Portable PCB needle file welding jig

A welding fixture and PCB board technology, applied in the field of component welding, can solve problems such as easy to be pulled, low work efficiency, influence of needle seat welding height, etc., and achieve the effect of improving work efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

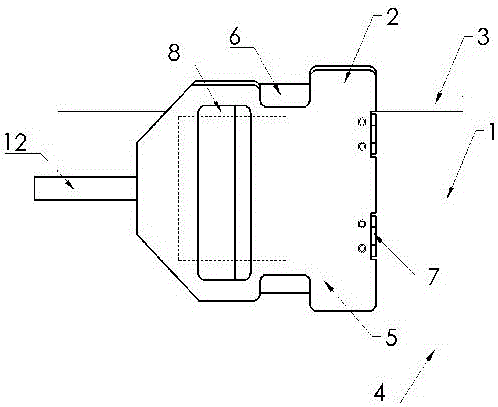

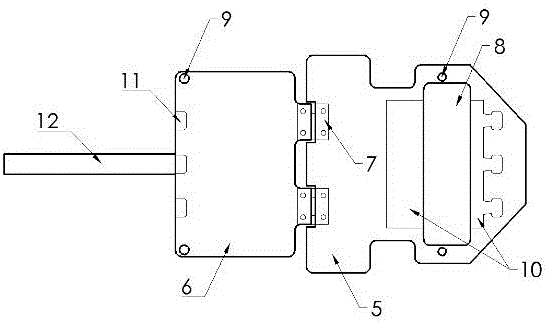

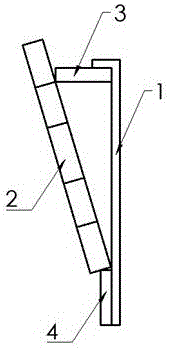

[0012] Depend on figure 1 , figure 2 , image 3 Known, a kind of portable PCB board needle base soldering fixture, comprises auxiliary table 1, welding fixture 2, and described auxiliary table 1 and welding fixture 2 are independent parts, and described auxiliary table 1 upper end is fixedly installed with supporting block 3, and lower end The limit block 4 is fixedly installed, the auxiliary table 1 is made of iron, the support block 3 and the limit block 4 are made of plastic materials, so that the auxiliary table will not move during use; the welding fixture 2 is composed of an upper splint 5 Composed with the lower splint 6, the upper splint 5 and the lower splint 6 are flexibly connected by the connecting piece 7, the upper splint 5 is provided with a welding window 8, a magnet block 9 is provided near the welding window 8, and the lower splint 6 is also provided with a magnet at the corresponding position Block 9, upper clamping plate 5 and lower clamping plate 6 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com