A method for installing a flat film mirror

An installation method and thin-film mirror technology, which are applied in installation, optics, instruments, etc., can solve problems such as the installation method of precision thin-film mirrors, etc., so as to reduce the low precision of the surface shape, the weight of the supporting structure, and the precision of the surface shape Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

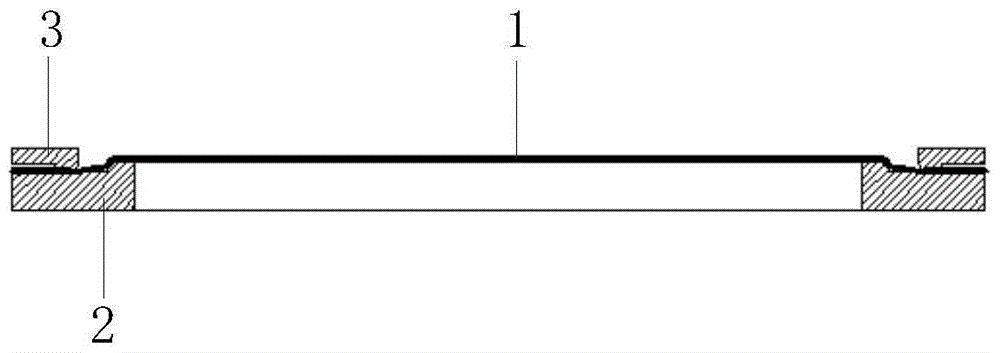

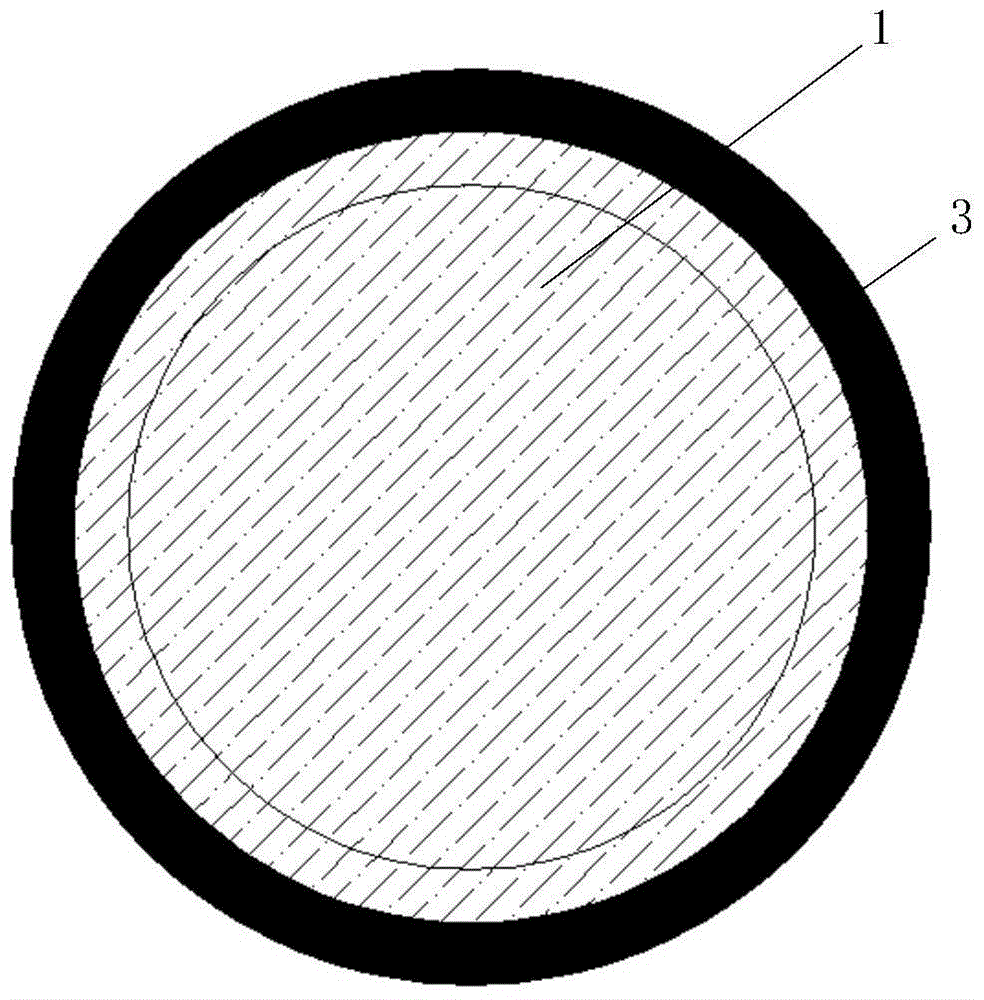

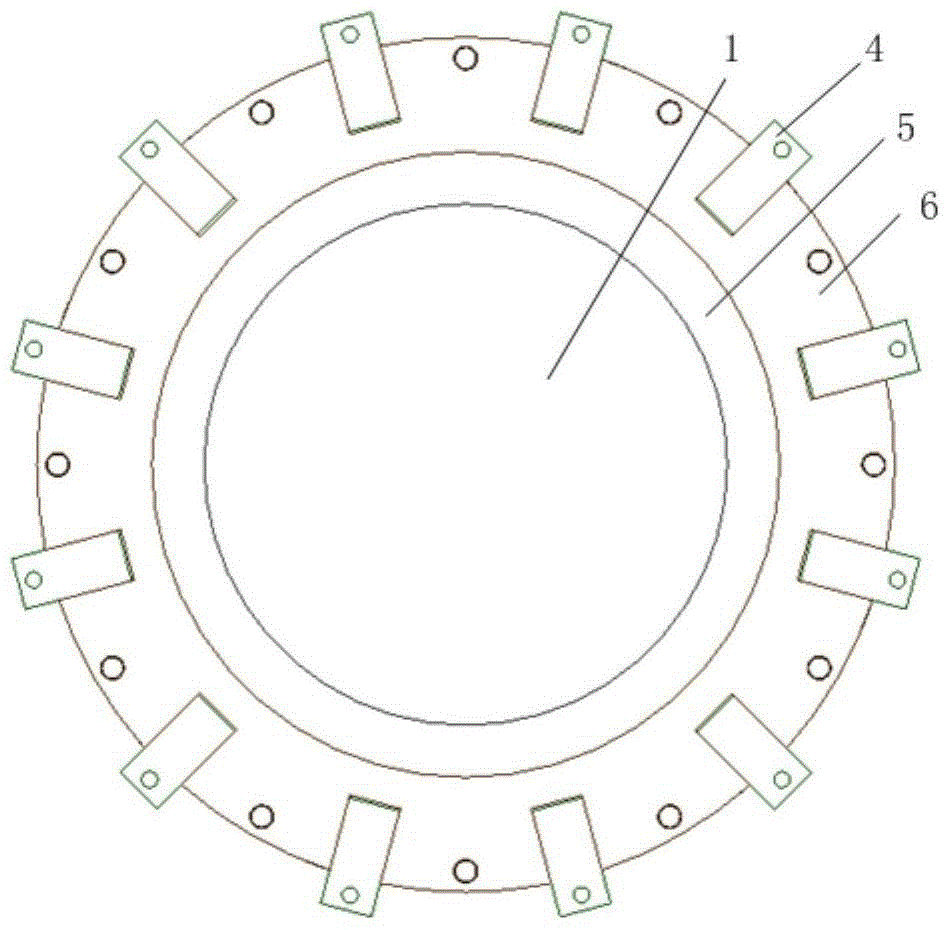

[0045] The surface shape index of the film mirror 1 depends on the surface shape accuracy of the film itself, the precision and rigidity of the precision support ring, and is also related to the internal stress of the film. Here, the surface accuracy of the film mirror 1 itself and the surface accuracy of the annulus 2-1 of the precision support ring 2 are limited, and it is guaranteed that this limitation is easy to realize in engineering, and the method of the present invention is premised on this Make an introduction.

[0046] Firstly, the parameters of the thin film mirror 1 are limited. In this embodiment, in order to meet the requirement that the optical diameter of the final formed thin film mirror assembly is Ф200 mm, the diameter of the thin film mirror itself is Ф250 mm, the thickness is 20 μm, and the surface shape accuracy is better than λ / 10 (λ = 0.632 μm).

[0047] Then limit the performance of the precision support ring 2, the inner diameter is Ф220mm, a certai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com