Straight tube butt-welding machine with parallelism correcting mechanism

A parallelism, butt welding machine technology, used in welding equipment, welding accessories, arc welding equipment and other directions, can solve the problems of poor sealing of welds, poor appearance, inconvenient output, etc., and achieve good effect and high quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to enable those skilled in the art to better understand the technical solution of the present invention, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

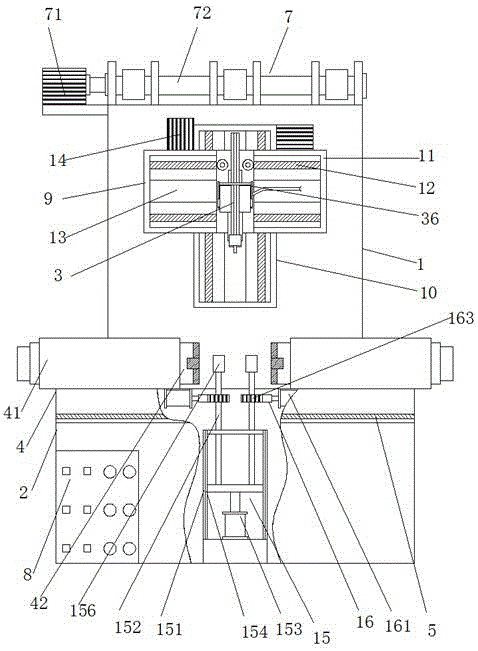

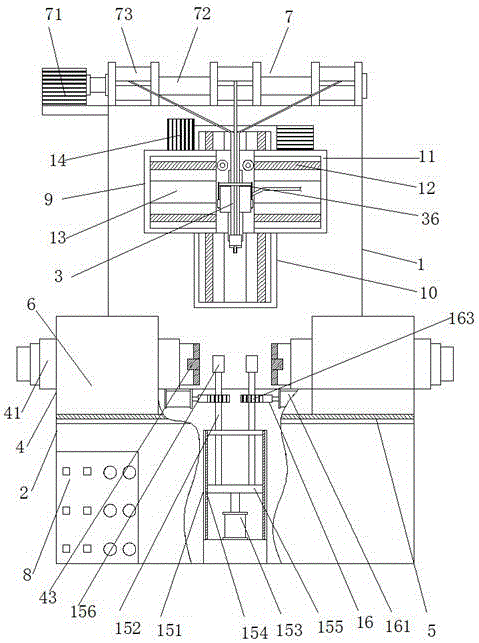

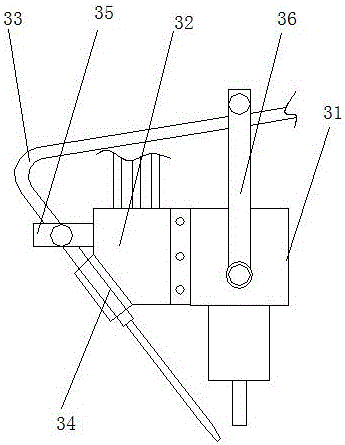

[0028] Refer to attached Figure 1-6 The shown straight pipe butt welding machine with a parallelism correction mechanism includes a welding host 1 and an operating table 2, a control system 8 is set on the operating table 2, and a push-pull track 5 is set on the side of the operating table 2, and the push-pull track 5 slides Two protective plates 6 are provided, and the two protective plates 6 are moved toward each other to close during the welding process, so as to realize the personal protection of the operator and have high safety. 1 is provided with an unwinding mechanism 7, the unwinding mechanism 7 includes a motor 71, a roller shaft 72 and a drive roller body 73, the motor 71 is connected to the roller shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com