Multi-angle non-dead-angle welding device and using method thereof

A welding device and no dead angle technology, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of reducing welding efficiency, reducing welding safety performance, and inability to weld workpieces at multiple angles, and achieve the effect of broadening the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

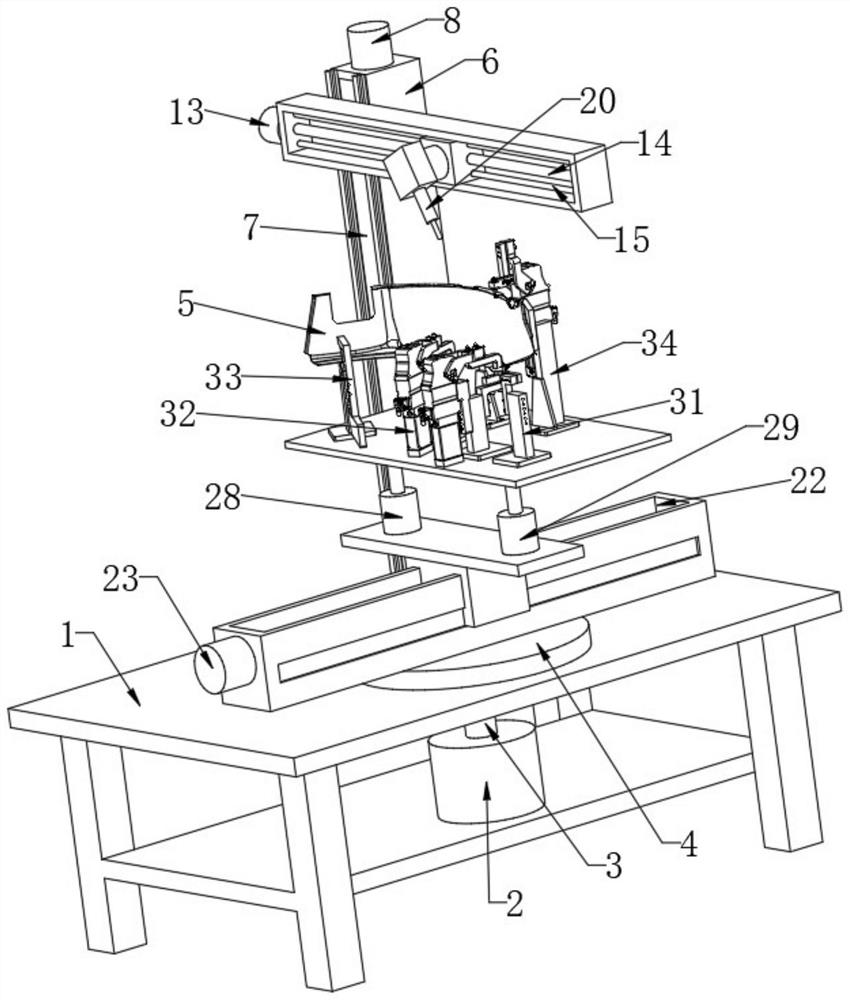

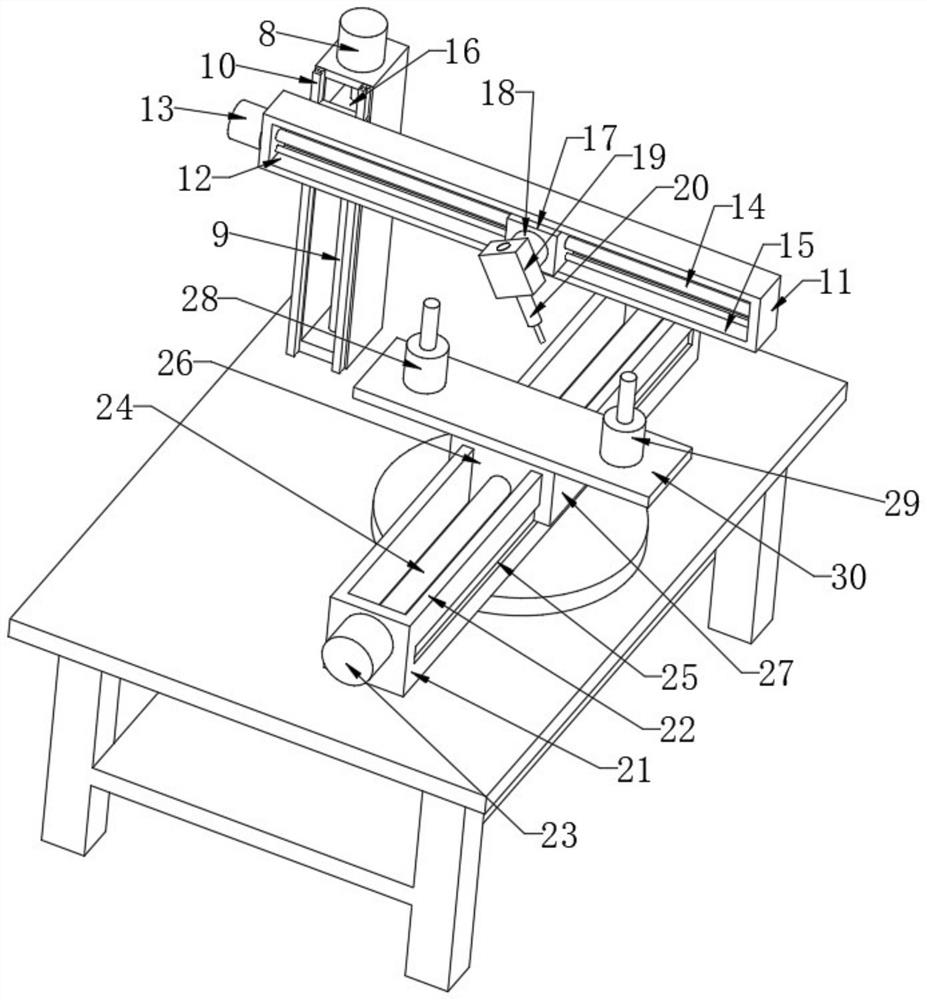

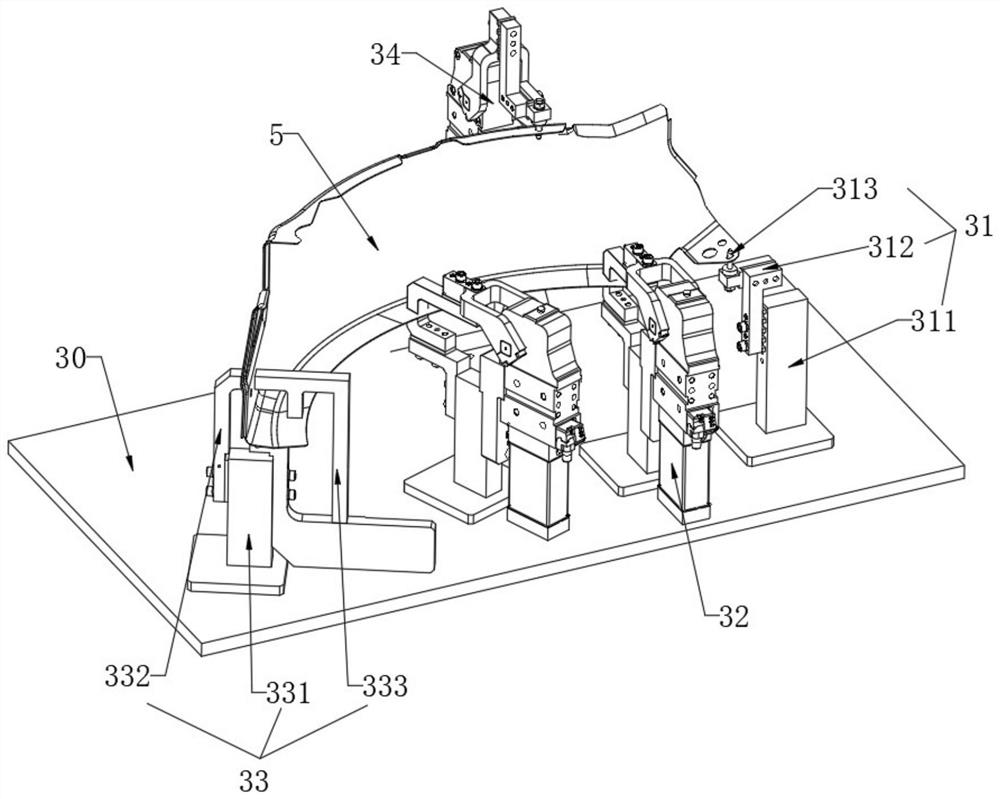

[0032] see Figure 1-2, a welding device with multiple angles and no dead ends, comprising a workbench 1, a first motor 2 is installed on the bottom of the workbench 1, the output end of the first motor 2 is fixedly connected with a rotating rod 3, and the rotating rod 3 runs through the workbench 1, The rotating rod 3 is connected to the workbench 1 through bearings, the output end of the rotating rod 3 is fixedly connected to the turntable 4, the surface of the turntable 4 is provided with the workpiece 5, the surface of the workbench 1 is fixedly connected to the vertical plate 6, and the side of the vertical plate 6 There is a first groove 7 in the wall, a second motor 8 is installed on the upper end of the vertical plate 6, the output end of the second motor 8 is fixedly connected with a first screw 9, the first screw 9 runs through the vertical plate 6, and the first screw 9 passes through The bearing is rotatably connected with the vertical plate 6, and the outer wall o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com