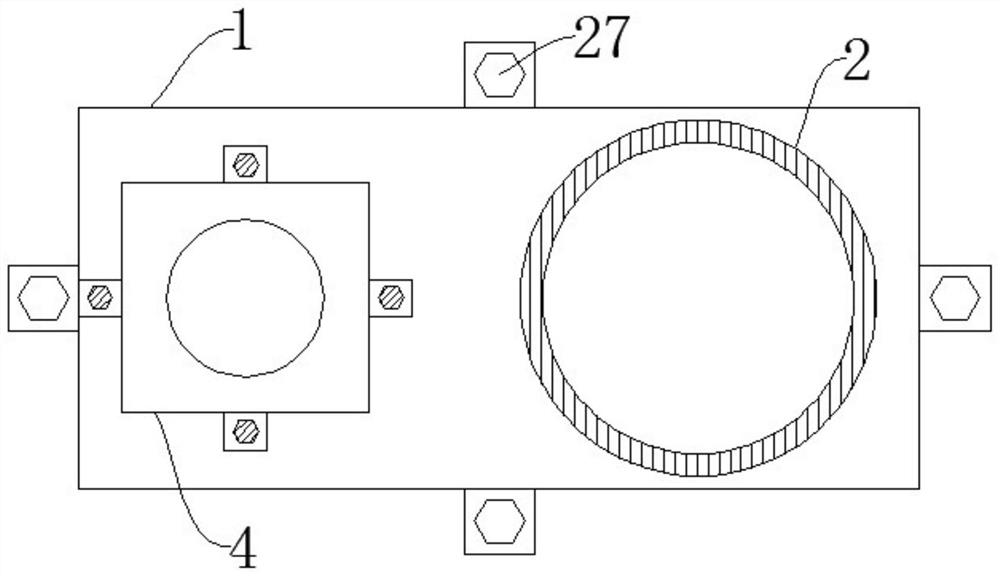

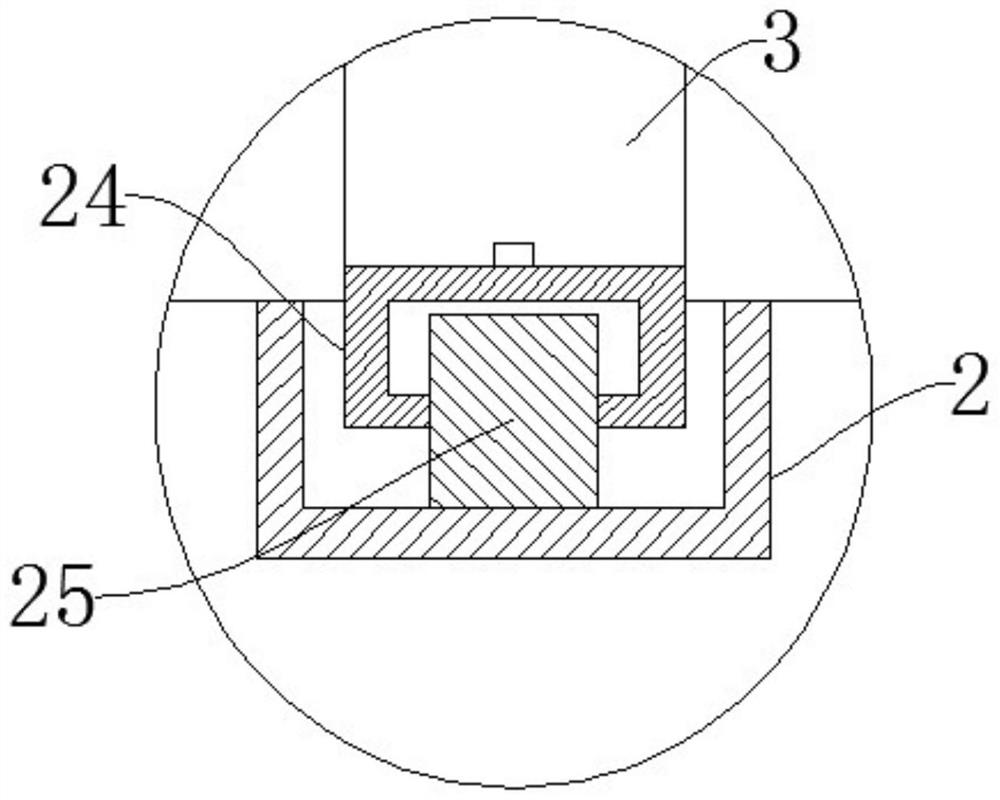

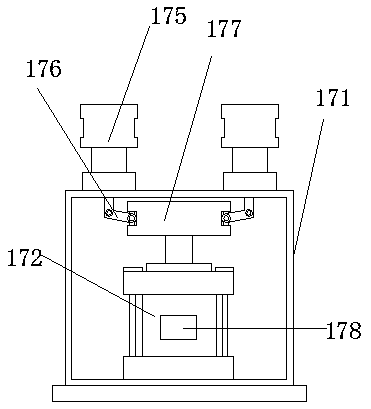

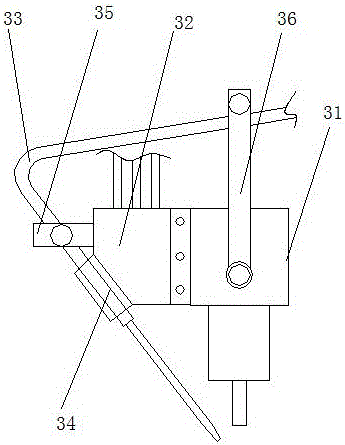

Friction-stir welding blank-making device for aluminium alloy hub, and treatment process thereof

ActiveCN107116298APrecise positioningEasy to installVehicle componentsMetal working apparatusCompression deviceAlloy wheel

The invention provides a friction-stir welding blank-making device for an aluminium alloy hub, and a treatment process thereof, and belongs to the technical field of hub welding. The friction-stir welding blank-making device for the aluminium alloy hub comprises a rotary device arranged on a workbench, a location device arranged on the rotary device and a compression device arranged on the location device, wherein the compression device comprises a compression head arranged on a lower hub sheet in a sleeving manner and a compression disc compressing an upper hub sheet. According to the friction-stir welding blank-making device for the aluminium alloy hub, and the treatment process thereof, the upper hub sheet with a thickened weld and the lower hub sheet with a thickened weld are installed between the rotatable compression head and compression disc, and welding for the upper hub sheet and the lower hub sheet is realized through rotation and in combination with the welding of a welding head, so that production for the hub is realized; and the hub is subjected to cutting machining after being welded, a thermal mechanical affected zone formed due to welding is removed, and the consistency of the performance of the welds and the performance of a matrix is ensured, so that a better product quality and a wider application range are achieved.

Owner:宁波路威汽车轮业有限公司

Steel welding process

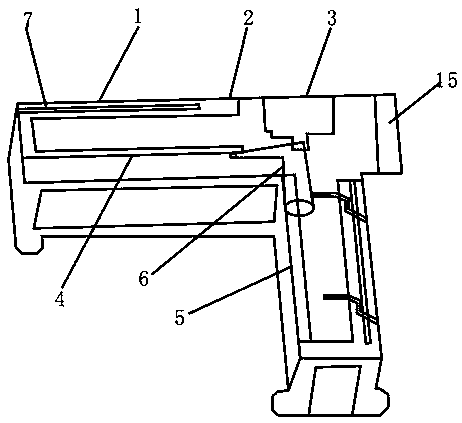

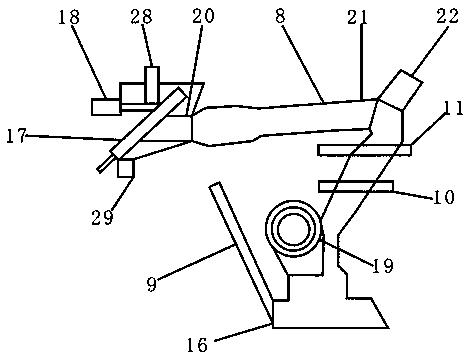

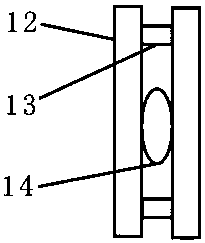

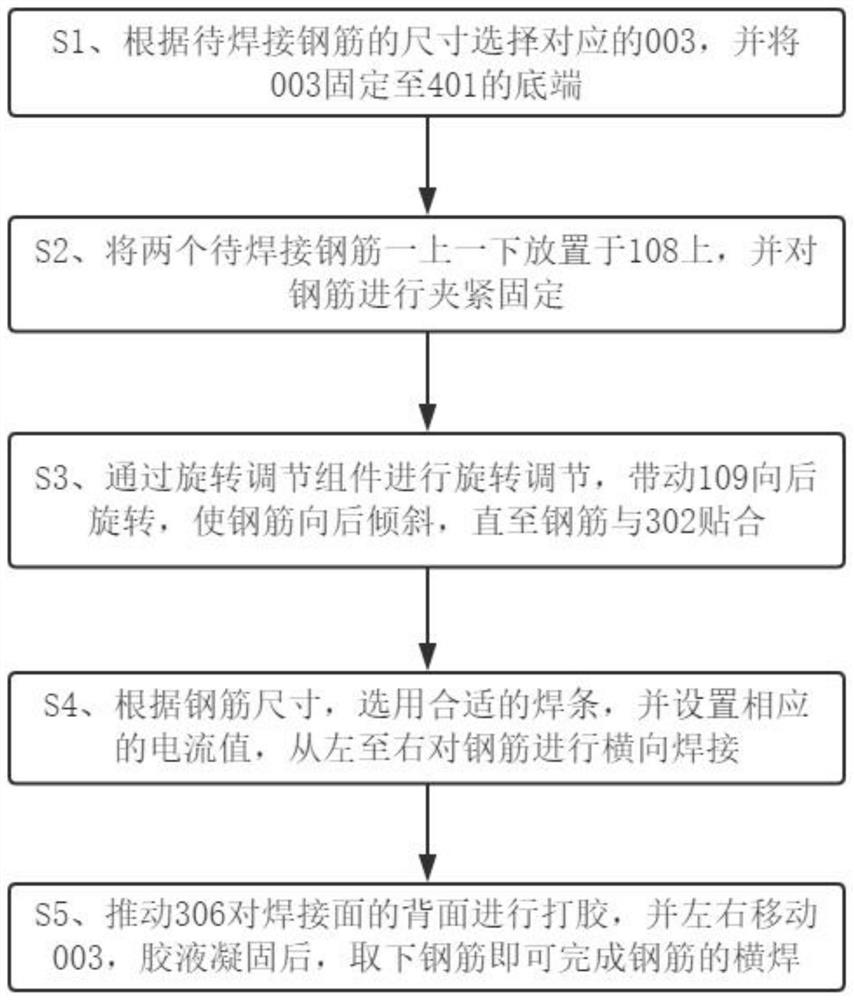

ActiveCN112427761AEasy to adjustImprove comfortLiquid surface applicatorsCoatingsRebarUltimate tensile strength

The invention discloses a steel welding process, and belongs to the technical field of steel welding. A convenient auxiliary device matched with the process for use is arranged, the comfort degree ofwelding personnel can be greatly improved, the fatigue of the welding personnel is relieved, and a rotary adjusting assembly in the convenient auxiliary device can rotate reinforcing steel bars to incline backwards and be fixed during welding, so that the welding personnel performs welding operation conveniently, molten iron is effectively prevented from falling down in the welding process, the welding quality and the welding efficiency are improved, a specially-made gluing and reinforcing assembly is further arranged, gluing can be conveniently conducted on the back faces of the welding facesof the reinforcing steel bars, the connecting strength between the reinforcing steel bars is greatly enhanced, a connecting adjusting assembly matched with the gluing and reinforcing assembly is arranged, the connecting adjusting assembly can play a role in supporting and connecting the gluing and reinforcing assembly, meanwhile, the gluing and reinforcing assembly can slide leftwards and rightwards conveniently, the gluing area is enlarged, and the height of the gluing and reinforcing assembly can be adjusted.

Owner:广西天正钢结构有限公司

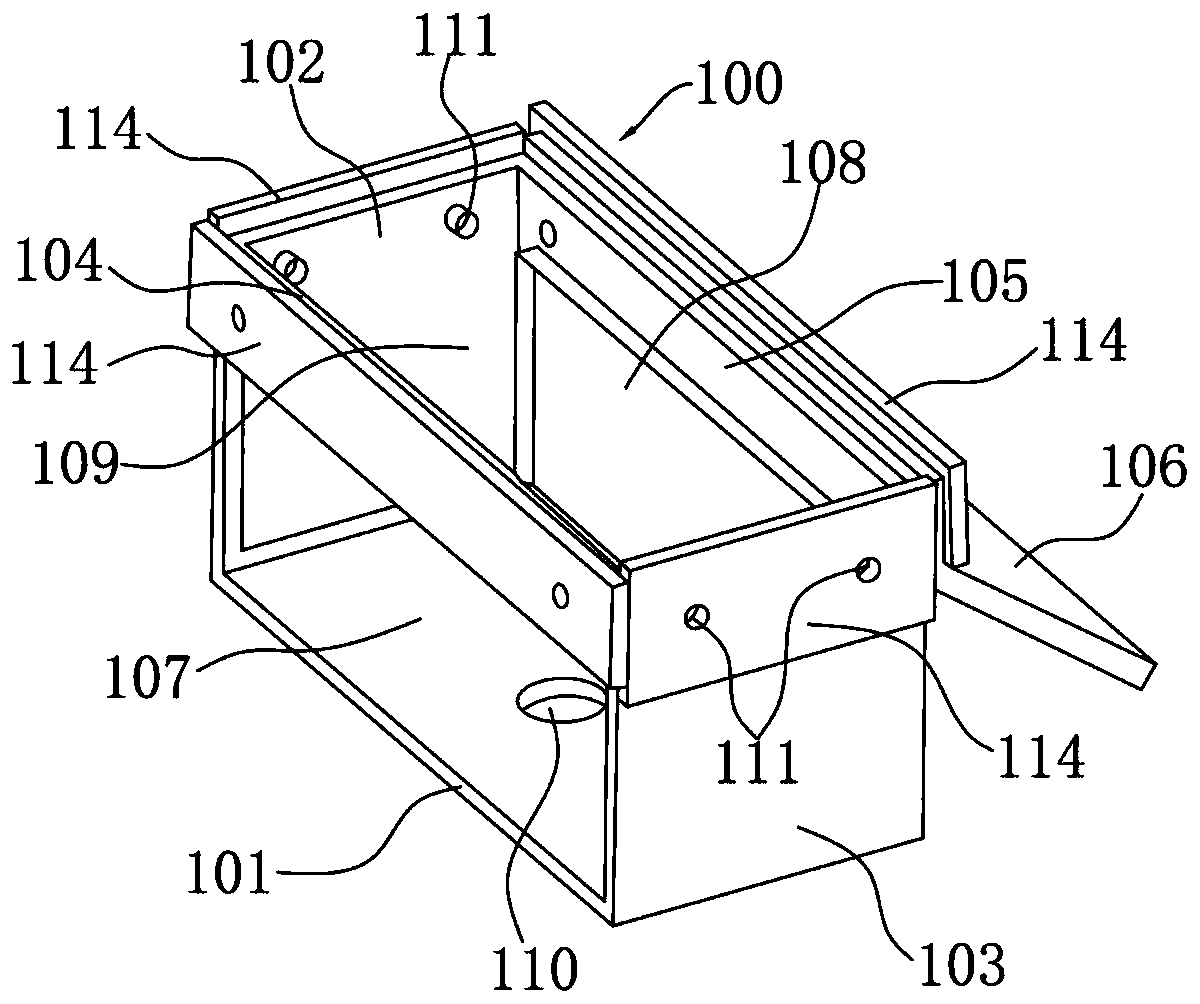

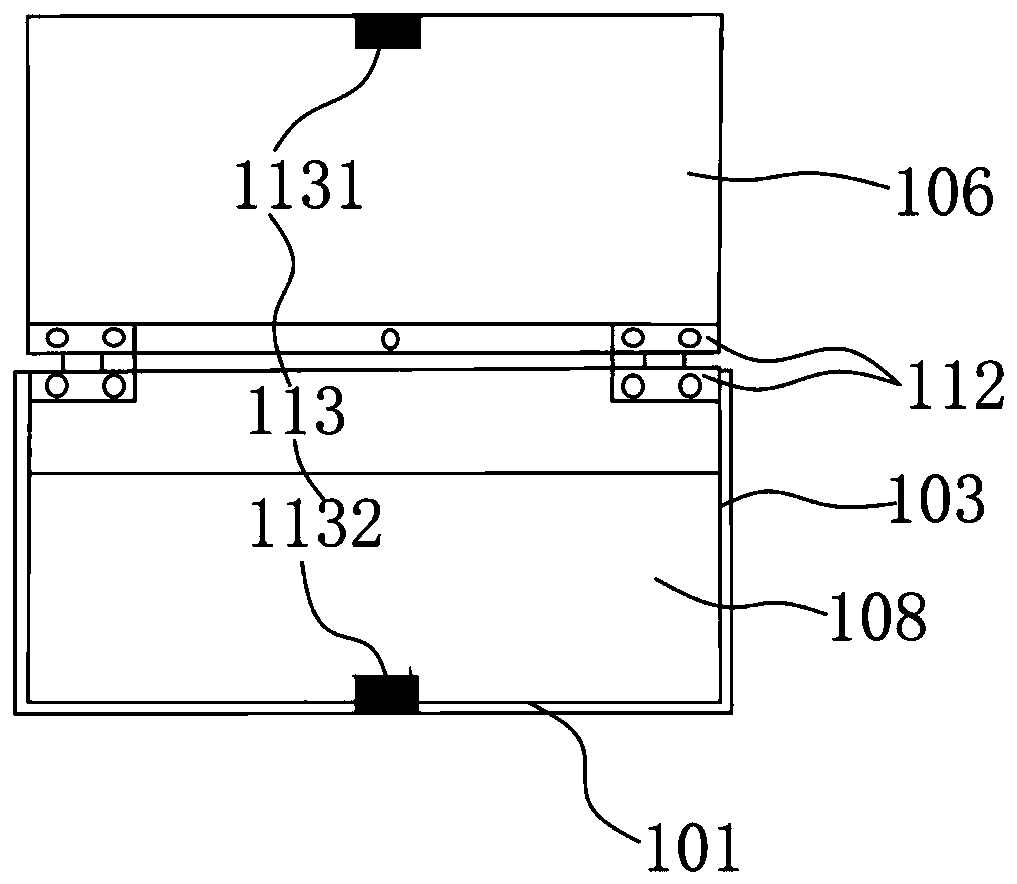

Windproof auxiliary welding tool

InactiveCN111390444AGuaranteed visibilityGuaranteed aestheticsWelding/cutting auxillary devicesAuxillary welding devicesWeld seamFastener

The invention relates to the technical field of welding tools and discloses a windproof auxiliary welding tool. The upper portion of a tool frame body is opened to form a welding observation area, welding personnel can carry out welding operation conveniently, and the welding process can be monitored in real time. A bottom plate is provided with a welding gun hole for a welding gun to penetrate through. The welding gun penetrates through the welding gun hole and is located in the tool frame body. The tool frame body protects the welding process and has a windproof welding function, the weldinggun is prevented from being exposed to the outside, the influence of outside environment to the welding process is reduced, attractiveness of weld seams is ensured, and it is ensured that a production plan is carried out on schedule. A first side plate or / and a second side plate is / are provided with a connecting hole / connecting holes used for being connected with the welding trolley. By means offasteners such as screws or bolts, the connecting holes and the welding trolley are connected, thus the windproof auxiliary welding tool and the welding trolley are fixedly connected, the auxiliary tool is prevented from shaking in the welding process of the trolley, and the welding quality is influenced.

Owner:CSSC HUANGPU WENCHONG SHIPBUILDING COMPANY

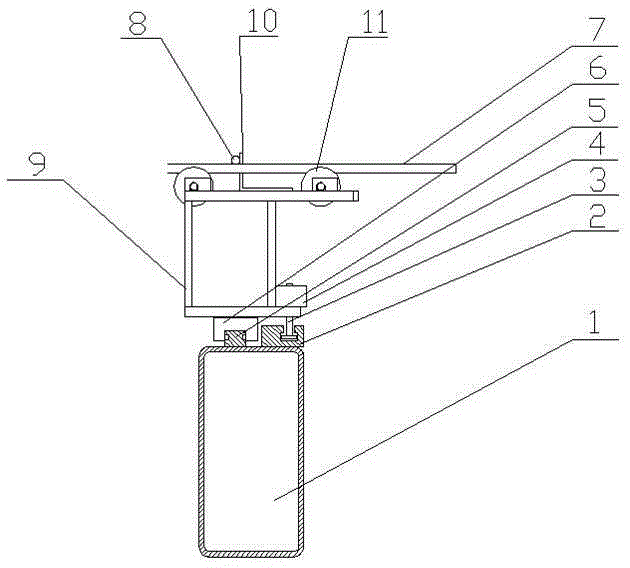

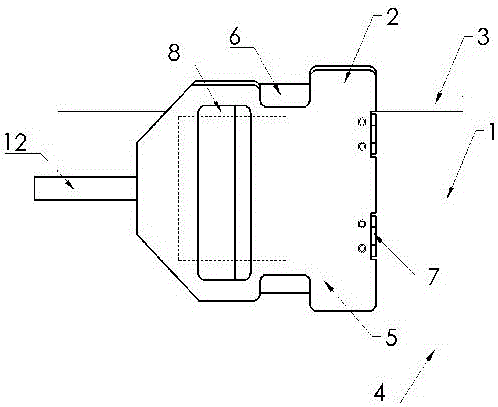

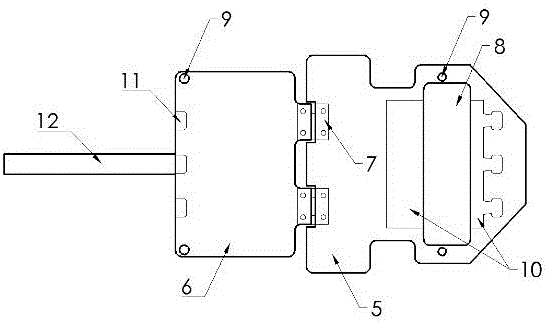

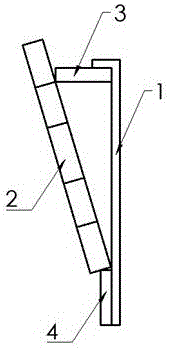

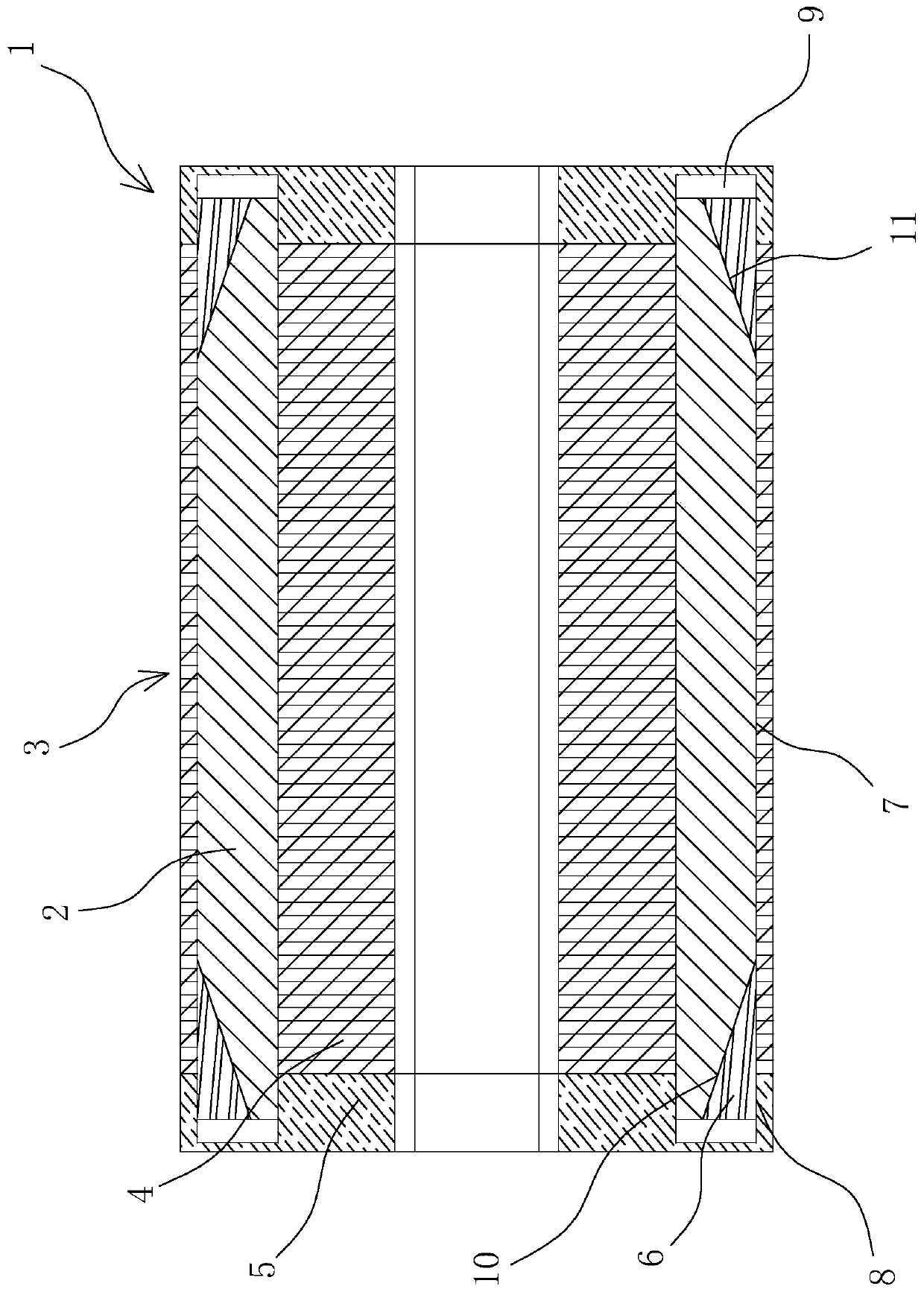

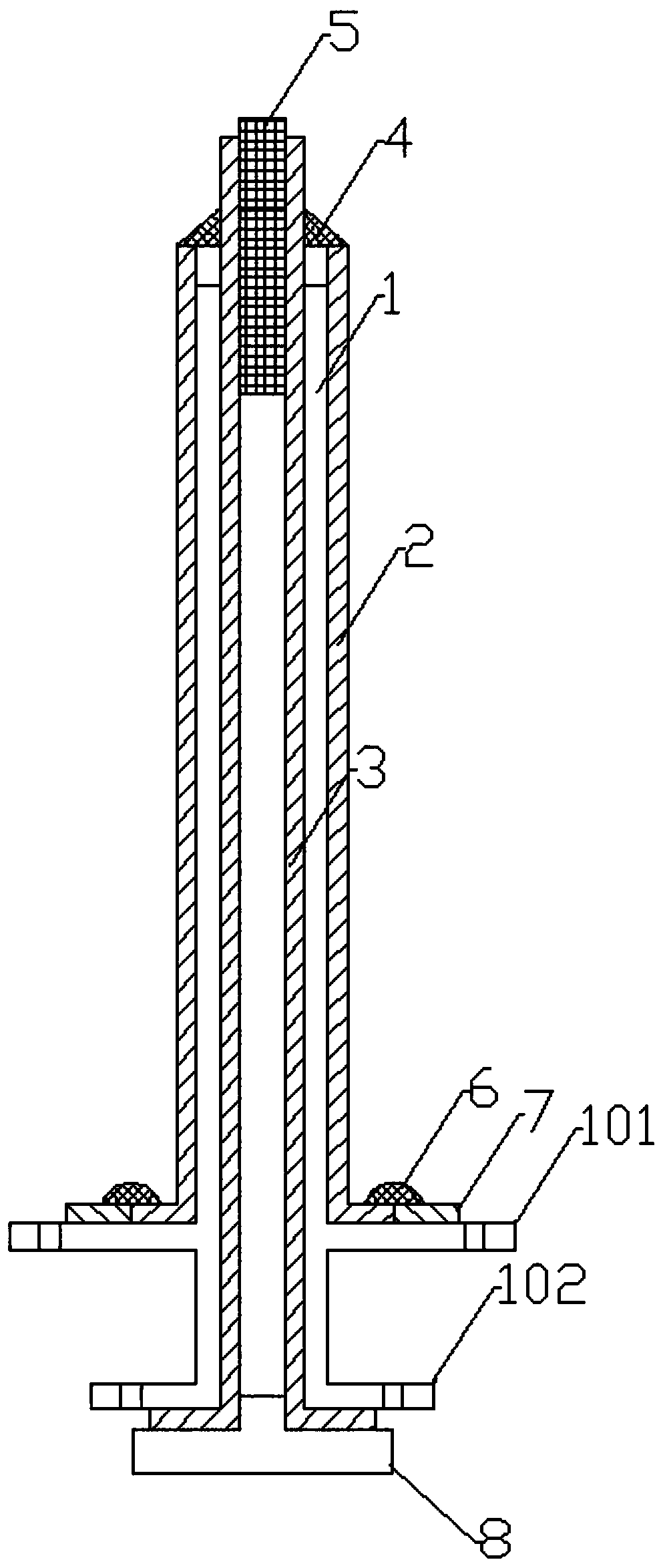

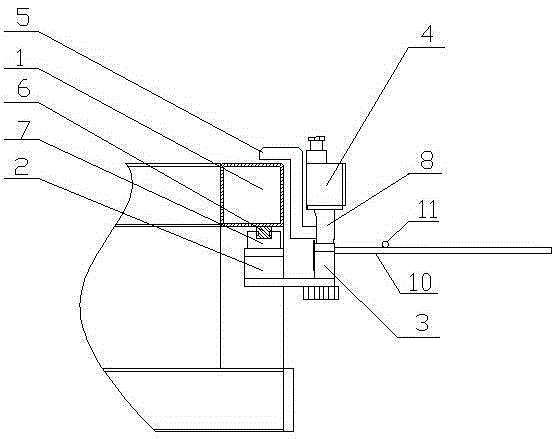

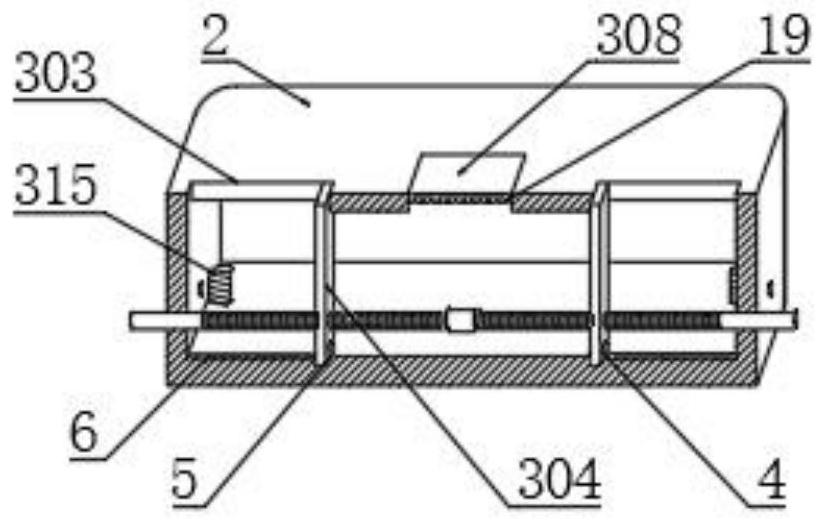

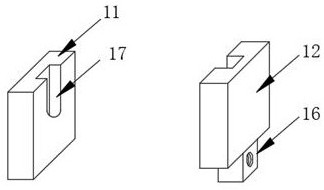

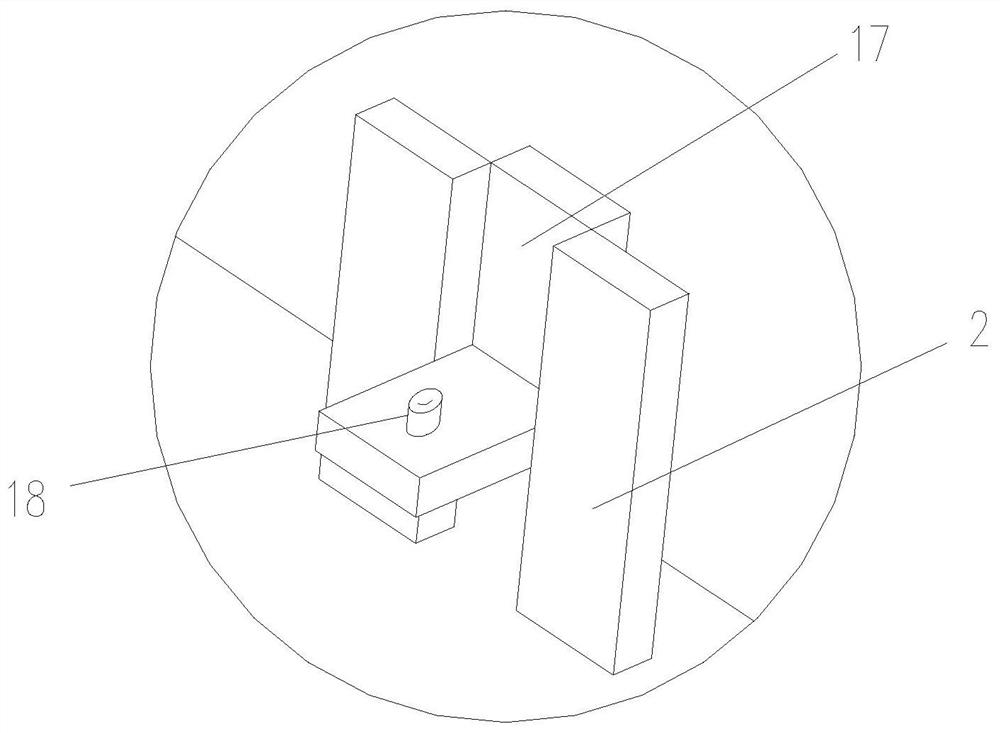

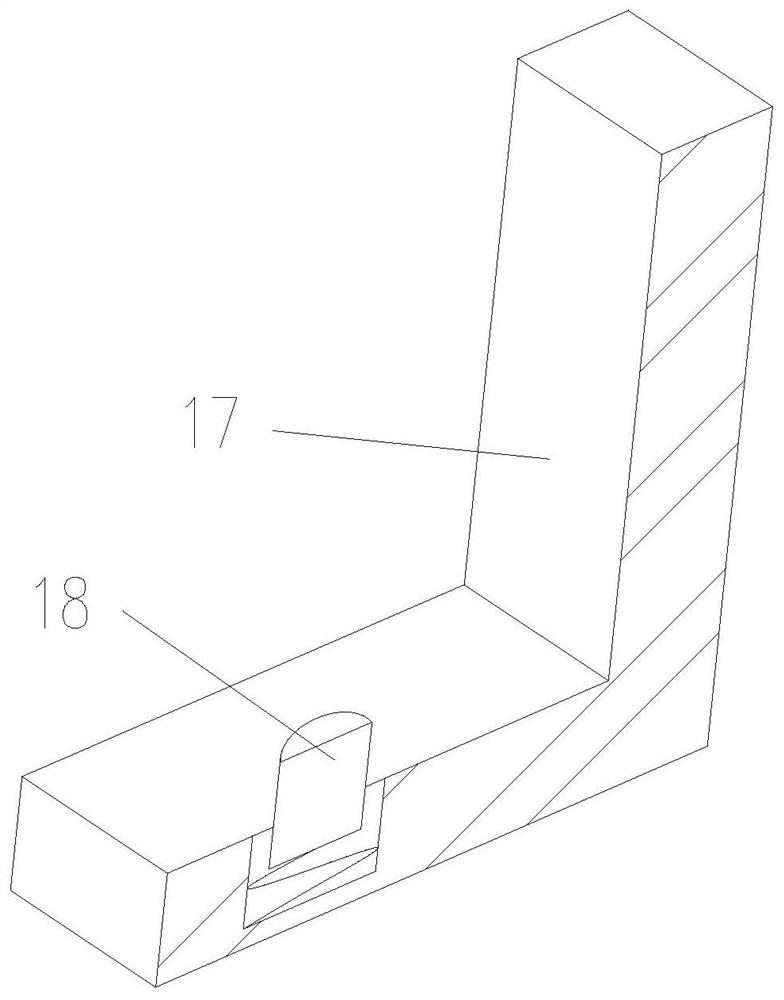

Portable PCB needle file welding jig

InactiveCN106077879AEasy to operatePrevent affecting welding qualityPrinted circuitsMetal working apparatusIndependent elementEngineering

Disclosed is a portable PCB needle file welding jig. The portable PCB needle file welding jig comprises an auxiliary station (1) and a welding jig body (2). Both the auxiliary station (1) and the auxiliary jig body (2) are independent elements. The upper end of the auxiliary station (1) is fixedly provided with a supporting block (3) and the lower end of the auxiliary station (1) is fixedly provided with a limiting block (4). The welding jig body (2) is composed of an upper clamping plate (5) and a lower clamping plate (6). The upper clamping plate (5) is movably connected with the lower clamping plate (6) through connecting pieces (7). The upper clamping plate (5) is provided with a welding window (8). Magnet blocks (9) are arranged close to the welding window (8) and magnet blocks (9) are also arranged in the corresponding positions of the lower clamping plate (6). The upper clamping plate (5) is closely clamped to the lower clamping plate (6) through the magnetic blocks (9). The portable PCB needle file welding jig is simple in structure and greatly improves the welding quality and working efficiency.

Owner:JIANGSU FUXIN ELECTRONICS LIGHTING TECH

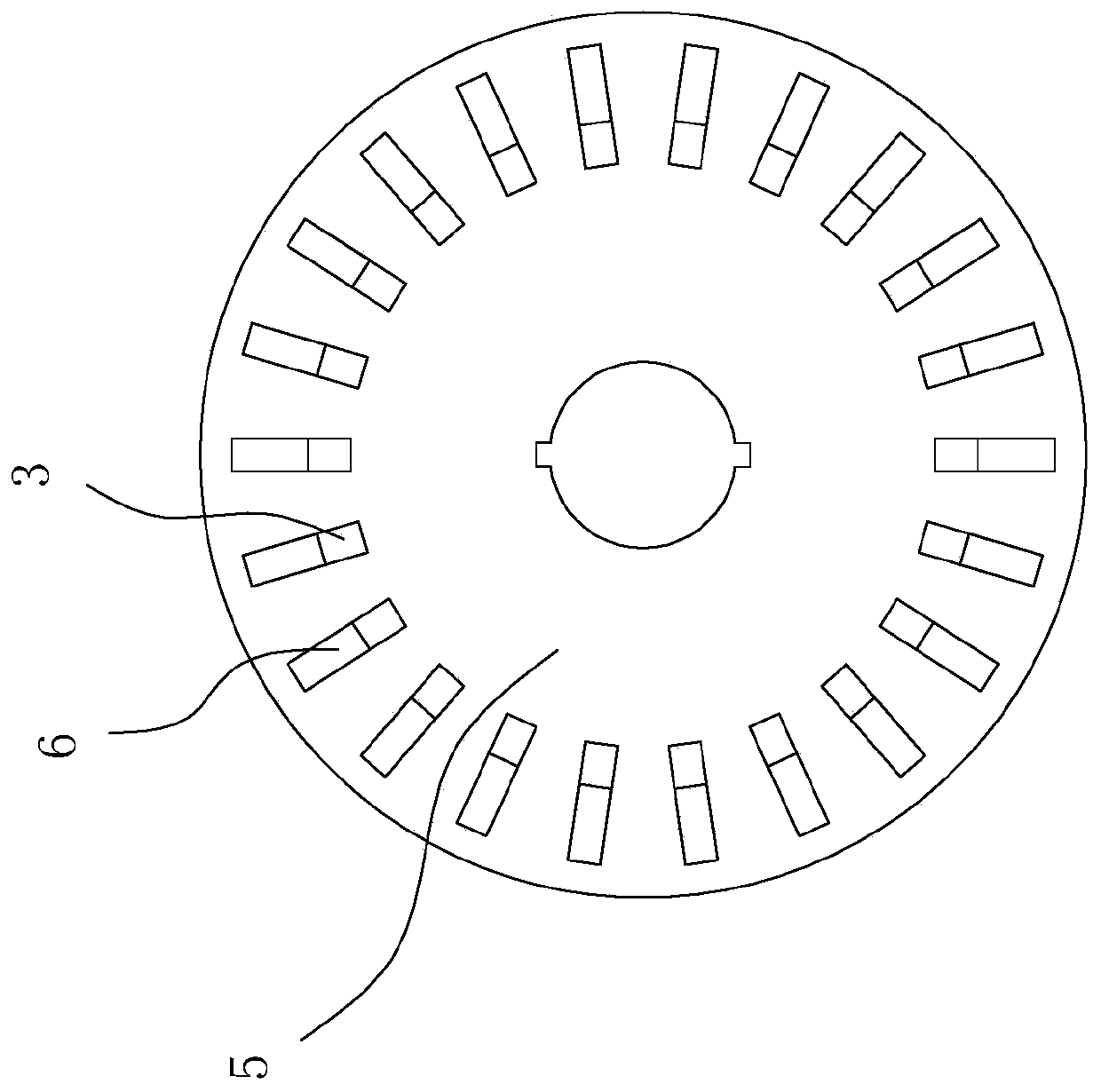

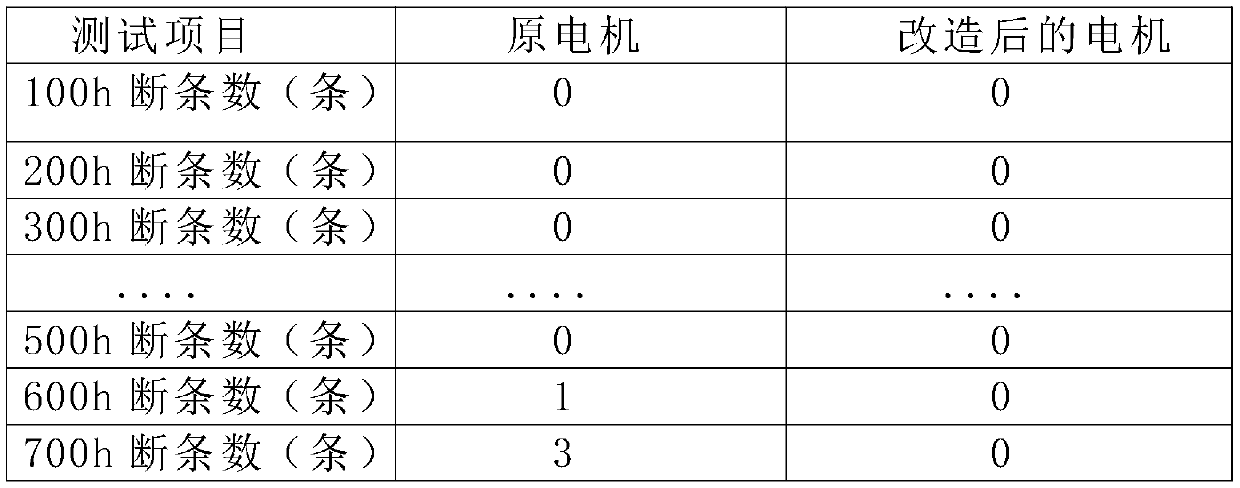

Transformation method for making motors never have bar breaking fault

ActiveCN110299802AEffective tensionLarge starting torqueAsynchronous induction motorsManufacturing cage rotorsEngineeringWeld seam

The invention provides a transformation method for making motors never have a bar breaking fault, which belongs to the technical field of motors. A motor rotor is composed of rotor cage bars, an ironcore and end rings. The rotor cage bars are inserted into the iron core. Each of the two ends of the iron core is sleeved with one end ring. The rotor cage bars are high-precision trapezoidal copper bars made of T2 red copper. The end rings are T2 red copper forging parts. The rotor cage bars of a trapezoidal copper bar structure can be prevented from being broken because of favorable factors suchas good heat dissipation, effective tightening of the copper bars and large starting torque. By using the rotor cage bars made of high-precision trapezoidal copper bars together with high-precision bar guide slots, the rotor cage bars can be prevented from being broken when the weld seams between the rotor cage bars and the end rings are cracked by shaking due to the loosening of the bar guide slots during the working of the motor.

Owner:上海电机集团梅山电机有限公司

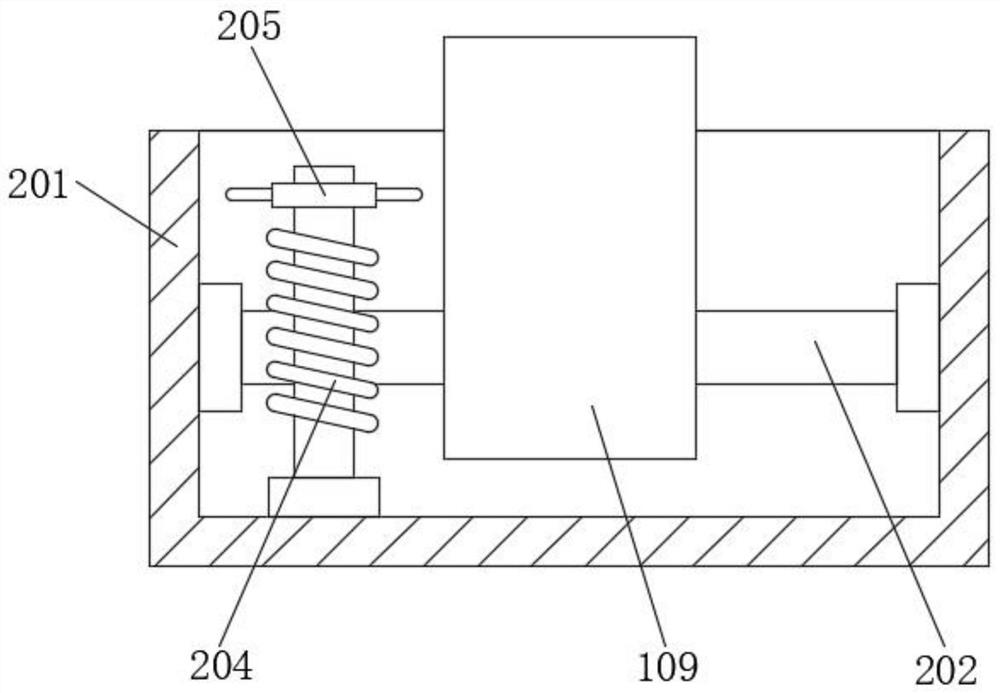

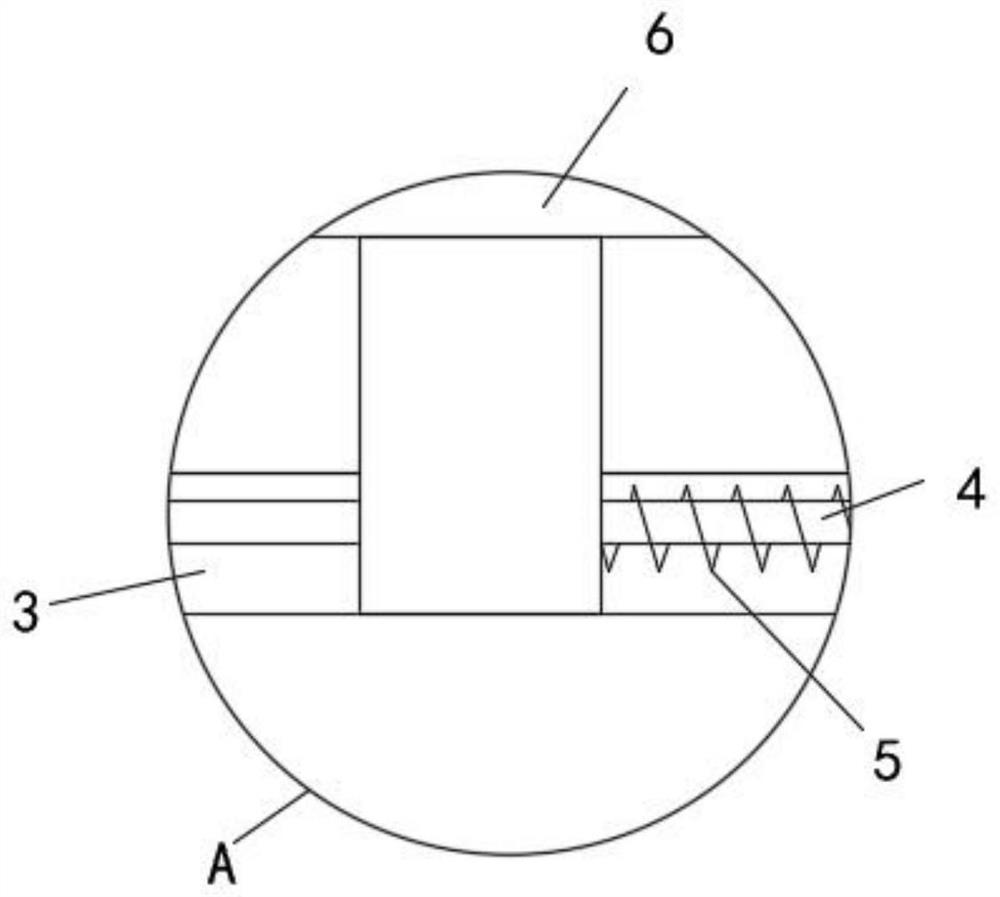

Spot welding tool for hose support assembly

InactiveCN112372200APrecise positioningPrevent affecting welding qualityWelding/cutting auxillary devicesAuxillary welding devicesElectric machinerySlide plate

The invention discloses a spot welding tool for a hose support assembly. The spot welding tool comprises two oppositely-arranged supporting seats; a positioning table is fixed to the top ends of the two supporting seats; positioning grooves are formed in the two sides of the top of the positioning table; transverse rods are assembled on the two sides of the inner walls of the positioning grooves;the outer parts of the transverse rods are sleeved with reset springs; one end of each reset spring is fixedly matched with an extrusion plate; upper clamping plates are elastically connected to the sides, close to each other, of the two extrusion plates; extrusion wheels are arranged on the sides, away from each other, of the two extrusion plates in a contact mode; L-shaped plates are assembled on the extrusion wheels; sliding plates are fixed to the two sides of the top of the positioning table; first push rod motors are connected between the positioning table and the L-shaped plates; and electric sliding table sets are assembled at the tops of the two sliding plates. The situation that the welding quality is affected due to the fact that a hose support inclines and slides in the spot welding process is prevented, welding can be smoothly conducted, the spot welding quality of the hose support is improved, operation is easy, the practicability is high, and the spot welding tool is suitable for popularization.

Owner:十堰昌旺工贸有限公司

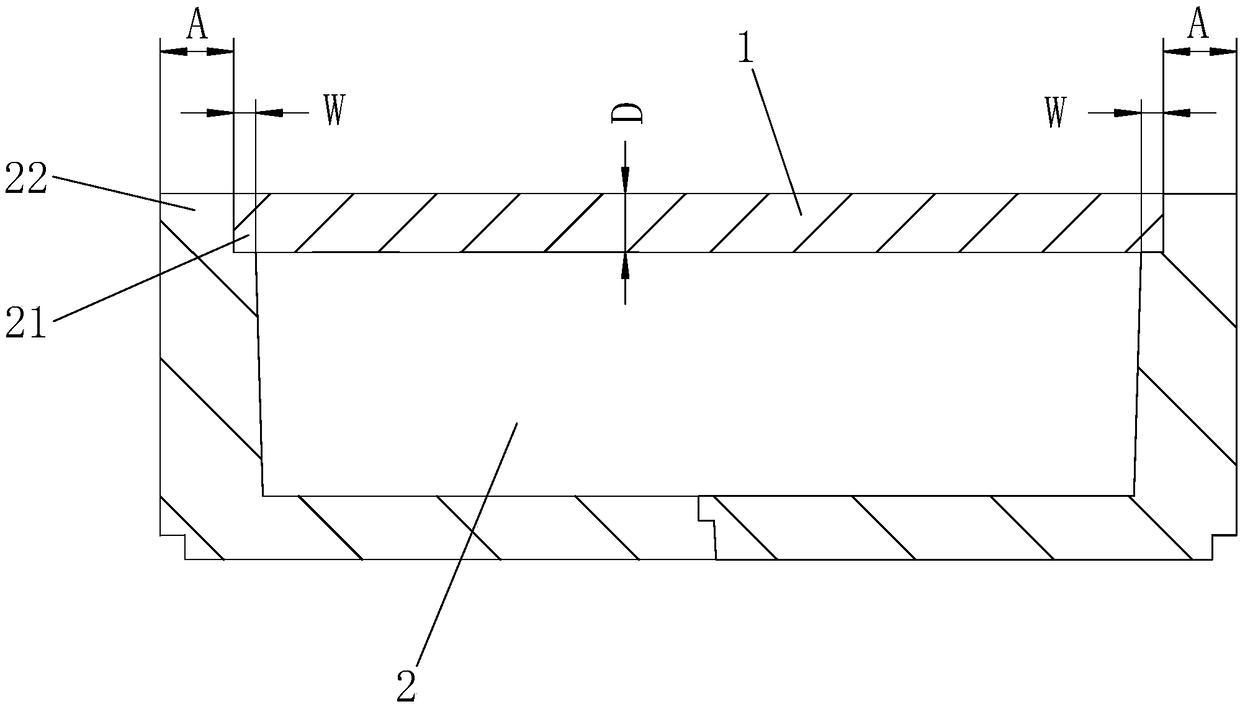

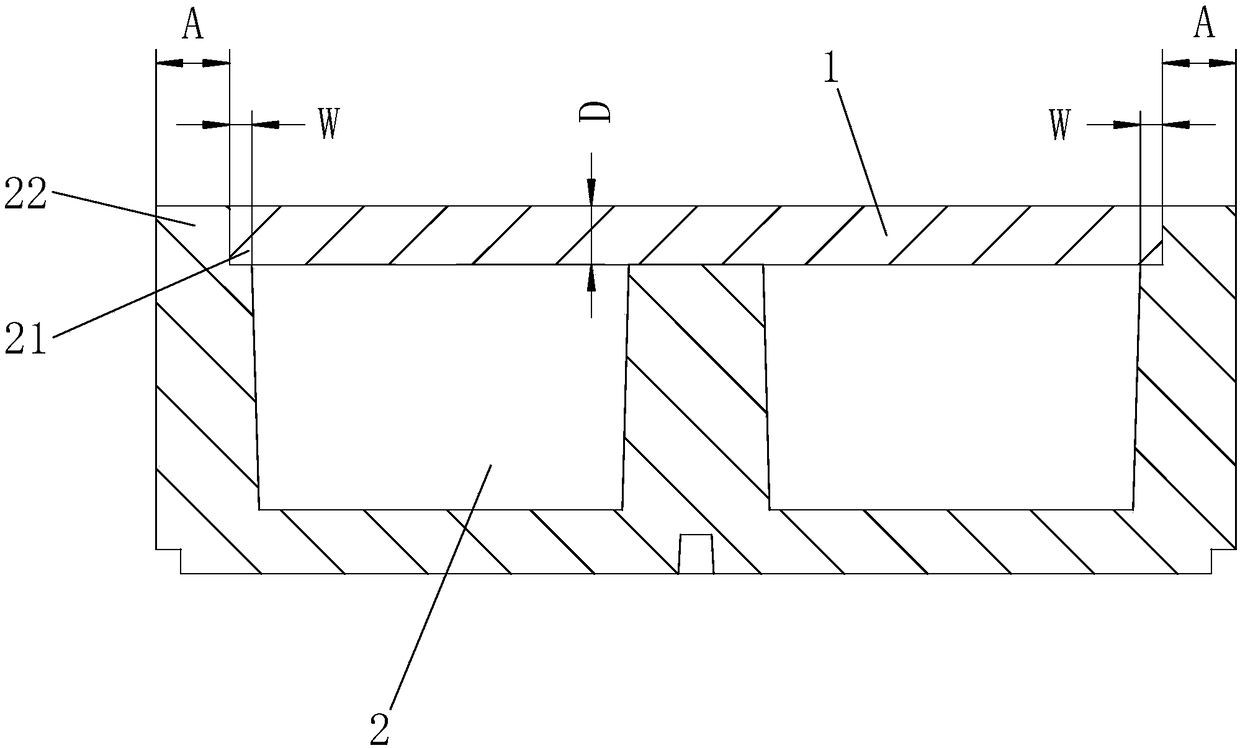

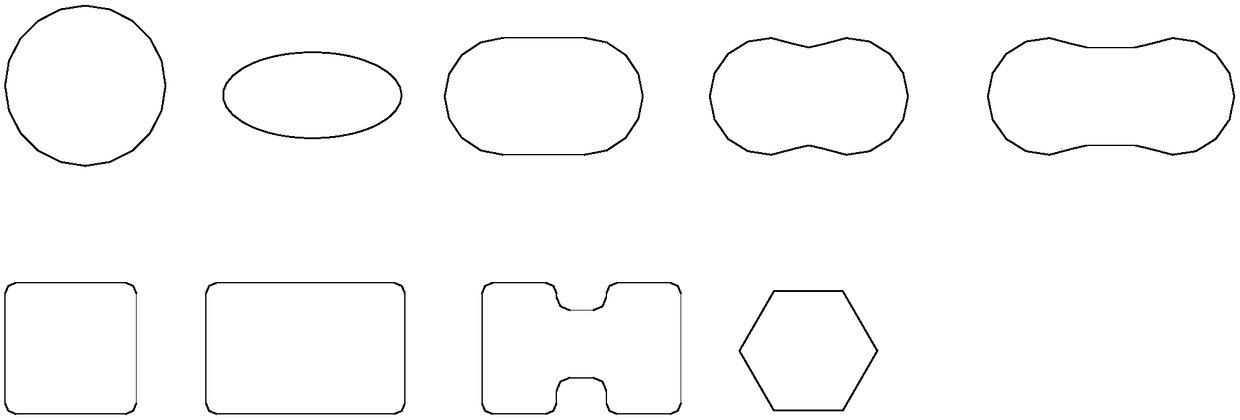

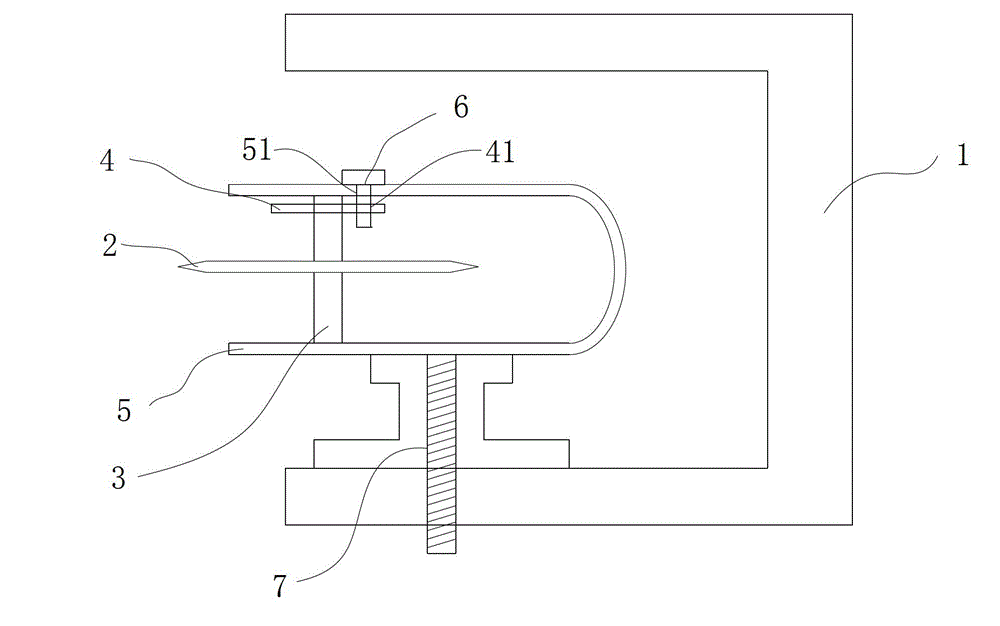

Sealed-type cavity welding connector structure and welding clamp and welding method thereof

PendingCN108145365AAvoid edge saggingRapid positioningWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding defect

The invention discloses a sealed-type cavity welding connector structure. The sealed-type cavity welding connector structure comprises a cavity and a cover plate; a supporting step is arranged on thecavity; a step wall is arranged on an outer side of the supporting step; the thickness of the cover plate is D; the width of the supporting step is W; the thickness of the step wall is A; and when D is smaller than or equal to 8 mm, the thickness A of the step wall is smaller than or equal to D plus 1, and the width W of the supporting step is greater than or equal to 0.5 multiplied by D. A welding clamp comprises a fixing device, a clamping device which is matched with the fixing device to clamp two sides of a workpiece and a supporting and positioning device which is used for supporting andpositioning the workpiece; and the supporting and positioning device is arranged between the fixing device and the clamping device. A welding method comprises fixing, clamping, welding and other steps. The welding connector structure, the welding clamp and the welding method have the advantages of being good in welding quality, applicable to batch welding of special materials, capable of effectively preventing welding defects and the like.

Owner:HUNAN JOINFRONT WELDING TECH

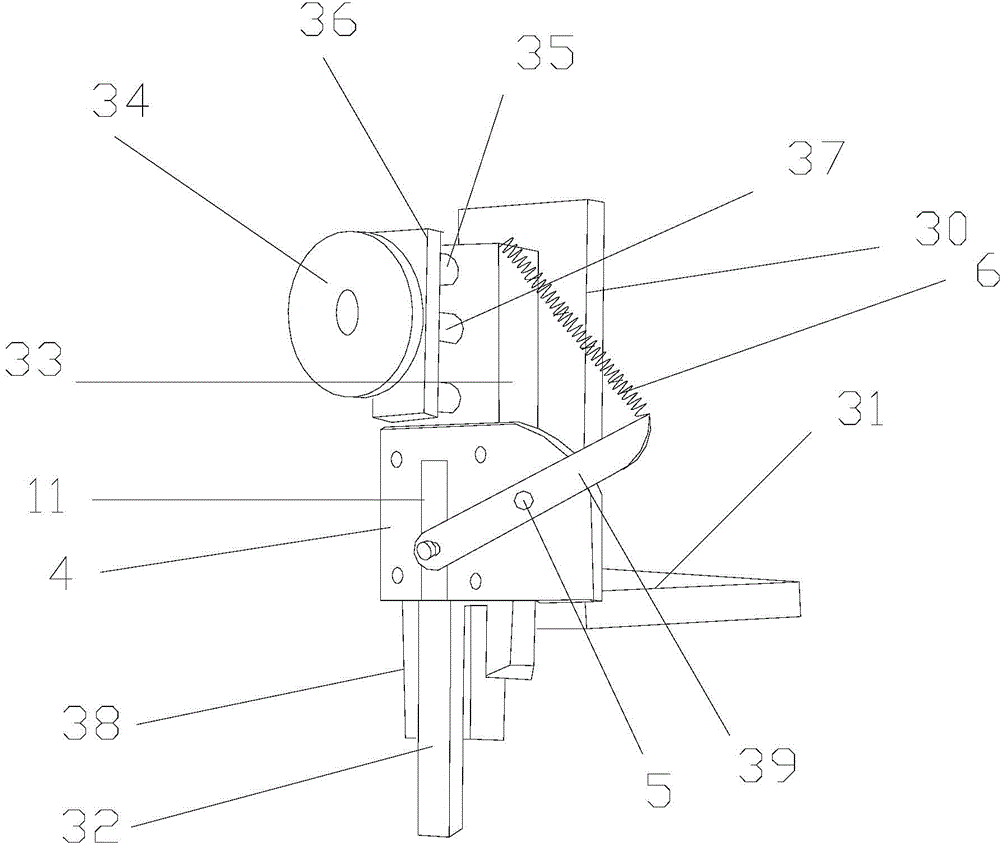

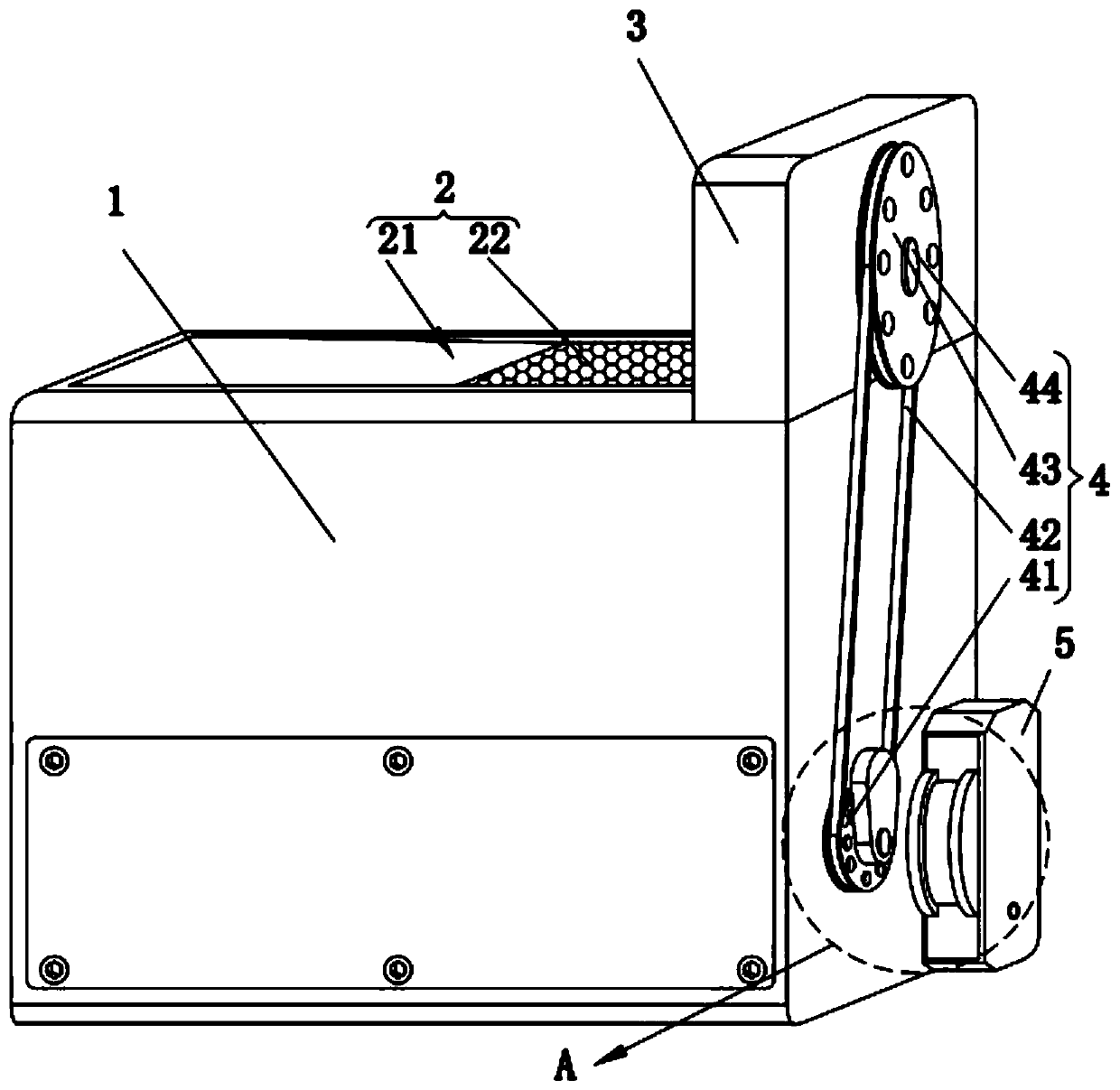

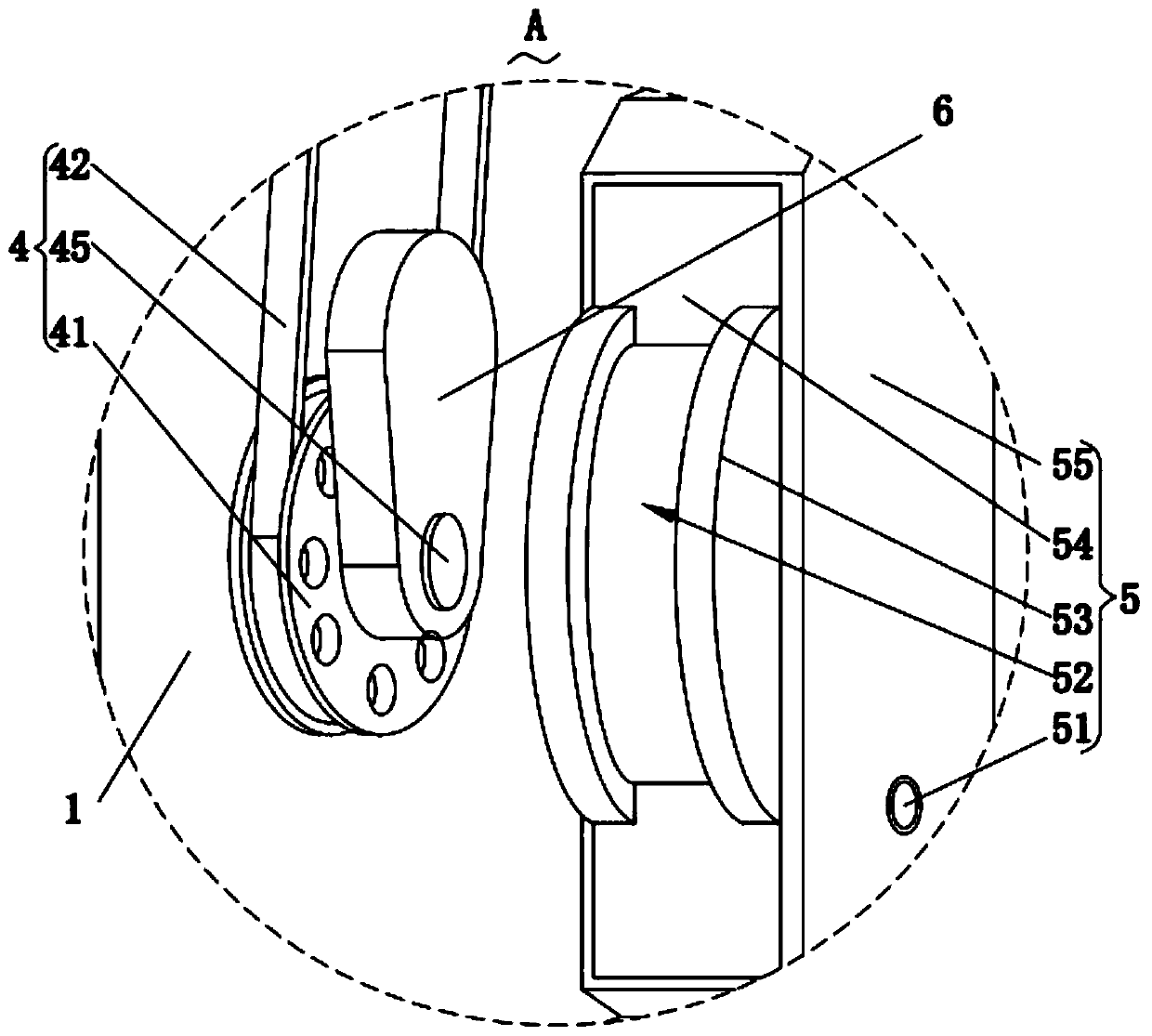

Blade positioning apparatus capable of optimizing optical-fiber cutting quality

ActiveCN103941338APrevent affecting welding qualityEasy to adjustGlass making apparatusCoupling light guidesEngineeringMechanical engineering

The invention relates to a blade positioning apparatus capable of optimizing optical-fiber cutting quality. The apparatus is arranged on a cutting apparatus of an optical-fiber cutting tool. A circular blade on the cutting apparatus is positioned and mounted by the blade positioning apparatus. The blade positioning apparatus comprises a height adjusting mechanism and a cutting-plane conversion mechanism. The circular blade is disposed on the cutting-plane conversion mechanism. The cutting-plane conversion mechanism is arranged on the height adjusting mechanism. The height adjusting mechanism is connected with the cutting apparatus of the optical-fiber cutting tool. Compared with the prior art, the blade positioning apparatus provided by the invention has the advantages of being high in operation efficiency and being capable of optimizing optical-fiber cutting quality.

Owner:SHANGHAI GONGLIAN COMM INFORMATION DEV

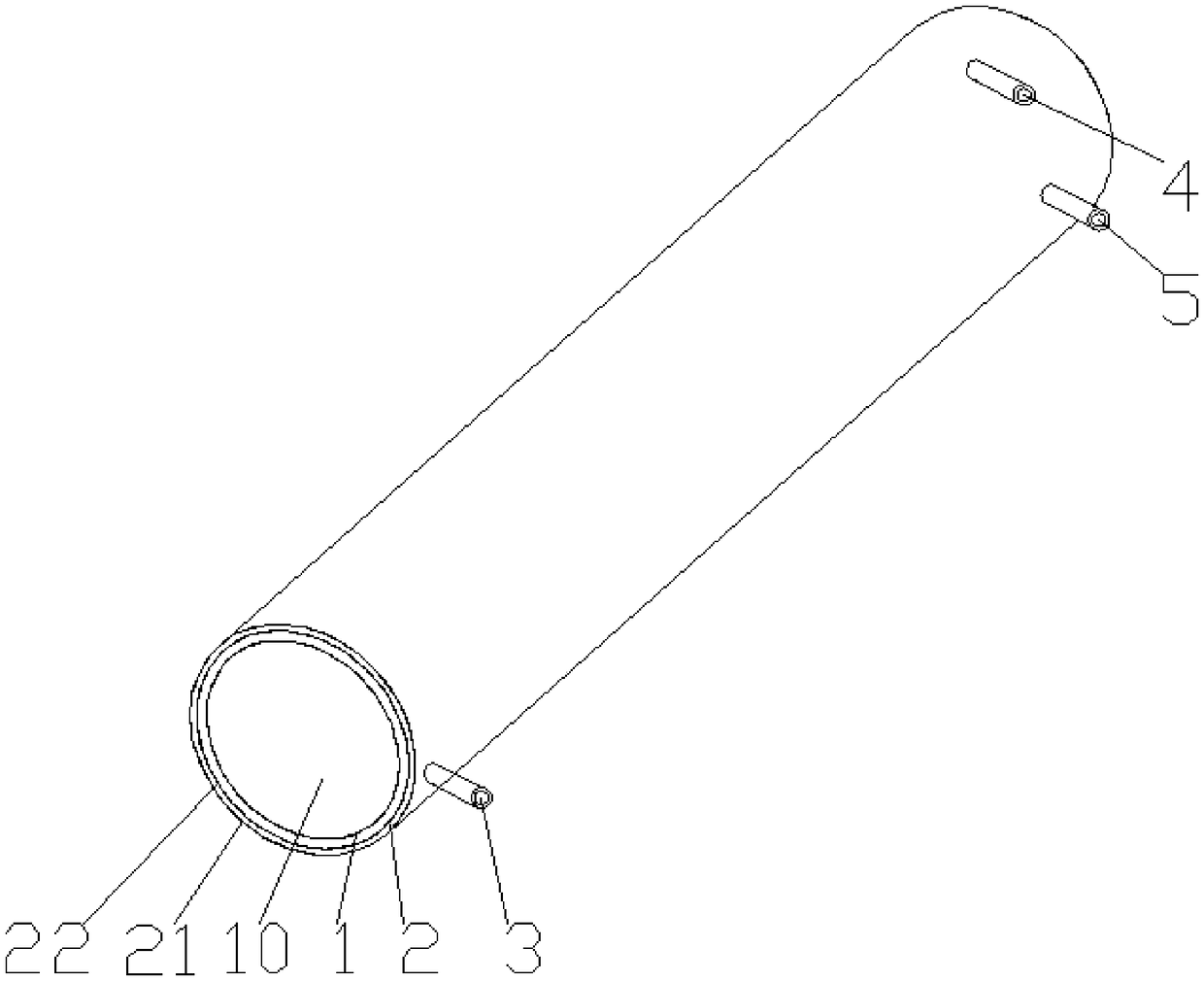

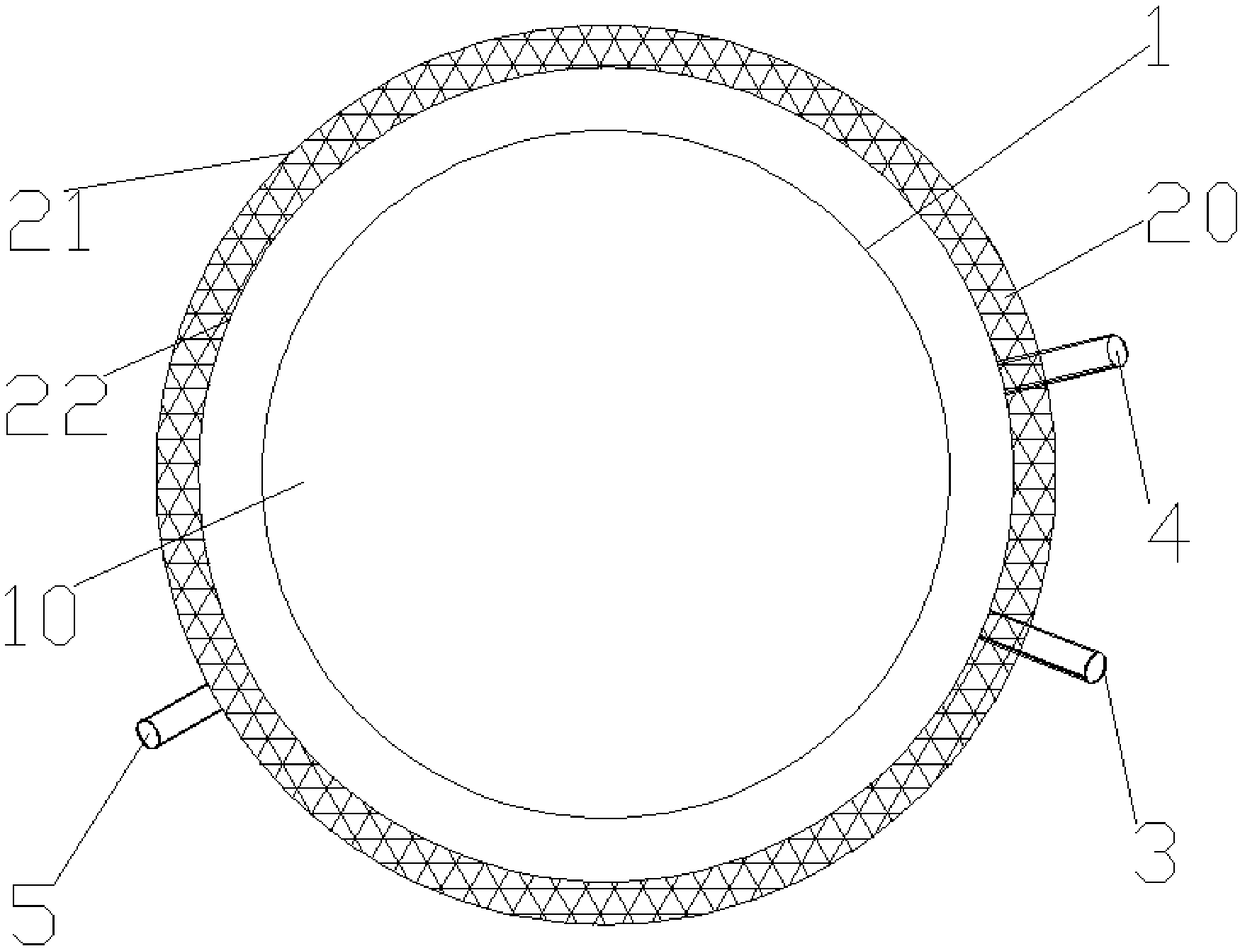

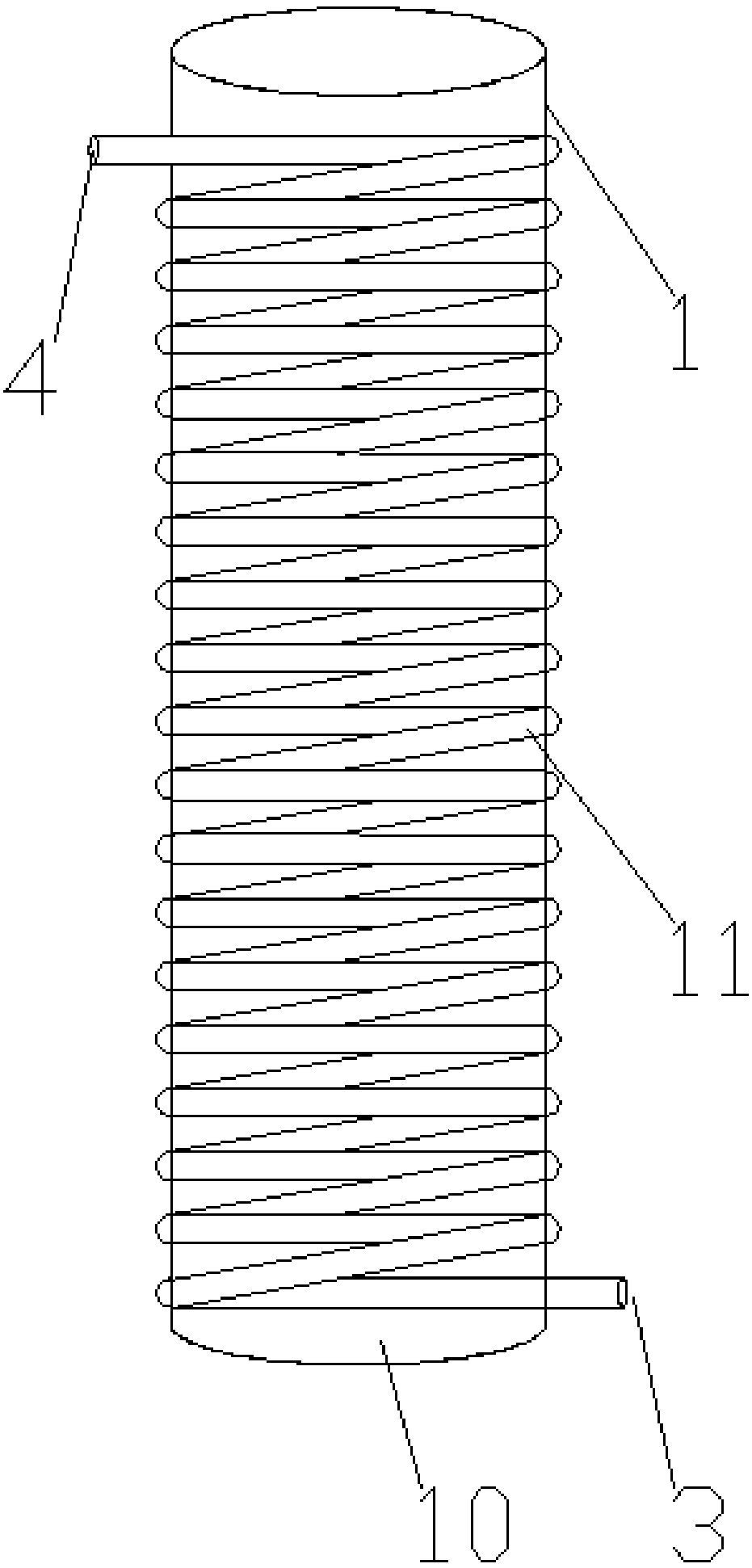

Cooling device for laser welding

PendingCN108311802APrevents the problem of weld porosityPrevent affecting welding qualityLaser beam welding apparatusLaser solderingMode change

The invention discloses a cooling device for laser welding. The cooling device comprises a light-transmitting pipe, a hollow, a water inlet pipe, a water outlet pipe and an air inlet pipe. The light-transmitting pipe is composed of a light-transmitting pipe shell. A coil pipe is arranged outside the light-transmitting pipe shell. The coil pipe is a half pipe, the lower portion of the coil pipe isconnected with a water inlet pipe, and the upper portion of the coil pipe is connected with a water outlet pipe. The cavity serves as an annular air channel, and is formed by a cavity outer wall and acavity inner wall. The upper portion of the cavity outer wall is connected with the air inlet pipe. The cavity is closely connected with the coil pipe, and an isolating screen is arranged on the lower portion of the cavity. The cavity serves as the annular air channel, and an air curtain is formed around a laser welding nozzle, and dust is prevented from entering a laser beam channel to contaminate a lens. Meanwhile, a welded workpiece can be purged, and the problem of weld porosity caused due to the fact that a workpiece is not cleared up is avoided; and in cooperation coil pipe cooling, thesituation that the temperature rises in the transmission process of laser beams in a laser channel is avoided, and consequently the laser mode changes, and the welding quality is influenced is avoided.

Owner:合肥市弘泽机械加工有限公司

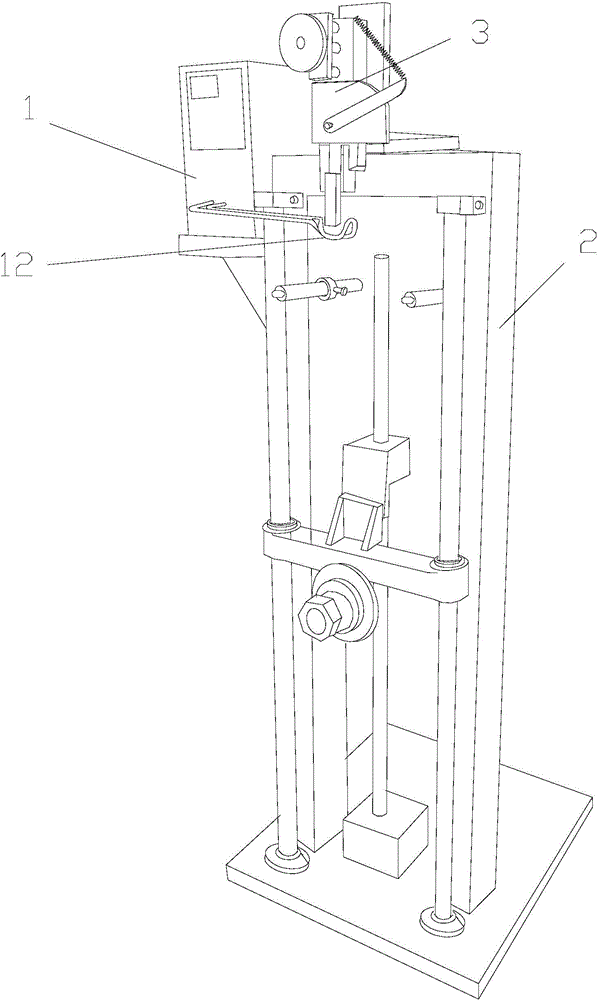

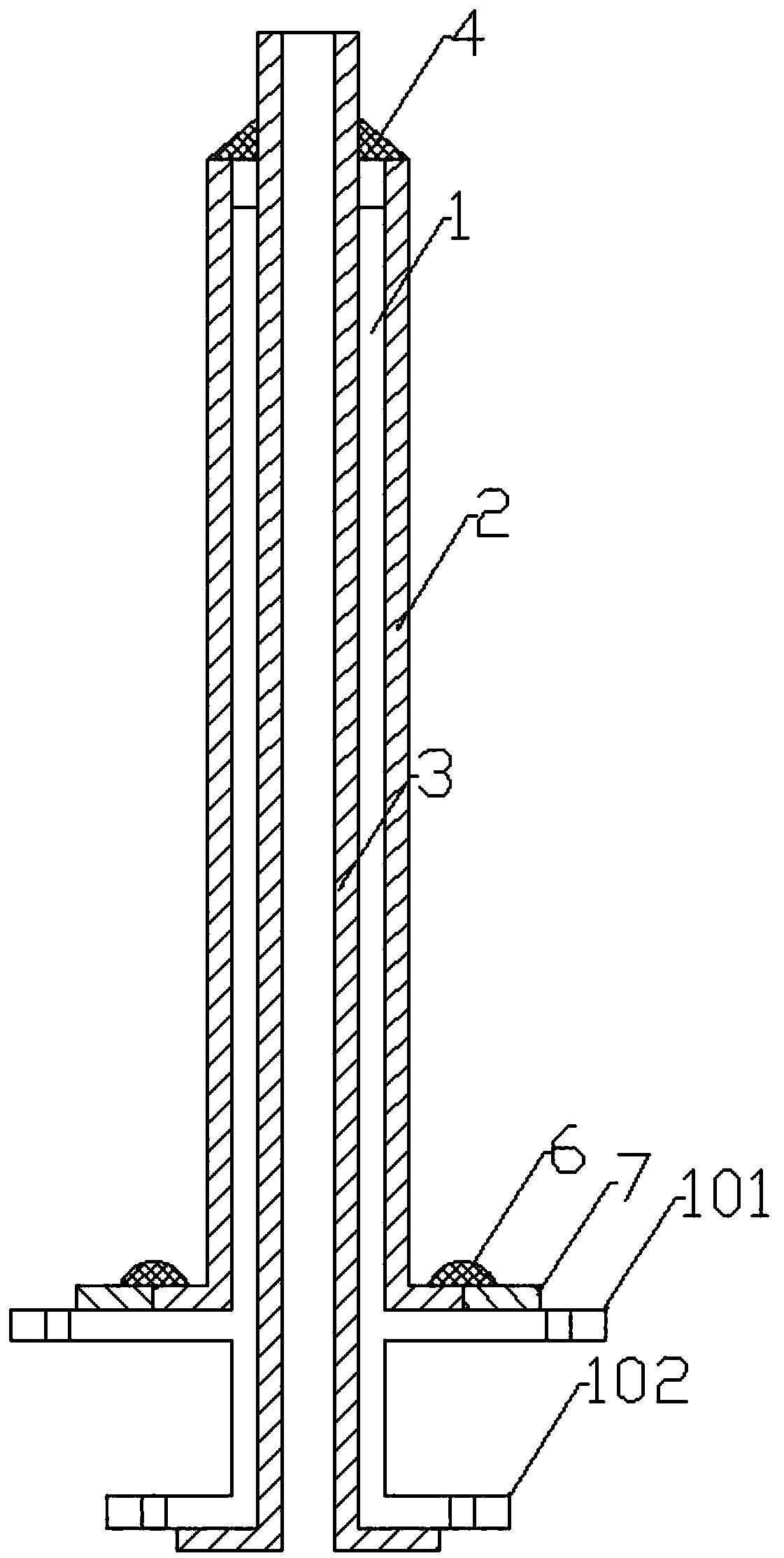

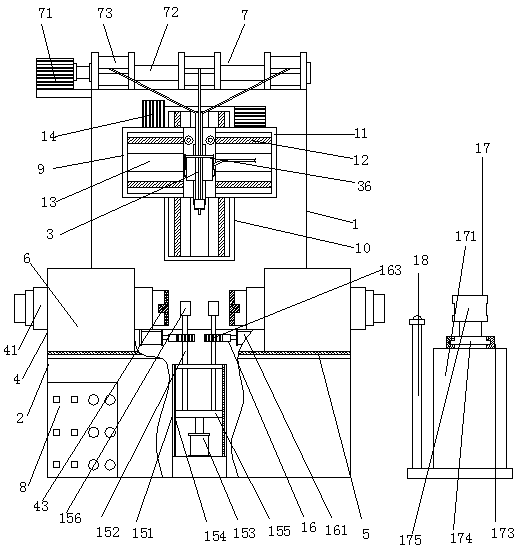

Straight tube butt-welding machine with parallelism correcting mechanism

The invention discloses a straight tube butt-welding machine with a parallelism correcting mechanism. The straight tube butt-welding machine comprises a welding main machine and an operation platform, wherein the welding main machine is fixed on the operation platform; a wire unwinding mechanism is arranged at the top end of the welding main machine; a vertical moving mechanism and a transverse moving mechanism are arranged on the front side of the welding main machine; the transverse moving mechanism is slidably arranged on the vertical moving mechanism; a welding main body is arranged on the transverse moving mechanism; two automatic rotation clamps are oppositely arranged on the operation platform; a parallelism correcting mechanism is arranged in the operation platform and is located at a middle position between the two automatic rotation clamps; and a positioning mechanism is also arranged on the parallelism correcting mechanism. Through the straight tube butt-welding machine, the problems of low sealing performance, poor appearance, low quality and inconvenience output of welding seams are solved; the straight tube butt-welding machine has the advantages of high welding parallelism, high sealing performance and stable output of the welding seams; the welding quality is improved.

Owner:江苏汇能锅炉有限公司

Forming process for teflon inside and outside linings of chlorine through pipe

InactiveCN108859093APrevent affecting welding qualityQuick insertTubular articlesCircular discStraight tube

The invention discloses a forming process for teflon inside and outside linings of a chlorine through pipe. The forming process comprises the following steps that (1) the bottom of an outside lining teflon pipe is subjected to edge overturning by 5 cm-8 cm, the overturned short edge is clamped to be sleeved with a straight pipe from the front end, and the overturned edge is pressed flatly to the upper end of a first flange; (2) a teflon disc is sleeved with the straight pipe from the outer end to be flatly pressed to the upper end of the first flange, and full welding is carried out on the joint positions of the teflon disc and the overturned edge of the outside lining teflon pipe through teflon welding rods; (3) the bottom of an inside lining teflon pipe is subjected to edge overturning by 10 cm-14 cm, the overturned end is sleeved with an edge overturning tool, the overturned end and the edge overturning tool are inserted into the straight pipe from one end of a second flange; (4) acore rod is inserted into the inside lining teflon pipe, the side face connecting positions of the outside lining teflon pipe and the inside lining teflon pipe are subjected to full welding through teflon welding rods; and (5) the core rod and the edge overturning tool are dismounted, welding seams are checked, welding slags are removed, and the surfaces are removed. According to the teflon chlorine through pipe manufactured through the process, steel pieces are completely wrapped with the inside lining teflon pipe and the outside lining teflon pipe, protection is provided, and various seriousstorage and transferring environments in chemical production are met.

Owner:安徽高旭新材料科技有限公司

Automatic robot welding auxiliary tool

InactiveCN113369757AReduce productionChange the size of the angleGas treatmentDispersed particle filtrationElectric machineryEngineering

The invention discloses an automatic robot welding auxiliary tool, and belongs to the technical field of welding auxiliary tools. The automatic robot welding auxiliary tool comprises a workbench, and further comprises a mounting frame, a cylinder, a sliding rod, a first sliding block and a second sliding block, wherein the mounting frame is fixedly connected to the workbench, the cylinder is connected to the mounting frame, one end of the sliding rod is fixedly connected to the cylinder, the first sliding block slides on the sliding rod, and the second sliding block is fixedly connected to the tail end of the sliding rod. According to the automatic robot welding auxiliary tool, the first sliding block drives a connecting rod to change the angle between the connecting rod and the sliding rod, then the distance between an arc-shaped plate and the sliding rod is changed, so that the automatic robot welding auxiliary tool is suitable for tubular parts with different inner circle diameters, the tubular parts are rapidly fixed, and time and labor are saved; meanwhile, a plurality of tools do not need to be manufactured, so that the cost expenditure is saved; and meanwhile, a double-shaft motor is used for driving the cylinder to rotate, then the tubular parts are driven to rotate, and welding is more convenient.

Owner:NANJING YUQUN COMM TECH CO LTD

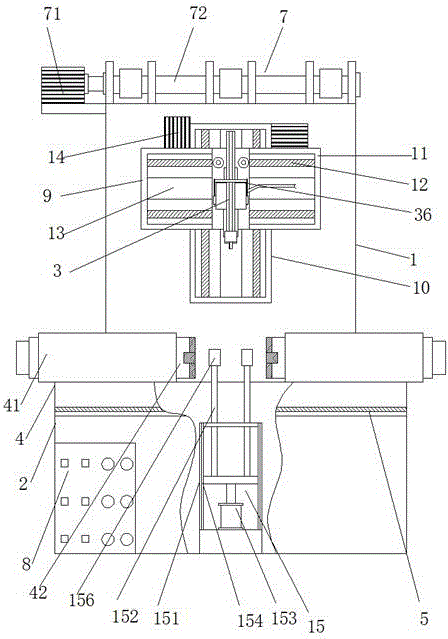

Thin plate laser tailor welding system for high-strength steel structural parts

The invention provides a laser splice welding system for high-strength steel structure thin plates. The laser splice welding system comprises a welding portal frame and the like. A fixed pressing device, a movable pressing device and a welding platform are all located below the welding portal frame. The fixed pressing device and the movable pressing device are located on the two sides of the workpiece welding platform correspondingly. A transversely-moving trolley is arranged on the welding portal frame, a robot level laser composite welding system is fixed to the position below the transversely-moving trolley, and a workpiece transferring device is located on the side faces of a front welding material frame and a rear welding material frame. The welding portal frame is sleeved with a laser protective door, and the front welding material frame and the rear welding material frame are located below one side of the fixed pressing device. According to the laser splice welding system for the high-strength steel structure thin plates, the diversified welding methods such as self-fusible welding, laser filler wire welding and laser electric-arc hybrid welding can be achieved, automatic locating can be conducted before welding; and in the welding process, real-time tracing of welding joints can be achieved, the welding technological parameters are adjusted in real time according to slope gap and misalignment changing, and self-adaptation filling of welding wires is achieved. According to the laser splice welding system, teaching programming is easy, and operating is convenient.

Owner:SHANGHAI JIAO TONG UNIV +2

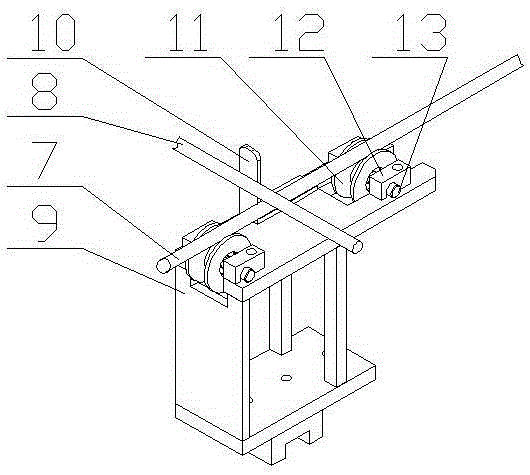

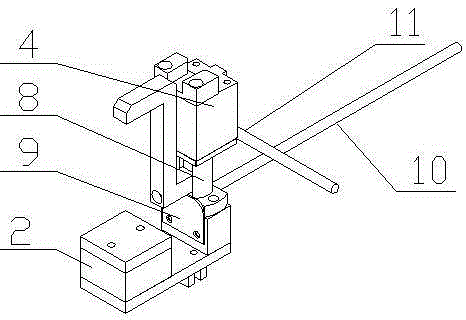

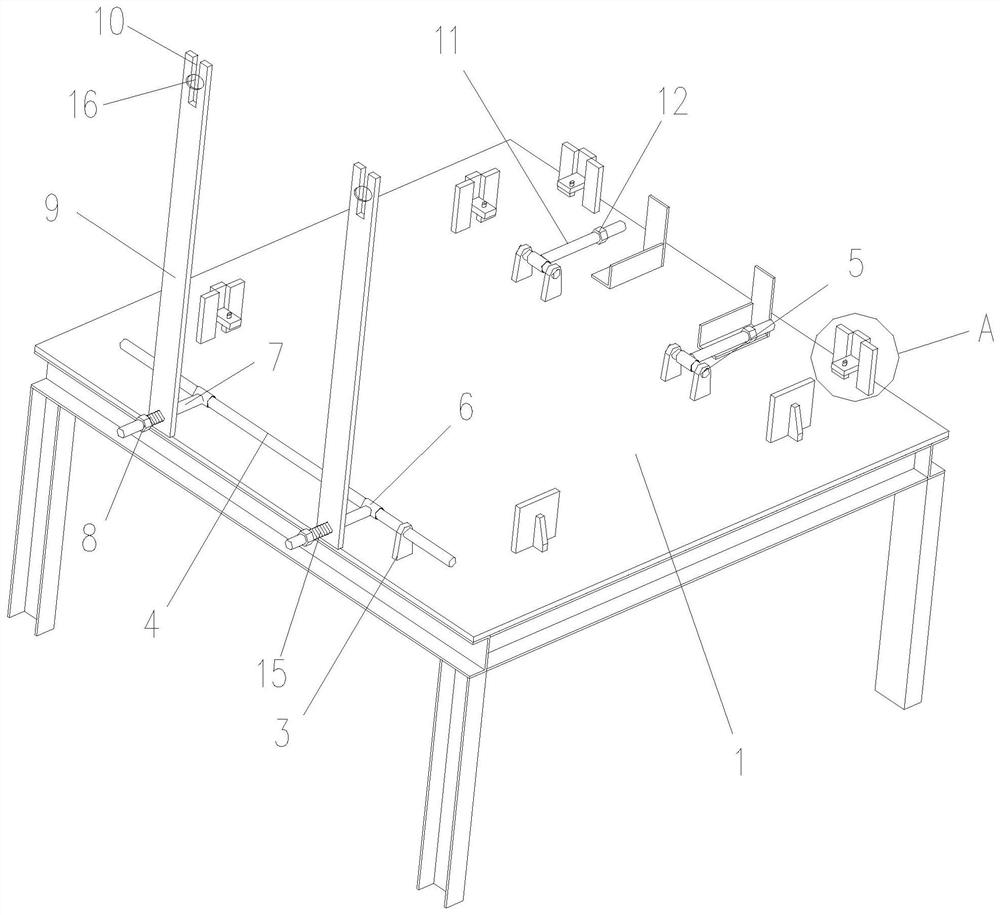

Clamping mechanism for reinforcing bar mesh welding

ActiveCN105269204AEasy to movePrevent affecting welding qualityWelding/cutting auxillary devicesAuxillary welding devicesTraction frameEngineering

The invention discloses a clamping mechanism for reinforcing bar mesh welding. The clamping mechanism comprises a clamping base, a lower base, a short-range air cylinder and a drag hook, wherein the clamping base is in sliding connection with a reinforcing bar traction frame; the lower base is fixed on the clamping base; a baffle plate is arranged at the front end of the lower base; one end, on the lower base, of a vertical reinforcing bar abuts against the baffle plate; a position, above the lower base, is connected with the short-range air cylinder through a connecting sleeve; and the drag hook is movably connected with the reinforcing bar traction frame. The clamping mechanism can move the position of a reinforcing bar according to welding dimension requirements and can clamp the reinforcing bar to position, so that the welding quality is prevented from being affected by phenomena such as reinforcing bar sliding and the like in a welding process.

Owner:JINAN HUAXIN AUTOMATION ENG

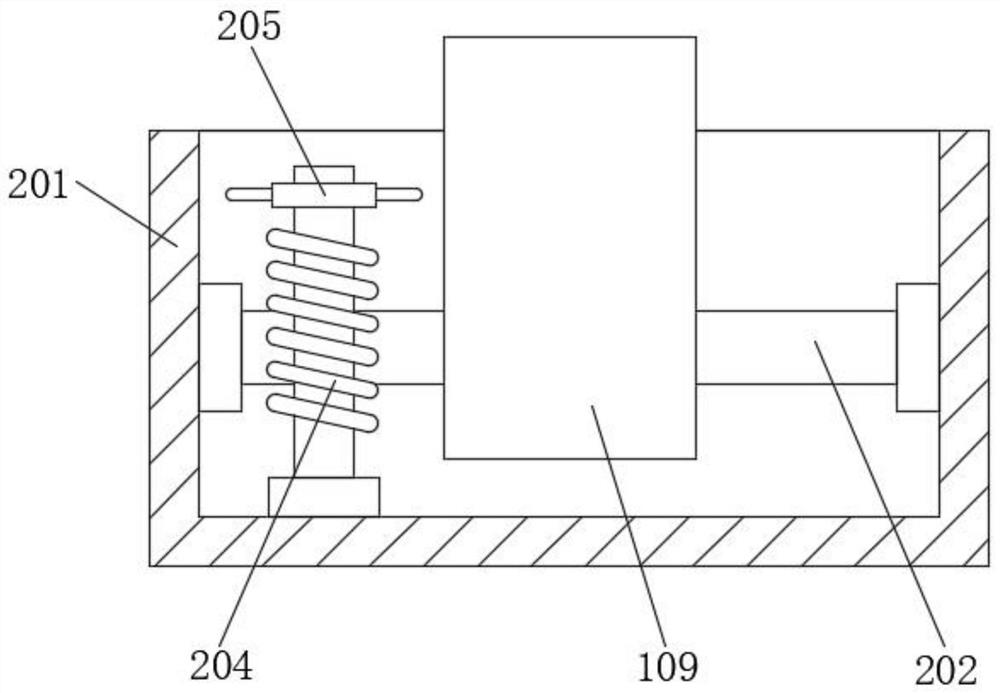

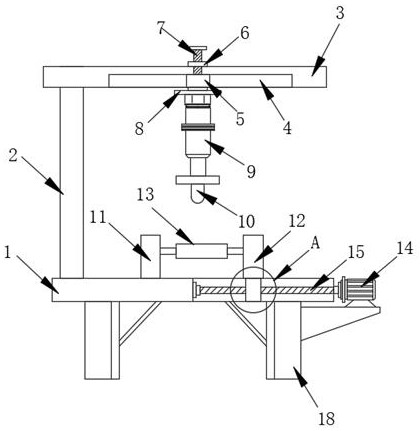

High-stability automatic straight pipe butt welding machine for boiler

ActiveCN106181095AQuality improvementQuality assuranceWelding/cutting auxillary devicesAuxillary welding devicesButt weldingStraight tube

The invention discloses a high-stability automatic straight pipe butt welding machine for a boiler. The high-stability automatic straight pipe butt welding machine for the boiler comprises a welding main machine and an operating stand. The welding main machine is fixed to the operating stand; an automatic feeding mechanism is arranged on the discharging end of the welding main machine; a discharging mechanism is arranged on the top end of the welding main machine; a vertical moving mechanism and a horizontal moving mechanism are arranged on the front side face of the welding main machine; the horizontal moving mechanism is slidably arranged above the vertical moving mechanism; a welding main body is arranged on the horizontal moving mechanism; two automatic rotating fixtures are oppositely arranged on the operating stand; a parallelism correcting mechanism is arranged in the operating stand, and is located in the middle position of the two automatic rotating fixtures; and a positioning mechanism is also arranged on the parallelism correcting mechanism. The straight pipe butt welding machine provided by the invention solves the problems of poor weld joint airtightness, poor appearance, poor quality, and inconvenience in output, is good in parallelism of weld joint welding, good in airtightness and stable in output, and the welding quality is improved.

Owner:江苏汇能锅炉有限公司

Automatic welding machine, welding tool and welding process

InactiveCN111940970APrevent affecting welding qualityImprove stabilityWelding/cutting auxillary devicesAuxillary welding devicesRelative displacementPipe

The invention discloses an automatic welding machine, a welding tool and a welding process, and belongs to the technical field of welding tools. The automatic welding machine comprises a base, whereina circular track is arranged on the base, a moving rod is arranged on the circular track, the moving rod is slidably connected to the circular track through rolling wheels, a circular ring disc is fixedly connected to the upper end of the moving rod, first locking plates are fixedly connected to the two sides of the lower end of the circular ring disc, a flange is placed on the circular ring disc, the upper end of the flange is provided with a circular pipe, and the two sides of the upper end of the flange are connected to second locking plates. According to the automatic welding machine, through arrangement of a nut and a first pressing plate, the circular pipe and the flange can be locked into a whole, and therefore when the circular pipe is rotated, the flange and the circular pipe canrotate at the same time, the situation that the flange and the circular pipe do not have relative displacement is avoided, and the welding quality is improved.

Owner:NANJING YUZHI INTELLIGENT TECH CO LTD

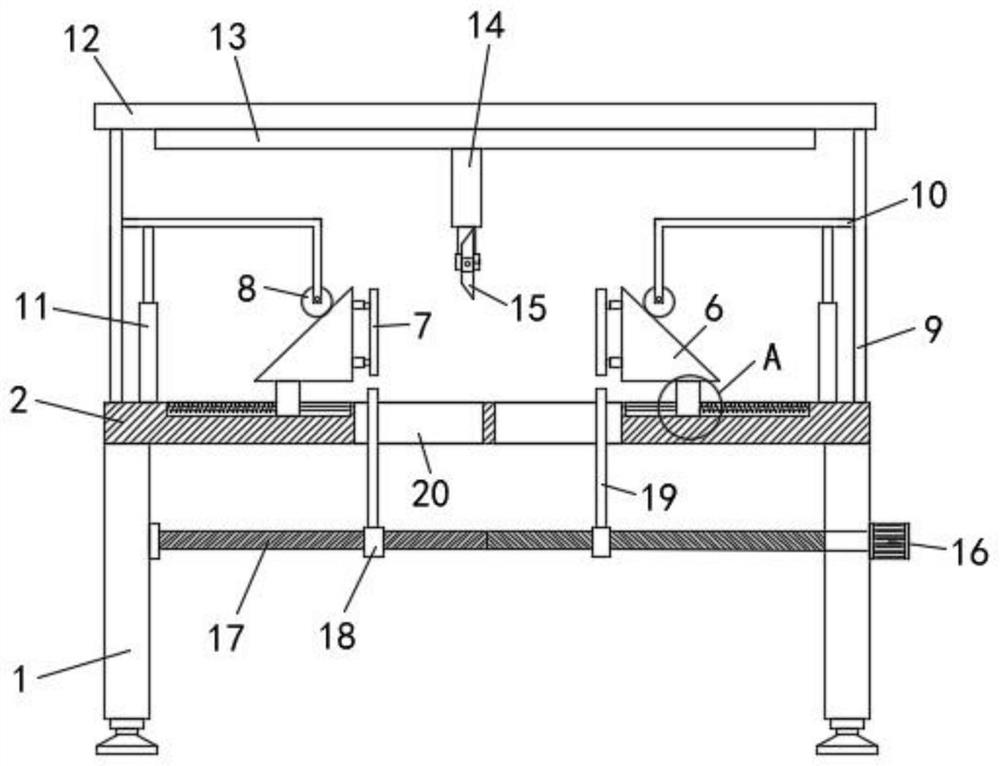

A dual-station intelligent welding robot

InactiveCN105710496BReduce labor intensityPrevent affecting welding qualityWelding accessoriesControl systemSurface mounting

The invention discloses a double-station intelligent welding robot and a control system of the double-station intelligent welding robot. The double-station intelligent welding robot comprises a welding platform, wherein a mobile platform and a slidable and adjustable workpiece clamp are fixedly arranged on the upper surface of the welding platform, a material loading rest and a material unloading rest are fixedly arranged between the mobile platform and the slidable and adjustable workpiece clamp, suspension arms are arranged on the material loading rest and the material unloading rest respectively, a sliding guide rail is arranged on the upper surface of the mobile platform, a welding machine is arranged on the sliding guide rail, a single wire feeding mechanism and a welding gun cleaning and wire shearing mechanism are arranged on the side surface of the welding machine, the slidable and adjustable workpiece clamp comprises a welding line clamping mechanism, the welding line clamping mechanism is connected with a servo motor by a pneumatic control valve, the servo motor is also connected with the mobile platform, the welding machine comprises a welding robot and a welding gun, a 2D laser scanning system is fixed above the welding gun, a driving motor is arranged at the bottom of the welding robot, and the driving motor is connected with a welding gun clamping arm by a welding track recognizer so that the welding orbit can be automatically and intelligently recognized and the all-directional welding is realized.

Owner:GUANGZHOU RUISU INTELLIGENT TECH CO LTD

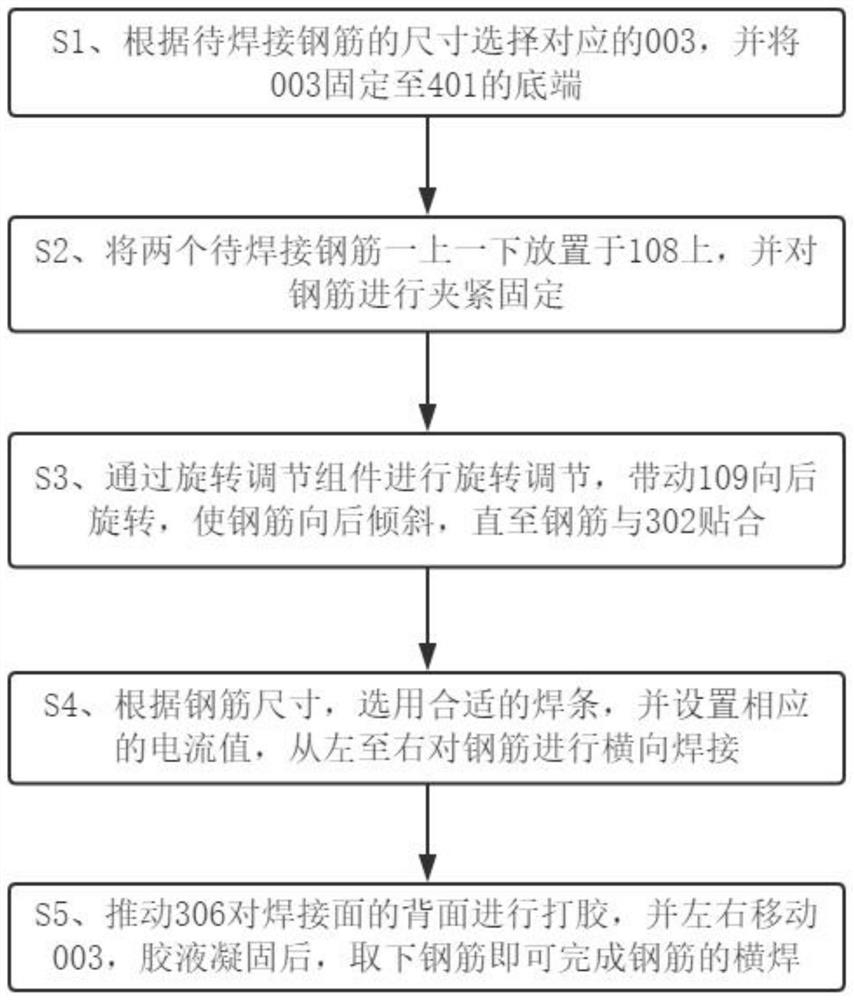

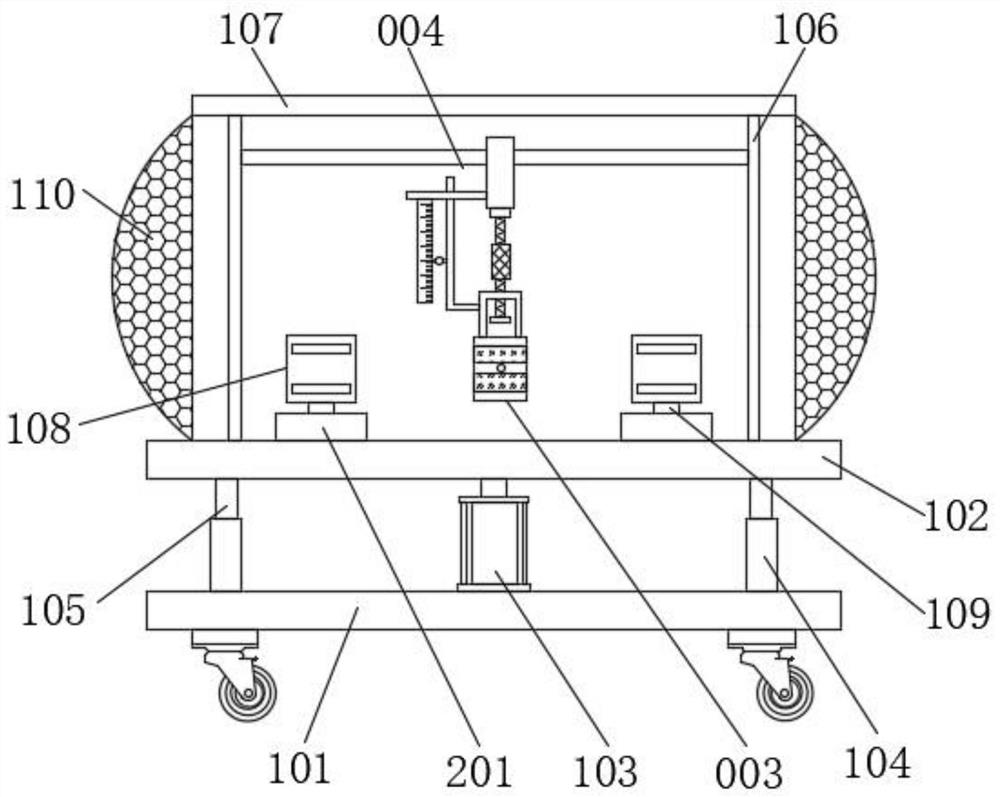

A steel welding process

ActiveCN112427761BImprove comfortRelieve fatigueLiquid surface applicatorsCoatingsRebarUltimate tensile strength

The invention discloses a steel welding process, which belongs to the technical field of steel welding, and can be equipped with a convenient auxiliary device used in conjunction with the process, which can greatly improve the comfort of the welding personnel, relieve the fatigue of the welding personnel, and facilitate the rotation adjustment in the auxiliary device When welding, the steel bar can be rotated to tilt backwards and fixed, which is convenient for welding personnel to carry out welding operations, and can effectively prevent molten iron from falling during welding, improving welding quality and welding efficiency. There is also a special punch The glue reinforcement component is convenient to apply glue to the back of the welding surface of the steel bar, which greatly enhances the connection strength between the steel bars, and is equipped with a connection adjustment component set up with the glue reinforcement component. The connection adjustment component can not only play a role in the glue reinforcement component The role of a supporting connection also makes it easy for the glued reinforcement component to slide left and right, thereby expanding the glued area, and can also adjust the height of the glued reinforcement component.

Owner:广西天正钢结构有限公司

A method for surface treatment of weldments

ActiveCN109530882BPrevent splashPrevent affecting welding qualityArc welding apparatusGrinding machinesPolishingMaterials science

The invention relates to the technical field of welding technologies, in particular to a surface treatment method of a weldment. According to the method, a to-be-welded part of the weldment is cleanedwith deionized water, the to-be-welded part is cleaned for preliminary impurity removal, preparations are made for following polishing, impurities attached to the weldment originally are prevented from splashing during polishing, the cleaned weldment is placed into polishing equipment, the to-be-welded part is polished by the aid of the polishing equipment, the to-be-welded part is subjected to polishing treatment, the surface is rough, and the welding effect can be improved indirectly; the polished weldment is cleaned with the deionized water again, impurities produce due to polishing are cleaned and are prevented from affecting the welding quality, the workpiece is aired after being cleaned, and then welding operation can be performed. By the aid of the method, the welding quality can be improved, and the welding speed can be increased.

Owner:ZHEJIANG YOTRIO GRP CO LTD

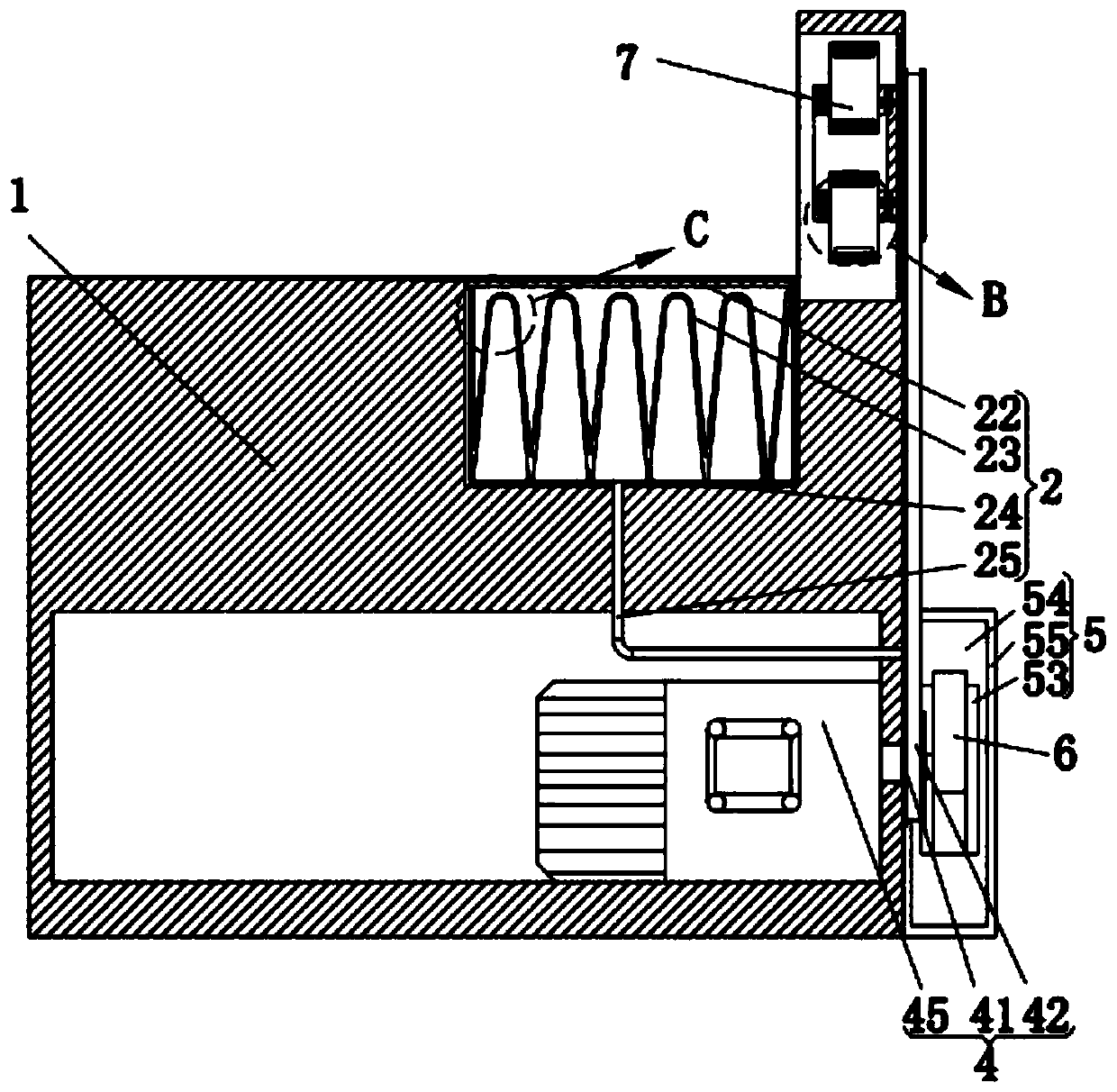

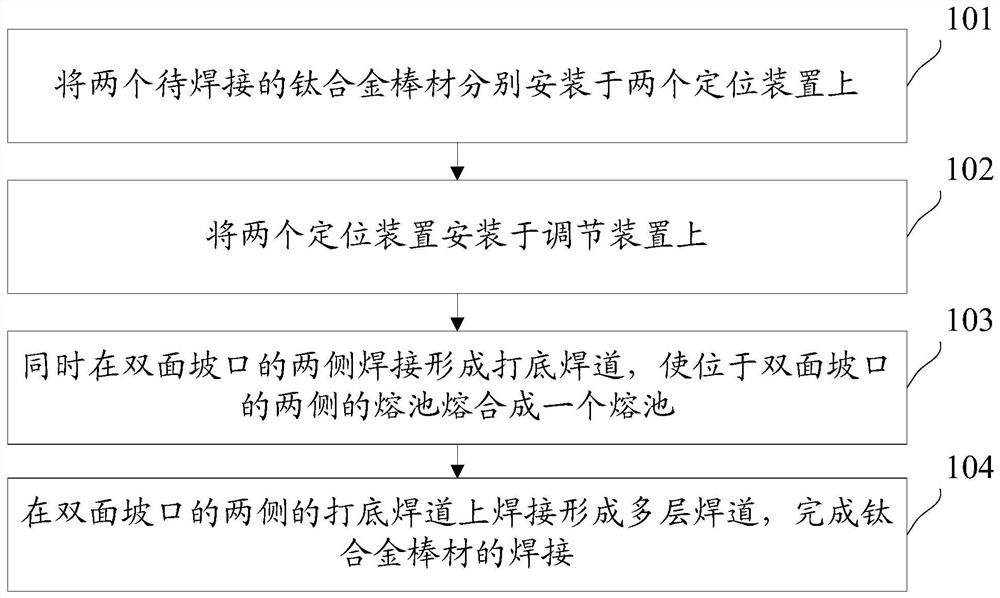

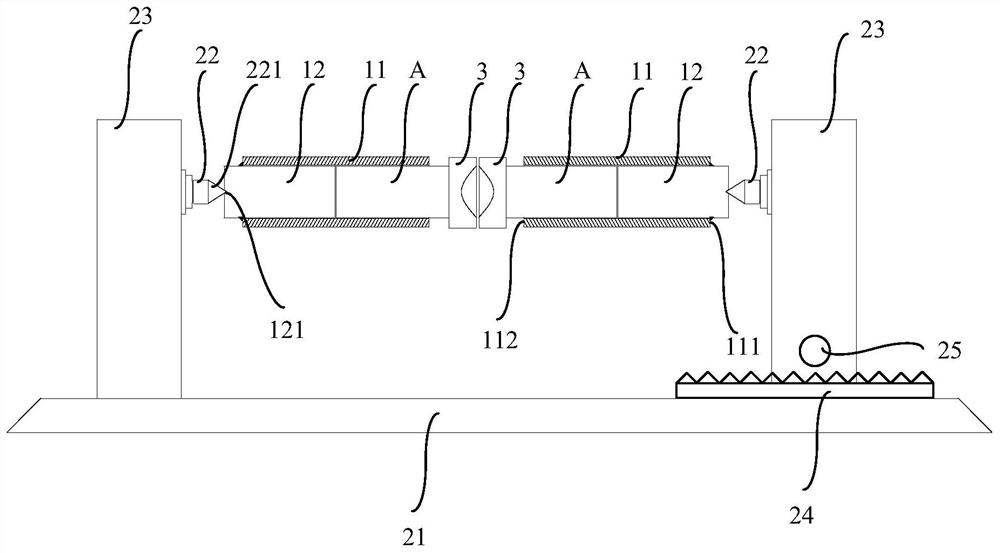

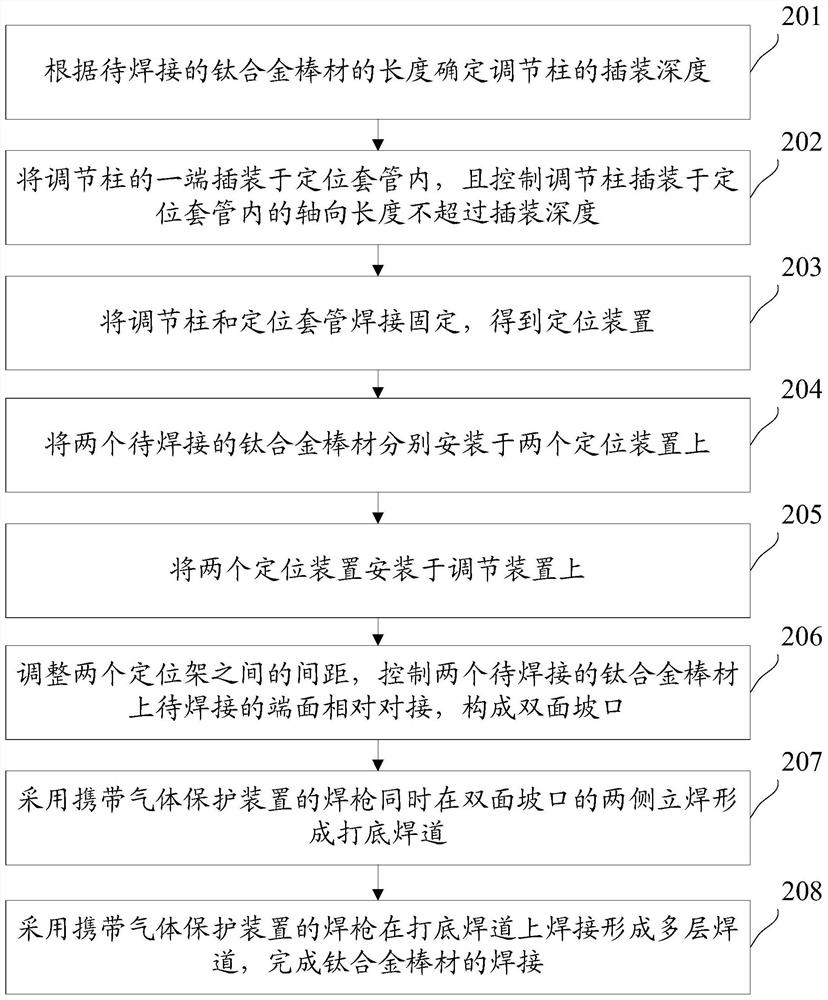

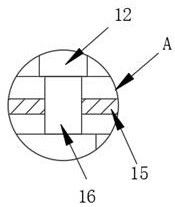

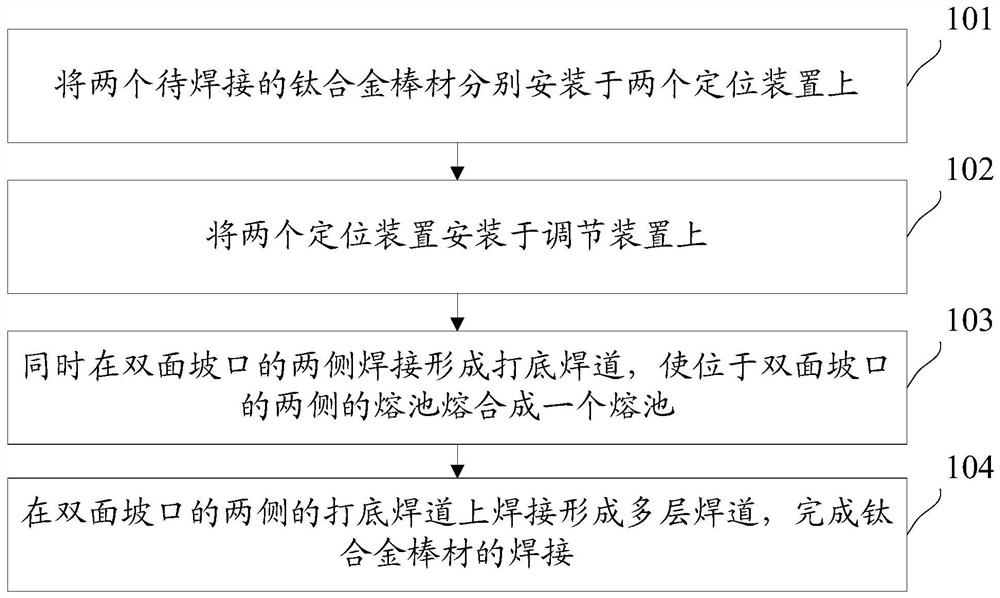

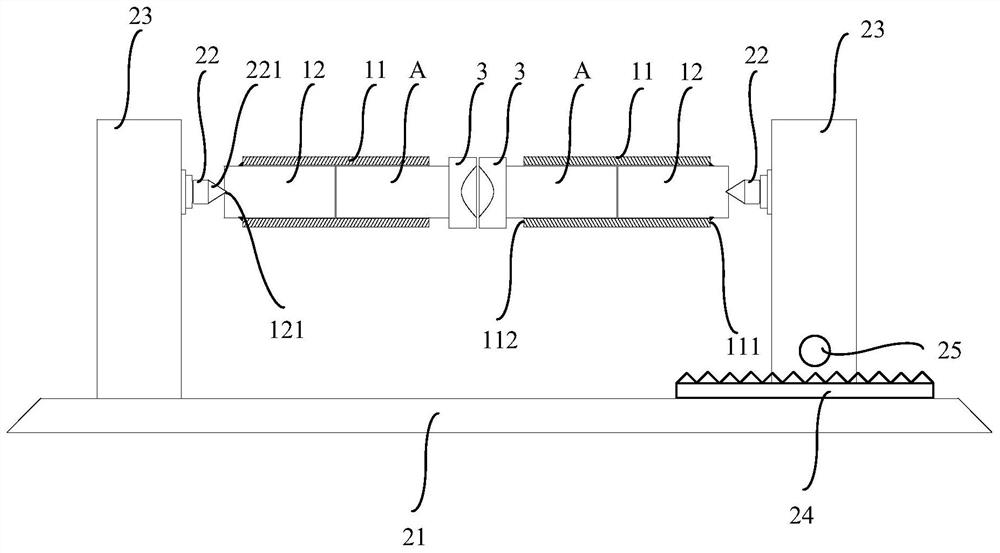

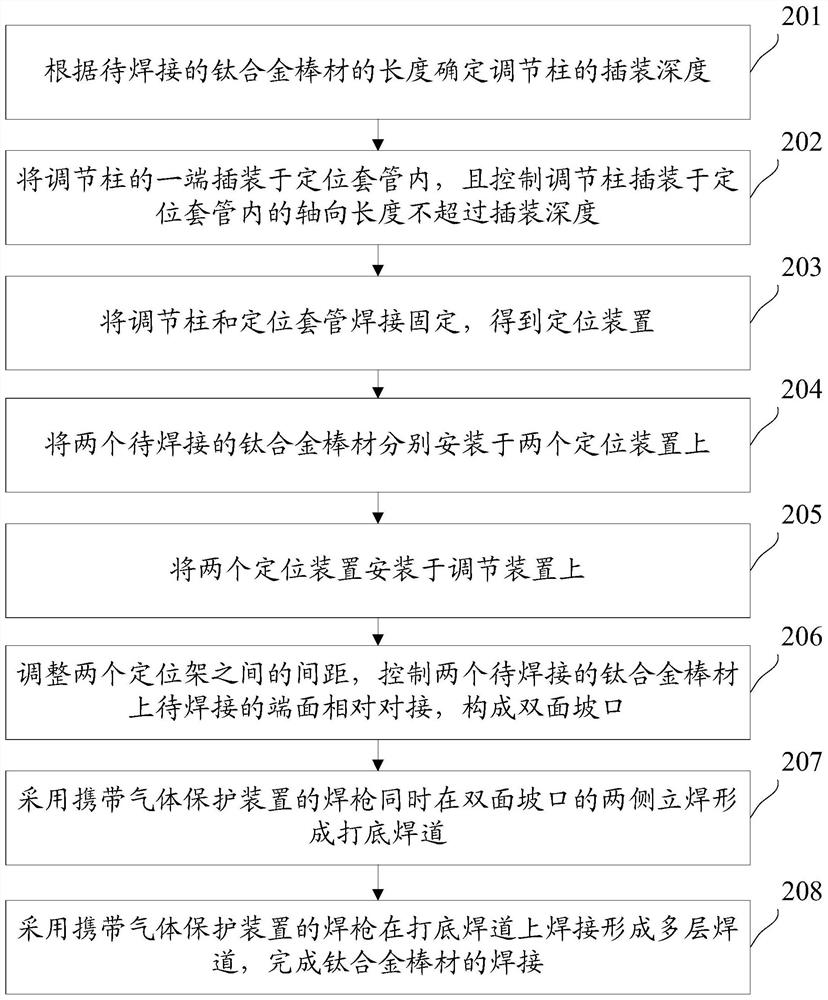

Welding method of titanium alloy bar

ActiveCN111822815BStraightness meets the requirementsConvenient and fast preparation work before weldingWelding/soldering/cutting articlesWelding accessoriesButt jointTitanium alloy

The disclosure provides a welding method for titanium alloy rods, belonging to the field of welding technology, comprising: installing two titanium alloy rods to be welded on two positioning devices respectively; installing the two positioning devices on the adjusting device ;Adjust the distance between the two positioning frames, and control the opposite butt joint of the end faces to be welded on the two titanium alloy bars to be welded to form a double-sided groove; at the same time, weld on both sides of the double-sided groove to form a bottom weld bead , so that the molten pools on both sides of the double-sided groove are fused into a molten pool; welding is formed on the bottom weld bead on both sides of the double-sided groove to form a multi-layer weld bead, and the welding of the titanium alloy bar is completed. The disclosure can ensure that the straightness of the bars after butt jointing meets the requirements, and avoid root cleaning after bottom welding, so as to ensure the welding quality.

Owner:WUHAN MARINE MACHINERY PLANT

Piezoelectric quartz sensor white sheet processing equipment and process

InactiveCN113084400AFaster welding workPrevent affecting welding qualityWelding/cutting auxillary devicesAuxillary welding devicesPhysicsElectric machinery

The invention discloses piezoelectric quartz sensor white sheet processing equipment and process. The equipment comprises a workbench, wherein a working box fixedly penetrates through the top end of the workbench, sealing plates are arranged on the two sides of the top end of the working box, a clamping block is fixedly connected to one end of each sealing plate, guide holes are formed in the two sides of the top end of the working box, a guide plate is slidably connected to the inner side of each guide hole, a double-thread screw movably penetrates through the middle of the side face of the working box, and the two ends of the outer side of the double-thread screw are fixedly sleeved with first gears. The clamping blocks on the two sides move oppositely under the action of a first motor and the double-thread screw until the two ends of a white sheet are clamped and fixed, and therefore the situation that the welding quality is affected by sliding of the white sheet during welding can be prevented; and after welding is finished, the clamping blocks on the two sides are separated, a heat dissipation box in the working box moves upwards to be attached to a heat conduction plate, cooling water is continuously introduced into the heat dissipation box, therefore, the cooling work of the white sheet can be accelerated, and the processing efficiency is improved.

Owner:江苏天企奥科技有限公司

High Stability Automatic Straight Tube Butt Welding Machine for Boiler

ActiveCN106181095BQuality improvementQuality assuranceWelding/cutting auxillary devicesAuxillary welding devicesButt weldingPoor quality

The invention discloses a high-stability automatic straight pipe butt welding machine for a boiler. The high-stability automatic straight pipe butt welding machine for the boiler comprises a welding main machine and an operating stand. The welding main machine is fixed to the operating stand; an automatic feeding mechanism is arranged on the discharging end of the welding main machine; a discharging mechanism is arranged on the top end of the welding main machine; a vertical moving mechanism and a horizontal moving mechanism are arranged on the front side face of the welding main machine; the horizontal moving mechanism is slidably arranged above the vertical moving mechanism; a welding main body is arranged on the horizontal moving mechanism; two automatic rotating fixtures are oppositely arranged on the operating stand; a parallelism correcting mechanism is arranged in the operating stand, and is located in the middle position of the two automatic rotating fixtures; and a positioning mechanism is also arranged on the parallelism correcting mechanism. The straight pipe butt welding machine provided by the invention solves the problems of poor weld joint airtightness, poor appearance, poor quality, and inconvenience in output, is good in parallelism of weld joint welding, good in airtightness and stable in output, and the welding quality is improved.

Owner:江苏汇能锅炉有限公司

Automatic welding machine for micro-motor rotor

InactiveCN111992843APlay the effect of locking and fixingAchieve left and right movementSoldering auxillary devicesHydraulic cylinderButt welding

The invention discloses an automatic welding machine for a micro-motor rotor. The machine comprises a base, a supporting column, a horizontal plate, a sliding groove and a sliding block, wherein the base is fixedly installed with supporting legs on both sides of the bottom end, the supporting column is installed on one side of the upper end of the base, the top of the supporting column is installed with a horizontal plate, the bottom surface of the horizontal plate is provided with the sliding groove, the sliding block is slidingly installed on the sliding groove, a bolt is installed on the top of the sliding block, a nut is installed on the bolt, and the bottom surface of the sliding block is fixedly installed with a mounting plate. The automatic welding machine realizes the left and right movement of a hydraulic cylinder through the coordinated use of the set sliding groove, sliding block, nut and bolt, thereby facilitating a welding head to be aligned with a welding wire groove of the rotor of the motor to be welded, and improving the accuracy of welding. When the sliding block needs to be moved, only the sliding block needs to be pushed to move in the sliding groove, and when the butt welding head is ready to be welded to the rotor, the worker manually turns the nut to make the nut lock and fix the sliding block, thereby preventing its movement from affecting the welding quality.

Owner:江苏银溢电机科技有限公司

Titanium alloy bar welding method

ActiveCN111822815AStraightness meets the requirementsConvenient and fast preparation work before weldingWelding/soldering/cutting articlesWelding accessoriesButt jointTitanium alloy

The invention provides a titanium alloy bar welding method, and belongs to the technical field of welding. The titanium alloy bar welding method comprises the following steps that two to-be-welded titanium alloy bars are correspondingly arranged on positioning devices; the two positioning devices are mounted on the two positioning devices; the distance between two positioning frames is adjusted, the to-be-welded end faces of the two to-be-welded titanium alloy bars are controlled to be in butt joint oppositely, and a double groove is formed; meanwhile, backing runs are formed on the two sidesof the double groove through welding, so that molten pools located on the two sides of the double groove are molten into one molten pool; and multiple layers of welding runs are formed on the backingruns on the two sides of the double groove in a welding mode, and welding of the titanium alloy bars are completed. According to the titanium alloy bar welding method, the straightness of the butted bars can meet the requirement, and back chipping treatment is avoided after backing weld, so that the welding quality is ensured.

Owner:WUHAN MARINE MACHINERY PLANT

Intelligent air compressor base positioning tool for serial bulk vehicle and application method

PendingCN111992962AGuarantee welding qualityGuaranteed compression effectWelding/cutting auxillary devicesAuxillary welding devicesControl engineeringProcess engineering

The invention discloses an intelligent air compressor base positioning tool for a serial bulk vehicle and an application method and belongs to the technical field of welding tools of air compressors for vehicles. The tool is provided with a working platform, a limiting plate, a compression unit and a locking unit. A rotating shaft is rotated above the air compressor base through a compression structure and then the compression structure is locked by a locking structure, so that the compression effect is ensured and deviation in a welding process is prevented, and therefore, the welding qualityof the air compressor base is further ensured. The technical problem that the follow-up assembling difficulty is great, the welding quality is poor, the work efficiency is low and the labor intensityof staff is large as the welding deformation cannot be reduced when the air compressor base is welded by existing workshop staff effectively.

Owner:ANHUI XINGMA SPECIAL PURPOSE VEHICLE

Automatic straight tube butt-welding machine applied to boilers

ActiveCN106425019AQuality improvementGood effectWelding/cutting auxillary devicesAuxillary welding devicesWeld seamStraight tube

The invention discloses an automatic straight tube butt-welding machine applied to boilers. The automatic straight tube butt-welding machine comprises a welding main machine and an operation platform, wherein the welding main machine is fixed on the operation platform; a wire unwinding mechanism is arranged at the top end of the welding main machine; a vertical moving mechanism and a transverse moving mechanism are arranged on the front side of the welding main machine; the transverse moving mechanism is slidably arranged on the vertical moving mechanism; a welding main body is arranged on the transverse moving mechanism; two automatic rotation clamps are oppositely arranged on the operation platform; a parallelism correcting mechanism is arranged in the operation platform and is located at a middle position between the two automatic rotation clamps. Through the straight tube butt-welding machine, the problems of low sealing performance, poor appearance, low quality and inconvenience output of welding seams are solved; the straight tube butt-welding machine has the advantages of high welding parallelism, high sealing performance and stable output of the welding seams; the welding quality is improved.

Owner:江苏汇能锅炉有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com