Forming process for teflon inside and outside linings of chlorine through pipe

A molding process and a technology for passing chlorine pipes, which can be used in tubular articles, other household appliances, household appliances, etc., and can solve the problems of insufficient strength and weak corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

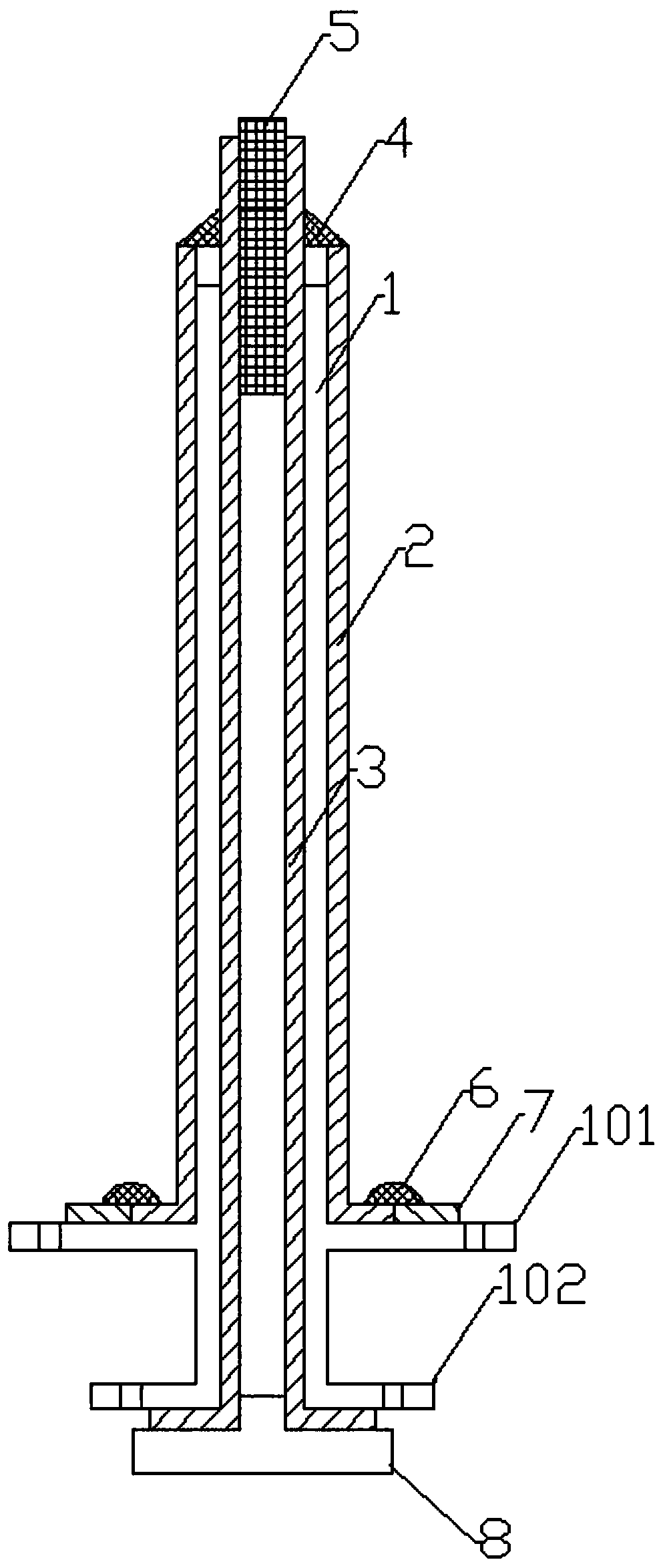

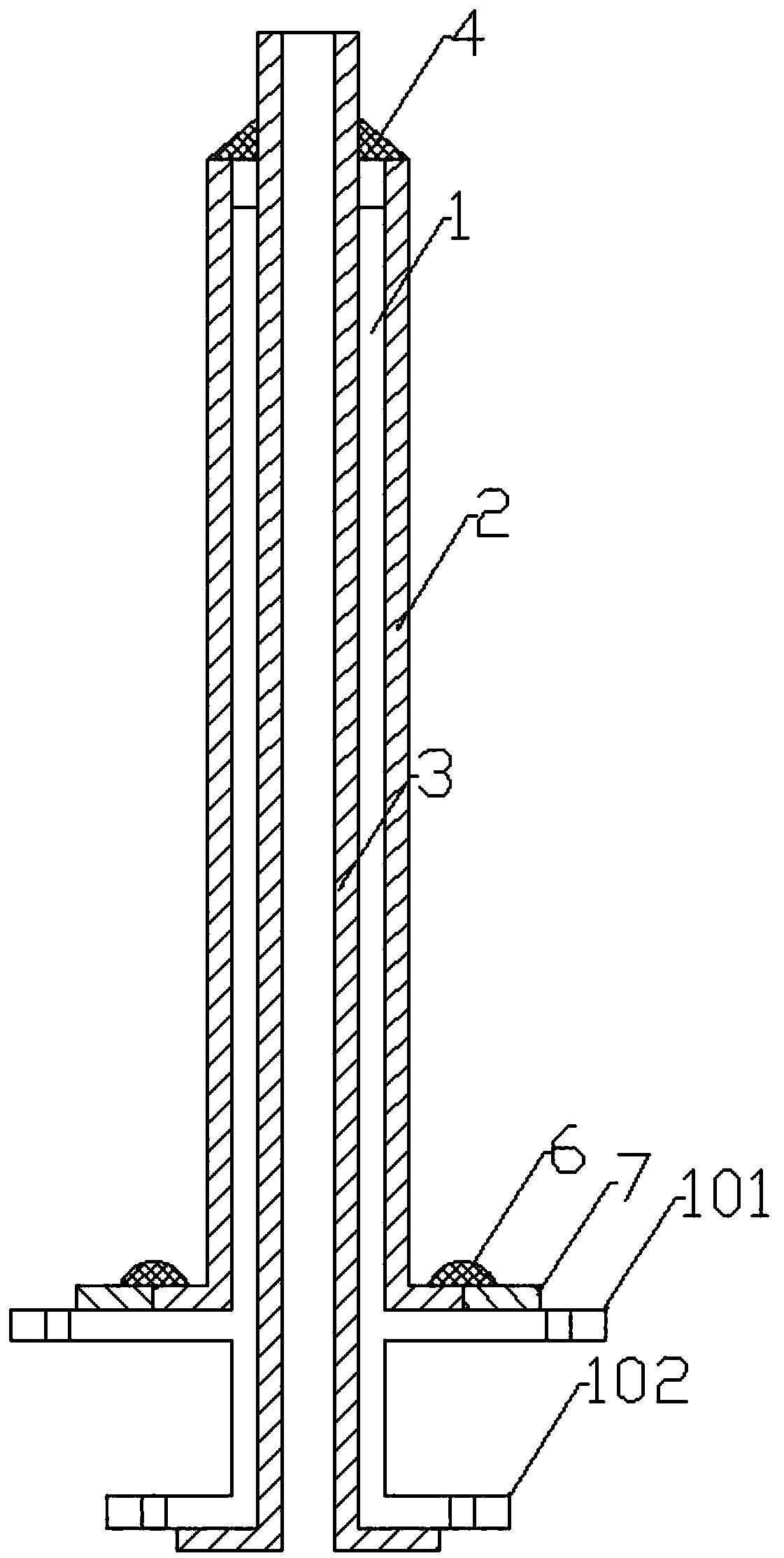

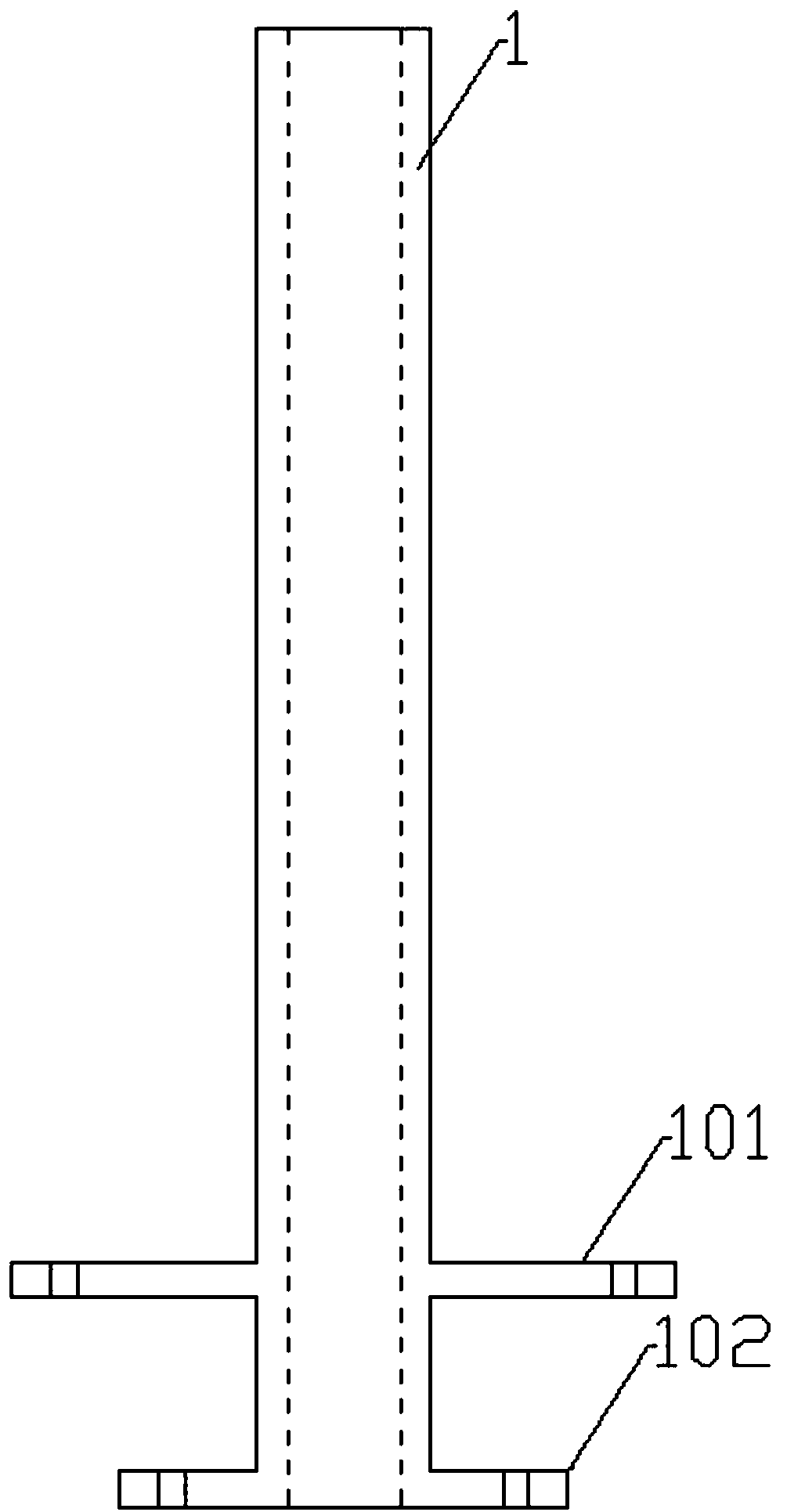

[0016] Figure 1-4 Show the specific embodiment of the present invention: a kind of forming process of the tetrafluoro inner and outer lining of the chlorine pipe, comprising the following steps: (1) the outer lining tetrafluoro tube 2 bottom flanging 5-8cm, clamps the short side turned over from straight Insert the front end of the tube 1, and flatten the flanging on the upper end of the flange 101; (2) Insert the tetrafluoro disc 7 from the outer end of the straight tube 1 and press it flat on the upper end of the flange 101, Weld the junction of the disk 7 and the flanging of the outer lined PTFE tube 2 with a PTFE welding rod; (3) flang the bottom of the lined PTFE tube 3 by 10-14 cm, and put one end of the flanging into the flanging tooling 8 And together with the flanging tooling 8, insert the inside of the straight pipe 1 from one end of the second flange 102; (4) insert the mandrel 5 into the lined PTFE tube 3, and connect the outer lined PTFE tube 2 with the side of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com