A dual-station intelligent welding robot

A welding robot and dual-station technology, applied in welding equipment, welding accessories, manufacturing tools, etc., can solve the problems of high comprehensive cost, workpiece welding, time-consuming and labor-intensive, etc., and achieve the effect of reducing manual operation and labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

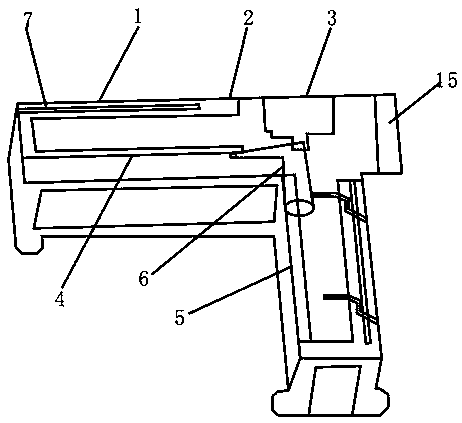

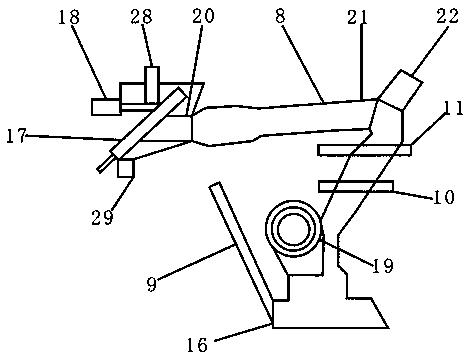

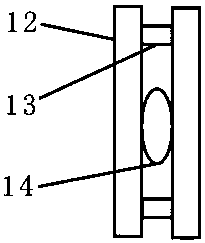

[0021] see Figure 1-Figure 4 , the present invention provides a technical solution: a double-station intelligent welding robot, including a welding platform 1, a mobile platform 2 and a sliding adjustable workholding fixture 3 are fixedly installed on the upper surface of the welding platform 1, and the sliding and adjustable workholding fixture 3 will The workpiece to be welded is clamped, and the welding machine 8 is moved at different stations through the mobile platform 2 to realize double-station welding. The mobile platform 2 has an "L"-shaped structure, and the mobile platform 2 can cover the entire work area , to realize the all-round coverage welding of the workpiece, between the mobile platform 2 and the sliding adjustable workpiece fixture 3, a loading frame 4 and a blanking frame 5 are fixedly installed, and both the loading frame 4 and the blanking frame 5 are equipped with The boom 6 is used to load and unload the workpiece through the boom 6, reducing manual op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com