A steel welding process

A welding process and steel technology, applied in the field of steel welding, can solve the problems of easy fatigue of welding personnel, harsh construction site environment, affecting construction efficiency, etc., and achieve the effects of improving welding quality and welding efficiency, improving comfort, and preventing molten iron from falling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

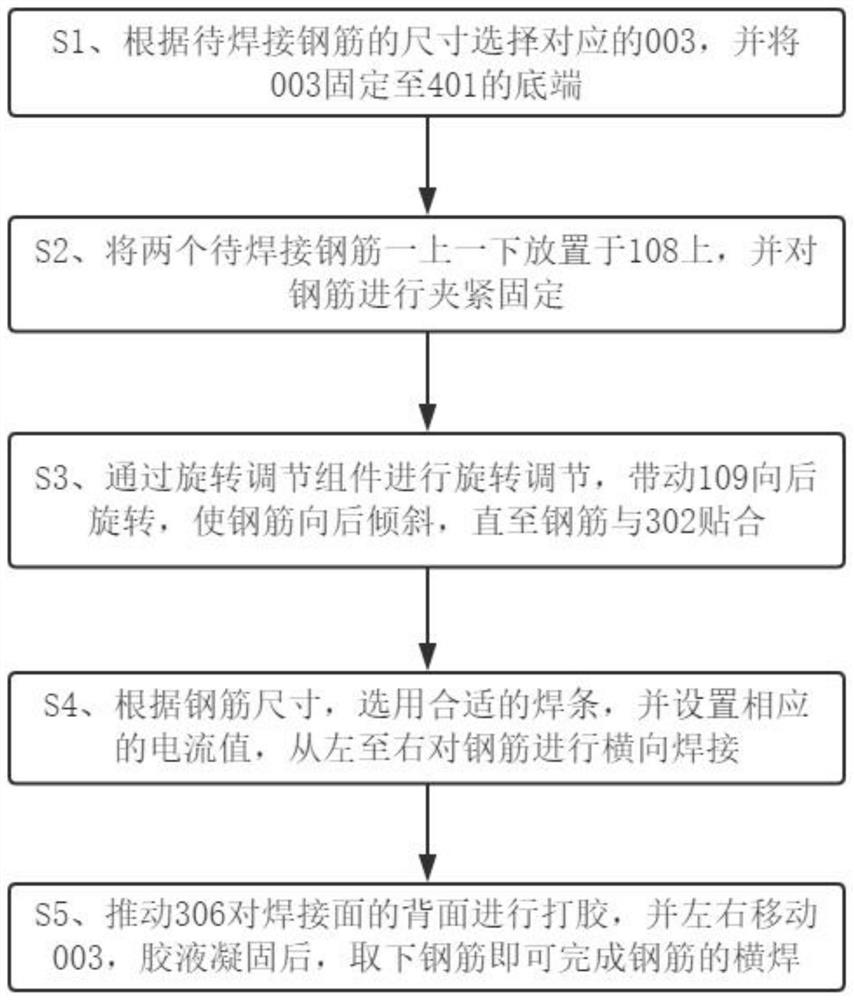

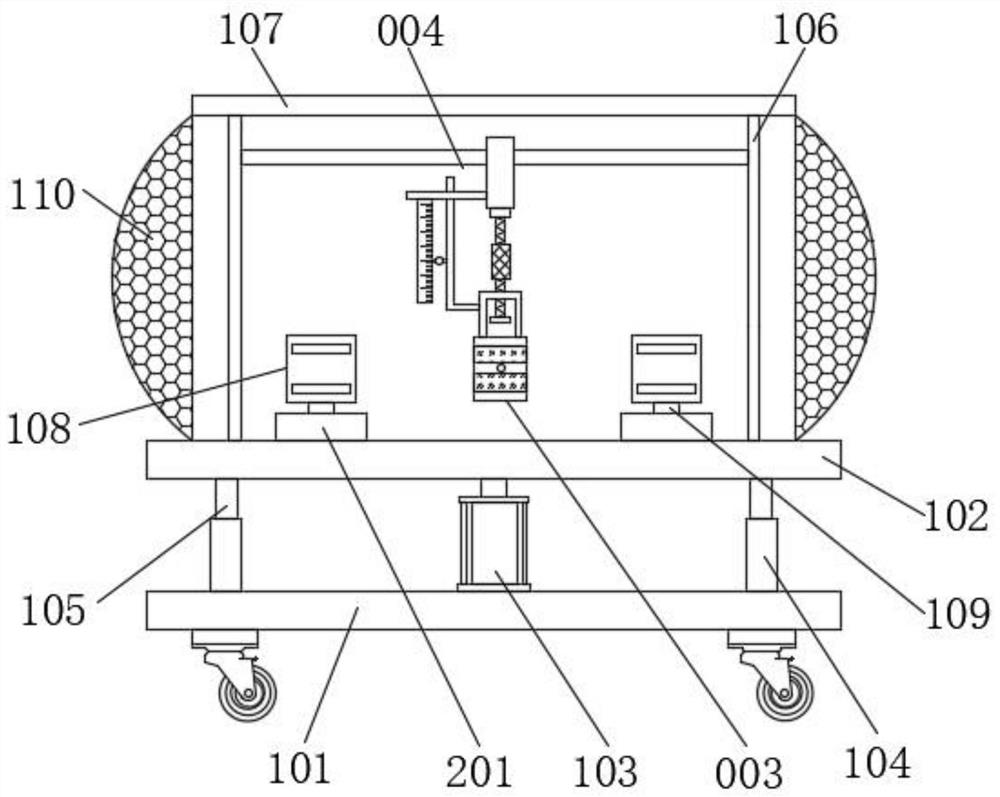

[0046] see Figure 1-7 , a steel welding process, comprising the following steps:

[0047] S1. Select the corresponding glue reinforcement assembly 003 according to the size of the steel bar to be welded, and fix the glue reinforcement assembly 003 to the bottom end of the fixed slide bar 401;

[0048] S2. Place the two steel bars to be welded one above the other on the centering fixture 108, and clamp and fix the steel bars;

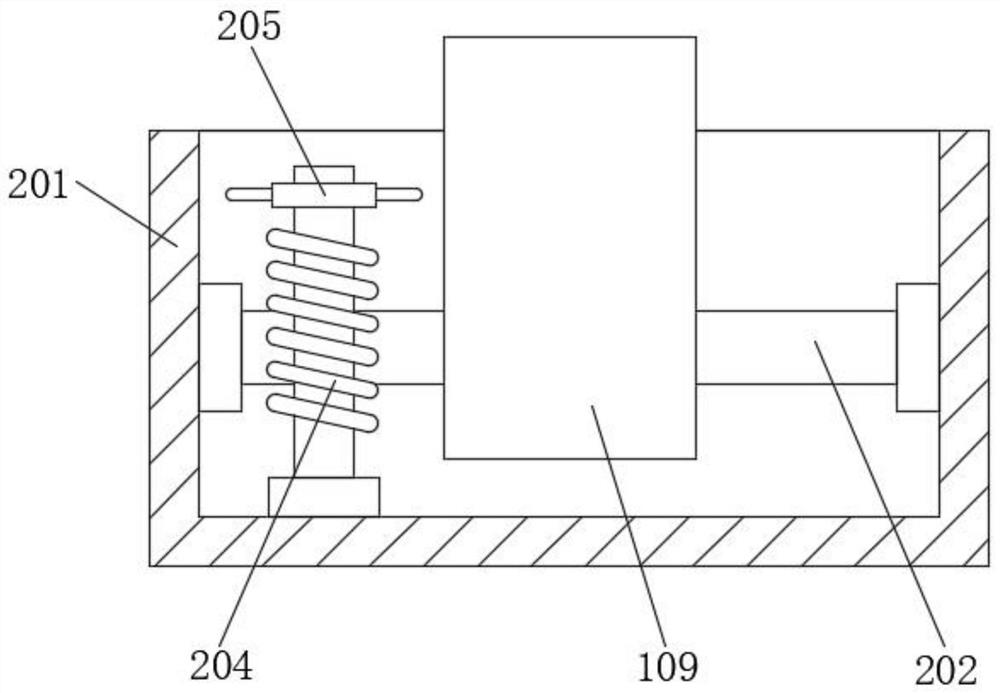

[0049] S3, perform rotation adjustment through the rotation adjustment assembly, drive the adjustment connection block 109 to rotate backward, and make the steel bar tilt backward until the steel bar and the anti-flow rubber pad 303 fit together;

[0050] S4. According to the size of the steel bar, select the appropriate welding rod, and set the corresponding current value, and perform horizontal welding on the steel bar from left to right;

[0051] S5. Push the gluing handle bar 306 to apply glue to the back of the welding surface, and move the gluin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com