Clamping mechanism for reinforcing bar mesh welding

A technology of clamping mechanism and steel mesh, which is applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of uneven mesh of steel mesh, large human operation error, and failure to meet the requirements of steel mesh. , to achieve the effect of accurate, rapid and efficient completion of the welding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments.

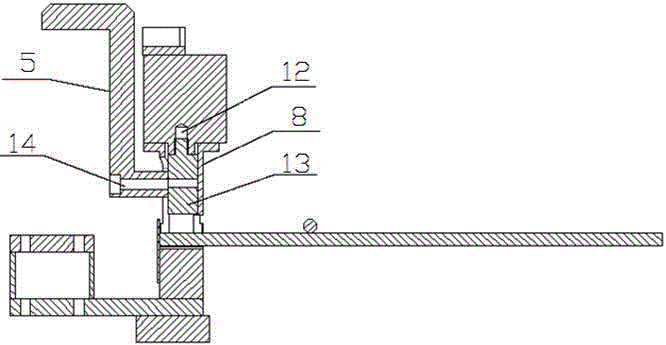

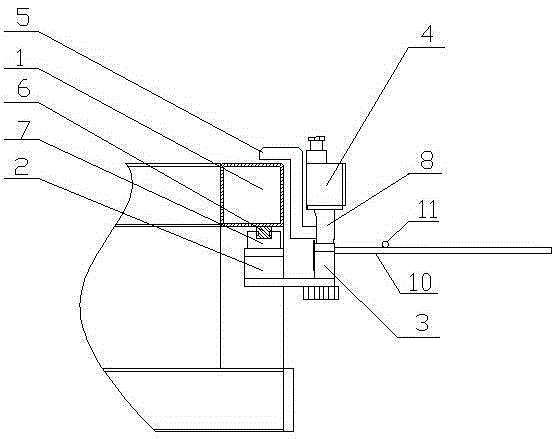

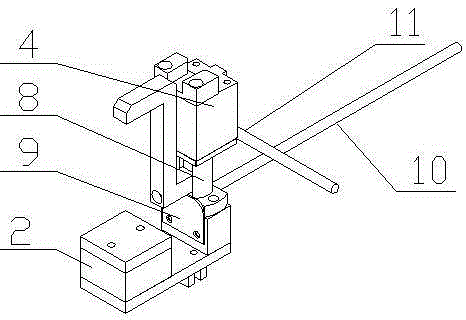

[0015] The accompanying drawing is an embodiment of the present invention. This embodiment includes a clamping base 2 , a lower base 3 , a short-range cylinder 4 and a hook 5 , a sliding block 7 is installed on the clamping base 2 , a linear guide rail 6 is installed on the rebar traction frame 1 , and the sliding block 7 and the linear guide rail are installed on the clamping base 2 . 6 sliding connection; the lower seat 3 is fixed on the clamping seat 2, the front end of the lower seat 3 is provided with a baffle 9, and the vertical steel bar 10 is placed on the upper end of the lower seat 3 to withstand the baffle 9; the upper part of the lower seat 3 is connected by The sleeve 8 is connected with the short-range cylinder 4; the draw hook 5 is movably connected with the reinforcement draw frame 1, and the lower end of the piston rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com