Sealed-type cavity welding connector structure and welding clamp and welding method thereof

A technology for welding joints and welding fixtures, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of easy generation of pores, collapse of welding seam, low product qualification rate, etc., and achieve the effect of improving work efficiency and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

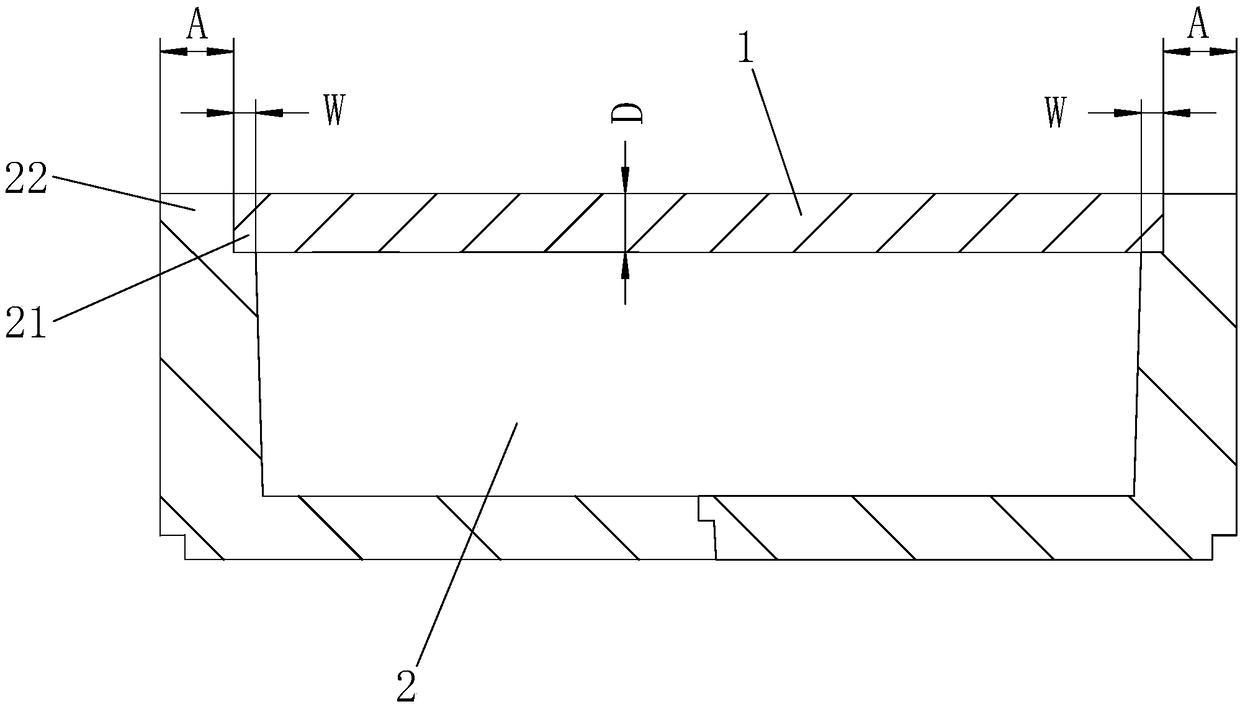

[0029] like figure 1 As shown, the sealed cavity welded joint structure of this embodiment includes a cavity 2 and a cover plate 1, the cover plate 1 is a rectangle, and the cavity 2 is provided with a support step for the cover plate 1 to cover the cavity 2. 21. The outer side of the support step 21 is provided with a step wall 22 that prevents the cover plate 1 from moving horizontally. The thickness of the cover plate 1 is D=6mm. Since D<8mm, the minimum width of the support step 21 is 0.5×6=3mm. The minimum thickness of 22 is 6+1=7mm, that is, W≥3mm, A≥7mm.

Embodiment 2

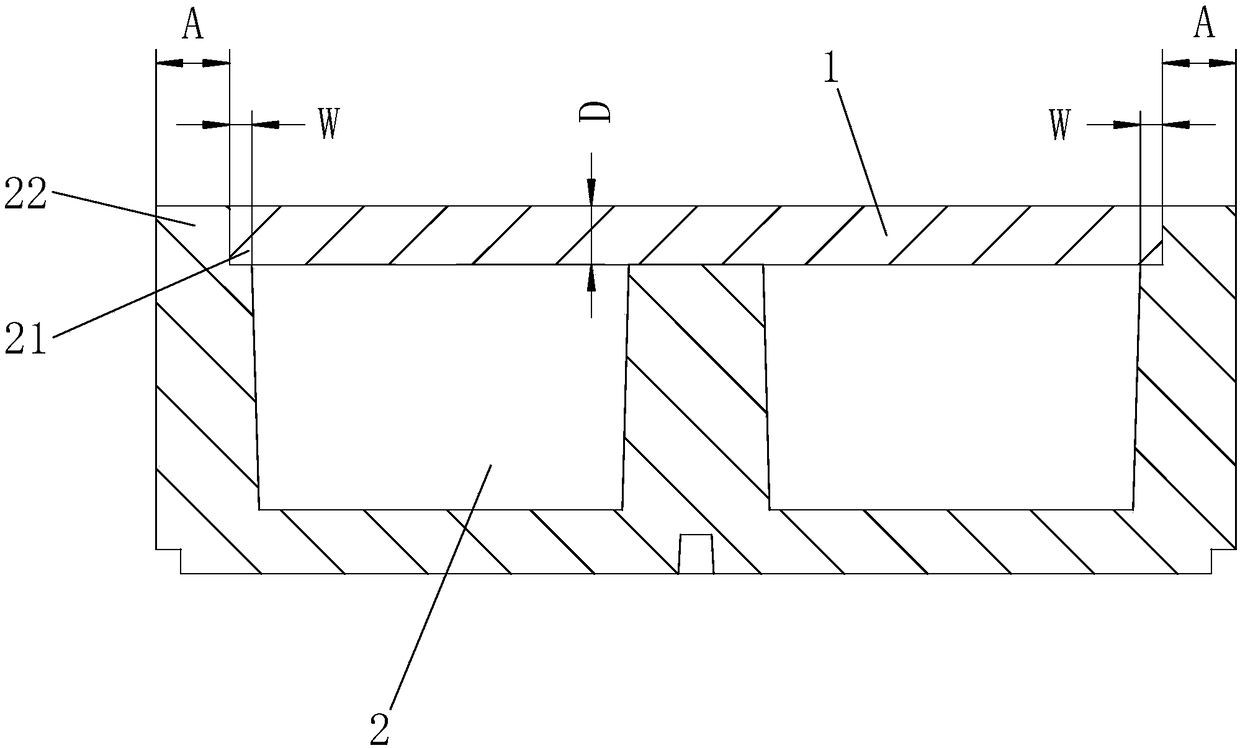

[0031] like figure 2 As shown, the cavity-type water-cooling plate to be welded in this embodiment includes a cavity 2 and a cover plate 1, the cover plate 1 is circular, and the cavity 2 is provided with a support step for the cover plate 1 to cover the cavity 2. 21. The outer side of the support step 21 is provided with a step wall 22 that prevents the cover plate 1 from moving horizontally. The thickness of the cover plate 1 is D=10mm. Since D>8mm, the minimum width of the support step 21 is 4mm, and the minimum thickness of the step wall 22 is 10mm, that is, W≥4mm, A≥10mm.

[0032] The designed structural dimensions of the above two embodiments can effectively prevent welding defects such as edge collapse and welding seam collapse during the welding process, and improve the welding quality.

[0033] like Figure 4 and Figure 5 As shown, Embodiment 1 adopts a welding fixture to clamp the above-mentioned workpiece for welding, and the welding fixture includes a fixing d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com