Automatic welding machine, welding tool and welding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

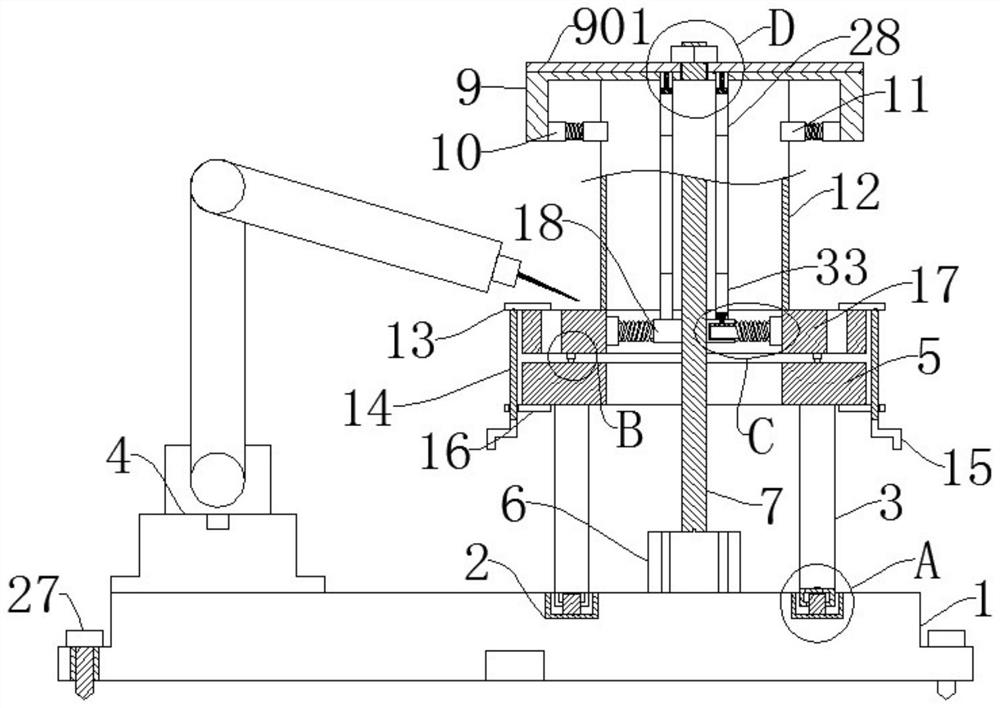

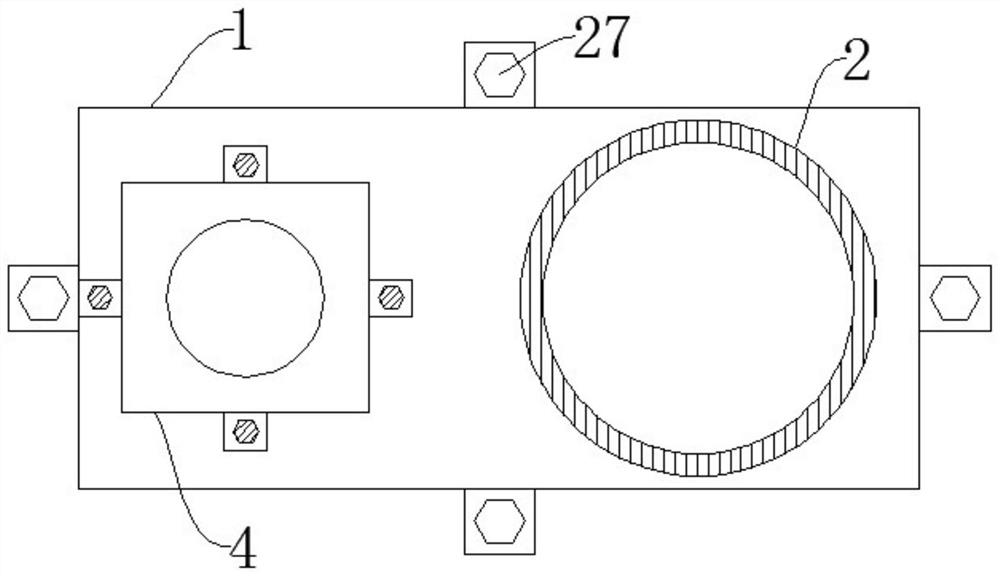

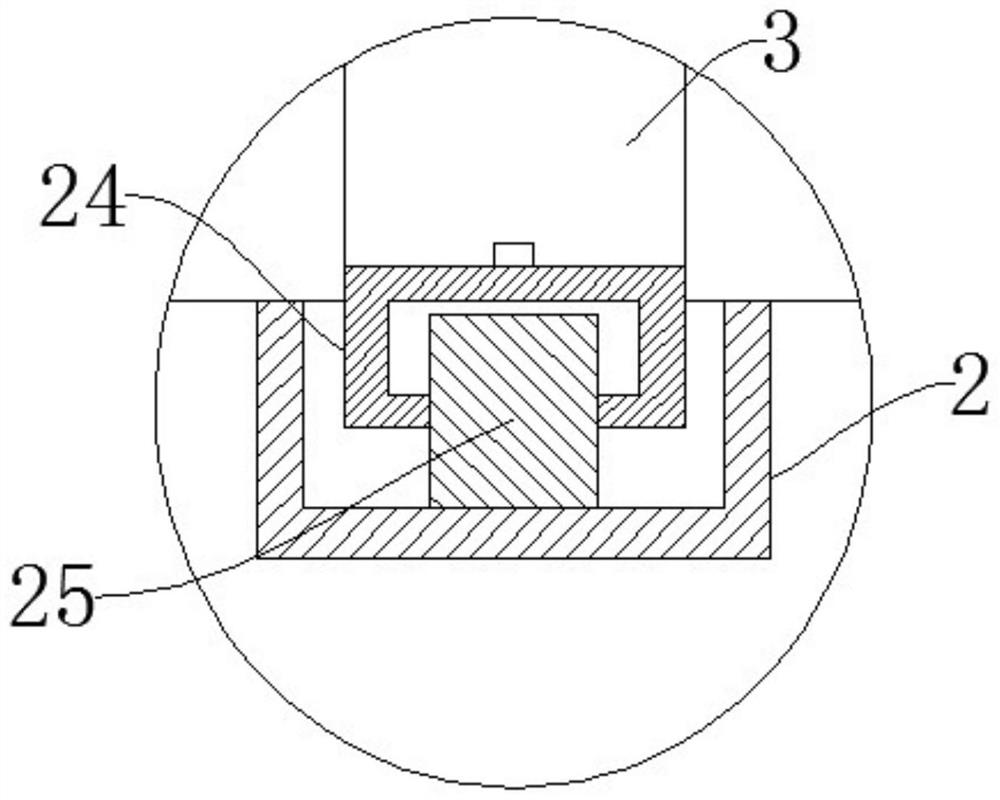

[0034] refer to Figure 1-9 , an automatic welding machine, a welding tool and a welding process, including a base 1, a circular track 2 is arranged on the base 1, a moving rod 3 is arranged on the circular track 2, and a supporting rod 24 is connected to the bottom of the moving rod 3 in rotation , the support rod 24 is rotatably connected with a roller 25, the moving rod 3 and the circular track 2 are slidably connected by the roller 25, the upper end of the moving rod 3 is fixedly connected with a circular disk 5, and the lower end of the circular disk 5 is fixedly connected with a second ring disk on both sides. A locking plate 16, a flange 17 is placed on the ring disc 5, a round pipe 12 is arranged on the upper end of the flange 17, a second locking plate 13 is connected to both sides of the upper end of the flange 17, and the first locking plate 16 passes through Threaded rotation is connected with threaded rod 14, and the upper end of threaded rod 14 is connected on th...

Embodiment 2

[0037] refer to Figure 1-9 , a kind of automatic welding machine, welding tooling and welding process, are basically the same as embodiment 1, further is: first sleeve 18 is fixedly connected with rotating rod 7 both sides, and first sleeve 18 is slidingly connected with first sleeve 18 The sliding rod 21, the end of the first sliding rod 21 away from the first sleeve 18 is fixedly connected with the limit block 23, the side of the limit block 23 far away from the first slide rod 21 is in close contact with the inner surface of the flange 17, the first slide The rod 21 is sleeved with a first spring 22, and the two ends of the first spring 22 are respectively fixedly connected with the first sleeve 18 and the stop block 23, and the first sleeve 18 is fixedly connected with a second hard tube 33, and the second The hard tube 33 is fixedly connected with a fixed block 29, the middle of the fixed block 29 is provided with an air inlet, the lower end of the fixed block 29 is prov...

Embodiment 3

[0040] refer to Figure 1-9 , a kind of automatic welding machine, welding tooling and welding process, are basically the same as embodiment 1, further is: the surface of semicircle arc plate 11, limit block 23 is all provided with rubber cushion, prevents semicircle arc plate 11 1. The limit block 23 scratches the contact surface with the round pipe 12 and the flange 17, improving the practicability of the welding tool.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com