Friction-stir welding blank-making device for aluminium alloy hub, and treatment process thereof

A technology of friction stir welding and aluminum alloy wheels, which is applied in the direction of manufacturing tools, metal processing, metal processing equipment, etc., can solve the problems of product application of unfavorable welding methods, product performance lower than matrix structure, and low strength of joint performance, etc., to achieve Avoid product performance degradation, improve welding efficiency, and high adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

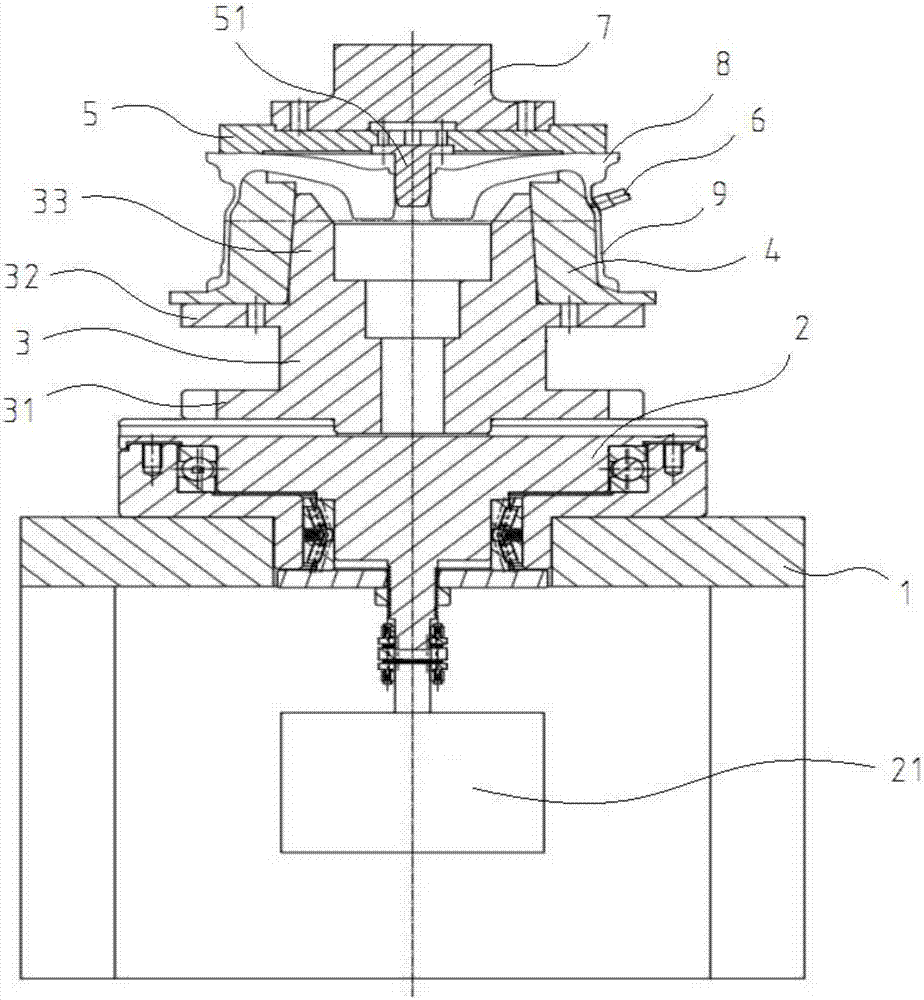

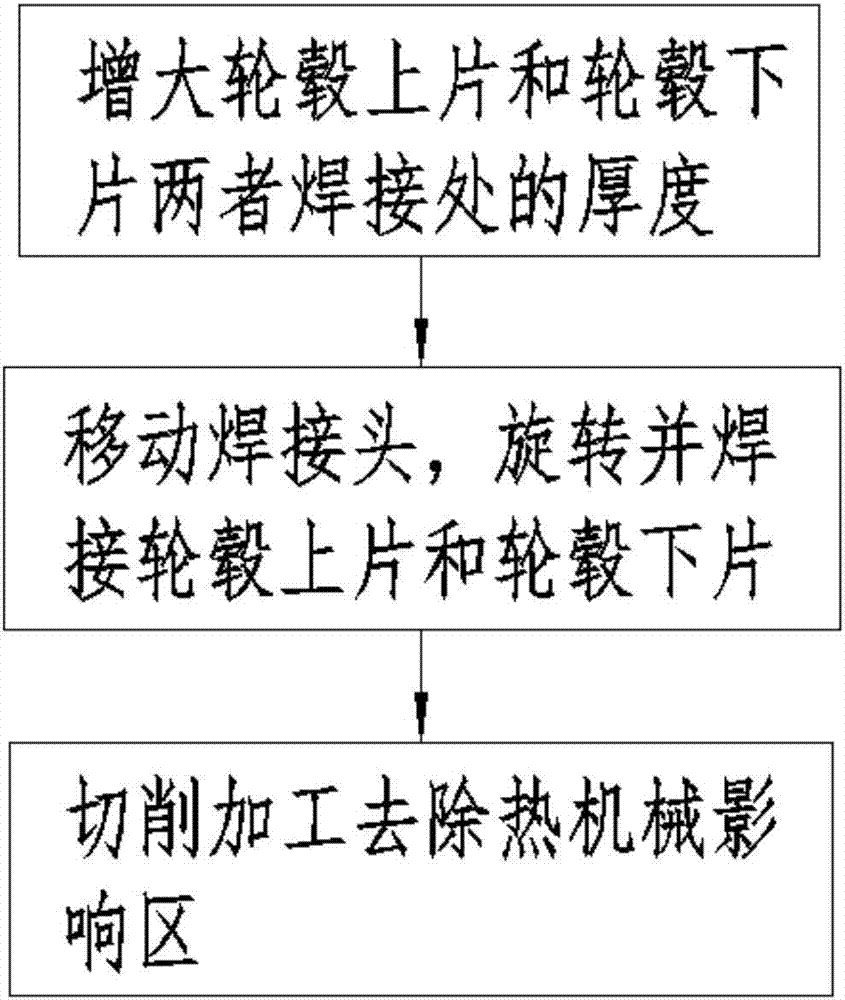

[0025] In order to make it easy to understand the technical means, creative features, goals and effects achieved by the present invention, the following examples are combined with the appended figure 1 To attach image 3 The technical solutions provided by the present invention are described in detail, but the following content is not intended as a limitation of the present invention.

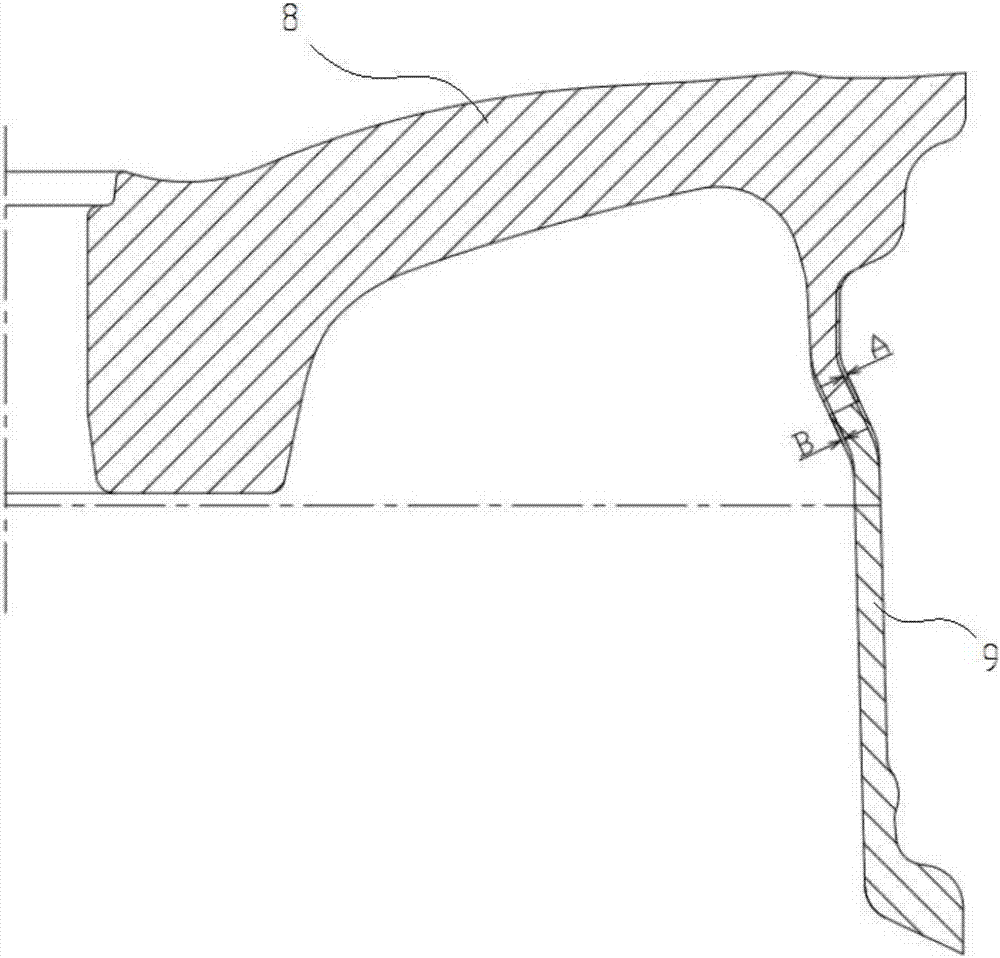

[0026] figure 1 It is a structural diagram of an embodiment of an aluminum alloy wheel hub friction stir welding blank making device of the present invention. Such as figure 1 As shown, the aluminum alloy hub friction stir welding billet forming device provided in this embodiment includes: a workbench 1, a rotating disk 2, a motor 21, a positioning device 3, a lower layer 31, an upper layer 32, a protruding shaft 33, a pressing head 4, a pressing Tight disc 5, protrusion 51, welding head 6, power cylinder 7, hub upper piece 8 and wheel hub lower piece 9.

[0027] Specifically, the workbench...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com