Photosensitive resin composition

A technology of photosensitive resin and composition, applied in the field of photosensitive resin composition, can solve the problems of not obtaining high-definition line shape, not obtaining coating film appearance, insufficient coating film sensitivity, etc., and achieving excellent coating film appearance and Insulation properties, excellent clarity, excellent appearance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

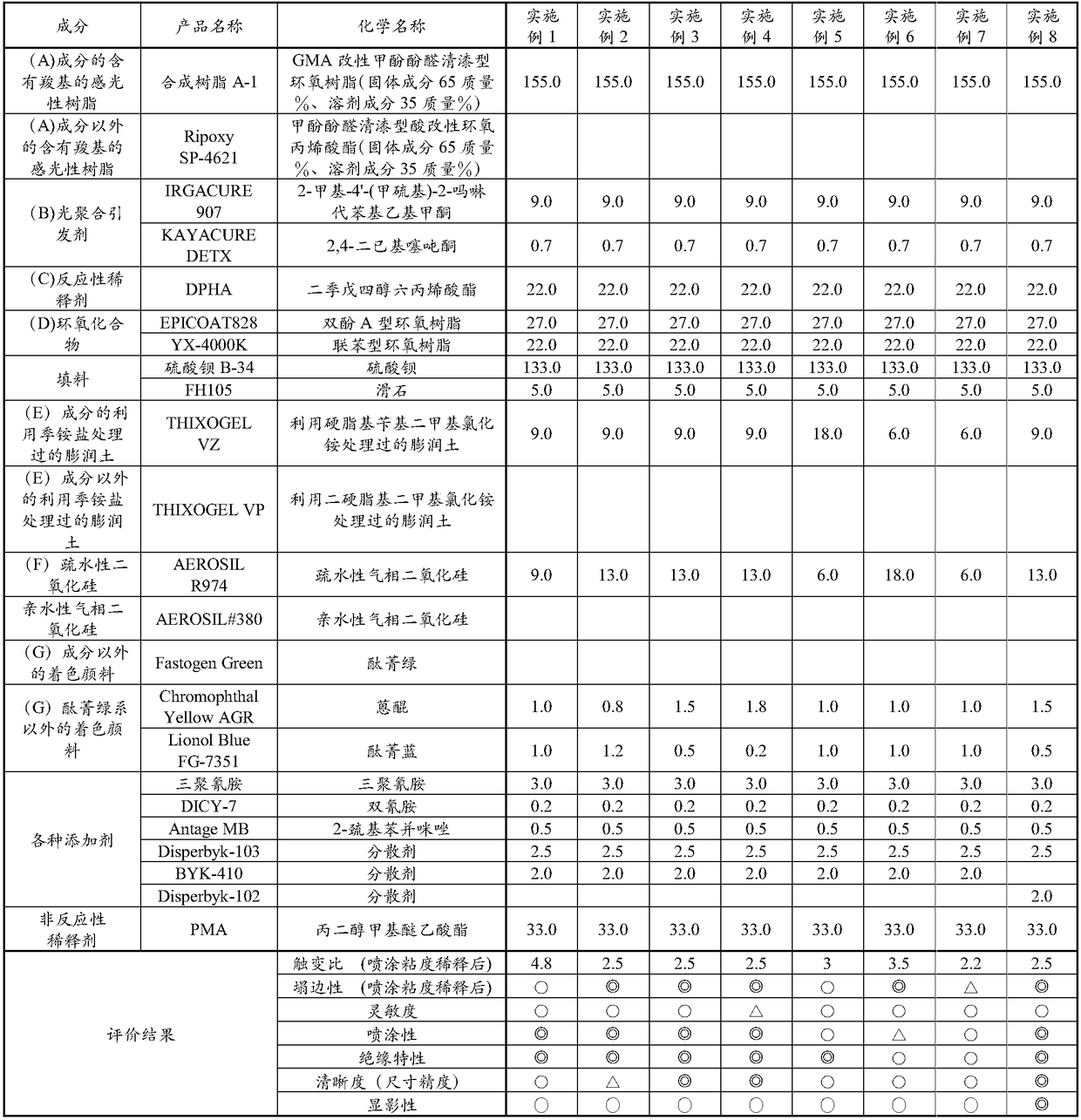

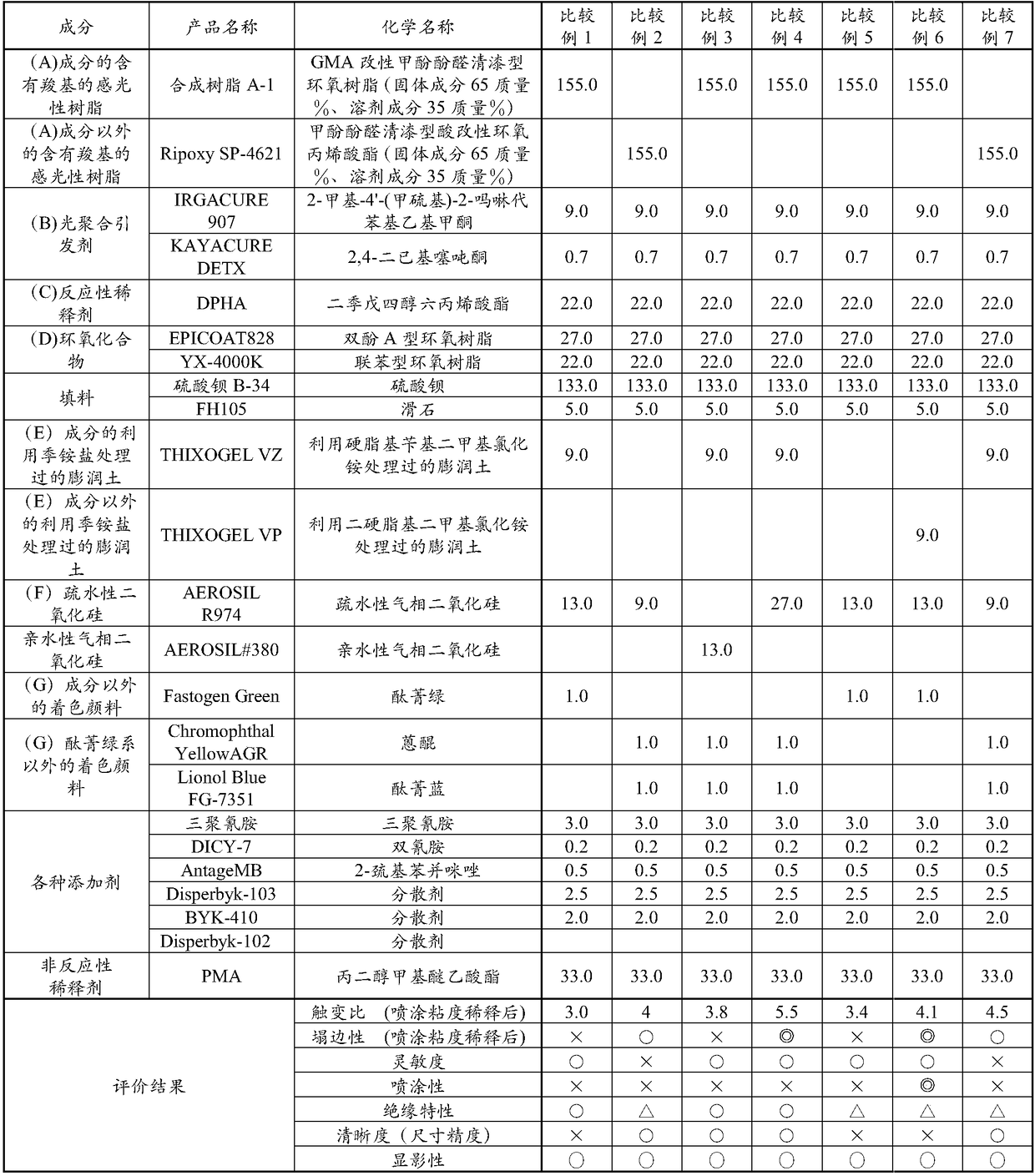

Embodiment 1~8、 comparative example 1~7

[0094] Mix the components shown in the following Tables 1 and 2 at the ratios shown in the following Tables 1 and 2, and mix and disperse them at room temperature using a triple roller to prepare the compounds in Examples 1 to 8 and Comparative Examples 1 to 7. The photosensitive resin composition used. Then, the prepared photosensitive resin composition was apply|coated as follows, and the test piece was produced. The numbers in the following Tables 1 and 2 represent parts by mass. In addition, blank columns in the following Tables 1 and 2 indicate that they were not mixed.

[0095] [Table 1]

[0096]

[0097] [Table 2]

[0098]

[0099] In addition, the details about each component in Tables 1 and 2 are as follows.

[0100] (A) Carboxyl group-containing photosensitive resin of component

[0101] In 250 parts by mass of carbitol acetate, 220 parts by mass of cresol novolac epoxy resin (manufactured by Sumitomo Chemical Industries, Ltd., ESCN-220, epoxy equivalent w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com